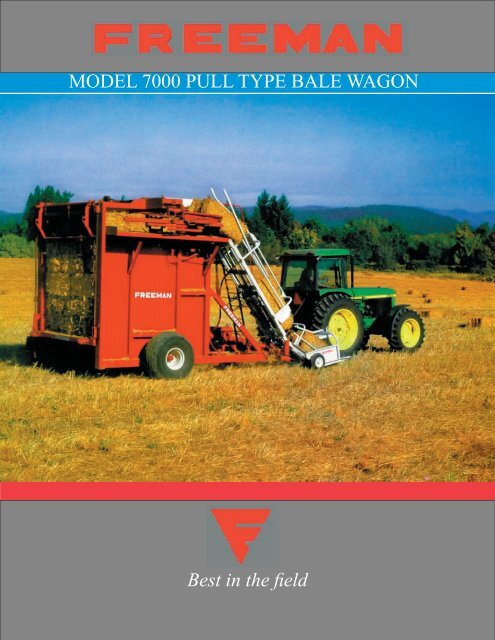

model 7000 pull type bale wagon - Allied Systems Company

model 7000 pull type bale wagon - Allied Systems Company

model 7000 pull type bale wagon - Allied Systems Company

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

MODEL <strong>7000</strong> PULL TYPE BALE WAGONBest in the field

The <strong>7000</strong> Pull Type Bale Wagon - Low Cost Automated Bale Han-The <strong>7000</strong> Pull Type Bale Wagon stacks the block stacks hay buyers and truckers prefer.Fast Automated Field Stackingor Roadside StackingSpeed and reliability of your<strong>bale</strong> handling system can mean thedifference between profit and lossin the hay business In the field theFreeman <strong>7000</strong> Pull Type BaleWagon will pick up complete loads,stack at selected stack sites in thefield, and be ready for another loadin as little as 5 mmutes.The <strong>7000</strong> automatically stacksthe industry standard block stackhay buyers prefer of fifty-six threetie<strong>bale</strong>s These weather resistantblock stacks with operator selectedtie-tierpatterns will stand alone withoutany support for worry-free transportand storage.The automatic loading system issimple to operate The building of aFreeman block stack is controlledby an electronic <strong>bale</strong> control systemat each hale tier level throughoutthe stacking process.Changing from three-tie totwo-tie <strong>bale</strong>s is quick and easy,Just flip a switch on the main controlbox and move two brackets. Inten minutes or less, you are readyto pick up two-tie <strong>bale</strong>s Take thework and worry out of stackinghay with the Freeman <strong>7000</strong> BaleWagon.Will stack two-tie or three-tie <strong>bale</strong>sinto block stacks for automated stackhandling.

Low Cost of a Pull Type Plus Benefit of Hillside StackingEconomical to Operate andEnclosed sides on <strong>7000</strong> Pull Type Bale Wagon eliminates <strong>bale</strong> and stack slippage when picking up <strong>bale</strong>s on hillsides.Built to be ReliableInstead of relying on custom haystackers to stack your hay, preserveworking capital and enjoy thebenefits of automated halehandlinby using a tractor you may alreadyown with the <strong>7000</strong> Pull Type BaleWagon to economically stack yourhay.With the <strong>7000</strong> you have less downtime and low maintenance, whichincreases productivitThe <strong>7000</strong> hydraulic system is fullyself-contained and operates off thetractor PTO The exclusive 540hydraulic PTO system allows you tomake sharp turnswithout any drive linechatter and eliminatesthe danger of a spinningdrivehne shaft Thisfeature limits the wearand tear on your tractorand increases operatorsafety.The Bale Wagonswide pickup handleshales from any angleThis maneuverabilityeliminates any need for straighteningor aligning hales in the field Even onhillsides hales enter flat and arequickly and gently conveyed up theelevator onto the stacking deck.Hydraulic FF0 eliminates driveline chatter whenmaking sharp turns.

Stacking Features Increase ProductivityBALE TIER STACK PATTERNSFOR 3-TIE BALESPATTERN NO. 1PATTERN NO.2Tractor mounted reliable electronic <strong>bale</strong>controlsystem.Easy to Operate and MaintainBale Control SystemThe Freema square blockstacking process is controlledby an electronic <strong>bale</strong> controlsystem. The electronic controlmonitors the hydraulic systemstep by step through the entirestacking process. A light displaysystem displays the progressof the loading operation, andcontrol buttons on the tractormounted operator control boxenables the operator to oven-idethe system at any time if necessary.The operator can also selectan alternate stack pattern customizedto meet specific stackingrequirements, or select thepreset standard stack pattern forworry-free hauling and stacking.The loading system is completelyautomatic for simple operationeven with inexperiencedoperators.Cut Hay Handling Costs andStack DamageThe Freeman <strong>7000</strong> stacks a loadvertically from the bottom tier up,eliminating the need to build thestack on its side and tip the stack 90PATTERN NO.3BALE TIER STACK PATTERNSFOR 2-TIE BALESPATTERN NO. 1PATTERN NO.2PATTERN NO.3Stack pattern allows for easier stack retrieval and more durable stacks.degrees to unload, which loosens thestack Each hale tier built by the <strong>7000</strong>is also hydraulically compressed,building a weather tight stack.These features ensure block stacksbuilt by the <strong>7000</strong> Bale Wagon hold togetherbetter during hauling and handlingthan stacks built byotherautomatic hale <strong>wagon</strong>s.7654321TIER7654321TIERBALE PATTERNBALE PATTERN12312111231211

The Full Line OfHay Handlers....S P E C I F I C A T I O N SPull Type Balers 2 or 3 TieSelf Propelled Balers 2 or 3 TieModel 1390 Inline BalerModel 8000 Bale WagonGeneralWorking Length: 20 Feet (6.1m)Working width: 11 feet 10 inches (3.6m)Working height: 13 feet 11 inches (4.24 m)Overbead clearance required for stacking: 13 feet 11 inches (4.24m)Weight: 8500 pounds (3856 kg)Wheel base from tractor hitch: 12 feet (3.66m)Rear tire size:21L X 16.1, 14 ply flotationPickup tire size: 4.80 x 8, 4 plyTractor RequirementsHorsepower: 50 hp or greater to PTOPTO standard speed: 540 rpmElectrical system: 12V DCHydraulic system: Self-contained hydraulic system operated by tractor PTOStack SizeHeight: To 9 feet 4 inches (2.84m)Width: 8 feet x 8 feet (2.44m x 2.44m)Number of 16" x 22" or 15" x 22" 3-tie <strong>bale</strong>s per stack: 56Number of 16" x 18" 2-tie <strong>bale</strong>s per stack: 67Number of 14" x 18" 2-tie <strong>bale</strong>s per stack: 77Bale length required: 45-48 inches (1.14m - 1.22m)<strong>7000</strong> Bale Wagon CapacityTons per load w/140 pound 16" x 22" <strong>bale</strong>s: 3.92 ton(3,556kg)Average number of loads per hour: 6Average capacity* per 10 hour day (<strong>bale</strong>s): 3360Average capacity* per 10 hour day ( tons): 235 (213 metric tons)*Average capacity refers to stacking 140 pound <strong>bale</strong>s with distanceto stacking area figured at up to 1/8 mile ( and capacities may varydepending on field conditions and operator.Model 1592 Big BalerModel 5300 Big Bale RoadsiderJ.A. FREEMAN & SON, INC.2034 NW 27th avenuePortland, Oregon 97210(503)222-1971, FAX (503)228-9668Quality Hay Equipment Since 1889Best in the Field