GERMAN AMERICAN - Strothmann

GERMAN AMERICAN - Strothmann

GERMAN AMERICAN - Strothmann

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

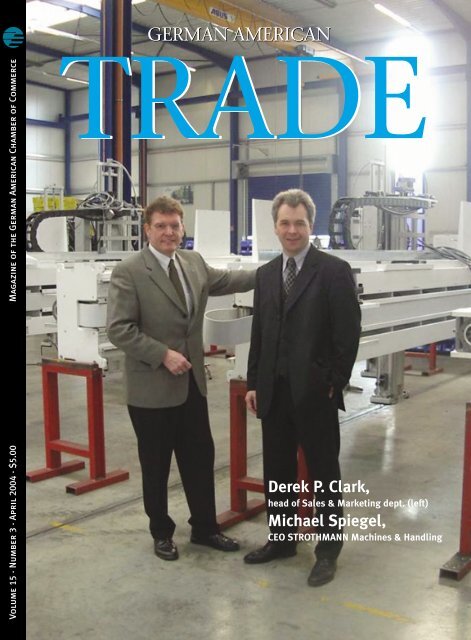

Volume 15 · Number 3 · April 2004 · $5.00 Magazine of the German American Chamber of Commerce<br />

<strong>GERMAN</strong> <strong>AMERICAN</strong><br />

TRADE<br />

Derek P. Clark,<br />

head of Sales & Marketing dept. (left)<br />

Michael Spiegel,<br />

CEO STROTHMANN Machines & Handling

Cover Story<br />

Cover Story<br />

6<br />

The RoundTrack rail system in elevator flow production:<br />

Arch-shaped rollers and a hardened steel rail for low rolling resistance<br />

German American Trade · Vol. 15 · No. 3

Innovation In Motion<br />

“We can handle it” – a statement which carries more<br />

than a figurative meaning for STROTHMANN customers,<br />

like for example Tower Automotive at Milwaukee, a tier<br />

one supplier for the U.S. American automotive industry.<br />

Here, body frames for all-terrain vehicles weighing –<br />

including the grippers – about as much as a complete mid-size<br />

European car, have to be transferred within welding lines.<br />

Sure, conveyors could do<br />

the job – but they take up<br />

lots of floor space, and<br />

Another exemplary application<br />

is the manufacturing of<br />

hoods for air conditioning sys-<br />

the mechanics is complicated, tems at Trane’s, a Texas-based<br />

too. The STROTHMANN solu- company. Here, STROTHtion<br />

employs linear robots, MANN implemented a han-<br />

which lift up<br />

dling system capa-<br />

the frame, Customers in the ble of processing a<br />

move it rapidly<br />

to the next<br />

U.S. include Ford and<br />

wide variety of<br />

blanks and sizes.<br />

welding sta- DaimlerChrysler and Without complicattion,<br />

and put it major component ed servo-motors, a<br />

down again.<br />

The robots can<br />

suppliers for the<br />

specially developed<br />

end of arm tooling<br />

carry up to automotive industry<br />

adapts automatical-<br />

3,500 lbs.,<br />

ly to the size of the<br />

cover distances of 40 ft., and blank, a solution which<br />

also operate much faster than reduces moving masses and<br />

conveyor systems.<br />

saves costs.<br />

Machines for Handling<br />

Since 1976, STROTH-<br />

MANN GmbH & Co.<br />

KG develops and<br />

builds machines and<br />

implements solutions<br />

for all kinds of<br />

logistic and handling<br />

problems. Products<br />

and services range<br />

from linear shuttles<br />

and gantries, destackers<br />

and centering stations,<br />

end of arm tools<br />

and the patented<br />

RoundTrack floor rail<br />

system to complete press<br />

line automation and<br />

refurbishing. Customers in<br />

Cover Story<br />

German American Trade · Vol. 15 · No. 3 7

Cover Story<br />

Destacker and<br />

linear robot<br />

8<br />

Founded<br />

Ever since W. STROTHMANN<br />

GmbH & Co. KG was founded in<br />

1976, the development and<br />

implementation of effective<br />

solutions in machine engineering<br />

and handling technology<br />

was the governing principle for<br />

our company.<br />

STROTHMANN has been in the<br />

U.S. since 1998.<br />

Corporate Credo:<br />

Innovation in Motion means to<br />

constantly find innovative solutions<br />

in order to get things<br />

moving for our customers.<br />

U.S. Products<br />

DualFeeder, MagShuttle,<br />

RoundTrack.<br />

Corporate Fact-sheet<br />

The STROTHMANN Brand<br />

STROTHMANN has earned its<br />

reputation for the linear shuttles<br />

and destacker concepts.<br />

North America Headquarters<br />

ATR STROTHMANN<br />

400 Collier – McMillan Drive<br />

Cambridge, Ontario<br />

N1R 7H7/ Canada<br />

http://www.atrsi.com<br />

Sales Offices in USA and Mexico<br />

Industry Scope LLC<br />

733 Mornigside Drive<br />

Grand Blanc, Michigan 48439,<br />

USA<br />

www.industry-scope.com<br />

U.S. Sales<br />

$ 3 Million<br />

the U.S. include Ford and<br />

DaimlerChrysler and major<br />

component suppliers for the<br />

automotive industry like Tower<br />

Automotive or the Magna<br />

Group.<br />

“Being a special engineering<br />

company”, says Derek P. Clark,<br />

head of Sales & Marketing,<br />

“means that we can do both –<br />

assemble a solution using standardized<br />

components just as<br />

well as develop and build a<br />

dedicated system tailored to<br />

the individual application at<br />

hand.” As part of the globally<br />

operating Siempelkamp holding<br />

(with businesses in<br />

Machinery and Plant<br />

Manufacturing, Industrial<br />

Automation, Foundry<br />

Products, Nuclear Engineering,<br />

and Metal Forming), STROTH-<br />

MANN can draw from the<br />

know-how of other group<br />

members as well. A good example<br />

is the motion control soft-<br />

German American Trade · Vol. 15 · No. 3

ware for the linear robots<br />

which is provided by ATR, the<br />

group’s specialist for system<br />

integration.<br />

KISS – Keep it simple, STROTH-<br />

MANN<br />

“Often, a simple solution<br />

brings about the greatest<br />

effect”, says Derek P. Clark.<br />

“The linear robot, for example,<br />

with its clearly defined movements<br />

along linear axes, greatly<br />

simplifies control. And there<br />

are almost no centrifugal<br />

forces. Even large blanks can be<br />

transferred at high speeds without<br />

bending or buckling. The<br />

high degree of dynamism of<br />

the shuttles is also based on a<br />

simple idea: The smaller the<br />

mass, the more easily it can be<br />

accelerated. That’s why the<br />

German American Trade · Vol. 15 · No. 3<br />

A glimpse into the near future: Vision based centering station<br />

The trend towards increased<br />

flexibility within the automotive<br />

industry continues. The<br />

ability to process a larger<br />

range of blanks (from ashtraysized<br />

sheets to complete body<br />

sides) as well as single or double<br />

blanks improves utilization<br />

rates and reduces costs, but<br />

also puts enormous demands<br />

on the devices which position<br />

the blanks for optimum press<br />

loading. A tried and tested<br />

solution is STROTHMANN’s<br />

mechanical centering station<br />

whose overall breadth is continuously<br />

adjustable to fit<br />

sheet size. But high flexibility<br />

means also high complexity,<br />

which limits the possibility of<br />

further improvement. Because<br />

of this, STROTHMANN is developing<br />

a new system: “At the<br />

moment, we are working on<br />

reducing the number of<br />

mechanical components by<br />

integrating an image processing<br />

system into the centering<br />

station”, explains head of<br />

development Rainer Massow.<br />

Our goal is not only to increase<br />

flexibility, but also to be considerably<br />

faster than the<br />

mechanical solution.”<br />

STROTHMANN will present the<br />

new device at the 18th<br />

International Sheet Metal<br />

Working Technology Exhibition<br />

(Euroblech) in Hanover /<br />

Germany, in Oct. 2004.<br />

Cover Story<br />

Linear<br />

movements and<br />

a stationary<br />

motor provide<br />

a high level of<br />

dynamism<br />

9

Cover Story<br />

10<br />

STROTHMANN linear robots robot delivered to him for a<br />

feature a stationary motor with machine tool, remembers Mr.<br />

a timing belt transmission for Clark. But the scale is different,<br />

the vertical movement.” of course: The new MagShuttle<br />

features a virtually limitless<br />

Next step: The MagShuttle travel length – combined with<br />

With the development of the a load capacity of 150 kg,<br />

world’s first shuttle with syn- velocities up to 5.5 m/s (nearly<br />

chronous linear direct drives in twice the speed of a belt shut-<br />

both horizontal and<br />

tle) and an accelera-<br />

vertical axes, Often, a simple tion up to 20 m/s_ –<br />

STROTHMANN<br />

managed to speed up<br />

its robots even fur-<br />

solution brings<br />

about the<br />

that’s four times<br />

faster than a conventional<br />

shuttle.<br />

ther. The force of the greatest effect Without transmis-<br />

motor is directly<br />

sion elements, linear<br />

applied to the shuttle carriage, direct drives also operate with<br />

which is floating magnetically less vibration as well as lower<br />

along the horizontal beam. wear and tear rates. The posi-<br />

Since this type of drive is often tioning accuracy is in the range<br />

used for machine tool, a cus- of ±0.1 mm, both vertically<br />

tomer even mistook a linear and horizontally. “Since these<br />

STROTHMANN stacker<br />

German American Trade · Vol. 15 · No. 3

Interview with Michael Spiegel,<br />

CEO STROTHMANN Machines & Handling<br />

Q: Mr. Spiegel, STROTH-<br />

MANN started as a small<br />

machine engineering com-pany<br />

in East Westphalia / Germany.<br />

Today, STROTHMANN handling<br />

systems can be found all<br />

over the world – in the U.S. for<br />

example at the Magna plant at<br />

Spartanburg / South Carolina.<br />

What’s the STROTHMANN<br />

secret?<br />

A: Actually, it’s no secret, but<br />

all too obvious: Keep innovating,<br />

improve your know-how,<br />

keep moving – the STROTH-<br />

MANN formula for this is<br />

“Innovation in Motion”. Our<br />

products – RoundTrack, linear<br />

shuttles, destackers, centering<br />

stations – are notable for presenting<br />

simple and effective<br />

answers to the handling and<br />

transportation needs of our customers.<br />

Q: Who are your customers?<br />

A: Customers include companies<br />

from branches like furniture<br />

industry, machine engineering,<br />

even Airbus Industries.<br />

Metal sheet processing, especially<br />

the automotive industry, is of<br />

course very important. Here,<br />

STROTHMANN has gathered<br />

considerable expertise over the<br />

years through implementing<br />

systems for press line automation<br />

all over Germany and<br />

Europe.<br />

Q: So, if I am in the auto<br />

business, what’s my STROTH-<br />

MANN advantage?<br />

A: There are very rigid<br />

demands concerning quality<br />

standards and delivery reliability,<br />

because in this field, all<br />

chances to cut the costs have to<br />

be pursued to stay ahead of the<br />

global competition. Think of<br />

concepts like just in time or lean<br />

production, platform and modular<br />

strategies – many of these<br />

stem from the automotive<br />

industry. In a situation like this,<br />

the suppliers are under constant<br />

pressure. And a production line<br />

that isn’t operated efficiently,<br />

suffers from frequent downtimes,<br />

slow tooling, ineffective<br />

handling etc. is wasting a lot of<br />

money. Dynamic handling<br />

solutions are a key factor to face<br />

the competition.<br />

Q: Which means: Press line<br />

automation “Made in<br />

Germany” for the rest of the<br />

world?<br />

A: Well, that’s too strong a<br />

statement. Of course, the global<br />

scope and structure of the<br />

industry, with production lines<br />

and suppliers distributed all<br />

over the world, was definitely a<br />

reason to expand our business<br />

beyond Germany and Europe –<br />

and to open up the enormous<br />

North American market. But<br />

when I mentioned moving and<br />

mobility a little earlier, I was<br />

also driving at the ability to<br />

adapt to a particular market.<br />

Q: So, what is special about<br />

the American market?<br />

A: The first which comes to<br />

my mind is the service, which is<br />

at least as impor-tant as the<br />

technology. The consequences<br />

are far beyond establishing a<br />

service network. It’s more about<br />

construction and design of your<br />

machines: One must be able to<br />

eliminate failures and malfunctions<br />

in the easiest way possible.<br />

In Europe, you often rely on the<br />

experts on site, who will investigate<br />

and fix the problem (sooner<br />

or later). In the U.S., you<br />

exchange a module – and production<br />

continues. Another specialty<br />

are FMEA- (Failure Mode<br />

and Effect Analysis) and RCM-<br />

/R&M- (Reliability Centered<br />

Maintenance) studies. They are<br />

costly, of course, but in the long<br />

run, you benefit from an<br />

extended know-how and<br />

improved product quality. And<br />

last but not least: We learned<br />

that flexibility in product management<br />

is an important quality<br />

while working together with<br />

our American partners.<br />

“Nothing is as sure as change”,<br />

as you say – but nevertheless<br />

you have to keep the deadline.<br />

So engineering, structured planning<br />

and coordination skills<br />

must go hand-in-hand.<br />

Q: Taking the other perspective,<br />

are there any special characteristics<br />

of Ger-man automation?<br />

A: Americans like the high<br />

quality standards of our<br />

machine building. “Made in<br />

Germany” has a good ring to it.<br />

True, there are many areas<br />

where Americans are using<br />

domestic automation parts, but<br />

for many key components –<br />

especially in the automotive<br />

industry – the label “Made by<br />

STROTHMANN” is very important<br />

– and that’s a major stimulus<br />

for us, to keep on innovating.<br />

Cover Story<br />

German American Trade · Vol. 15 · No. 3 11

12<br />

Features<br />

STROTHMANN<br />

facility at Schloß<br />

Holte-Stukenbrock,<br />

Westphalia, Germany<br />

Company Background<br />

W. STROTHMANN GmbH &<br />

Co. KG has been a force of<br />

innovation in transport and<br />

handling facilities ever<br />

since the company was<br />

founded in 1976. With 86<br />

employees worldwide,<br />

STROTHMANN manufactures<br />

linear and rotary robotic<br />

components and systems,<br />

including end of arm tooling,<br />

employed for handling<br />

a host of materials in a wide<br />

variety of process applications.<br />

STROTHMANN feeders<br />

and shuttles are typically<br />

used in sheet metal destacking<br />

and stacking,<br />

bodyshop transfers, part<br />

and pallet racking and<br />

stacking, inter-press<br />

automation, linear and<br />

gantry robots for transferring<br />

parts and machine tool<br />

load and unload systems.<br />

STROTHMANN is also the<br />

inventor of the patented<br />

Round Rail Floor System.<br />

Due to an extremely low<br />

rolling resistance, it allows<br />

for simple and inexpensive<br />

planar transport of large<br />

loads within a production<br />

site. Running on concave<br />

roller profiles, even 10 ton<br />

devices can easily be moved<br />

by hand by a single person<br />

along a round track protruding<br />

only millimeters from<br />

the floor.<br />

advantages have gotten around millimeters from the ground,<br />

in the meantime, I don’t expect and is therefore no hindrance<br />

any more mix-ups”, Mr. Clark to persons or vehicles.<br />

believes.<br />

Cleaning is also simple.<br />

Ever since its introduction,<br />

On the RoundTrack<br />

the system has proven its suit-<br />

The RoundTrack floor rail ability for daily use, be it at the<br />

system also embraces the KISS- Airbus facilities in Hamburg /<br />

principle. Key elements are a Germany, where body parts of<br />

round rail made from hardened up to 25 tons are moved via<br />

and polished steel, and rollers carts of about 69 ft. length, or<br />

with a “gothic-arch-shaped at various press lines for metal<br />

profile”, which together pro- sheet and die transport. Here,<br />

vide for an extremely low the combination of<br />

rolling resistance and high RoundTrack-based blank carts<br />

durability. One single person and fast destackers ensures a<br />

can move 10<br />

tons of equip- STROTHMANN is<br />

continuous “head of<br />

line” material feed.<br />

ment by hand, the right partner Whenever classical<br />

and carts with<br />

geared motors<br />

can carry<br />

to get things<br />

moving quicker<br />

band-conveyors are not<br />

applicable, the<br />

RoundRail system can be<br />

weights up to 50 and smoother<br />

used to establish flow<br />

tons. The system<br />

production assembly<br />

is easy to install: An aluminum lines and improve in-house<br />

profile is inset and cast flush logistics. The international oper-<br />

with the floor, in which the ating Trumpf Company, which<br />

round rods are laid in. With is well known for its machine<br />

crossover tracks and platforms, tools and laser technology, man-<br />

a complete logistical concept aged to further improve produc-<br />

can be designed around the tivity and quality by introduc-<br />

system. The round upper edge ing a RoundTrack-based flow<br />

of the rail protrudes only a few production system.<br />

German American Trade · Vol. 15 · No. 3

The STROTHMANN way<br />

Finding and implementing<br />

effective solutions in machine<br />

engineering and handling<br />

technology is STROTHMANN’s<br />

key competence. Derek P.<br />

Clark: “Being able to run a<br />

press line at almost the theoretical<br />

limit of the maximum<br />

stroke rate because of<br />

improved handling and tooling,<br />

or to rely upon logistics<br />

tailored to the requirements of<br />

the manufacturing process is a<br />

major advantage in competition.<br />

With its expertise and<br />

ongoing history of innovation,<br />

STROTHMANN is the<br />

right partner to get things<br />

moving quicker and smoother<br />

– that’s what we want to<br />

be known for.”<br />

Contact:<br />

STROTHMANN<br />

Machines & Handling<br />

Derek Clark<br />

Altenkamp 5<br />

D-33758 Schloss Holte-<br />

Stukenbrock<br />

Fon: +49 5207 / 9122-50<br />

Fax: +49 5207 / 9122-96<br />

e-mail:<br />

d.clark@STROTHMANN.com<br />

www.STROTHMANN.com<br />

Magnetic<br />

Shuttle with<br />

tooling<br />

Features<br />

German American Trade · Vol. 15 · No. 3 13