GENERAL INFORMATION The Badger class dredge is offered in an ...

GENERAL INFORMATION The Badger class dredge is offered in an ...

GENERAL INFORMATION The Badger class dredge is offered in an ...

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

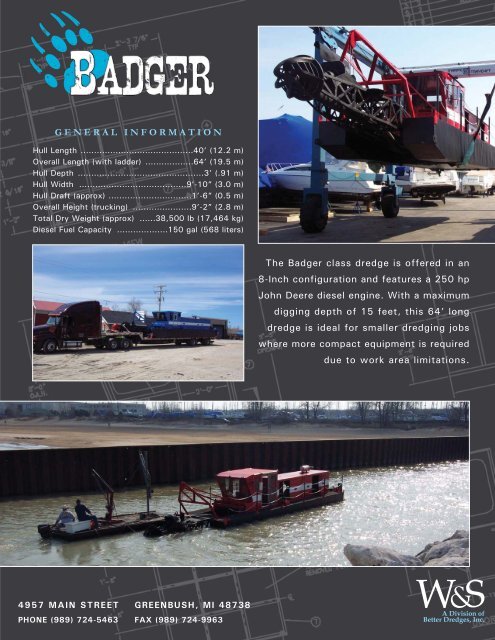

<strong>GENERAL</strong> <strong>INFORMATION</strong>Hull Length ..........................................40’ (12.2 m)Overall Length (with ladder) ..................64’ (19.5 m)Hull Depth ...............................................3’ (.91 m)Hull Width ........................................9’-10” (3.0 m)Hull Draft (approx) ...............................1’-6” (0.5 m)Overall Height (truck<strong>in</strong>g) ......................9’-2” (2.8 m)Total Dry Weight (approx) ......38,500 lb (17,464 kg)Diesel Fuel Capacity ...................150 gal (568 liters)<strong>The</strong> <strong>Badger</strong> <strong>class</strong> <strong>dredge</strong> <strong>is</strong> <strong>offered</strong> <strong>in</strong> <strong>an</strong>8-Inch configuration <strong>an</strong>d features a 250 hpJohn Deere diesel eng<strong>in</strong>e. With a maximumdigg<strong>in</strong>g depth of 15 feet, th<strong>is</strong> 64’ long<strong>dredge</strong> <strong>is</strong> ideal for smaller dredg<strong>in</strong>g jobswhere more compact equipment <strong>is</strong> requireddue to work area limitations.4957 MAIN STREET GREENBUSH, MI 48738PHONE (989) 724-5463 FAX (989) 724-9963

BADGER CLASS8x8 Cutterhead DredgePrelim<strong>in</strong>ary SpecificationsSERVICE PUMP<strong>The</strong> service pump <strong>is</strong> provided to supply flush<strong>in</strong>g water to the <strong>dredge</strong>pump pack<strong>in</strong>g gl<strong>an</strong>d, water to the cutter drive bear<strong>in</strong>gs <strong>an</strong>d for useat a deck connection. <strong>The</strong> pump <strong>is</strong> a 2½” x 2” (6.4 cm x 5.1 cm) <strong>an</strong>d<strong>is</strong> rated 75 psi @ 125 GPM (7.9 liters per second).DETAILS OF HULL CONSTRUCTION<strong>The</strong> hull <strong>is</strong> composed of three (3) compartments. <strong>The</strong> center compartment<strong>is</strong> the eng<strong>in</strong>e <strong>an</strong>d pump compartment. <strong>The</strong> other (2) two compartmentsare the side t<strong>an</strong>ks; also know as sponson t<strong>an</strong>ks or pontoons. <strong>The</strong> sidet<strong>an</strong>ks are framed with <strong>an</strong>gle iron <strong>an</strong>d truss type cross brac<strong>in</strong>g. <strong>The</strong>plate <strong>is</strong> then welded <strong>in</strong>side <strong>an</strong>d outside for structural <strong>in</strong>tegrity. <strong>The</strong> t<strong>an</strong>ksare pressure tested for leakage. <strong>The</strong> side t<strong>an</strong>ks are assembled to formthe eng<strong>in</strong>e <strong>an</strong>d pump compartment. <strong>The</strong> hull <strong>is</strong> turned right side up <strong>an</strong>dthe <strong>in</strong>terior brac<strong>in</strong>g <strong>is</strong> <strong>in</strong>stalled to accept the mount<strong>in</strong>g of the eng<strong>in</strong>e,pump <strong>an</strong>d other components. <strong>The</strong> bottom of the hull <strong>is</strong> constructedfrom 10-gauge plate (3.57 mm). <strong>The</strong> hull sides <strong>an</strong>d deck are constructedfrom 10-gauge plate (3.57 mm). <strong>The</strong> lever room <strong>an</strong>d the pump/eng<strong>in</strong>eroom enclosure are constructed from 12-gauge plate (2.78 mm).HYDRAULIC SYSTEM<strong>The</strong> hydraulic pump <strong>is</strong> a 4-section pump that provides service to thecutter head motor, sw<strong>in</strong>g w<strong>in</strong>ches, spud w<strong>in</strong>ches <strong>an</strong>d ladder w<strong>in</strong>ch.<strong>The</strong> hydraulic system <strong>is</strong> protected by relief valves <strong>an</strong>d the system hasreplaceable <strong>in</strong>l<strong>in</strong>e filters. <strong>The</strong> hydraulic system has <strong>an</strong> approximatecapacity of 100 gallons (379 liters).HOISTINGHydraulic w<strong>in</strong>ches are used for sw<strong>in</strong>g<strong>in</strong>g the <strong>dredge</strong>, lift<strong>in</strong>g the spuds<strong>an</strong>d lift<strong>in</strong>g the ladder. All five (5) w<strong>in</strong>ches are rated 7,000 lb (3,175 kg)l<strong>in</strong>e pull capacity. All w<strong>in</strong>ches are complete with galv<strong>an</strong>ized cables.<strong>The</strong> sw<strong>in</strong>g w<strong>in</strong>ches are equipped with 150’ (45. 7 meters) of ½” (1. 27 cm)6x37 cable.DETAILS OF LADDER CONSTRUCTION<strong>The</strong> ladder <strong>is</strong> constructed of 2” x 2” x 1/4” (5.08 cm x 5.08 cm x .635 cm)<strong>an</strong>gle iron with a 10 gauge (3.57 mm) metal plate gusset. <strong>The</strong> gussetsare welded to the side of the ladder for structural <strong>in</strong>tegrity, res<strong>is</strong>t<strong>an</strong>ceaga<strong>in</strong>st bend<strong>in</strong>g, torsional load<strong>in</strong>g <strong>an</strong>d tr<strong>an</strong>sverse stresses. <strong>The</strong> ladderlength <strong>is</strong> 24’ (7.3 meters).OPERATING DETAILS<strong>The</strong> maximum dredg<strong>in</strong>g depth <strong>is</strong> 20’ (6.09 meters) <strong>an</strong>d <strong>is</strong> achieved ata 60° down <strong>an</strong>gle on the ladder. <strong>The</strong> maximum lateral cut, sw<strong>in</strong>g<strong>in</strong>g90°, at approximately 3’ (1 meter) of dredg<strong>in</strong>g depth <strong>is</strong> 70’ (21.3meters). <strong>The</strong> lateral cut, sw<strong>in</strong>g<strong>in</strong>g 90°, at a 20’ (6.09 meters) dredg<strong>in</strong>gdepth <strong>is</strong> approximately 50’ (15.2 meters).CUTTER HEAD<strong>The</strong> cutter head <strong>is</strong> designed with five (5) smooth blades that are caststeel. <strong>The</strong> cutter head <strong>is</strong> mounted to a 2-1/2” (6.35 cm) sta<strong>in</strong>less steelshaft that <strong>is</strong> attached to the cutter motor. <strong>The</strong> cutter head <strong>is</strong> driven bya five (5) cyl<strong>in</strong>der Staffa hydraulic motor, model #HMB-100. <strong>The</strong> cutterhead motor <strong>is</strong> m<strong>an</strong>ufactured by Kawasaki Motors. <strong>The</strong> hydraulic motorhas variable speed capability <strong>an</strong>d <strong>is</strong> reversible. Replaceable p<strong>in</strong> on teethc<strong>an</strong> be added to the cutter head as <strong>an</strong> option. <strong>The</strong> cutter head hasa 22” (55.9 cm) <strong>in</strong>side diameter back r<strong>in</strong>g with <strong>an</strong> outside diameterof 30” (76.2 cm).ENGINE<strong>The</strong> prime mover <strong>is</strong> a John Deere 250 hp (186 kW) 8.1 liter dieseleng<strong>in</strong>e. <strong>The</strong> eng<strong>in</strong>e <strong>is</strong> attached to a Tw<strong>in</strong> D<strong>is</strong>c clutch. <strong>The</strong> eng<strong>in</strong>e <strong>is</strong>radiator cooled <strong>an</strong>d <strong>in</strong>cludes a John Deere air cle<strong>an</strong>er, muffler <strong>an</strong>dgauge package. <strong>The</strong> eng<strong>in</strong>e meets Tier II compli<strong>an</strong>ce criteria.DREDGE PUMP<strong>The</strong> <strong>dredge</strong> pump <strong>is</strong> a Metso M<strong>in</strong>erals, Thomas Simplicity series <strong>dredge</strong>pump, model #H24. <strong>The</strong> pump <strong>is</strong> rated 160’ TDH @ 2500 GPM(49 meters TDH @ 158 liters per second). <strong>The</strong> maximum particle clear<strong>an</strong>ce<strong>is</strong> 4” (10.2 cm).SPUDSTwo (2) spuds are located on the stern of the <strong>dredge</strong>. <strong>The</strong> spuds are8-5/8” (21.9 cm) diameter x 20’ (6.1 meter) long.ELECTRICAL SYSTEM<strong>The</strong> electrical system cons<strong>is</strong>ts of a 12-volt 65-amp alternator <strong>an</strong>d a240 amp/hr battery. <strong>The</strong> wir<strong>in</strong>g <strong>is</strong> a complete circuit with one (1) wireto ground through a full breaker p<strong>an</strong>el. <strong>The</strong> light<strong>in</strong>g cons<strong>is</strong>ts of seven(7) floodlights that are mounted on the <strong>dredge</strong>. Light<strong>in</strong>g <strong>is</strong> also provided<strong>in</strong> the eng<strong>in</strong>e/pump compartment, on the <strong>in</strong>strument p<strong>an</strong>el <strong>an</strong>d overhead<strong>in</strong> the lever room.LEVER ROOM<strong>The</strong> lever room measures 5’-9” wide x 6’-5” long x 6’-2” high(1.75m x 1.96m 1.88m). All glass <strong>is</strong> LEXON 500 with 360° v<strong>is</strong>ibility.<strong>The</strong> control p<strong>an</strong>el has sta<strong>in</strong>less steel gauges. An upholstered seat <strong>is</strong> providedfor the operator. <strong>The</strong> lever room <strong>is</strong> <strong>in</strong>sulated to reduce no<strong>is</strong>e <strong>an</strong>d fortemperature control. <strong>The</strong> lever room <strong>is</strong> f<strong>in</strong><strong>is</strong>hed with a p<strong>an</strong>eled <strong>in</strong>terior.ENGINE/PUMP COMPARTMENT<strong>The</strong> eng<strong>in</strong>e/pump compartment <strong>is</strong> equipped with slid<strong>in</strong>g lockable doors.Th<strong>is</strong> allows for easy access <strong>an</strong>d <strong>is</strong> a deterrent for v<strong>an</strong>dal<strong>is</strong>m. <strong>The</strong> roof<strong>is</strong> removable for major service of the <strong>dredge</strong> pump or diesel eng<strong>in</strong>e.General ma<strong>in</strong>ten<strong>an</strong>ce c<strong>an</strong> be accompl<strong>is</strong>hed by use of the Ibeam. Th<strong>is</strong>compartment <strong>is</strong> equipped with four (4) floodlights.SAFETY EQUIPMENTMach<strong>in</strong>ery guards are <strong>in</strong>stalled over all belts <strong>an</strong>d shafts. H<strong>an</strong>drails cons<strong>is</strong>tof two (2) str<strong>an</strong>ds of steel cha<strong>in</strong> between removable posts. A fire ext<strong>in</strong>gu<strong>is</strong>her<strong>an</strong>d bilge pump are provided. <strong>The</strong> decks are pa<strong>in</strong>ted with <strong>an</strong>ti-skid pa<strong>in</strong>t.PREPARATION AND PAINTAll exposed hull <strong>an</strong>d lever room surfaces are s<strong>an</strong>dblasted before theprimer coats are applied. <strong>The</strong> hull <strong>is</strong> pa<strong>in</strong>ted with coal-tar epoxy. <strong>The</strong>superstructure <strong>is</strong> pa<strong>in</strong>ted blue with a white stripe us<strong>in</strong>g <strong>an</strong> epoxy pa<strong>in</strong>t.