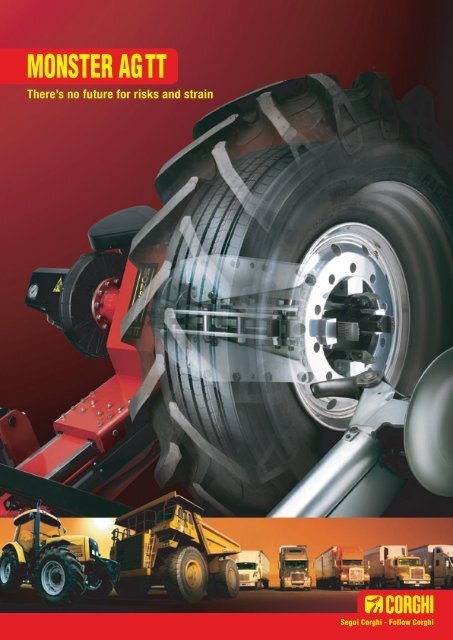

MONSTER AG TT

MONSTER AG TT

MONSTER AG TT

- No tags were found...

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

<strong>MONSTER</strong> <strong>AG</strong> <strong>TT</strong>There’s no future for risks and strainSegui Corghi - Follow Corghi

<strong>MONSTER</strong> <strong>AG</strong> <strong>TT</strong>SMART CORGHI SystemThe only onein the worldwith ‘leva la leva’technology

A “monster” of performance for industrial tyre professionalsCorghi, a leading manufacturer of tyre changers with extensive knowledge of the sector, has opened a new frontier forprofessionals of the heavy-duty tyre industry.Following the pressing demands of tyre specialists in the truck, earth movement and farming machine field andof technicians of workshops of fleets of transport vehicles, the Corghi researchers have developed and patented anew and revolutionary heavy-duty tyre changer.Together with the best of cutting edge technologies, Monster <strong>AG</strong> <strong>TT</strong> also integrates all the features that make it afundamental and irreplaceable tool for the working quality and safety of industrial tyre operators.Outstanding advantages in 5 strongholds:12345· Significant reduction in strain· High protection of rims and tyres· High performance· Maximum safety· Absolutely universal applicationThanks to Monster <strong>AG</strong> <strong>TT</strong>, the profession of tyrespecialists now changes substantially, guaranteeingtechnicians and their customers anadditionally efficient, rapid and top qualityservice.

1· Significant reduction in strainMonster <strong>AG</strong> <strong>TT</strong> is a super automatic and revolutionary tyre changer. It is the only one in the world to fit the “Leva la Leva” device. It significantlyreduces strain and risks for specialized professionals in changing all types of tyres on trucks, buses, farming and earth movement machines.Equipped with automatic and self-centring wheel clamping device (without using extensions), Monster <strong>AG</strong> <strong>TT</strong> offers an electronic system to save thediameters of the rims and the position of the wheel and the “Side To Side” device that enables the tools to move automatically from one side of the tyreto the other.2 · Very high protection of rims and tyresThe whole tool block is operated hydraulically. It comprises the “Leva la Leva”device, which performs tyre changing in a completely automated manner and aspecial bead loosening disc which, based on the hydraulic movement, reaches the perfect inclination in each phase of the process. A fundamental feature ofthe system is that the arm that operates the tool block makes a coordinated movement with the turntable and always keeps the wheel and the tools perfectlytangent in all situations. This reduces tension and avoids contact, consequently totally safeguarding the integrity of the rims and tyres.3 · High performanceElectro-hydraulic control unitMonster <strong>AG</strong> <strong>TT</strong> is designed and manufactured to guarantee maximumversatility and efficiency for the operator. The single position of thetool block on the carriage makes tyre changing jobs easier and quicker.The new play recovery pads eliminate play due to wear; the memoryfunction used to save the position of the tools speeds-up positioningduring tyre changing. The synchronised movement between tool chuckand carriage, the electro-hydraulic control unit with display, whichcan be adjusted at pleasure by the user, and the possibility to automaticallyposition the finger and the disc tangent with the rim, make Monster<strong>AG</strong> <strong>TT</strong> unmatchable and one of a kind.4 · Maximum safetyNot only is Monster <strong>AG</strong> <strong>TT</strong> designed to reduce strain, but also toguarantee maximum operator integrity and safety. The design of thetyre changer is devised to eliminate the need for a base, whichconsequently eliminates any unbalanced situations, which arecertainly dangerous when loading large and heavy wheels. Thissolution allows the operator to work in complete safetywith the wheel raised off the ground by justa few centimetres. What’s more, the newcontroller with very handy controlsallows the operator to command allmovements without touching thetool block.5 · Absolutely universal applicationThe universality of Monster <strong>AG</strong> <strong>TT</strong> is guaranteed by the newself-centring locking turntable made up of tilting jaws with 9 directlockable positions, from 14” to 48” and with tilt up to 58”. Thesystem is pre-arranged to lock rims with minimum centre hole diameterof 90 mm . The turntable is equipped with a drive inverter thatautomatically enables the output of the optimal speed for each job,including tyre groove forming.

“Leva la Leva” device (SMART CORGHI System)Locking turntableBead loosening discRadio transmittercontrol unit

Corghi’s research and experience for an unmatchable productThe new and exclusive tilting jaw adapts perfectly to all types of rims.From 9 mm to 58”, Monster <strong>AG</strong> <strong>TT</strong> can be used for the tyres of any vehicle.90 mm58”The S. T. S. device (Side To Side) enablesthe automatic switching of the toolblock from one side of the tyre to theother.The new controller with very handycontrols enables efficient operation ofthe tyre changer without the operatortouching the tools.

1 2 3Sequence of automatic movements of the tool:1 bead clamping position 2 rim tangency position3 “Leva la Leva” changing position1 2 3Sequence of automatic movements of the bead loosener : disc:1 disc tangent with rim(minimum inclination)2 disc inclinable to maximuminclination3 tool block rotationThe electro-hydraulic control unit withdisplay can be positioned at pleasure bythe user and used to related to the tyrebeing changed.The independentwheel-mountedergonomic controlunit (trolley style)makes thetechnician’s jobmuch easier.<strong>MONSTER</strong> <strong>AG</strong> <strong>TT</strong>From now on,no more levers,no more strain,no more damagesto rims and tyresand no more risks for the operator.

Tecnnical dataTool armChanging typeLeva la LevaTool-rim tangency type YESAutomatic “S.T.S” wheel turnover movementYESBead loosening discwith “patented” hydraulic movementAxial travel1120 mmDisplacement axial speed100 mm/sOperating axial speed40 mm/sMaximum internal axial bead loosening force30.000 NMaximum external axial bead loosening force25.000 NRotationHydraulicLockingHydraulicTool arm liftHydraulicChuck holding carriageHydraulic axial travel670 mmOperating axial speed70 mm/sChuckLocking systemHydraulic turntableRotation motorDrive inverterRotation speed3 speed 1 – 3.5 – 7.8 RPMMaximum rotation torque5.500 NmLocking unit4 tilted jaws (patented)Locking capacity from 14” to 58”Locking positions 9Maximum locking force40.000 NMaximum hydraulic pressure180 barMaximum tyre diameter2500 mmMaximum tyre width1600 mmMaximum wheel weight1700 kgMinimum wheel centre hole Ø90 mmMinimum working height to chuck shaft450 mmBaseWheel loading areafloor levelHydraulic control unit – electrical equipmentStand-by functionYESDisplay for setting wheel size in inchesYESOperationElectricalMotor3.3 - 4 kWAdjustable hydraulic pressurefrom 80 to 180 barOil tank15 lPower supplyElectrical 3ph 230/400 V - 5 kWOperating noise level63 dB (A)ControllerTransmission of commandsvia radioEmergency buttonYESVoltage24 VWeight8 kgDimensionsLength2400 mmWidth2200 mmMaximum height1800 mmWeight1300 kgAuthorised dealerThe manufacturer reserves the right to modify thecharacteristics of its products at any time.Cod. DPCG000141A - 05/09To protect the planet and reduce paper usage, our cataloguesare viewable online at the website www.corghi.com. Printingresponsibly contributes to saving the environment.CORGHI S.p.A. - Starda Statale 468 n° 9 - 42015 CORREGGIO - RE - ITALYTel ++39 0522 639.111 - Fax ++39 0522 639.150 - www.corghi.com - info@corghi.com