Stewart & Stevenson EMDSI

Stewart & Stevenson EMDSI

Stewart & Stevenson EMDSI

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

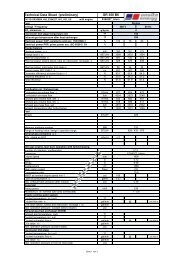

<strong>Stewart</strong> & <strong>Stevenson</strong>Custom Marine Packages for Commercial, Naval and Government VesselsCustom marine packages from <strong>Stewart</strong> & <strong>Stevenson</strong>provide power for propulsion and ships service generators onferries, offshore tugboats, offshore supply vessels, harbor tugsand towboats.Our marine packages feature EMD Series 710 marine enginesthat offer 2000 to 5000 continuous horsepower at 900 rpm.Marine Equipment Sets For Marine Propulsion (ABS Ratings)*MODEL DESIGNATIONENGINE MODEL800 RPM ENGINE RATINGSBHPkW900 RPM ENGINE RATINGSBHPkW1000 RPM ENGINE RATINGSBHPkWME8G7C 8-710G7C 1760 1310 2000 1500 – –ME12G7C 12-710G7C 2650 1976 3000 2240 – –ME16G7C 16-710G7C 3525 2628 4000 2985 – –ME20G7C 20-710G7C 4400 3280 5000 3730 – –Whether for a Fixed Pitch Propeller, Variable Pitch Propeller or SCR propulsion application, the Series 710 engines deliver 2000 to 5000continuous bhp with a 50% reduction in lube oil consumption and improved fuel economy. The two-cycle engine provides superior loadresponse characteristics and approximately 60% of the torsion and vibration output of comparable four-cycle engines.*Subbase, controls and customized final assembly furnished by <strong>Stewart</strong> & <strong>Stevenson</strong>, authorized Electro-Motive Diesel distributor.4

EMD Powered ProductsMarine Equipment Sets For Ships Service (Generator Set Units)*MODEL DESIGNATIONENGINE MODELCONTINUOUS OUTPUT**50 Hz - 750 RPM 60 Hz - 900 RPMME8G7C 8-710G7C 1200 kW /1675bhp 1440 kW /2000bhpCONTINUOUS OUTPUT**50 Hz - 1000 RPM 60 Hz - 900 RPMME12G7C 12-710G7C 1790 kW /2495bhp 2150 kW /3000 bhp – –ME16G7C 16-710G7C 2385 kW /3325bhp 2865 kW /4000bhpME20G7C 20-710G7C 2980 kW /4155 bhp 3580 kW /5000 bhp – 3865 kW/5400bhpEMD Features: Proven offshore reliability. Durable medium speed engines. Extended TBO intervals. EPA Tier 3 and IMO Tier 2Certification for 60 Hz Ratings. Less maintenance = higher availability. Powerful, responsive two-cycle design.*Subbase, controls and customized final assembly furnished by <strong>Stewart</strong> & <strong>Stevenson</strong>, authorized Electro-Motive Diesel distributor.** Based on 96% generator efficiency.5

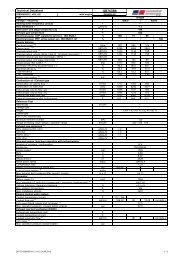

<strong>Stewart</strong> & <strong>Stevenson</strong>Custom Marine Packages for Offshore Rigs<strong>Stewart</strong> & <strong>Stevenson</strong> builds power generation packages using 8,12, 16 and 20 cylinder EMD 710 engines coupled with electroniccontrols and diagnostic systems. The U.S. EPATier 3 and IMO Tier 2 Emissions Compliant EMD enginesoffer continuous power ratings ranging from 2000 up to5400 horsepower. Skid mounted marine drilling unitsprovide power for drilling, dynamic positioning, propulsionand ships service generators on offshore rigs.• EMD generators offer 1440 to 3850kWe of ships service power• EMD drilling power units offer from2200 to 5500 bhp6

EMD Powered Products<strong>Stewart</strong> & <strong>Stevenson</strong> manufacturescustom EMD marine packages thatprovide power for offshore drilling.Marine Equipment Sets For Marine Drilling Power Unit Ratings* * * *MODEL DESIGNATION ENGINE MODEL RATED SPEED RPM ENGINE BHP GENERATOR SET kW**ME8G7C 8-710G7C 900 2200 1575ME12G7C 12-710G7C 900 3300 2350ME16G7C 16-710G7C 900 4400 3150ME20G7C 20-710G7C 900 5500 3950EMD skid-mounted marine drilling units meet ABS and other certification requirements for offshore rigs. These compact unitsprovide power for drilling, dynamic positioning, propulsion and ships service. They are designed for use on semi-submersible,jack-up and other drilling vessels. Marine drilling units are designed for parallel operation with similar units permitting a widerange of power availability.*Subbase, controls and customized final assembly furnished by <strong>Stewart</strong> & <strong>Stevenson</strong>, authorized Electro-MotiveDiesel distributor.**Based on 96% efficiency.*** Special duty ratings available upon request.7

<strong>Stewart</strong> & <strong>Stevenson</strong>Stationary Power and Industrial ApplicationsElectro-Motive Dieselpowered stationaryunits can provide 800to 5000 brake horsepowerfor GeneratorSet and MechanicalDrive applications usingtwo-cycle roots blownor turbochargedengines. These heavy duty units have been applied as baseload generating sets in remote locations, emergency standbysets in hospitals, land-based drilling, nuclear power generatingplants and pipeline and dredge pump applications.Stationary Equipment Sets (SE) For Stationary Power Unit Ratings* * * *MODEL DESIGNATIONENGINE MODELFULL LOADRATED SPEED RPMCONTINUOUS OUTPUTENGINE BHPGENERATOR SET kW**SE8G4C 8-710G4C 750 1675 1200900 2000 1440SE12GVC 12-710G4C 750 2495 1790900 3000 2150SE16G4C 16-710G4C 750 3325 2385900 4000 2865SE20G4C 20-710G4C 750 4155 2980900 5000 3580*Subbase, controls and customized final assembly furnished by <strong>Stewart</strong> & <strong>Stevenson</strong>, authorized Electro-MotiveDiesel distributor.** Based upon 96% generator efficiency.***Special duty cycle ratings available upon request.8

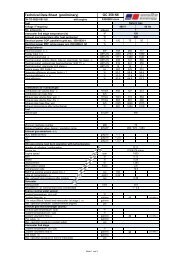

EMD Powered ProductsControl Systems<strong>Stewart</strong> & <strong>Stevenson</strong> custom builds engine controlsystems for EMD power generation systems. Our custombuilt panels are engineered to meet the needs of eachspecific application and range with the following features:• 316 Stainless Steel construction• Stainless steel, liquid filled pressure gauges withisolation valves• 30 mm operator interface• Color graphic touch displays with historical alarm logging• EMDEC (Electro-Motive Diesel Engine Control) J1939CAN communication interface• Remote data monitoring via integrated communications• Upgrade/retrofit of existing control systems• Society Class ApprovalGenerator and Motor Rebuild<strong>Stewart</strong> & <strong>Stevenson</strong> provides solid electrical equipmentexperience and equipment support through its servicecenter for electric motors and generators. Experiencedtechnicians service and/or rebuild AC and DC generators,motors and control panels. We are an authorized servicecenter for Kato, Marathon-Lima, EMD/Baylor, Newage-AVK, Delco and Electric Machinery (EM).Shop service support:• EMD and GE traction repairs• Generator and motor rewind repair• VPI system equipped• Rotors rewound up to 26˝• Pole pieces wound to 3000 kW• Dynamic balancing• Systems troubleshooting and repairs• Voltage regulator repairs• Complete inventory of new regulators• Factory generator repair partsField Service Support• 24/7/365 emergency support, parts and service• Electrical troubleshooting, generators and/or controls• Megger testing, D.C. high-pot testing• Vibration analysis and field balancing servicesSpecialized services• Engine control and monitoring system designand production• Preventive maintenance and service contracts forengine and generators• Engine control panels logic, design and manufacture• PLC Based monitoring systems design and manufacture9Capabilities• In house design and manufacturing of EMDpowered equipment• Integration of propulsion, power generation,industrial and drill rig systems• Control systems troubleshooting and repairs• Engine parts repairs and remanufacturing• Engine overhaul and conversions• Engine load testing• Unit exchange parts• Complete EMD parts inventory• Vibration analysis and troubleshooting• Engine systems integration• Remanufactured engine generator setpackaging• Engineering support for repower orupgrades of existing EMD powered systemsWith many years of EMD product expertise, thededicated <strong>Stewart</strong> & <strong>Stevenson</strong> team providesunparalleled product support before and afterthe sale. Continuous parts and service supportfor onshore, offshore, domestic and internationalbusiness is available 24/7/365.

<strong>Stewart</strong> & <strong>Stevenson</strong>The <strong>Stewart</strong> & <strong>Stevenson</strong> AdvantageComprehensive EngineeringMechanical and electrical engineers, CAD designers andconfiguration administrators provide a 3-D engineeringdocumentation package that includes system schematicsfor all electrical and mechanical operating systems, generalarrangement and interface control diagrams to assist withlocation critical installation details, and interactive CD-ROMtechnical manuals that facilitate operating, troubleshootingand training. Finite element analysis ensures design integrity;virtual prototyping enables flexible and fast configurationchanges; design assistance with vessel arrangement ensuresproper installation of all equipment subsystems.Advanced Control System DesignAdvanced control system designs that increase the durability,efficiency and safety of power generation products include:• PLC-based control systems housed in stainlesssteel NEMA enclosures• Color touch screen HMI panels permit clear and intuitiveaccess to all genset control and monitoring functions• MODBUS and other protocols enable remote monitoringand diagnostics of all vital generator functions10

EMD Powered ProductsManufacturingISO 9001 certified manufacturing facilities feature:• Non-conformance Reporting System that tracts andcorrects design, manufacturing and supplier quality issues• Certified Project Management (PMP) staff who ensureperformance to contractual elements and act ascustomer’s liaison during and after project executionEMD Power Generation units are produced to thefollowing standards:• Fluid handling instrumentation lines smaller than 2 inchesmade of ASTM304 stainless steel tubing• Steel piping meets ASME B31.1 and B31.3 standards• Structural welding meets ANSI/AWS D1.1/D1.1M:2006standards• Critical structural welds receive NCE magnetic article testing• Marine grade 3-coat paint (S&S specification ES-502)• Mechanical gauges provide redundant instrumentation ofcritical operating parameters• Electrical control interfaces in stainless steel NEMAjunction boxesIndoor Testing Facility features:• Full load test capacity via PC-controlled resistive/reactiveload bank• Generator output voltages from 480V to +15kV• Data Acquisition System records all vital operatingparameters during Factory Acceptance Test• Data records are archived for future reference andcomparison with onsite performanceAdded Value• Equipment commissioning• Operator training• Aftermarket service and parts11

For EMD Powered Product Solutions, Contact Us TodayLouisianaNew Orleans1400 Destrehan AvenueHarvey, LA 70058+1 504-347-4326TexasHouston8631 East FreewayHouston, TX 77029+1 713-671-6220Singapore Branch7 Joo Koon Crescent#02-01 Maintech Engr. BuildingSingapore 629024+1 65 6863 9137Fax: +1 65 6863 3381Argentina BranchEsmeralda 847, 7th Floor, Office JC1007AB1 - Buenos Aires, Argentina+1 54 11 4313 6399+1 54 11 4313 3084Authorized Service CentersSingaporeKim Huat Engineering Pte Ltd37 Tannery Lane#01-02 Tannery HouseSingapore 347790Contact: Mr. E. J. Onnemail: sales@kimhuat.com.sgAustralia, Indonesia, Philippines,New Zealand, ThailandDrivetrain Power and PropulsionLevel 8, 15 Talavera RoadMacquarie Park NSW 2113PO Box 1472 Macquarie Centre NSW 2113+1 61 2 9805 4000+1 61 2 9805 4055Contact: Lewin Johnstoneemail: lewin.johnstone@drivetrainpower.comVietnamMega International506 16th StreetMoline, Illinois 61265+1 309 764 5310+1 309 764 7153Contact: Mr. Thom Phamemail: thom@megaintl.netwww.stewartandstevenson.comCompany Headquarters1000 Louisiana, Suite 5900Houston, TX 77002+1 713-751-2700Headquarters@ssss.comCopyright © 2013 <strong>Stewart</strong> & <strong>Stevenson</strong> 13-04-10