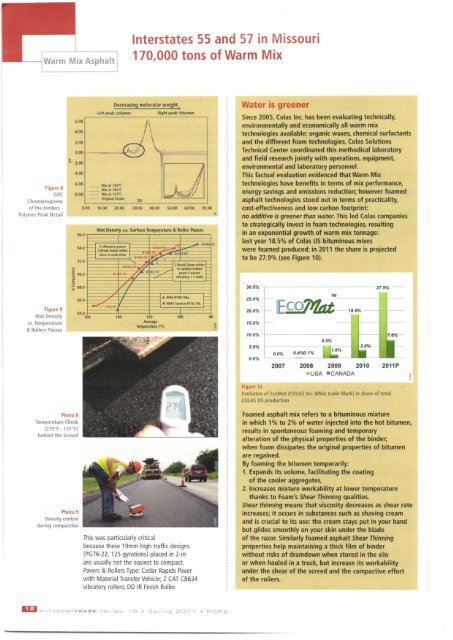

Interstates 55 and 57 in Missouri170,000 tons of <strong>Warm</strong> <strong>Mix</strong>Figure 8GPCChromatogramsof the binders -Polymer Peak Detail6.004.002.000.00>.. -2.00·4.00-6.00·8.00Decreasing molecular weight Ileft peak: polymerMrxa119JOCMueat 1ar cMlx at lSr cOrigIna l binder30Right peak: bitumen0.00 10.00 20.00 30.00 40.00 50.00 60.00 70.00oMat Density vs. Surface Temperature & Roller Passes94.0 ~ 5 vibratory passes2 BrNk Down rollfl'Sclose 10 each other92.0is} 90.02 Break Down rollers, gin tandem behindpaver 6 passesvibratory + 1 statkISWater is greenerSince 2005, Colas Inc. has been evaluating technically,environmentally and economically all warm mixtechnologies available: <strong>org</strong>anic waxes, chemical surfactantsand the different foam technologies. Colas SolutionsTechnical Center coordinated this methodical laboratoryand field research jointly with operations, equipment,environmental and laboratory personnel.This factual evaluation evidenced that <strong>Warm</strong> <strong>Mix</strong>technologies have benefits in terms of mix performance,energy savings and emissions reduction; however foamedasphalt technologies stood out in terms of practicality,cost-effectiveness and low carbon footprint:no additive is greener than water. This led Colas companiesto strategically invest in foam technologies, resultingin an exponential growth of warm mix tonnage:last year 18.5% of Colas US bituminous mixeswere foamed produced; in 2011 the share is projectedto be 27.9% (see Figure 10).Figure 9Mat Densityvs. Temperature& Rollers Passes~ 88.086.084.0160 140 120AverageTemperature (0C)• HMA B 1/82 Vibr. t:=.. WMA Tandem 81182 Vib. 1:::100 8030.0% 27.9%25.0%20.0% 18.5%15.0%10.0%5.5%5.0% 3.6%0.0% 0.4".0.1%0.0%2007 2008 2009 2010 2011PWUSA • CANADAFigure 10Evolution of EcoMat (COLAS Inc. WMA trade Mark) in share of totalCOLAS US production~;3Photo 8Temperature Check(279°F - 137°C)behind the ScreedPhoto 9Density controlduring compactionThis was particularly criticalbecause these 19mm high traffic designs(PG76-22, 125 gyrations) placed in 2-inare usually not the easiest to compact.Pavers & Rollers Type: Cedar Rapids Paverwith Material Transfer Vehicle; 2 CAT CB634vibratory rollers; DD IR Finish Roller.Foamed asphalt mix refers to a bituminous mixturein which 1 % to 2% of water injected into the hot bitumen,results in spontaneous foaming and temporaryalteration of the physical properties of the binder;when foam dissipates the original properties of bitumenare regained.By foaming the bitumen temporarily:1. Expands its volume, facilitating the coatingof the cooler aggregates,2. Increases mixture workability at lower temperaturethanks to Foam's Shear Thinning qualities.Shear thinning means that viscosity decreases as shear rateincreases; it occurs in substances such as shaving creamand is crucial to its use: the cream stays put in your handbut glides smoothly on your skin under the bladeof the razor. Similarly foamed asphalt Shear Thinningproperties help maintaining a thick film of binderwithout risks of draindown when stored in the siloor when hauled in a truck, but increase its workabilityunder the shear of the screed and the compactive effortof the rollers.lIB europea"roads revIew 1 B • Spring 2011 • RGRA

Average <strong>Warm</strong> <strong>Mix</strong> density behind the screedmatched HMA's at 85% MTDbut at about 20 0 ( lower temperature(137-1400( vs. 156°(). The two breakdownrollers were moved up in tandem closerto the paver and after the fourth pass,WMA mat density matched HMA.Target 94% MTD density was achievedat an average 20°C lower temperaturewith the same compaction energy thanksto the enhanced Foam <strong>Mix</strong> workability.Plant controlsAll mixes were produced from Delta'smobile Cedar Rapids 400 tlh parallelflow plant equipped with a 70 tons surgebin (photo 8). The plant is equipped MaxamAquablack foam device (photo 9)Plant controls included temperatures checks;Oxygen O 2; emissions of (arbon Monoxide (0,and Nitrogen Oxides NO x ; as well as energyconsumption. Main results are summarizedbelow (Table 3 & Table 4).Conclusions1-55/1-57 project, the largest <strong>Warm</strong> <strong>Mix</strong>road project ever completed to date,successfully met all contract technicalspecifications and confirmed severalof <strong>Warm</strong> <strong>Mix</strong>es' benefits: lower emissions,reduced energy consumption and enhancedconstructability. In addition the performanceevaluation conducted pointed out that not only<strong>Warm</strong> <strong>Mix</strong> Technologies allow reducingasphalt binders aging, but they also permitto preserve the elastomeric propertiesof the polymer-modified binders.Performance<strong>Mix</strong> Rutting tests and binder MS(R testinghave evidenced the better resistanceof the polymer modified <strong>Warm</strong> <strong>Mix</strong> productionto large nonlinear plastic deformations.As opposed to testing in the linear viscoelasticdomain where mix and binder showed slightlylower dynamic and shear moduli, respectively.Th is differentiated response is attributed tothe lower production temperatures which(1) preserved the elastomeric propertiesof the polymer (better resistance to plasticdeformations);(2) reduced the aging of the viscoelastic asphaltbinder (lower moduli). This reduced agingalso translates into higher resistanceto low temperature cracking.June throughDecember 2009<strong>Mix</strong> Tons Av. <strong>Mix</strong> TO Av. Agg. Moist (%) Av. KBTUs(1)/tonHMA 85,467 175°C 1.8 241WMA 70,644 149°C 1.7 205156,11 1 -26°C -15%II) A BTU (British thermal unit) is the amount of heat required to raise1 pound (454g) of water. 1 degree Fahrenheit (O.55' C)Table 3Energy Consumption on 2009 I-55 ProductionAv. HMA Av.WMA I':..<strong>Mix</strong> chute TO 177°C 153"CCO ppm 1308.0 465.2Table 4HMA, WMA productions comparative CO emissionsConstructabilityThanks to foamed asphalt increased workabilitydensity goals were met at 20 0 ( lower temperaturewith the same compaction energy as hot mixes.Emissions & EnergyMeasures on I-55 production showedthat an average 30 0 ( temperature drop resultedin a 64% Carbon-Monoxide ((0) reductionand 15% Energy Savings . •111 Bunlal. W.G .• Ahmed. S .• Dave. E. V. and Blaham, A. f. (2010)."Complehensive Database of <strong>Asphalt</strong> Concrete fracture Energy and Links tofield Performance," Paper presented at the 89th Annual Meeting of theTransportation Research Boa rd, Washington, D.C., January 20 10[2[ D'Angelo, J., Klunz, Robert Q, Dongre, Raj, and Stephens Keith ., "Revisionof the Superpave High Temperature Binder Specification: The Multiple StressCreep Recovery Test," Journal of The Association of <strong>Asphalt</strong> PavingTechnologists, Vol. 76, pp. 123, 2007Photo 8-24°C-64%0Delta CedarRapid Mobile Plantwith Water TankPhoto 9Maxam AquablackFoam Device0european r o a d s review 1 B • Spring 2011 • RGRA &I

- Page 1 and 2: europeanrr;»adsrev lew

- Page 3 and 4: Jean-louis MarchandPublication Mana

- Page 5 and 6: europeanroadsrev i e wSustainable D

- Page 7 and 8: of the aggregate particles. Product

- Page 9 and 10: lean-Paul FORTDirectorCOLAS Solutio

- Page 11 and 12: significant with the Hamburg Loaded

- Page 13: Site informationOriginal PG binderR

- Page 17 and 18: They are usually used at lower dosa

- Page 19 and 20: Example Field JobsA few examples of

- Page 21 and 22: 170160E 150.. 140~ 130! 120~ 110100

- Page 23 and 24: Sundaram lOGARAJBusiness Developmen

- Page 25 and 26: Mix temperature, °CCore density Re

- Page 27 and 28: Texas Type D surface course with 5.

- Page 29 and 30: the optimum additive contentand the

- Page 31 and 32: Thus, it was observed a great reduc

- Page 33 and 34: 14,000 --HF8M (HMA 50/70)---HF8M (W

- Page 35 and 36: AIPCRComite franc;ais~~ ......... ,

- Page 37 and 38: In land waterway 3.6".Rail 10.8%AJr

- Page 39 and 40: Theresa ROMEllSenior Transportation

- Page 41 and 42: The basic method for measuring prev

- Page 43 and 44: **.• ** *The Voice of the Europea

- Page 45 and 46: IBEF: raising global awarenessand r

- Page 47 and 48: The damage observed on some roads,

- Page 49 and 50: 70%60%50%40%30%20%10%0%90%In Irelan

- Page 51 and 52: 15 years after, the new editionof t

- Page 53 and 54: • • ~;, "~.Photo 1HTPT Simulato

- Page 55 and 56: Table 1Vehicle simulatorloading cas

- Page 57 and 58: As a result, the impact of wheel-lo

- Page 59 and 60: In Switzerland, standard asphalt mi

- Page 61 and 62: Swiss referencesTo date, over 30,00

- Page 63 and 64: Fran~oi s OLARDPatrick HUONStephane

- Page 65 and 66:

DDDMix with highfines contentP < Px

- Page 67 and 68:

This parameter, of primary importan

- Page 69 and 70:

Thick Bituminous Pavement Structure

- Page 71 and 72:

Lars LADEHOFFLaboratory ManagerCola

- Page 73 and 74:

The findings are detailed in Table

- Page 75 and 76:

Nanosoft developmentResearch perfor

- Page 77 and 78:

Safety-enhancing achievements .~Ant

- Page 79 and 80:

www.eecongress2012.org