January 2007 - Institute of Refractories Engineers

January 2007 - Institute of Refractories Engineers

January 2007 - Institute of Refractories Engineers

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

IRE <strong>January</strong> 07 15/2/08 16:50 Page 1

IRE <strong>January</strong> 07 15/2/08 16:50 Page 2<br />

THE REFRACTORIES ENGINEER<br />

THE OFFICIAL JOURNAL OF THE INSTITUTE OF REFRACTORIES ENGINEERS<br />

Incorporating news from the Electric Steel Makers Guild <strong>January</strong> <strong>2007</strong><br />

FEATURES IN THIS ISSUE<br />

● From Industrial Heritage To Industrial<br />

Revelation<br />

● Big Money Still Heading For China<br />

● First Triad ® No Cement Technology<br />

Aluminium Furnace Lining<br />

● Re-Pr<strong>of</strong>iling Of Blast Furnace<br />

Refractory Linings With Jet Casting<br />

● Advanced Solutions For Lining<br />

Coreless Induction Furnaces Melting<br />

Non-Ferrous Alloys<br />

● Innovative Lining Concepts For Iron<br />

Melting And Holding Furnaces

IRE <strong>January</strong> 07 15/2/08 16:50 Page 3<br />

www.ireng.org

IRE <strong>January</strong> 07 15/2/08 16:50 Page 4<br />

The <strong>Institute</strong> <strong>of</strong><br />

<strong>Refractories</strong> <strong>Engineers</strong><br />

is dedicated to<br />

fostering the science,<br />

technology and skills <strong>of</strong><br />

refractories engineering<br />

and to serving the<br />

needs <strong>of</strong> refractories<br />

engineers worldwide.<br />

Aims<br />

To raise the standard <strong>of</strong><br />

ability and training in<br />

this field <strong>of</strong> science and<br />

technology.<br />

To promote and<br />

maintain the character,<br />

status and interest <strong>of</strong><br />

members <strong>of</strong> the<br />

<strong>Institute</strong>.<br />

To disseminate<br />

information, facts,<br />

ideas, news or<br />

suggestions that may<br />

be <strong>of</strong> interest to<br />

members.<br />

To encourage the<br />

exchange <strong>of</strong> ideas and<br />

information among<br />

members to their<br />

benefit and to the<br />

benefit <strong>of</strong> the industries<br />

they serve.<br />

The <strong>Institute</strong> is a nonpr<strong>of</strong>it<br />

making body and<br />

its entire income is<br />

applied solely to the<br />

promotion <strong>of</strong> these<br />

aims.<br />

<strong>January</strong> <strong>2007</strong> Issue<br />

www.ireng.org<br />

4 <strong>Institute</strong> News<br />

4 President’s Column<br />

4 Editor’s Column<br />

5 Minutes <strong>of</strong> the 45th<br />

AGM<br />

5 ESMG column<br />

6 Obituaries<br />

8 Branch News UK<br />

and Australian<br />

11 Company News<br />

14 New Management<br />

Rescues Once<br />

Failing Engineering<br />

Giant<br />

16 Re-Pr<strong>of</strong>iling Of Blast<br />

Furnace Refractory<br />

Linings With<br />

Jetcasting<br />

20 CPS – An Advanced<br />

Solution For Lining<br />

Coreless Induction<br />

Furnaces Melting<br />

Non-Ferrous Alloys<br />

25 Innovative Lining<br />

Concepts For Iron<br />

Melting And Holding<br />

Furnaces<br />

30 Appointments<br />

31 Classified Buyers<br />

Guide<br />

38 Officers and<br />

Council<br />

38 Date for Your Diary<br />

39 Quick Shot<br />

Contents<br />

Contents<br />

Late news flash.<br />

The 5th <strong>Institute</strong> <strong>of</strong> <strong>Refractories</strong> <strong>Engineers</strong> Conference<br />

(Australian Branch) - Monday 2 July <strong>2007</strong> Training<br />

Workshop - Tuesday 3 July http://www.ireaus.org.au<br />

Visit the <strong>Institute</strong> <strong>of</strong> <strong>Refractories</strong> <strong>Engineers</strong> website at: www.ireng.org<br />

THE REFRACTORIES ENGINEER page 3

IRE <strong>January</strong> 07 15/2/08 16:51 Page 5<br />

page 4 THE REFRACTORIES ENGINEER<br />

www.ireng.org<br />

President’s Column<br />

The Lancashire and North West Dinner Dance in November was an excellent, sold out event. It<br />

was very pleasing to see so many people there and the support from major players in our<br />

industry was evident and very much appreciated. Anne and I greatly enjoyed ourselves and I<br />

would like to thank Eric Alsop as host and Elaine Gower as social secretary for putting together<br />

such an enjoyable event. I was also delighted to be able to present a Certificate <strong>of</strong> Fellowship<br />

to Eric in recognition <strong>of</strong> many years service to the <strong>Institute</strong> as branch chairman and author <strong>of</strong><br />

several <strong>Institute</strong> Conference papers. During Eric’s presentation at the IRE National Conference<br />

in 2005 proceedings were disrupted by a fire alarm and so he became the first speaker to give<br />

a paper to a joint meeting <strong>of</strong> the IRE and fire brigade! He nearly repeated this in the hotel the<br />

following morning but it was a false alarm. A certificate was also presented to Mr R Williams in<br />

recognition <strong>of</strong> his long and significant contribution to <strong>Refractories</strong> Engineering and the <strong>Institute</strong> over 40 years <strong>of</strong> service<br />

Unfortunately Ron was unable to be present in person to receive his certificate owing to ill health. I would like to<br />

congratulate both <strong>of</strong> them, and to wish Ron good health for the future.<br />

I have been travelling in Taiwan and China on business, and have been trying to recruit some <strong>of</strong> my contacts into IRE<br />

membership. On receiving a copy <strong>of</strong> the journal, in reply I got “Would you please send details on how to join". I hope to<br />

follow this up.<br />

We cannot but be aware <strong>of</strong> the Chinese refractories industry, but most <strong>of</strong> our members will not have visited. The<br />

modernisation and change in the country is astonishing in its speed, scale and extent. Shanghai now looks and feels like an<br />

Oriental New York. China's refractories industry is also changing but it will continue to be the dominant factor in our industry<br />

for some time. The effect <strong>of</strong> changes in China and the strength <strong>of</strong> the Chinese economy is, <strong>of</strong> course, much wider than our<br />

industry. All the big cities I visited have prominent advertisements for ‘Roewe’ cars, which used to be made in the UK.<br />

There are tremendous opportunities in China but also significant difficulties in doing business there. One useful phrase I<br />

learned is – ‘Ting Bu Dong’ which means ‘I don't understand’. I find knowing even a very little Chinese is a big help on both<br />

sides <strong>of</strong> the Taiwan Straights.<br />

In the UK, I gave a talk to the Sheffield Branch, met with their committee and was impressed with their strong and varied<br />

programme, but like many branches they find that getting attendance at meetings is more and more difficult. Our institute<br />

has been built up from the branches and they can only survive with YOUR support. I urge all members to support their<br />

branch committee and to attend the events they work so hard to organize.<br />

Sadly, we have learned <strong>of</strong> the death <strong>of</strong> our founding President, Reg Mayorcas. A tribute to him appears elsewhere in the<br />

Journal. The institute that exists today is built on the ideas and vision <strong>of</strong> our founders, and the continued existence <strong>of</strong> the<br />

IRE for all people associated with refractories is a fitting memorial. I am proud to be able to follow in his footsteps as<br />

President.<br />

All members will have recently received their renewal notice for <strong>2007</strong> subscriptions. I would ask all members to make an<br />

effort to pay promptly, considerable effort is spent each year on chasing up slow payers which diverts us from work running<br />

and developing the IRE. Payment is now made by cheque, card or bank transfer, please do not leave this until later but pay<br />

this month if at all possible.<br />

I will finish by wishing members, especially in the Far East, best wishes for Lunar New Year - it will soon be the Year <strong>of</strong> the<br />

Pig.<br />

Sam Franklin, President Jan <strong>2007</strong><br />

The Editor Speaks Out<br />

Hello All Readers.<br />

The start <strong>of</strong> another year, one that we here at the Journal are looking forward to again with<br />

some optimism.<br />

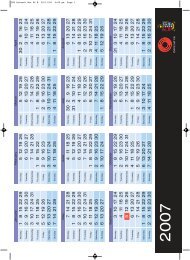

Apologies for the late delivery <strong>of</strong> your November Journal, we after a monumental effort to be<br />

on time missed our printing slot and had to take a week delay on the chin. We are hoping for<br />

better things from our <strong>January</strong> edition. November was the longest Journal for some time and<br />

contained our first attempt at producing a calendar effect with the first pages. Thanks to<br />

Intocast UK – Handsworth <strong>Refractories</strong> for supporting us with this new idea. We are already in<br />

the process <strong>of</strong> negotiations with an advertiser to support the calendar in <strong>2007</strong>. It was our first<br />

attempt and we think we could improve for this year. Your comments would be welcome.<br />

This first issue completes our publication <strong>of</strong> the papers given at the Foundries Convention last year, together with a paper<br />

from Refry Refractoriness in Germany on stack gunning in Blast Furnaces.<br />

We have been looking at our programme for <strong>2007</strong>, and the possible themes, which we could run during the year. I am not<br />

convinced <strong>of</strong> the benefits in using “ themes “ in the Journal simply because we run into availability <strong>of</strong> quality papers. Again we<br />

would like your comments on this topic to give us some idea on what you would like to see in your Journal. We will always try<br />

to group like papers so getting the best from our topics. Anyone wishing to have a technical paper published in the Journal<br />

should submit it for consideration to any Officer <strong>of</strong> the <strong>Institute</strong> or myself.<br />

Past President David Woodhead has been appointed by Council to head up a Journal Editorial team to look at the future <strong>of</strong><br />

your Journal and help formulate the basic parameters for the long-term future. It is becoming obvious the Journal will<br />

become in the future the only point <strong>of</strong> contact for the vast majority <strong>of</strong> members, and therefore will require changes to fulfil<br />

this role. Once again any thoughts you have on this topic please let us have them sooner rather than later.<br />

We cannot finish this Journal editorial without mention <strong>of</strong> the passing <strong>of</strong> one <strong>of</strong> our former Editors, George Seeley. A full<br />

obituary can be found together with the ones for our former Presidents, Reg Mayorcas, and Dermot Quirk. We hope George,<br />

you approve <strong>of</strong> what we are doing, we are proud to be carrying on with the traditions you set for the Journal.<br />

John May, Editor<br />

<strong>January</strong> <strong>2007</strong> Issue

IRE <strong>January</strong> 07 15/2/08 16:51 Page 6<br />

<strong>January</strong> <strong>2007</strong> Issue<br />

www.ireng.org<br />

Minutes <strong>of</strong> the 45th AGM<br />

Minutes <strong>of</strong> the 45th Annual General Meeting held at<br />

the Carlton Park Hotel, Rotherham on Friday 15th<br />

September 2006.<br />

31 members were present with Mr. P.Bottomley, President,<br />

in the chair.<br />

1. Apologies were received from P Atkinson, A J Baylay, P F<br />

Bell, M R Clark, B M Davies, R M Hanley, G A Hughes, D A<br />

Jarvis, S J Lee, S Smith, P C Stevens, D S Taylor, J A Yardy.<br />

2. The minutes <strong>of</strong> the 44th Annual General Meeting held on<br />

Friday 9th September 2005, having been circulated to all<br />

members in the November 2005 issue <strong>of</strong> ‘The <strong>Refractories</strong><br />

Engineer’ were taken as read and confirmed as a correct<br />

record <strong>of</strong> the proceedings.<br />

3. The following were appointed as Officers <strong>of</strong> the <strong>Institute</strong><br />

for the year 2006/<strong>2007</strong><br />

President: Dr. S A Franklin<br />

Senior Vice President: Mr. T Staton<br />

4(a). One member <strong>of</strong> the General Council was re-elected as<br />

follows:- Mr. S Smith<br />

4(b). Two new members <strong>of</strong> the General Council were<br />

elected as follows:- Mr. A S Bowden<br />

Mr. M Frith<br />

5. Review <strong>of</strong> Management and Operations <strong>of</strong> the <strong>Institute</strong><br />

A joint report by the Chairman <strong>of</strong> the Executive Committee<br />

and the General Secretary was read in full by Mr A Hey.<br />

(attached to minute book only as Appendix 1 and published<br />

in full in the November 2006 issue <strong>of</strong> “The <strong>Refractories</strong><br />

Engineer”)<br />

Subscriptions<br />

Once again many thanks to all members who have promptly<br />

renewed their subscriptions, and as always, for those who<br />

have not yet renewed, please do so as soon as possible.<br />

Unfortunately, a significant number <strong>of</strong> invoices involving card<br />

payments are being returned without all the necessary<br />

information being completed.<br />

For Credit Card payments the following must be quoted<br />

otherwise payments cannot be processed:<br />

• 16 digit number on front <strong>of</strong> card<br />

• Expiry date<br />

• Security code <strong>of</strong> last 3 digits in signature strip on<br />

reverse <strong>of</strong> card<br />

The Electric Steelmakers Guild<br />

Well, 2006 for the electric steelmakers has seen the<br />

greatest changes to UK electric steelmaking for many<br />

years, along with the ongoing battle for Corus ownership.<br />

Celsa UK, at its Cardiff site, started up a completely new<br />

melt shop on the 16th November 2006. This is a single 140<br />

tonne AC electric arc furnace with a six-strand caster. As I<br />

understand it, they will operate the new melt shop on a<br />

Monday to Friday mornings and afternoon shifts basis whilst<br />

running the old melt shop on night shifts and weekends.<br />

This is to allow for new equipment commissioning and<br />

training to be completed. This mode <strong>of</strong> operation will, as I<br />

understand it, continue into the New Year when they will<br />

finally close the old Tremorfa melt shop.<br />

Thamesteel, at its Sheerness site, has replaced the shaft<br />

furnace with a conventional furnace. The project included<br />

the removal <strong>of</strong> over 300 tonnes <strong>of</strong> reinforced concrete<br />

foundations and replacement <strong>of</strong> over 250 tonnes <strong>of</strong> new<br />

foundations. The 95 tonne shaft furnace was removed and<br />

replaced with a state <strong>of</strong> the art conventional EOBT furnace<br />

as well as a new, in house designed, doghouse and ro<strong>of</strong><br />

6. The published audited accounts were presented. The<br />

General Council’s recommendation that the published<br />

accounts be accepted was approved.<br />

7. The General Council’s recommendation that the Rules <strong>of</strong><br />

the <strong>Institute</strong> as published in the July 2006 issue <strong>of</strong> The<br />

<strong>Refractories</strong> Engineer be adopted with effect from 15th<br />

September 2006 was approved.<br />

8. Subscriptions <strong>2007</strong>-The General Council’s<br />

recommendations that subscriptions be increased to<br />

£35-00 for cheque and debit card payments, and to £37-00<br />

for credit card payments was approved.<br />

9. Shorts Accountants <strong>of</strong> Ecclesall Road, Sheffield were<br />

appointed as the <strong>Institute</strong>’s auditors for the financial year<br />

2006/<strong>2007</strong>. Thanks were placed on record for the work<br />

carried out over a long period by the previous auditors,<br />

Baldwin & Co <strong>of</strong> Bilston.<br />

10. Presentation <strong>of</strong> a Certificate <strong>of</strong> Fellowship for Mr. P F<br />

Bell was deferred to a suitable future occasion.<br />

11. Mr. P Bottomley, President, introduced Dr. S A Franklin<br />

and invested him with the badge <strong>of</strong> <strong>of</strong>fice for 2006/<strong>2007</strong>.<br />

12. Dr. S A Franklin delivered his Presidential address<br />

(Appendix 2, Minute Book only and published in full in the<br />

November 2006 issue <strong>of</strong> “The <strong>Refractories</strong> Engineer”).<br />

13. Dr. S A Franklin, President, presented the Past<br />

President’s Medal and Certificate <strong>of</strong> Fellowship to Mr. P<br />

Bottomley.<br />

The meeting closed at 1-10pm<br />

For Debit Card payments the following additional<br />

information must also be quoted:<br />

• Valid from date<br />

• Issue number if applicable<br />

Please help us to ensure prompt processing by double<br />

checking that all requested data is quoted.<br />

canopy hood, new fume extraction systems and complete<br />

reworking <strong>of</strong> all the support services. The project time scale<br />

was very ambitious at 3 months and Thamesteel achieved 3<br />

months and one day, shutting down on the 1st September<br />

2006 and starting up on the 2nd December 2006. The<br />

furnace achieved 25 heats in one day on the 23rd<br />

December 2006 with still many areas <strong>of</strong> the operation to be<br />

optimised.<br />

The guild congratulates both companies in having the guts<br />

to make major investments in the future <strong>of</strong> UK electric<br />

steelmaking. This appears only to be the start <strong>of</strong> further<br />

capital investment programmes.<br />

We hope that <strong>2007</strong> proves to be a good year for all<br />

steelmakers and, in turn the associated<br />

refractory suppliers. We are all looking<br />

forward to our last Guild dinner <strong>of</strong> the 50th<br />

year at the Cutlers’ Hall, in Sheffield.<br />

John C Twiselton<br />

ESMG President<br />

THE REFRACTORIES ENGINEER page 5

IRE <strong>January</strong> 07 15/2/08 16:51 Page 7<br />

Obituaries<br />

Reginald<br />

Yomtov<br />

Mayorcas<br />

BSc, FInstE, FIRefEng<br />

It was with much<br />

sadness that we<br />

learned that Reginald<br />

Mayorcas, inaugural<br />

President <strong>of</strong> the<br />

<strong>Institute</strong> in 1961, died<br />

on 3rd December<br />

2006 at the age <strong>of</strong> 86<br />

years. The Funeral<br />

Service, held at<br />

Chester Crematorium on Friday, 8th December<br />

2006, was attended by his family and some 150<br />

friends and former colleagues, testifying to the high<br />

regard in which he was held by all who came into<br />

contact with him.<br />

Reg or Reggie as he was known to many friends,<br />

was born and brought up in Chiswick, West<br />

London. In 1949, he was invited to become the first<br />

resident investigator at the International Flame<br />

Research Foundation at Ijmuiden, Holland , a<br />

research facility that was serviced by an<br />

international team <strong>of</strong> research scientists and<br />

engineers. In 1956, he was appointed Deputy Head<br />

<strong>of</strong> the Steelmaking Division, at British Iron and Steel<br />

Research Association (BISRA) in Sheffield.<br />

On his appointment as Head <strong>of</strong> Steelmaking<br />

Research at John Summers & Sons Ltd in 1957, the<br />

family moved to Chester and Reg worked at<br />

Shotton until 1980. In the wake <strong>of</strong> BSC’s<br />

rationalisation, he took early retirement but neither<br />

his travels nor his commitment to the steel industry<br />

stopped there. He worked on a number <strong>of</strong><br />

consultancy assignments for British Steel’s<br />

overseas arm, for Rio Tinto Zinc and for AEA<br />

Harwell and also made three trips to the Durgapur<br />

steelworks in India to help with modernisation, and<br />

wrote a number <strong>of</strong> reports on energy use and<br />

efficiency.<br />

The founders <strong>of</strong> the <strong>Institute</strong> in 1961 wanted a<br />

suitable person to become their first President. Reg<br />

was a graduate Physicist and Fuel Technologist,<br />

and whilst occupying a Senior Management<br />

position within British Steel based at Shotton, his<br />

remit extended to a number <strong>of</strong> other <strong>of</strong> the<br />

Corporation’s plants. He was responsible for the<br />

complete fuel balance <strong>of</strong> the Shotton plant, at that<br />

time operating open hearth furnaces, and when<br />

part <strong>of</strong> the coke oven gas production at Shotton<br />

was being supplied to the National Grid as 'towns<br />

gas'<br />

page 6 THE REFRACTORIES ENGINEER<br />

www.ireng.org<br />

Reg was very interested in education and was a<br />

mentor for many young people in the Steel Industry,<br />

which together with his other experience and<br />

attributes, made him the ideal candidate to become<br />

the first President <strong>of</strong> the <strong>Institute</strong>. In addition to<br />

encouraging his many contacts to take up<br />

membership, he presented Technical Papers to<br />

several branches and a major keynote lecture at<br />

one <strong>of</strong> the early conferences, at a time when there<br />

was concern caused by rapidly diminishing stocks<br />

<strong>of</strong> fossil fuels. A few years before the closure <strong>of</strong> the<br />

Shotton Works, Reg took on the job <strong>of</strong> Coke Oven<br />

Manager, and although this was a completely new<br />

field for him, he quickly earned the respect <strong>of</strong> his<br />

peers in the industry. He ran the plant there until his<br />

retirement on the closure <strong>of</strong> the works.<br />

During in his career with British Steel, he held many<br />

responsible positions in technical committees <strong>of</strong> the<br />

Corporation and <strong>of</strong> the <strong>Institute</strong> <strong>of</strong> Metals, and was<br />

past Chairman <strong>of</strong> IOM’s Conference Committee for<br />

the Steelmaking Division. He was also a former<br />

Chairman <strong>of</strong> the North Wales Metallurgical Society.<br />

Although he suffered a major heart attack in 1984<br />

he quickly regained his fitness to the extent that he<br />

was able to celebrate his 75th birthday by playing<br />

tennis at his old club in his native Chiswick.<br />

In the latter twenty years <strong>of</strong> his life, he took on<br />

various responsibilities within the community and<br />

devoted his mind and energies to many local<br />

organisations and projects, rewarding him with the<br />

success he achieved in his pr<strong>of</strong>essional life.<br />

On the <strong>Institute</strong>’s 40th Anniversary, in 2002, Reg<br />

was the guest speaker at the commemorative<br />

Dinner, which was held at The De Vere Belfry,<br />

Sutton Coldfield. True to his ingenuity and creativity,<br />

Reg secured permission from the organisers to<br />

make the speech before the meal, so ensuring that<br />

he did not have sacrifice his enjoyment <strong>of</strong> the meal<br />

and the occasion prior to actually speaking. His<br />

motives were not entirely selfish, as he was<br />

conscious <strong>of</strong> a similar benefit accruing to the<br />

assembled audience. He also commented that his<br />

wife, Adèle, read The <strong>Refractories</strong> Engineer from<br />

cover to cover, and Reg quipped that because<br />

there was no asterisk before his name, he must still<br />

be alive. Sadly, an asterisk will now prefix Reg’s<br />

name in the Roll <strong>of</strong> Honour <strong>of</strong> Past Presidents, and<br />

although gone from us, he will certainly not be<br />

forgotten.<br />

To his widow, Adèle, his three daughters and all the<br />

family we <strong>of</strong>fer our sincere condolences.<br />

<strong>January</strong> <strong>2007</strong> Issue

IRE <strong>January</strong> 07 15/2/08 16:51 Page 8<br />

Dermot John<br />

Quirk,<br />

BEng, FIRefEng,<br />

1925-2006<br />

As reported in the<br />

President’s column in<br />

the November issue,<br />

Dermot John Quirk,<br />

Past President <strong>of</strong> the<br />

<strong>Institute</strong> died on 20th<br />

October 2006 at the<br />

age <strong>of</strong> 81years. The<br />

funeral service was<br />

held at St. Claire’s,<br />

Lache, Chester on<br />

October 31st, when<br />

Dermot’s family and numerous friends and<br />

colleagues were present to celebrate his life.<br />

Although Dermot was brought up and educated in<br />

Liverpool, he was nevertheless proud <strong>of</strong> his Irish<br />

forebears. After graduating as a Civil Engineer, he<br />

joined the Mersey Docks and Harbour Board. After<br />

working for Land and Marine Engineering dredging<br />

the wharf at John Summers and Sons, Shotton<br />

Steel Works he later joined the steel works as Civil<br />

Engineer. He soon found that his remit extended to<br />

a far greater field then civil engineering. His title<br />

was 'Building Manager' and he had responsibility<br />

for all the trade artisans employed on the plant,<br />

which included plumbers, painters, joiners and well<br />

over 100 refractory bricklayers who were employed<br />

on the many different furnaces.<br />

On the closure <strong>of</strong> Shotton Works, Dermot joined the<br />

George Edward<br />

Seeley,<br />

F I Ref Eng, 1923-2006<br />

George Seeley, who was a<br />

staunch supporter <strong>of</strong> the <strong>Institute</strong><br />

died on 28th August 2006 aged<br />

83 years.<br />

On leaving school, he joined<br />

Appleby Frodingham Steelworks in Scunthorpe, and<br />

continued his education in engineering subjects<br />

whilst there.George served his country in the Royal<br />

Air Force from 1941 to 1946, and on demobilisatlon<br />

rejoined Appleby Frodingham as General<br />

Engineering Buyer. Following a period in steel sales<br />

for Richard Thomas and Baldwin, he became<br />

Senior Raw Materials Buyer. With the formation <strong>of</strong><br />

British Steel Corporation, George was appointed<br />

Purchaser <strong>of</strong> <strong>Refractories</strong>. He joined the<br />

Scunthorpe branch <strong>of</strong> the <strong>Institute</strong> in 1968.<br />

subsequently serving as Secretary, Treasurer and<br />

Vice-Chairman. George became involved with the<br />

editing and publishing <strong>of</strong> the <strong>Institute</strong>'s Journal,<br />

renamed The <strong>Refractories</strong> Engineer in 1995, and<br />

was responsible for sustaining the success <strong>of</strong> the<br />

publication from 1976 to 1983.<br />

George's contribution to the <strong>Institute</strong> was<br />

<strong>January</strong> <strong>2007</strong> Issue<br />

www.ireng.org<br />

Clwyd County Council who had taken on<br />

responsibility for the redevelopment <strong>of</strong> the Shotton<br />

site, thus he found himself back in the area which<br />

he knew so well, and where he had spent the<br />

majority <strong>of</strong> his working years.<br />

Dermot developed a keen interest in refractories,<br />

and he was one <strong>of</strong> the founder members <strong>of</strong> the<br />

Lancashire and North Wales Branch, becoming the<br />

first Branch Chairman. In this position he was an<br />

enthusiastic and regular attendee at General<br />

Council Meetings.<br />

There was a proposal that the <strong>Institute</strong> should hold<br />

a technical conference, and Dermot together with<br />

C K (Ken) Walker, President in 1974/75, arranged<br />

The <strong>Institute</strong>s first Annual Conference, which was<br />

held over 2 days at Southport. In the 2 succeeding<br />

years the same team arranged 2-day conferences<br />

at Buxton.<br />

Dermot was very honoured to be elected President<br />

in 1970, and took his responsibilities very seriously,<br />

believing that a strong <strong>Institute</strong> existed because <strong>of</strong><br />

the branch structure.<br />

Dermot was a solid family man with strong religious<br />

beliefs, and after the sad early death <strong>of</strong> his wife, he<br />

lived alone in Chester, but still kept in very close<br />

contact with his children and their families. He<br />

played a very active part in the catholic community,<br />

and was chair <strong>of</strong> governors for the local school for<br />

many years.<br />

To Dermot’ s family, we extend our sincere<br />

condolences.<br />

recognised by the award <strong>of</strong> Honorary Membership<br />

in September 1988, and subsequently Fellowship in<br />

September 1990.<br />

He was also an active member <strong>of</strong> the Scunthorpe<br />

Probus Club, wrote poetry, and was proud <strong>of</strong> his<br />

achievement in helping to form the Humber branch<br />

<strong>of</strong> Air-Sea Rescue in1977. He had also traced his<br />

family tree back to 1762.<br />

Unfortunately, George's health deteriorated over<br />

the past few years, but supported by his daughter,<br />

Heather Spindley and family, he had managed to<br />

overcome most <strong>of</strong> his health problems until around<br />

three months before his death. Following a fall on<br />

25th August 2006, George was admitted to hospital<br />

and passed away surrounded by his family on<br />

August 29th.<br />

The funeral service was held at Scunthorpe<br />

Crematorium on 6th September and was attended<br />

by his family and numerous friends and former<br />

colleagues.<br />

To all his family, we extend our sincere<br />

condolences.<br />

THE REFRACTORIES ENGINEER page 7

IRE <strong>January</strong> 07 15/2/08 16:51 Page 9<br />

Branch News<br />

Introduction<br />

Since the success <strong>of</strong> the first <strong>Institute</strong> <strong>of</strong> <strong>Refractories</strong><br />

<strong>Engineers</strong> (Australian Branch) held in 2001, interest and<br />

support for this informative and dedicated refractories<br />

event has continued to grow. The focus on practical<br />

rather than theoretical aspects <strong>of</strong> refractory engineering<br />

appealing to industrial practitioners both domestically and<br />

internationally. Not only does this event enable delegates<br />

to learn more about refractories technology, it also<br />

provides a networking opportunity through participation<br />

with manufacturers, installers, researchers and a variety<br />

<strong>of</strong> industrial end users. This is the fifth conference to be<br />

held since establishing an Australian Branch <strong>of</strong> the IRE<br />

and Conference <strong>2007</strong> and for the first time will include a<br />

second day dedicated to a training workshop.<br />

Potential Conference Technical Topics<br />

● Anchors<br />

● Insulating materials<br />

● Installation<br />

● Plant commissioning and steam explosions<br />

● Service performance issues<br />

● Steel & non-ferrous applications & experiences<br />

Training Workshop<br />

This is the first time that the Australian Branch <strong>of</strong> the<br />

<strong>Institute</strong> <strong>of</strong> <strong>Refractories</strong> <strong>Engineers</strong> has attempted to <strong>of</strong>fer<br />

generic refractories training aimed at the young engineer<br />

and those who want to achieve a basic understanding <strong>of</strong><br />

refractories engineering and technology. The workshop<br />

will involve a number <strong>of</strong> respected speakers presenting<br />

areas such as:<br />

● Refractory materials (acid bricks, basic bricks,<br />

monolithics, manufacturing methods).<br />

● General applications (i.e. choice <strong>of</strong> bricks versus<br />

monolithics)<br />

● Installation (casting, gunning & bricking)<br />

● Failure modes (Chemical corrosion, thermal,<br />

mechanical, erosion etc)<br />

Who should attend?<br />

● Plant Maintenance personnel<br />

● Plant Managers and supervisors<br />

● Purchasers<br />

● <strong>Refractories</strong> <strong>Engineers</strong><br />

● Refractory Installers<br />

● Refractory Manufacturers<br />

● Researchers<br />

● Users<br />

Exhibition & Sponsorship<br />

Depending on response, it is hoped that an exhibition <strong>of</strong><br />

equipment, suppliers, installers, manufacturers and<br />

foundry products and services will be held, providing an<br />

opportunity for delegates to view a wide range <strong>of</strong><br />

products and services. In addition a call for sponsors will<br />

be made shortly.<br />

Cost <strong>of</strong> attendance<br />

Australian Branch News<br />

The 5th <strong>Institute</strong> <strong>of</strong> <strong>Refractories</strong> <strong>Engineers</strong> Conference<br />

(Australian Branch) - Monday 2 July <strong>2007</strong><br />

Training Workshop - Tuesday 3 July http://www.ireaus.org.au<br />

Costs include morning and afternoon tea and light lunch<br />

on both days PLUS the conference dinner on the evening<br />

<strong>of</strong> July 2nd.<br />

page 8 THE REFRACTORIES ENGINEER<br />

Conference Training<br />

(July 2) (July 3)*<br />

Member $320 $50<br />

Non-member $400 $70<br />

Bona Fida Student $250 $40<br />

*As part <strong>of</strong> the IRE’s commitment to training, this event<br />

will be heavily subsidised.<br />

Venue and Accommodation<br />

Novotel Brighton Beach<br />

Cnr. The Grand Parade and Princess Street<br />

Brighton-le-Sands, Sydney NSW 2216<br />

Australia<br />

Tel: (+61) 2 9556 5111, Fax: (+61) 2 9556 5119<br />

A limited number <strong>of</strong> rooms are available at the conference<br />

venue. Delegates should arrange accommodation directly<br />

with the hotel. Rooms are available on a first come - first<br />

served basis. Should additional days be required please<br />

advise at the time <strong>of</strong> booking.<br />

Room price -<br />

Standard room - $204.00 or Bayview Suite - $239.00.<br />

Breakfast is available at an additional cost <strong>of</strong><br />

$20/person/day.<br />

To qualify for these rates please advise the hotel that your<br />

booking is for the IRE Conference.<br />

Car parking is available at $8.00 for day delegates and<br />

$15.00 overnight.<br />

Registration / Expression <strong>of</strong> Interest<br />

Name:<br />

Title:<br />

Affiliation:<br />

Address:<br />

Tel:<br />

Fax:<br />

I am interested in attending<br />

I am interested in exhibiting<br />

I am interested in sponsorship<br />

Please email to: Alan Blanch - <strong>Institute</strong> <strong>of</strong> <strong>Refractories</strong><br />

<strong>Engineers</strong> - aeblanch@bigpond.com<br />

Organising Committee<br />

Nigel Stone (Conference Chairman)<br />

Alan Blanch (Conference Secretary)<br />

John Gilbert (Treasurer)<br />

Dave MacDonald (Training Workshop Coordinator)<br />

Wayne Wright (Technical Program Chairman)<br />

Contacts<br />

Conference Chairman: Nigel Stone<br />

Tel: (+61) 3 9545 2790<br />

Fax: (+61) 3 9544 1128<br />

Email: Nigel.stone@csiro.au<br />

Secretariat: Alan Blanch<br />

Phone: (+61) 2 4955 7555 or (+61) 02 9914 5500<br />

Mobile: 0418 607920<br />

Fax: (+61) 2 4955 6464<br />

Email: aeblanch@bigpond.com<br />

<strong>January</strong> <strong>2007</strong> Issue

IRE <strong>January</strong> 07 15/2/08 16:52 Page 10<br />

Sheffield Branch News<br />

It Shouldn’t Happen To The President <strong>of</strong> The<br />

<strong>Institute</strong> Of <strong>Refractories</strong> <strong>Engineers</strong>!<br />

Members <strong>of</strong> the Sheffield Branch spent the<br />

evening <strong>of</strong> the 9th November listening to tales <strong>of</strong><br />

our intrepid President’s three month stint in China<br />

supervising the construction <strong>of</strong> some new coke<br />

ovens.<br />

Along with the technicalities <strong>of</strong> the actual<br />

construction work we learned about, Tottenham<br />

Hotspur memorabilia, bicycle riding, carpet slippers<br />

instead <strong>of</strong> work boots, self made Christmas dinner,<br />

and some “extremely interesting” cuisine. To top it<br />

all <strong>of</strong>f one lucky member present was presented<br />

with an “absolutely genuine” Rolex watch just for<br />

answering one simple question.<br />

Many thanks to Sam for an entertaining evening.<br />

John Bates<br />

After spending the last 33 years (yes I did say 33)<br />

as a member <strong>of</strong> the Sheffield Branch John has<br />

decided to “call it a day”.<br />

John modestly says “I joined the <strong>Institute</strong> around<br />

1971, was elected to the Committee in 1973, and<br />

have been there ever since”.<br />

The Sheffield Branch wish to thank John for all his<br />

considerable efforts over the years and wish him<br />

“all the best” for the future.<br />

NEW<br />

Branch News<br />

<strong>January</strong> <strong>2007</strong> Issue THE REFRACTORIES ENGINEER page 9

IRE <strong>January</strong> 07 15/2/08 16:52 Page 11<br />

Advertisement Feature<br />

Magna Encounters an<br />

Industrial Revelation<br />

Magna is an awe-inspiring and breathe taking venue in<br />

Rotherham, South Yorkshire. Winner <strong>of</strong> the Enjoy England<br />

Award for Business Tourism in 2006, and formerly the<br />

Templeborough Steelworks, Magna has been open for<br />

over four years and has welcomed a wide range <strong>of</strong><br />

corporate clients including O2, Argos, Mercedes, LDV,<br />

NPower, AEG, and even the Arctic Monkeys, who held<br />

their home-coming gig at Magna in April 2006.<br />

<strong>2007</strong> is possibly the most exciting year yet for Magna,<br />

with a £2.7 million corporate development plan in<br />

progress. Funding from Objective 1, Yorkshire Forward,<br />

SRIP, SRB6 and IFG has been matched by Magna to<br />

create an array <strong>of</strong> new facilities, including a new 600sqm<br />

event space in the Red Hall; a new glass fronted 150<br />

seater restaurant with an external terraced area ideal for<br />

dinners, events and exhibitions; seven new flexible<br />

syndicate rooms; a new glazed walkway leading to the<br />

Big Hall; and new kitchen and toilet facilities to service the<br />

main events space. The new facilities will enable Magna<br />

to provide more high quality events as well as<br />

accommodating small meetings and large conferences<br />

which require breakout areas.<br />

Magna hosts a series <strong>of</strong> unique spaces which inspire and<br />

encourage event organisers to use their imagination to<br />

create an unforgettable event. Spaces include the Big Hall<br />

and Magna Arena, a giant blank canvas that can be<br />

transformed into just about anything. Magna also has a<br />

multi-story, multi-media space in the Face <strong>of</strong> Steel as well<br />

as the Red Hall, pavilions Earth, Air, Fire and Water as well<br />

as smaller meeting rooms ideal for training and seminars.<br />

All areas are suitable to host any event whatever the<br />

scale and are perfect for banquets, product launches,<br />

page 10 THE REFRACTORIES ENGINEER<br />

conferences, concerts and even weddings. Magna is a<br />

truly unique and innovative venue; the only limit when<br />

holding an event at Magna is the client’s imagination as<br />

the team ensure to create one-<strong>of</strong>f successful events.<br />

For further information regarding the new facilities at<br />

Magna, or to enquire about holding an event, please<br />

contact Magna’s corporate team direct on 01709 723118<br />

Magna, Sheffield Road, Templeborough, Rotherham,<br />

S60 1DX.<br />

T: 01709 720002<br />

W: www.visitmagna.co.uk<br />

<strong>January</strong> <strong>2007</strong> Issue

IRE <strong>January</strong> 07 15/2/08 16:52 Page 12<br />

SFIL Human Resources Manager Steve Tagg joins the<br />

Forgemasters graduates.<br />

SHEFFIELD COMPANY<br />

PRODUCES AWARD WINNING<br />

WORKFORCE<br />

Sheffield Forgemasters’ latest tranche <strong>of</strong> highly skilled<br />

award winning apprentices have now graduated as full<br />

time employees.<br />

The 200-year-old company prides itself on putting crucial<br />

skills back into the British steel industry and building an<br />

expert workforce through its outstanding apprenticeship<br />

scheme and this year’s graduates are once again the<br />

cream <strong>of</strong> the crop.<br />

Company News<br />

Three <strong>of</strong> this year’s graduates from the engineering giants<br />

also finished second, third and fourth in the the 2006<br />

Metals Industry Apprentice <strong>of</strong> the Year (MIAY) -<br />

coordinated by the metals industry’s skills body, MetSkill in<br />

partnership with the Worshipful Company <strong>of</strong> Tin Plate<br />

Workers alias Wire Workers.<br />

Their success comes on the back <strong>of</strong> last year’s first place<br />

win at the awards for James Ayabina, a metallurgist at<br />

Sheffield Forgemasters International Ltd (SFIL).<br />

In a double triumph, electrician Shaun Rochester was<br />

awarded the 2005/6 EEF Young Engineer <strong>of</strong> the Year<br />

Award as well as picking up a third for the 2006 MIAY<br />

while studying for his ONC and HNC in Engineering<br />

Maintenance.<br />

The SFIL apprentices study for a variety <strong>of</strong> qualifications<br />

across a range <strong>of</strong> engineering disciplines including<br />

electrical engineering, metallurgy, lab-work, machining,<br />

engineering maintenance, mechanical engineering, metals<br />

processing, and fabrication and welding.<br />

Graham Honeyman, Chief Executive at SFIL, said: “The<br />

UK steel industry has lost a lot <strong>of</strong> important skills over the<br />

years and we need to find ways <strong>of</strong> putting that knowledge<br />

back.<br />

“SFIL is in a strong position to do just that and we have<br />

been careful in the selection <strong>of</strong> our apprentices, a<br />

decision borne out by the hard work that they have<br />

returned and the excellent awards that they have won.<br />

We are extremely proud <strong>of</strong> our graduates and I <strong>of</strong>fer them<br />

all my warmest congratulations.”<br />

This year’s SFIL graduates are Rob Woodhouse, Shaun<br />

Rochester, Michael Umpleby, James Ayabina, Jonathan<br />

Hoare, Stuart Lancaster, Ben Hargreaves, Wesley Mundy,<br />

Chris Wenham, John Parkin, Jonathon Bright, Stuart<br />

Fletcher, Ryan Laybourne and Richard Dixon.<br />

Veusvius commissions first Triad ® no cement technology aluminium<br />

furnace<br />

The newly sited tilting furnace was installed at Mil-Ver<br />

Metal Company Ltd (part <strong>of</strong> AMC Group) at their Coventry<br />

Works. This furnace brings extra production capacity to<br />

Mil-Ver’s Coventry Site as part <strong>of</strong> their long term<br />

consolidation project, headed up by Jim Wilkinson, Mil-Ver<br />

Foundry Manager and Colin Jackson, AMC Group Health,<br />

Safety & Environmental Manager.<br />

The furnace lining utilises Vesuvius’ Triad® range <strong>of</strong><br />

cement free materials throughout, including:-<br />

● Triad 70AL Aluminium resistant cement free castable,<br />

used in all metal contact areas <strong>of</strong> the furnace (hearth,<br />

ramps, sill, bath walls etc);<br />

● Triad 70 High alumina cement free castable used<br />

throughout the upper walls;<br />

● Triad 45AL Mid alumina cement free castable with<br />

added aluminium resistance, used in the backing lining<br />

in the bath area;<br />

● Triad 45 Mid alumina cement free castable used in the<br />

furnace ro<strong>of</strong>.<br />

All the above products can be installed by traditional<br />

casting with vibration, pump casting, or shotcreting. The<br />

materials were selected for their ease <strong>of</strong> installation and<br />

ability to be dried out rapidly. A complete furnace reline<br />

installed using traditional low cement and standard<br />

castable typically requires a dry-out <strong>of</strong> 150 hours; this<br />

furnace was safely and successfully dried out and<br />

commissioned in half that time. This enables producers to<br />

be back in production much more quickly than with<br />

traditional furnace lining materials, saving money by<br />

reducing furnace down time.<br />

<strong>January</strong> <strong>2007</strong> Issue THE REFRACTORIES ENGINEER page 11

IRE <strong>January</strong> 07 15/2/08 16:52 Page 13<br />

Company News<br />

Kerneos China Ltd<br />

announces further<br />

investments in its Chinese<br />

facilities<br />

Kerneos China Ltd. has increased its manufacturing<br />

capacity for SECAR ® products at its TEDA (China) plant.<br />

Further capacity extension is scheduled to come on<br />

stream in the early months <strong>of</strong> <strong>2007</strong>, as well as expanded<br />

laboratory facilities to meet the technical demands <strong>of</strong><br />

Asian customers locally.<br />

Christian Sacchetti, CEO <strong>of</strong> Kerneos (formerly Lafarge<br />

Aluminates), commented:<br />

“The adoption <strong>of</strong> high quality SECAR ® products in the<br />

Almatis CEO turns<br />

over leadership<br />

Frankfurt, December 6th, 2006. Almatis announces that<br />

as <strong>of</strong> November 28, 2006, Oscar Groomes has stepped<br />

down from his position as CEO <strong>of</strong> Almatis.<br />

Mr. Groomes will assume a new role within the group as a<br />

non-executive board member, following his decision to<br />

relocate to the USA due to personal reasons.<br />

Hervé de Carmoy has reassumed the role <strong>of</strong> Executive<br />

Chairman to lead the Company’s top management team<br />

and effect a smooth transition. Furthermore, Almatis<br />

expects to appoint a Chief Operating Officer (“COO”) who<br />

will assume full day-to-day management responsibility for<br />

all business areas in early <strong>2007</strong>.<br />

“The key to a successful transition lies in having built a<br />

solid foundation <strong>of</strong> growth and pr<strong>of</strong>itability. Over the past<br />

two years as CEO, Oscar Groomes has turned Almatis<br />

into a growing enterprise and truly global organization. We<br />

page 12 THE REFRACTORIES ENGINEER<br />

fiercely competitive Chinese market has been very<br />

positive, we see in China a real demand for high quality<br />

products.<br />

The extra capacity will allow Kerneos to meet the forecast<br />

future demands <strong>of</strong> the Asian refractory market for many<br />

years to come and is a strong statement <strong>of</strong> our<br />

confidence in our Chinese team. The improved laboratory<br />

facilities will allow our technical team to address customer<br />

demands and help Kerneos to boost further its customers<br />

training programmes and development initiatives.”<br />

look forward to a continued relationship as he joins the<br />

board. The top management team <strong>of</strong> Almatis will continue<br />

to expand customer service and industrial excellence,<br />

thus extending value to our customers, stakeholders and<br />

business partners around the world”, states Hervé de<br />

Carmoy.<br />

About Almatis<br />

Almatis is the global leader in the development,<br />

manufacture and supply <strong>of</strong> highquality specialty alumina<br />

products. With near 900 employees worldwide, the<br />

company’s products are used in a wide variety <strong>of</strong><br />

industries, including steel production, cement production,<br />

non-ferrous metal production, plastics, paper, ceramics,<br />

carpet manufacturing and electronic industries. Almatis is<br />

headquartered in Frankfurt, Germany.<br />

<strong>January</strong> <strong>2007</strong> Issue

IRE <strong>January</strong> 07 15/2/08 16:52 Page 14

IRE <strong>January</strong> 07 15/2/08 16:52 Page 15<br />

SFIL<br />

NEW MANAGEMENT<br />

RESCUES ONCE<br />

FAILING<br />

ENGINEERING GIANT<br />

Only 12 months ago one <strong>of</strong> the UK’s manufacturing giants,<br />

Sheffield Forgemasters International (SFIL), stood on the<br />

brink <strong>of</strong> disaster.<br />

In a remarkable turnaround the historic company has<br />

moved from being hours from complete closure to<br />

amazing success in just one year.<br />

The company was saved by a management buy out,<br />

engineered by Dr Graham Honeyman, Chief Executive <strong>of</strong><br />

Forgemasters, which secured 600 jobs and paved the<br />

way for a phenomenal one-year turnaround - the first<br />

anniversary <strong>of</strong> which was on September 19, 2006.<br />

For more than four years Graham, together with a closeknit<br />

team, maintained a vision for the 200-year-old<br />

engineering company in the face <strong>of</strong> complete adversity,<br />

staving <strong>of</strong>f liquidation to save jobs, pensions and 1,200<br />

suppliers from possible economic collapse.<br />

The team were aided by tactical support from the former<br />

Corus Chief Executive and now SFIL Chairman, Tony<br />

Pedder, and former Managing Director <strong>of</strong> the company,<br />

Peter Birtles - now an SFIL Director, as they worked with<br />

administrators PriceWaterhouseCoopers to save the<br />

company.<br />

Now with a turnover <strong>of</strong> £100 million, SFIL exports 80<br />

percent <strong>of</strong> its products, has <strong>of</strong>fices worldwide and an<br />

order book worth £100 million.<br />

This was made possible through a complex landmark deal<br />

aided by the government’s Pension Protection Fund (PPF)<br />

– only the second ever resolution worked on by the PPF -<br />

which solved the bankrupt company’s pension fund deficit<br />

and enabled the buyout to succeed but also through the<br />

hard work and determination from Honeyman and his<br />

colleagues.<br />

Graham and his dedicated management team worked<br />

tirelessly to protect Forgemasters future and to secure<br />

the MBO deal, winning full backing from the government,<br />

the SFIL workforce and the involved trade unions.<br />

Graham said: “This has been a consuming passion <strong>of</strong><br />

ours for a long time now. We have never let go <strong>of</strong> the fact<br />

that this company did not deserve to be put in<br />

administration.<br />

“Forgemasters is one <strong>of</strong> the last great British companies<br />

and every day we feel proud that our belief was right and<br />

that this buyout is working better than anyone would have<br />

believed.”<br />

SFIL now has the biggest order book in its history, its<br />

highest ever level <strong>of</strong> sales predicted for next year and an<br />

award-winning apprentice trained workforce, putting<br />

valuable specialist knowledge back into the British steel<br />

industry. It now also has 40 new apprentices on its books<br />

– an important benchmark for the future.<br />

page 18 14 THE REFRACTORIES ENGINEER<br />

Graham Honeyman started working for Forgemasters in<br />

1988 as a technical director and was made managing<br />

director under an American owned administration in<br />

December 1998 before leaving the company in early 1999.<br />

Two years later, the American owners asked him back to<br />

work as a consultant in a bid to regain some stability for<br />

the company. Graham worked hard to streamline<br />

operations, build a strong management team and to get<br />

rid <strong>of</strong> loss making contracts.<br />

These efforts culminated in his appointment as MD and<br />

subsequently leading the management buy out in 2005.<br />

Their over-arching notion for a MBO remained totally<br />

averse to putting the company in administration - which<br />

would only retain the company’s assets and some <strong>of</strong> its<br />

workforce.<br />

Graham said: “Things were looking very bad when I went<br />

back to Forgemasters. The American owners were having<br />

massive problems across their organisation and none <strong>of</strong><br />

that was reflecting well on their UK operations. We started<br />

work almost immediately to build relationships with<br />

creditors.<br />

“Forgemasters had been beset by problems for many<br />

years, culminating in a period in 2005 when we literally<br />

had hours before we closed.”<br />

Peter Kenny, Finance Director at SFIL, said: “Our concern<br />

was that the situation we were in – facing administration -<br />

was going to strip the workforce <strong>of</strong> their hard-earned<br />

pensions, make us lose our customers and cripple many<br />

<strong>of</strong> our suppliers. It would have created a situation that<br />

Forgemasters could not have recovered from. We had to<br />

find another way.”<br />

Graham added: “We weren’t going to let the people here<br />

down. These people are specialists working in a specialist<br />

organisation and would have found it extremely hard to<br />

get another job. We worked closely with the government<br />

to keep the company going and never gave up.”<br />

Graham’s pioneering view <strong>of</strong> SFIL in his earliest days with<br />

the company was, and still is, based upon SFIL embracing<br />

increasingly technical bespoke contracts and working to<br />

diversify the business.<br />

The MBO deal hinged around a £65m deficit carried by<br />

Forgemasters £120m pension fund, which made a buyout<br />

implausible. This was compounded by a £10m intercompany<br />

debt and a possible £10m clean up cost for a<br />

French Foundry left by the US owners.<br />

The government’s PPF stepped in as a contingent<br />

creditor and pursued its objective <strong>of</strong> maximising a return<br />

to the pension scheme. The PPF agreed to a cash<br />

amount <strong>of</strong> more than was available through liquidation<br />

and a 26 percent share in the newly established company<br />

(SFIL).<br />

<strong>January</strong> <strong>2007</strong> Issue

IRE <strong>January</strong> 07 15/2/08 16:52 Page 16<br />

“The idea <strong>of</strong> administration never held any sway with us,<br />

but our creditors didn’t think it could be done any other<br />

way,” said Peter.<br />

“Without the support <strong>of</strong> MPs like Richard Caborn, Clive<br />

Betts and Helen Jackson, and local civic leaders like Sir<br />

Bob Kerslake, who had the confidence and integrity to<br />

support our strategy for Forgemasters MBO, the whole<br />

shooting match would have gone, including the pensions<br />

<strong>of</strong> a dedicated workforce. The Government recognised<br />

that as one <strong>of</strong> the biggest employers in Sheffield it was a<br />

hugely important institution to keep.”<br />

Clive Betts, MP for Attercliffe, said: “Sheffield<br />

Forgemasters International Ltd is a world class company<br />

employing a highly skilled workforce.<br />

“I am really pleased that with help from other local MP’s<br />

<strong>January</strong> <strong>2007</strong> Issue<br />

SFIL<br />

and myself, the PPF was persuaded to <strong>of</strong>fer assistance to<br />

ensure that a successful MBO secured the future <strong>of</strong> the<br />

company.”<br />

This view was reflected by Sir Bob Kerslake, Chief<br />

Executive <strong>of</strong> Sheffield City Council, who said: “The service<br />

that Sheffield Forgemasters provides to our national and<br />

regional industry cannot be ignored. They are an<br />

important employer and have a superb approach to<br />

putting skills back into the UK steel industry.<br />

“The vision that Graham Honeyman and the MBO team<br />

displayed has produced a company with an outstanding<br />

export record and a forward thinking approach to further<br />

developing the organisation.”<br />

THE REFRACTORIES ENGINEER page 19 15

IRE <strong>January</strong> 07 15/2/08 16:52 Page 17<br />

Jetcasting<br />

Re-pr<strong>of</strong>iling <strong>of</strong> Blast<br />

Furnace Refractory<br />

Lining with<br />

JETCASTING<br />

Tobias Dyck, S.M.Kumar, Mike F.Struzik, Betram Kesselheim, Dr. Rainer Gaebel REFRATECHNIK Steel GmbH<br />

Schiess Str. 58, D-40549 Duesseldorf, Germany, steel@refra.com<br />

INTRODUCTION<br />

Blast furnace shaft re-pr<strong>of</strong>iling has always been done by<br />

bricking-up the shaft wall. Burnt bricks guaranteed highest<br />

quality, however installation could take up to two months.<br />

Looking for a faster method <strong>of</strong> installation, conventional<br />

dry gunning material was considered, which did not meet<br />

required properties. Further development <strong>of</strong> medium<br />

cement gunnables could not satisfy the needs <strong>of</strong> blast<br />

furnace operators either. The alternative attempt to solve<br />

the time and quality issues by using self-flowing<br />

castables, did not succeed: Although the refractory quality<br />

could be increased, frame work took too long and was<br />

too expensive.<br />

Therefore the perfect solution would have been a<br />

gunnable casting material, which describes exactly what<br />

jetcasting® is. This paper will explain the experience <strong>of</strong><br />

REFRATECHNIK Steel GmbH in Jetcasting®, which is<br />

<strong>of</strong>ten known as shotcreting or shotcasting.<br />

WHAT IS JETCASTING?<br />

The jetcast material is delivered as dry mixture, usually in<br />

1000 kg bags. On site it will be treated like a usual<br />

castable initially: Together with a precise amount <strong>of</strong> water<br />

the material will be well mixed for a specified time. A<br />

chemical additive present in the mix prolongs the setting<br />

process thus allowing a longer handling <strong>of</strong> the mass. After<br />

the mixing process is completed, the mix is released into<br />

a hopper located directly below the mixer. A dual pistons<br />

mechanism (Photo 1) pushes the material through a pipe<br />

system.<br />

When the material reaches the nozzle end, high pressure<br />

air is injected into the ready mixed castable stream and<br />

tear it apart. At the same time a liquid accelerator is<br />

added to ensure that the material sticks to the installation<br />

surface (Photo 2).<br />

In contrast to conventional gunning jetcast material is<br />

applied to the wall in rings <strong>of</strong> several fields. A “frame” <strong>of</strong><br />

approximately 1.5 x 1.5 metre is built by the operator -<br />

usually a combination <strong>of</strong> cooling boxes on top/at bottom,<br />

the ready-installed neighbouring fields and wooden<br />

boards. The operator then completes the field by spraying<br />

up to the final thickness <strong>of</strong> the lining (See Photo 3). A<br />

lining thickness <strong>of</strong> up to one metre can be installed this<br />

way. When the ring is completed, the working platform is<br />

lifted up to the next ring.<br />

REFRATECHNIK has successfully completed six<br />

installations <strong>of</strong> Jetcast material in blast furnace shafts.<br />

Shotcrete machinery developed and built by the company<br />

Montanbüro <strong>of</strong> Bochum, Germany was utilized for these<br />

jobs. Practical experience shows, that up to 10 tons<br />

material per hour can be applied, though the ideal<br />

capacity is about 6 to 7 tons per hour. By the use <strong>of</strong> two<br />

machines simultaneously, the application capacity can be<br />

improved to a maximum <strong>of</strong> about 20 tons per hour.<br />

Following example shows the schedule <strong>of</strong> typical blast<br />

furnace re-lining with Jetcast material:<br />

● Height <strong>of</strong> the blast furnace shaft:<br />

Approximately 30.0 m (from tuyere level to throat<br />

armour).<br />

● Diameter <strong>of</strong> the blast furnace shaft:<br />

13.2 m (tuyere level), respectively 8.2 m (throat<br />

armour).<br />

● Jetcasting lining thickness: 350 mm<br />

● Jetcasting installation time:<br />

65 hours (time includes preparation & dismantling <strong>of</strong><br />

machinery)<br />

● Material applied: 395 tons<br />

Photo 1: Jetcast machinery (Photo courtesy -<br />

Montanbüro)<br />

page 16 THE REFRACTORIES ENGINEER <strong>January</strong> <strong>2007</strong> Issue

IRE <strong>January</strong> 07 15/2/08 16:52 Page 18<br />

LABORATORY TEST RESULTS<br />

Salzgitter-Mannesmann research GmbH, a high<br />

temperature process engineering laboratory, located in<br />

Salzgitter has tested 15 different refractory materials<br />

available in the market to compare and select the best for<br />

the planned ‘Blast Furnace A’ relining. The laboratory<br />

results showed excellent physical and chemical properties<br />

<strong>of</strong> the ‘REFRAJETCAST LC F-60 AR/R’ to be the best<br />

techno-commercially.<br />

A gist <strong>of</strong> conclusions from the laboratory report indicates<br />

the following salient features:<br />

- Excellent refractoriness combined with lowest<br />

creeping rates under load up to temperatures above<br />

1600 °C<br />

- No permanent elongation or shrinkage during setting<br />

and after firing<br />

- Optimum values for crushing strength in unfired and<br />

fired state<br />

- Feedstock material <strong>of</strong> high quality to achieve batch<br />

Jetcasting<br />

Photo 2: Jetcasting in action Photo 3: Installation <strong>of</strong> blast furnace shaft wall<br />

composition optimized for working conditions in the<br />

blast furnace shaft<br />

- Excellent resistance against alkali attack<br />

- Highest resistance against abrasion<br />

- Very low apparent porosity<br />

- Good processability due to minimum requirement <strong>of</strong><br />

water<br />

The minimum amount <strong>of</strong> water required leads to a lower<br />

porosity and to better heating-up characteristics.<br />

Another great advantage <strong>of</strong> jetcast material compared to<br />

conventional gunning mass is the far less re-bound loss:<br />

approx. 15 % at conventional gunning and only 2 % at<br />

jetcasting. Due to minimal material loss during installation,<br />

that makes the estimation <strong>of</strong> refractory required (volume)<br />

easier. Less re-bound means less cleaning up the blast<br />

furnace shaft floor.<br />

Besides the extensive laboratory tests carried out at<br />

Salzgitter-Mannesmann research laboratory,<br />

REFRATECHNIK Steel’s Research & Development centre,<br />

Properties worst test field value best test field value REFRAJETCAST test value<br />

Abrasion resistance @ 1300 °C, 4 hrs 13.5 % 0.65 % 0.65 %<br />

Cold crushing strength: unfired 10 N/mm 104 N/mm 90 N/mm<br />

fired @ 1300 °C 59 N/mm 129 N/mm 129 N/mm<br />

fired @ 1500 °C 11 N/mm 176 N/mm (sintering) 150 N/mm<br />

Hot crushing strength @ 1000 °C<br />

Alkali attack resistance<br />

8 N/mm 68 N/mm 68 N/mm<br />

Cold crushing strength: unfired 4 N/mm 44 N/mm 44 N/mm<br />

fired @ 1300 °C 8 N/mm 89 N/mm 89 N/mm<br />

fired @ 1500 °C 5 N/mm 85 N/mm 85 N/mm<br />

Apparent porosity fired @ 1300 °C 24.6 % 14.3 % 14.3 %<br />

fired @ 1500 °C 31 % 9.5 % 9.5 %<br />

Dilatometer test: t0-temperature 886 °C > 1600 °C > 1600 °C<br />

t1%-temperature 1230 °C 1571 °C 1571 °C<br />

t5%-temperature 1472 °C > 1600 °C > 1600 °C<br />

Required mixing water 11.5 % 5.5 % 5.5 %<br />

<strong>January</strong> <strong>2007</strong> Issue THE REFRACTORIES ENGINEER page 17

IRE <strong>January</strong> 07 15/2/08 16:52 Page 19<br />

Jetcasting<br />

Photo 4: REFRAJETCAST LC F-60 AR/R under oxidising<br />

atmosphere: excellent alkali resistance, no traces <strong>of</strong><br />

bursting or infiltration.<br />

PRACTICAL EXPERIENCES WITH RE-PROFILING<br />

REFRATECHNIK has done seven blast furnace shaft re-lining projects with jetcast® material since the first<br />

application in Salzgitter/Germany (April 2004).<br />

Salzgitter Flachstahl GmbH, Germany - Blast Furnace B (volume: 2530 m3) - April 2004<br />

Salzgitter Flachstahl GmbH, Germany - Blast Furnace C (volume: 1164 m3) - June 2004<br />

EKO Stahl AG, Germany - Blast Furnace 5A (volume:1770 m3) - November 2004<br />

Stahlwerke Bremen GmbH, Germany - Blast Furnace 3 (volume: 1424 m3) - June 2005<br />

Salzgitter Flachstahl GmbH, Germany - Blast Furnace A (volume: 2330 m3) - August 2005<br />

AG der Dillinger Hüttenwerke, Germany - Blast Furnace 5 (volume: 2581 m3) - <strong>January</strong> 2006<br />

Mittal Steel Poland S.A, Krakow, Poland - Blast Furnace 3 (volume: 1719 m3) - May 2005<br />

NTMK, Nishniy Tagil, Russia - Blast Furnace 5 (volume: 2200 m3) - July 2005<br />

Including the recent project in Dillingen, REFRATECHNIK has been chosen to carry out six <strong>of</strong> the seven<br />

shaft re-lining projects in Germany during the past two years.<br />

located in Bendorf near Koblenz, conducted alkali<br />

restistance tests in both oxidising and reducing<br />

atmosphere. After careful preparation <strong>of</strong> laboratory test<br />

samples, 64 grams <strong>of</strong> K2CO3 was filled inside these<br />

samples and fired at 1350°C for 5 hours. The material<br />

shows excellent resistance against alkali both in oxidising<br />

and reducing atmosphere.<br />

CONCLUSION<br />

For blast furnace shaft re-lining jetcasting® is a relevant<br />

alternative to brick lining, when time plays an important<br />

role to the construction schedule. Since physical<br />

properties <strong>of</strong> jetcast material are very close to those <strong>of</strong><br />

low cement castables, jetcasting material ensures highest<br />

installation quality. Combined with effective machinery and<br />

Photo 5: REFRAJETCAST LC F-60 AR/R under reducing<br />

atmosphere: excellent alkali resistance, no traces <strong>of</strong><br />

bursting or infiltration.<br />

an experienced installation team highest lining quality<br />

suitable to the demands <strong>of</strong> today’s blast furnace long<br />

campaign requirements.<br />

REFERENCES<br />

[1] Dr. Rudolf Gronebaum<br />

„ Presentation <strong>of</strong> the shot-cast mixes Refrajetcast LC F-<br />

50 and Refrajetcast LC F-60 in comparison to their<br />

competitives “ Page 9.<br />

page 18 THE REFRACTORIES ENGINEER <strong>January</strong> <strong>2007</strong> Issue

IRE <strong>January</strong> 07 15/2/08 16:52 Page 20<br />

What does <strong>2007</strong> hold for<br />

your company?<br />

B-J Construction<br />

Total Refractory Service<br />

✓<br />

✓<br />

✓<br />

✓<br />

Certificate No. BS 22780<br />

Coke Oven Repairs<br />

Maintenance<br />

Installation<br />

New Build<br />

Ceramic Welding<br />

Hot Repairs<br />

Design<br />

Supply<br />

For more information, please contact us at:<br />

B-J Construction<br />

Lancaster Approach,<br />

North Killingholme<br />

Immingham, DN40 3JZ<br />

Telephone: 01469 540478<br />

Facsimile: 01469 540548<br />

✓<br />

✓<br />

✓<br />

✓<br />

P.O.Box 4,<br />

Logans Road,<br />

Motherwell, ML1 3NP<br />

Telephone: 01698 267426<br />

Facsimile: 01698 269774<br />

<strong>January</strong> <strong>2007</strong> Issue THE REFRACTORIES ENGINEER page 19

IRE <strong>January</strong> 07 15/2/08 16:52 Page 21<br />

Coreless Induction Furnaces<br />

CPS ®<br />

: an advanced solution<br />

for lining coreless induction<br />

furnaces melting nonferrous<br />

alloys C. Scabini*. *Eredi Scabini, Italy.<br />

Abstract<br />

Coreless induction furnaces have been used for decades<br />

in many foundries for melting and / or holding non-ferrous<br />

alloys. The need to reduce the melting times and to<br />

optimize energy consumption, has forced the OEM<br />

(furnace builders) to develop medium frequency high<br />

power furnaces, in order to increase their productivity. In<br />

these conditions, the refractory lining is subject to a high<br />

thermal, chemical and mechanical abuse which reduces<br />

its life.<br />

The aim <strong>of</strong> this paper is to introduce an innovative solution<br />

to re-line coreless induction furnaces. This technology<br />

uses a combination <strong>of</strong> pre-formed shapes and dry<br />

ramming mixes. The goal is to simplify the installation and<br />

to increase the life <strong>of</strong> the refractory lining, making the<br />

cleaning easier and reducing the energy consumption <strong>of</strong><br />

the furnace.<br />

Introduction<br />

The coreless induction furnace lining is typically<br />

constructed as illustrated in [figure 1].<br />

Figure 1: standard lining<br />

The hot face lining, which is in<br />

contact with the metal, is<br />

made with a dry ramming mix<br />

that is installed using a<br />

metallic former. In order to<br />

obtain the desired density, the<br />

refractory is compacted by direct or<br />

indirect vibration.<br />

The direct vibration [figure 2] uses<br />

machinery that compacts the refractory by<br />

the combination <strong>of</strong> pressure made by the<br />

operator and vibrations produced by the<br />

vibrator.<br />

This procedure depends entirely on the<br />

operator.<br />

Figure 2: direct vibration<br />

With the indirect vibration, the refractory is compacted<br />

through vibrations transmitted via the former, onto which<br />

the vibrator is applied [figure 3].<br />

With this technical procedure, the operator is not involved,<br />

but because <strong>of</strong> the resonance phenomena connected<br />

with the geometrical shape <strong>of</strong> the former and the<br />

discontinuity <strong>of</strong> the refractory thickness in the tapered<br />

area, it is difficult to obtain the same homogeneous<br />

vibrations from the top to the bottom <strong>of</strong> the lining.<br />

Moreover, the high acoustic pollution and the strong<br />

vibrations can create problems for the operators.<br />

Figure 3: bottom/wall indirect vibration<br />

page 20 THE REFRACTORIES ENGINEER <strong>January</strong> <strong>2007</strong> Issue

IRE <strong>January</strong> 07 15/2/08 16:52 Page 22<br />

Figure 4: temperature spreading <strong>of</strong> the<br />

traditional lining (wall section)<br />

Once the<br />

installation is<br />

finished, the<br />

refractory<br />

lining should<br />

be sintered<br />

before starting<br />

production.<br />

Depending on<br />

the refractory<br />

design, the<br />

form could be<br />

removed and<br />

therefore reutilised<br />

or<br />

melted during<br />

the first heat.<br />

During the<br />

sintering<br />

schedule, as<br />

the temperature increases, chemical and ceramic bonding<br />

takes place. Therefore, the hot face develops a higher<br />

strength compared to the interface with the coil grouting.<br />

In this area the refractory will stay un-sintered due to the<br />

low temperature [figure 4].<br />

A loose back-up is<br />

considered an<br />

advantage as it is able<br />

to stop eventual metal<br />

infiltration. Therefore,<br />

it is fundamental that,<br />

during the sintering<br />

schedule, the<br />

refractory develops an<br />

homogeneous hot<br />

face, with a loose<br />

back up, throughout<br />

the entire furnace.<br />

This result is however<br />

difficult to obtain, as<br />

the cooling <strong>of</strong> the coils<br />

only affects part <strong>of</strong> the<br />