Safety of steel transports - Extranet

Safety of steel transports - Extranet

Safety of steel transports - Extranet

- No tags were found...

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

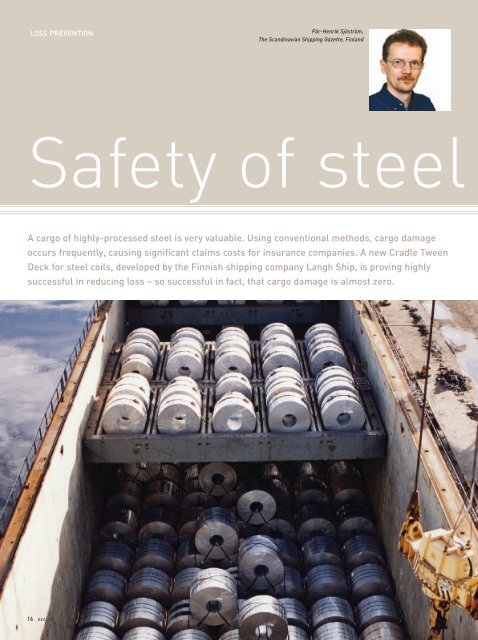

LOSS PREVENTIONPär-Henrik Sjöström,The Scandinavian Shipping Gazette, Finland<strong>Safety</strong> <strong>of</strong> <strong>steel</strong>A cargo <strong>of</strong> highly-processed <strong>steel</strong> is very valuable. Using conventional methods, cargo damageoccurs frequently, causing significant claims costs for insurance companies. A new Cradle TweenDeck for <strong>steel</strong> coils, developed by the Finnish shipping company Langh Ship, is proving highlysuccessful in reducing loss – so successful in fact, that cargo damage is almost zero.16 BEACON

<strong>transports</strong>Extreme movementsUsing conventional methods, <strong>steel</strong> coilsare carried on the bottom <strong>of</strong> the vessel’scargo hold. The heavy cargo tends tomake the vessel over-stable, causingviolent movements in heavy seas.The rolling period <strong>of</strong> the ship becomesextremely short. The vessel may heel fromher vertical position to her maximumheeling angle on both sides and returnback to the vertical position in just fiveseconds. As the maximum heeling anglemay exceed 30 degrees, cargo damageoccurs frequently in such circumstances.The cargo is valuable and the claims on theinsurance companies are high. In addition,stowing <strong>steel</strong> coils in this way is clearlydangerous. The heavy-weight cargo has tobe extremely well lashed otherwise, if itbecomes loose, the consequences may befatal. Experienced seafarers know the riskswith <strong>steel</strong> shipments in bad weather andtry to eliminate them as much as possible.However, the constant violent movements<strong>of</strong> the ship affect all activities on board,presenting a risk to safety at work as well.Insufficient rest causes tiredness and alack <strong>of</strong> alertness.The problems with carrying <strong>steel</strong> have beenacknowledged for a long time. They aremainly due to the practice <strong>of</strong> carrying heavy<strong>steel</strong> at the bottom <strong>of</strong> the hold. A higherlocation for the cargo means that thevessel is more stable but, until theintroduction <strong>of</strong> the Cradle Tween Decksolution, there had not been a safe methodfor securing the cargo on a higher deck.New innovationIn the late 1990s, after many years <strong>of</strong>transporting <strong>steel</strong> between Finland and theContinent, the shipping company LanghShip started developing new methods forreducing cargo damage and improving thequality <strong>of</strong> shipments. The owner HansLangh has been in charge <strong>of</strong> the projectfrom the beginning.– It is a result <strong>of</strong> many years <strong>of</strong> co-operationwith the Finnish <strong>steel</strong> manufacturers,Mr Langh explains.– I had some ideas about how the quality <strong>of</strong>the <strong>transports</strong> could be improved and westarted a development project within LanghShip. Now our invention has been thoroughlytested and proved to be successful inRuukki’s and Outokumpu’s demandingtransport systems, he continues.Langh Ship decided to adopt solutions wherethe cargo is stowed higher up in the cargohold. The idea itself was not new, but themethods were. The Company developed apurpose-designed tween-deck integratedcradle system for carrying <strong>steel</strong> coils. Thecoils are secured in the cradles and earlierproblems with inadequate lashing havebeen solved with a totally new and simplerapproach.The innovative Cradle Tween Deck from Langh Ship has drastically reduced damage to <strong>steel</strong> coilsTHE STEEL COILS ARE LIFTED INPOSITION BY CRANE AND LASHINGOF THE COILS WITH BELTS IN ASTANDARDISED WAY IS QUICKAND EASYCradle Tween DeckWith the Cradle Tween Deck (CTD) in use,the typical distribution <strong>of</strong> an all <strong>steel</strong> coilcargo is one layer on the bottom <strong>of</strong> the holdand one on the CTD. This also correspondsto the vessel’s maximum deadweight. The<strong>steel</strong> coils are lifted in position by crane andlashing <strong>of</strong> the coils with belts in astandardised way is quick and easy. CTDalso makes it possible to mix different types<strong>of</strong> cargo. It is, for example, possible to carry<strong>steel</strong> plates in the lower part <strong>of</strong> the holdand coils on the CTD.The system also shows its flexibility whenthe CTD is not in use. Designed as easilyliftable <strong>steel</strong> pontoons, the Cradle TweenDeck is mounted or stowed away with thesame cranes that handle the <strong>steel</strong> coils.When not in use, the cradles are stowed inthe hold, occupying only a minimal amount<strong>of</strong> cargo space, or in front <strong>of</strong> the deckhouse.The vessel can therefore carry other types<strong>of</strong> cargoes, e.g. raw materials back to the<strong>steel</strong> mill.No cargo damageThe prototype <strong>of</strong> the CTD was installed inLangh Ships dry cargo/container vesselChristina in the beginning <strong>of</strong> 2000. Theadvantages <strong>of</strong> this innovation becameBEACON 17

Easy access is the key to Langh Ship’s container solution for carriage <strong>of</strong> <strong>steel</strong>immediately evident. Now, as four LanghShip vessels are equipped with CTDs, therehas not been any cargo damage at sea tocoils transported by the new system. Inaddition, other cargo has greatly benefited.Damage is almost non-existent on thesevessels.A comparison <strong>of</strong> the sea-keeping qualities<strong>of</strong> two identical sister vessels carrying<strong>steel</strong> products – one with CTD and theother in the conventional way – showedamazing results. Both vessels weresimultaneously sailing in the same area inheavy weather. The heeling angle withconventional stowage <strong>of</strong> the cargo wasabout 30 degrees and the rolling periodfrom one side to another and back againwas as short as five seconds. In the sistership, the CTD reduced the maximumheeling angle to ten degrees while therolling period was prolonged to 12seconds. The working conditions on thefirst vessel were extremely difficult, whilecircumstances were regarded as quitenormal on the second ship.SavingsSeveral years <strong>of</strong> service have proved thatloss prevention is not the only advantage <strong>of</strong>the CTD. Cargo handling is faster andmore efficient without the need <strong>of</strong>additional investment in equipment orinfrastructure. Less labour is requiredwhen loading the vessel and disposablelashing is no longer needed.For lashing <strong>of</strong> <strong>steel</strong> coils, strong belts areused. The method is standardised and fast,significantly reducing the overall timespent in port. Even the need for lashingother cargo carried in the same vessel isreduced, as the vessel’s motions in roughweather are lessened.Special unitsAnother way to optimise a vessel’s stabilitywhile carrying <strong>steel</strong> is to unitise the cargo.If carried in containers, part <strong>of</strong> the cargomay be carried on deck, for example, thuseliminating over-stability. In this case, themain problem is that lashing <strong>of</strong> <strong>steel</strong>products inside a container is labourintensive,and therefore expensive andquite time consuming. The cargo has to besecured manually in a non-standardisedway. Therefore, containers have usuallybeen utilised for <strong>steel</strong> shipments only intransoceanic traffic.With short sea shipments in mind, LanghShip has developed a special container for<strong>steel</strong> products, allowing fast and easystuffing. At first glance, the unit looks justlike a standard 20 ft container, but thedifference becomes obvious when opened.Instead <strong>of</strong> being equipped with conventionaldoors at the end <strong>of</strong> the unit, the long sideThe tables below show the measured differences between two sister vessels carrying similar <strong>steel</strong> cargo and sailing in the same weather conditions (actually, they were evenwithin sight <strong>of</strong> each other). One was equipped with Cradle Tween Deck and the other with a traditional stowing solution18 BEACON

AS THE CARGO UNIT HAS STANDARDDIMENSIONS, THIS SOLUTION ALSOENABLES STEEL TRANSPORTATION ONCONTAINER FEEDER VESSELSis completely open. The cargo may then bequickly stored in the container by, forexample, a forklift truck.Lashing <strong>of</strong> the cargo inside the container isprovided by a new supporting system.Moveable stanchions may be placed indifferent positions to support a cargo <strong>of</strong> anykind. They are mounted between the floorand the ro<strong>of</strong> <strong>of</strong> the unit, and tightened witha clamping system against the goods. Asthe cargo unit has standard dimensions,this solution also enables <strong>steel</strong> transportationon container feeder vessels. This opens upnew possibilities for <strong>steel</strong> shipments, usingan extensive liner network made up <strong>of</strong>frequent feeder services.The payload <strong>of</strong> Langh Ship’s special unit is32 tonnes. After an extensive test programmewith prototypes that still serve Outokumpu’s<strong>transports</strong>, an improved series <strong>of</strong> containershave been produced for Ruukki. The resultsare encouraging and Langh Ship is developingother special units for transportation <strong>of</strong> heavyproducts.Widely acknowledgedLangh Ship’s cargo solutions have beenacknowledged all over the world. Theproducts are already patented in Europe,USA and the Far East. Outside Europe,marketing and sales are handled byMacGREGOR, which is a global marketleader in marine cargo flow solutions.Langh Ship also won the "Innovation inShip Operations" category in the SeatradeAwards 2003 and has been recognisedseveral times in Finland for its cargosolutions.Improved working conditionsCrews are pleased with the CTDs.– Working conditions have improvedremarkably, says Master Mariner MarkkuYli-Kahri, who is the Captain <strong>of</strong> LanghShip’s dry cargo vessel Aila. He explainsthat the violent rolling, which is typical for avessel carrying <strong>steel</strong> products, is no longera problem. As an experienced ‘old salt’ henow regards the conditions on board as"quite normal" even in rough weather.– Especially during the winter season,when one low pressure usually relievedanother, it was not possible earlier forthe crew to get a long undisturbed rest.Everyone used to be tired all the time,Captain Yli-Kahri says.For someone who has not been at sea inbad weather, it is difficult to imagine whatit is like to spend several weeks on duty ina place that is constantly rolling andpitching. It is impossible to sleep properlyand, when on watch on the bridge, theOfficer has to continuously struggle toremain seated in his chair. No wonder thepr<strong>of</strong>essionals responsible for carryingvaluable cargoes welcome such innovations.THIS OPENS UP NEW POSSIBILITIESFOR STEEL SHIPMENTS, USING ANEXTENSIVE LINER NETWORK MADE UPOF FREQUENT FEEDER SERVICESSecuring <strong>of</strong> <strong>steel</strong> coils in the CTD is quick and easyBEACON 19