pro & con: horizontal vs. vertical coupling - WatchTime

pro & con: horizontal vs. vertical coupling - WatchTime

pro & con: horizontal vs. vertical coupling - WatchTime

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

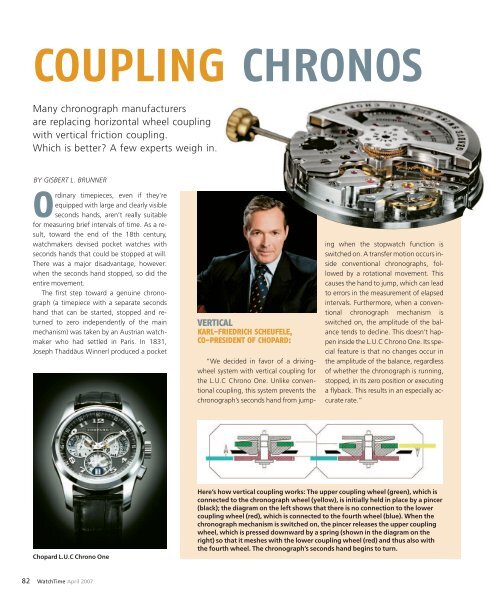

COUPLING CHRONOSMany chronograph manufacturersare replacing <strong>horizontal</strong> wheel <strong>coupling</strong>with <strong>vertical</strong> friction <strong>coupling</strong>.Which is better? A few experts weigh in.BY GISBERT L. BRUNNEROrdinary timepieces, even if they’reequipped with large and clearly visiblese<strong>con</strong>ds hands, aren’t really suitablefor measuring brief intervals of time. As a result,toward the end of the 18th century,watchmakers devised pocket watches withse<strong>con</strong>ds hands that could be stopped at will.There was a major disadvantage, however:when the se<strong>con</strong>ds hand stopped, so did theentire movement.The first step toward a genuine chronograph(a timepiece with a separate se<strong>con</strong>dshand that can be started, stopped and returnedto zero independently of the mainmechanism) was taken by an Austrian watchmakerwho had settled in Paris. In 1831,Joseph Thaddäus Winnerl <strong>pro</strong>duced a pocketVERTICALKARL-FRIEDRICH SCHEUFELE,CO-PRESIDENT OF CHOPARD:“We decided in favor of a drivingwheelsystem with <strong>vertical</strong> <strong>coupling</strong> forthe L.U.C Chrono One. Unlike <strong>con</strong>ventional<strong>coupling</strong>, this system prevents thechronograph’s se<strong>con</strong>ds hand from jumpingwhen the stopwatch function isswitched on. A transfer motion occurs inside<strong>con</strong>ventional chronographs, followedby a rotational movement. Thiscauses the hand to jump, which can leadto errors in the measurement of elapsedintervals. Furthermore, when a <strong>con</strong>ventionalchronograph mechanism isswitched on, the amplitude of the balancetends to decline. This doesn’t happeninside the L.U.C Chrono One. Its specialfeature is that no changes occur inthe amplitude of the balance, regardlessof whether the chronograph is running,stopped, in its zero position or executinga flyback. This results in an especially accuraterate.”Chopard L.U.C Chrono OneHere’s how <strong>vertical</strong> <strong>coupling</strong> works: The upper <strong>coupling</strong> wheel (green), which is<strong>con</strong>nected to the chronograph wheel (yellow), is initially held in place by a pincer(black); the diagram on the left shows that there is no <strong>con</strong>nection to the lower<strong>coupling</strong> wheel (red), which is <strong>con</strong>nected to the fourth wheel (blue). When thechronograph mechanism is switched on, the pincer releases the upper <strong>coupling</strong>wheel, which is pressed downward by a spring (shown in the diagram on theright) so that it meshes with the lower <strong>coupling</strong> wheel (red) and thus also withthe fourth wheel. The chronograph’s se<strong>con</strong>ds hand begins to turn.82 <strong>WatchTime</strong> April 2007

PRO & CON: HORIZONTAL VS. VERTICAL COUPLINGHORIZONTALANNEGRET FLEISCHERDESIGN ENGINEER AT A.LANGE & SÖHNE:“Vertical <strong>coupling</strong>s are particularlysuitable for watches with center-mountedse<strong>con</strong>ds hands. Here, the <strong>coupling</strong> sequenceoccurs directly at the fourthwheel. Our Datograph model has an offcenterdisplay for the se<strong>con</strong>ds, and a <strong>horizontal</strong><strong>coupling</strong> is better suited for thisarrangement. The chronograph’s <strong>coupling</strong>wheel and the chronograph’s centerwheel are located side by side. Theymesh with each other as soon as thechronograph is switched on. From thestart of the Datograph’s development<strong>pro</strong>cess, we knew we wanted to create aLange Datograph Caliber L951.1classical chronograph with the characteristicelements, and that includes <strong>horizontal</strong><strong>coupling</strong>. This system is more interestingfor Lange’s customers, who can observethe sequence of motions throughthe case’s transparent back. They enjoywatching the complex interplay of the severalcomponents. A <strong>vertical</strong> <strong>coupling</strong>, onthe other hand, puts the participatingwheels one atop the other, so anobserver sees much less excitingtechnology in action.”watch with a se<strong>con</strong>ds hand thatcould be halted without stopping themain mechanism. This timepiece lacked areturn-to-zero mechanism, so before beginninganother stop-time measurement, the userhad to wait until the restarted se<strong>con</strong>ds handcompleted its leisurely passage around the dialand back to the zero point. This shortcomingwas overcome in 1844 by Adolphe Nicole, whoinvented a small heart-shaped cam that madeit possible to instantaneously return a watch’sA. Lange & Söhne’s Datograph Flybackhand to its starting position. In 1880, AugusteBaud shifted the position of the chronographmechanism onto the back side of the movement,making it much easier for watchmakersto repair or service the device.A chronograph is essentially based on an ordinarywatch movement. The forward end ofthe arbor of its fourth wheel bears the smallse<strong>con</strong>ds hand. Toward the rear, the arbor’s pivotis elongated beyond the plate so that a socalled“driving wheel” can be affixed to the arbor.Like the se<strong>con</strong>ds hand, the driving wheelcompletes one rotation around its own axisevery 60 se<strong>con</strong>ds. The <strong>con</strong>nection and dis<strong>con</strong>nectionbetween the movement and the chronograph’shand occur with the aid of a <strong>coupling</strong>mechanism. Because the chronograph’shand should rotate in a clockwise direction, thedriving wheel cannot be directly <strong>con</strong>nected tothe chronograph’s center wheel; an intermediatewheel is necessary. These three wheels <strong>con</strong>stitutethe traditional geared <strong>coupling</strong>. The intermediate(or “<strong>coupling</strong>”) wheel is affixed toa moveable <strong>coupling</strong> lever. When the startstopbutton (usually situated at the 2 o’clockposition) is pressed, either the column wheelrotates one position farther along or else theoperating cam is moved. The <strong>coupling</strong> leverpivots slightly toward the right, allowing the intermediatewheel to create a <strong>con</strong>nection betweenthe driving wheel and the chrono-Continued on page 8884 <strong>WatchTime</strong> April 2007

PRO & CON: HORIZONTAL VS. VERTICAL COUPLINGA <strong>pro</strong>minent example of<strong>horizontal</strong> <strong>coupling</strong>:Zenith’s El Primero movement.Its latest versionticks inside the DefyXtreme Open (right).HORIZONTALTHIERRY NATAFPRESIDENT OF ZENITH:“Zenith’s decision to use <strong>horizontal</strong> <strong>coupling</strong>in the <strong>con</strong>struction of our El Primeromovement was primarily motivated by itsgreater reliability. Horizontal <strong>coupling</strong> occursthrough the motions of mechanicalcomponents, such as levers, whose motionscan be precisely adjusted to remain <strong>con</strong>stantover time. In addition to adjusting thetension in the spring, which is usually accomplishedby winding, <strong>vertical</strong> <strong>coupling</strong>generally also dependson frictionalelements which aresubject to the influencesof <strong>con</strong>tact betweenmaterials, the attributesof the surfaces and lubricants,as well as to thermal and galvanictreatments. A watchmaker cannotdiscern these influences with his naked eye.It’s well known that tensed springs tend tolose their tension slightly as the years go by,especially if they’re used frequently. Furthermore,oils become more viscous withage. And surfaces that are <strong>con</strong>tinually in<strong>con</strong>tact with one another suffer wear dueto friction. Consequently, it’s not only verydifficult to blindly adjust a <strong>vertical</strong> <strong>coupling</strong>or to regulate it when it’s manufactured; it’salso difficult to guarantee that it will <strong>con</strong>tinueto function <strong>pro</strong>perly over the long term.The <strong>horizontal</strong> system reduces costs, requiresa smaller volume of space and needsless complex components. For these reasons,Zenith uses a larger number of individualparts, although doing so generateshigher costs. The shapes andmotions of the individual partsare thoroughly studied prior totheir manufacture. The motionof the <strong>coupling</strong> yoke notonly triggers a rotation of thecolumn wheel (which is anepicyclic differential one), butis also precisely calculated toachieve optimal meshing incombination with the rotationalspeed of the pinion. Theclockwork of the chronograph’spinion has more than 150 microscopicallytiny leaves. Each of these individualparts undergoes a large number of precise,ultramodern manufacturing and quality-<strong>con</strong>troltests. The axis of the <strong>coupling</strong>yoke and the teeth on the column wheel areadjusted using blued, eccentric components.This type of adjustment allows awatchmaker to intervene directly and visuallyin the functioning of the chronograph.Furthermore, this clockwork benefits fromthe latest advances in materials technology,like the use of ‘zenithium,’ first-rate modernoils and state-of-the-art surface treatments.”Horizontal <strong>coupling</strong> in its typical form: thechronograph mechanism is currently motionless.When started, the intermediatewheel (center), which is always <strong>con</strong>nectedto the fourth wheel (left), is also made tomesh with the chronograph wheel (right).86 <strong>WatchTime</strong> April 2007

PRO & CON: HORIZONTAL VS. VERTICAL COUPLINGVERTICALMARC A. HAYEK,CEO OF BLANCPAIN:“Blancpain introduced Caliber 1185,with a height of just 5.5 mm, in 1987,and it remains the world’s slimmest selfwindingchronograph movement. It relieson a <strong>vertical</strong> <strong>coupling</strong> to avoid two of themost common <strong>pro</strong>blems that beset chronographmovements. On the one hand, agentle interaction between two disksstarts the chronograph. This is unlike thesituation in <strong>horizontal</strong>ly coupled devices,in which the gears mesh abruptly whenthe start or stop button is pushed. Ofcourse, if the teeth don’t immediatelymesh perfectly, this abrupt <strong>coupling</strong> cancause the chronograph’s se<strong>con</strong>ds hand tomake a small but noticeable jump. Furthermore,imperfect meshing can damagethe gears. That’s why the owner’smanuals accompanyingeven thefinest chronographsrecommendthat owners avoid too frequentuse of the stopwatchfunction because the additional energyrequired by the chronograph mechanismcan adversely affect the accuracyof the watch’s rate. Both of these shortcomingshave been rectified in Caliber1185 and in all the successive caliberswith additional functions based on the1185. A sudden jump by the chronograph’shand is eliminated. We have alsoensured that the operation of the chronographexerts only a minimal effect onthe watch’s rate behavior.”Top, right: Blancpain’s Caliber 1185, theforerunner of <strong>vertical</strong> <strong>coupling</strong>.Left: Blancpain’s Léman Flyback Chronowith big dateContinued from page 84graph’s center wheel, which causes the chronographhand to begin to move. Analogously,when this <strong>con</strong>nective bridge is removed, thehand instantaneously ceases to move.The chronograph’s center wheel and its teethcease their motion, but the movement (includingthe driving wheel and the intermediatewheel) <strong>con</strong>tinues to run.Admittedly, this technical description is a bittheoretical and paints a rosier picture thanwhat takes place in horological reality. A certainamount of play is unavoidable whenevergears transfer force, and this play interfereswith the uniform <strong>pro</strong>gress of the chronograph’shand. To prevent the notorious lurchingand trembling of this hand, watchmakersuse a little friction spring that presses against ametal disk bearing the finger that advances theelapsed-minutes counter. This spring minimizesvibrations, but it causes unavoidable frictionand also saps energy from the mainspring.The result is a decline in the amplitude of thebalance whenever the chronograph isswitched on. The art of fine adjustment involvesachieving a well-balanced com<strong>pro</strong>misebetween the braking effect and the loss oftorque.Another difficulty associated with traditionalwheel <strong>coupling</strong> <strong>con</strong>cerns the meshing of theteeth when the <strong>coupling</strong> occurs. The tooth ofone gear slips into the space between two adjacentteeth on the other gear, and this causesthe chronograph’s hand to jump a bit when itbegins to move. Furthermore, frequent <strong>con</strong>-88 <strong>WatchTime</strong> April 2007

PRO & CON: HORIZONTAL VS. VERTICAL COUPLINGtact between the teeth of the two gears makesthem wear out faster. Watchmakers try to alleviatethis <strong>pro</strong>blem by giving each tooth a triangular<strong>pro</strong>file and by cutting a large number offinely spaced teeth around the rim of thechronograph’s center wheel. The advantagesof the elaborate wheel-<strong>coupling</strong>system include its relativelyflat height and, above all, a visuallyappealing mechanism.The chronograph’s se<strong>con</strong>ds hand (below) onPatek Philippe’s calendar chronograph (bottomright) can also be used as an ordinary se<strong>con</strong>dshand. There is no separate and <strong>con</strong>tinuouslyrunning se<strong>con</strong>ds hand.A Simpler SolutionA <strong>coupling</strong> system thatEdouard Heuer registered forpatent <strong>pro</strong>tection on ChristmasEve in 1886 is <strong>con</strong>siderablysimpler. The so-called“rocking pinion” is a moveablymounted arbor with two s<strong>pro</strong>ckets.One s<strong>pro</strong>cket, affixed to thedial side, meshes directly with thefourth wheel of the movement. The oppositeone, into which fine teeth have beencut, pivots through a small arc and engageswith the chronograph’s center wheel after thestart button is pushed. When the <strong>con</strong>nection ismade, the chronograph hand begins to run.This mechanism eliminates the need for a drivingwheel and an intermediate wheel. Whenthe button is pressed again, the rocking pinionpivots away from the chronograph’s centerwheel, dis<strong>con</strong>necting it from the flow of forceand halting the motion of the chronographhand. This system was first used in wristwatchesin 1946. In an effort to <strong>pro</strong>duce a more e<strong>con</strong>omicalversion, Valjoux <strong>con</strong>structed columnwheelCaliber 77 ECO with a rocking pinion. Acurrent example of this not-especially-eyecatching<strong>coupling</strong> version is the well-knownand widely used ETA Valjoux 7750.An entirely different type of <strong>coupling</strong> wasdevised by Manufactures des Montres &Chronographes Pierce S.A., a firm founded inBienne, Switzerland in 1883. This companylaunched its Caliber 130 in 1936. Pierce wasforced to develop its own movement becauseit could no longer obtain movement blanksfrom the classical ébauches factories. Necessitybecame the mother of invention, and PierceVERTICALPHILIPPE STERNPRESIDENT OF PATEK PHILIPPE:“A <strong>vertical</strong> disk <strong>coupling</strong> between the<strong>con</strong>tinually turning axis of the fourthwheel and the pinion of the chronograph’shand allows an interruption ofthe flow of force to the chronographcounters without the need for interruptingthe rotation of the fourth wheel. Atthe same time, this eliminates the dangerof a jump or retrograde motion by thehand because no teeth need to meshwith one another. A <strong>con</strong>ventional solutionwith three chronograph wheels increaseswear. This does not occur in our<strong>coupling</strong>, so the chronograph hand canalso be used as an ordinary se<strong>con</strong>ds handwithout adversely affecting the rate ofthe movement, without reducing thepower reserve and without causing increasedwear.”90 <strong>WatchTime</strong> April 2007

PRO & CON: HORIZONTAL VS. VERTICAL COUPLINGEbel Caliber 137 (below, right, without itsrotor) powers, among other watches, thenew 1911 BTR Chrono (above).HORIZONTALMARC MIEHLBRADTDIRECTOR OF PRODUCT DEVELOPMENT AT EBEL:“Caliber E 137 was originally developedby our engineers and watchmakersprimarily as a very slender movement.That’s why we opted to use <strong>horizontal</strong><strong>coupling</strong> for its center-mounted se<strong>con</strong>dshand. Ebel has always strived to developelegant watches, and our slender movementsenable us to achieve this goal. The<strong>con</strong>struction, which relies on a series ofwheels, allows this <strong>coupling</strong> to be perfectlyintegrated into the movement sowe can build a self-winding, chronometer-certified,chronograph movementthat is a mere 6.4 mm tall. On the otherhand, the movement is also very durable,and longevity always plays an importantrole in the development of Ebel watches.Furthermore, the movement is easy toservice by our after-sales personnel becauseit seldom suffers wear. The systemis very easy to see: just look atthe two large, gold-plated wheelsat the upper left in the photo of amovement from which the oscillatingweight has been removed(right). This arrangementmakes a watchmaker’swork easier and also allowsthe watch’s owner to observethis highly precisemechanism in action. The influenceof a gear <strong>coupling</strong> onthe se<strong>con</strong>ds hand can beovercome through specificteeth and precise adjustment, askill which our watchmakers havefully mastered. Our experiencewith chronographs <strong>con</strong>firms that thissolution is the best com<strong>pro</strong>mise for ourelegant and sporty watches.”<strong>pro</strong>duced a 13-ligne hand-wound chronographwith <strong>vertical</strong>ly arranged friction <strong>coupling</strong>,distinguished by a small rubber disk.When the chronograph mechanism isswitched on, the sharply pointed <strong>pro</strong>ngs of adriving disk engage with the rubber disk. Thesystem functions well enough, but if it is usedfrequently, the rubber disk tends to wear outand needs to be replaced at regular intervals.On the other hand, the Pierce <strong>con</strong>struction offersthe advantage of minimized friction andless loss of torque when the chronographmechanism is on.It’s not clear how heavily Jean-Claude Biverand Jacques Piguet relied on this 50-year-oldcreation when they devised their <strong>coupling</strong>mechanism at Blancpain in 1986. In any case,the design engineers at Blancpain’s sister company,Frédéric Piguet S.A., were commissionedto develop a self-winding chronograph whosedimensions were to be significantly smallerthan those of all other comparable calibers.Caliber 1185 debuted in 1987. Its 304 compo-92 <strong>WatchTime</strong> April 2007

PRO & CON: HORIZONTAL VS. VERTICAL COUPLINGVERTICALJEROME LAMBERTCEO OF JAEGER-LECOULTRE:The Extreme WorldChrono (left) and itsmotor, JLC Caliber752, shown with itsrotor removed. The<strong>vertical</strong> <strong>coupling</strong>(center) has a returnto-zeroheart, achronograph wheeland a copper-coloredfourth wheel.“Jaeger-LeCoultre’s engineers andwatchmakers made reliability and precisiona priority when they developed thenew Caliber 753. For this reason, youwon’t find the <strong>con</strong>ventional toothedwheels of a <strong>horizontal</strong> <strong>coupling</strong> mechanismto operate the chronograph’s functions.Instead, you’ll find two disks locatedbetween the fourth wheel and thechronograph’s counters. These diskstransfer energy between those components.They also ensure that the chronographstarts precisely and reliably. Usersimmediately notice the difference becausethe center-mounted se<strong>con</strong>ds handstarts instantly, without delay and withoutthe backward motion often seen inchronographs with <strong>horizontal</strong> <strong>coupling</strong>.Other important advantages aren’t noticeableat first glance, but they play animportant role because they enhanceprecision. There are no teeth in the <strong>coupling</strong>,so the optimum transfer of energyoccurs without loss. This means that thebalance’s amplitude remains <strong>con</strong>stant, regardlessof whether the chronograph isswitched on or not. And our technicianswent one step further: they put two jewelsinto the interior of the <strong>coupling</strong> mechanism.These rubies reduce friction to anegligibly low value when the chronographis motionless (because the fourthwheel <strong>con</strong>tinues to turn <strong>con</strong>stantly). Furthermore,this <strong>coupling</strong> is extremelyshock-resistant, thus making the watchvery reliable on the wrist. A strong springholds the two disks together firmly whenthe chronograph is running. The disk<strong>coupling</strong> embodies precision and reliability.Why isn’t it used more often? Becauseit’s difficult to manufacture and assemble.The utmost meticulousness and precisionare required.”troduced in 2005, has 279 components. PatekPhilippe’s Caliber CH 28-520 IRM Q 24H optsto do without a <strong>con</strong>tinuously running se<strong>con</strong>dshand. Thanks to low-friction <strong>vertical</strong> <strong>coupling</strong>,this chronograph’s center-mounted se<strong>con</strong>dshand can be allowed to rotate <strong>con</strong>tinually. Itcan be started simply by operating the flybackbutton.Another development came in 2006 fromChopard. The L.U.C 10 CF combines <strong>vertical</strong>friction <strong>coupling</strong> and an instantaneous returnto-zeromechanism, along with a small and<strong>con</strong>tinually running se<strong>con</strong>ds hand that can doa rather nifty trick. If the return-to-zero buttonis activated while the crown is extracted intothe time-setting position, the se<strong>con</strong>ds hand returnsto 12 in the blink of an eye.Vertical <strong>coupling</strong> does, however, have onedisadvantage. As in an automobile, the <strong>coupling</strong>occurs largely out of sight, whereas the<strong>horizontal</strong> arrangement is much more attractiveand eye-catching. Once again, it appearsthat even for watch lovers, it is difficult to haveone’s cake and eat it too.■96 <strong>WatchTime</strong> April 2007