The use of anti-vibrating bearings in the Taiwan High ... - Alga S.p.A.

The use of anti-vibrating bearings in the Taiwan High ... - Alga S.p.A.

The use of anti-vibrating bearings in the Taiwan High ... - Alga S.p.A.

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

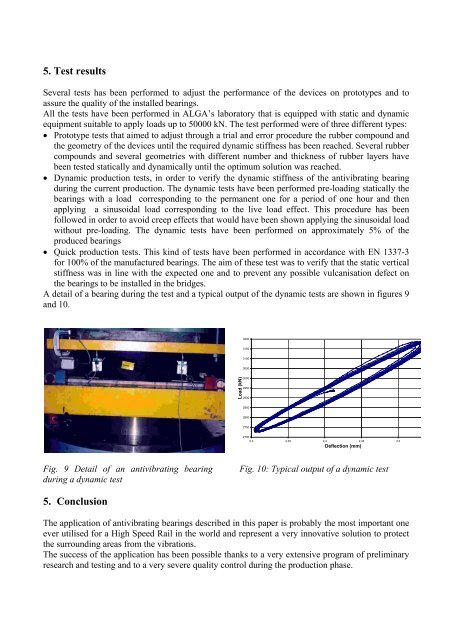

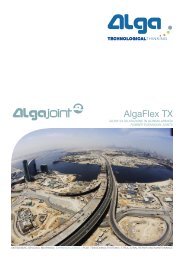

5. Test resultsSeveral tests has been performed to adjust <strong>the</strong> performance <strong>of</strong> <strong>the</strong> devices on prototypes and toassure <strong>the</strong> quality <strong>of</strong> <strong>the</strong> <strong>in</strong>stalled <strong>bear<strong>in</strong>gs</strong>.All <strong>the</strong> tests have been performed <strong>in</strong> ALGA’s laboratory that is equipped with static and dynamicequipment suitable to apply loads up to 50000 kN. <strong>The</strong> test performed were <strong>of</strong> three different types:• Prototype tests that aimed to adjust through a trial and error procedure <strong>the</strong> rubber compound and<strong>the</strong> geometry <strong>of</strong> <strong>the</strong> devices until <strong>the</strong> required dynamic stiffness has been reached. Several rubbercompounds and several geometries with different number and thickness <strong>of</strong> rubber layers havebeen tested statically and dynamically until <strong>the</strong> optimum solution was reached.• Dynamic production tests, <strong>in</strong> order to verify <strong>the</strong> dynamic stiffness <strong>of</strong> <strong>the</strong> <strong>anti</strong><strong>vibrat<strong>in</strong>g</strong> bear<strong>in</strong>gdur<strong>in</strong>g <strong>the</strong> current production. <strong>The</strong> dynamic tests have been performed pre-load<strong>in</strong>g statically <strong>the</strong><strong>bear<strong>in</strong>gs</strong> with a load correspond<strong>in</strong>g to <strong>the</strong> permanent one for a period <strong>of</strong> one hour and <strong>the</strong>napply<strong>in</strong>g a s<strong>in</strong>usoidal load correspond<strong>in</strong>g to <strong>the</strong> live load effect. This procedure has beenfollowed <strong>in</strong> order to avoid creep effects that would have been shown apply<strong>in</strong>g <strong>the</strong> s<strong>in</strong>usoidal loadwithout pre-load<strong>in</strong>g. <strong>The</strong> dynamic tests have been performed on approximately 5% <strong>of</strong> <strong>the</strong>produced <strong>bear<strong>in</strong>gs</strong>• Quick production tests. This k<strong>in</strong>d <strong>of</strong> tests have been performed <strong>in</strong> accordance with EN 1337-3for 100% <strong>of</strong> <strong>the</strong> manufactured <strong>bear<strong>in</strong>gs</strong>. <strong>The</strong> aim <strong>of</strong> <strong>the</strong>se test was to verify that <strong>the</strong> static verticalstiffness was <strong>in</strong> l<strong>in</strong>e with <strong>the</strong> expected one and to prevent any possible vulcanisation defect on<strong>the</strong> <strong>bear<strong>in</strong>gs</strong> to be <strong>in</strong>stalled <strong>in</strong> <strong>the</strong> bridges.A detail <strong>of</strong> a bear<strong>in</strong>g dur<strong>in</strong>g <strong>the</strong> test and a typical output <strong>of</strong> <strong>the</strong> dynamic tests are shown <strong>in</strong> figures 9and 10.3200315031003050Load (kN)30002950290028502800275027002,3 2,35 2,4 2,45 2,5Deflection (mm)Fig. 9 Detail <strong>of</strong> an <strong>anti</strong><strong>vibrat<strong>in</strong>g</strong> bear<strong>in</strong>gdur<strong>in</strong>g a dynamic testFig. 10: Typical output <strong>of</strong> a dynamic test5. Conclusion<strong>The</strong> application <strong>of</strong> <strong>anti</strong><strong>vibrat<strong>in</strong>g</strong> <strong>bear<strong>in</strong>gs</strong> described <strong>in</strong> this paper is probably <strong>the</strong> most important oneever utilised for a <strong>High</strong> Speed Rail <strong>in</strong> <strong>the</strong> world and represent a very <strong>in</strong>novative solution to protect<strong>the</strong> surround<strong>in</strong>g areas from <strong>the</strong> vibrations.<strong>The</strong> success <strong>of</strong> <strong>the</strong> application has been possible thanks to a very extensive program <strong>of</strong> prelim<strong>in</strong>aryresearch and test<strong>in</strong>g and to a very severe quality control dur<strong>in</strong>g <strong>the</strong> production phase.