Robot-assisted screwdriving system RSF - Weber Schraubautomaten

Robot-assisted screwdriving system RSF - Weber Schraubautomaten

Robot-assisted screwdriving system RSF - Weber Schraubautomaten

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

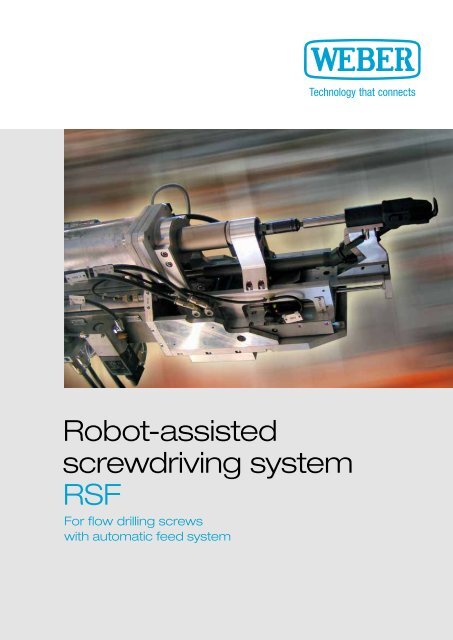

Technology that connects<strong>Robot</strong>-<strong>assisted</strong><strong>screwdriving</strong> <strong>system</strong><strong>RSF</strong>For flow drilling screwswith automatic feed <strong>system</strong>

<strong>Robot</strong>-<strong>assisted</strong><strong>screwdriving</strong> <strong>system</strong><strong>RSF</strong>For flow drilling screwswith automatic feed <strong>system</strong>Screwdriving process phases:1. Tip of fastener heats the material through high thrust and high RPM2. Material plasticized by conical screw tip3. Cylindrical passage formation4. Chip-free channelling of a metric True to gauge screw thread5. Normal <strong>screwdriving</strong> phase6. Torque-controlled screw tightening1. 2. 3.4. 5. 6.Source: EJOT FDS ®Spindle Technical Data:Mounting dimensions:W x H x L = ca. 810 x 500 x 2500 mmSpindle dimensions:W x H x L = ca. 730 x 230 x 250 mmWeight of <strong>RSF</strong> spindle:approx. 35 kgTransducer:up to 15 NmSpindle Speed:up to 5000 RPMMaximum axial force with 5 bar: 1.500 Ncycle time for screwing in a screw: aprox. 6 s (start / start)Pneumatic <strong>system</strong>:Operating pressure 5 barEnergy supply providedby customer:Power required 3 phase, 400 v, 50 hz.Technology that connects<strong>Weber</strong> <strong>Schraubautomaten</strong> GmbHHans-Urmiller-Ring 56D-82515 WolfratshausenPhone +49 (8171) 406-0Fax +49 (8171) 406-111info@weber-online.comwww.weber-online.comFeatures:_ Straight version for standard applications_ Compact version available for limited access applications_ Tool-less <strong>screwdriving</strong> tool replacement_ Screw seating height is relative to component surface_ Controllable thrust force_ Points <strong>system</strong> available for processing different screw lengths_ C50S controller with process & screwdriver controland optional touch screen_ Possible customer interfaces to C50S:a) Digital b) Interbus c) Profibus_ Cable and hose package suitable for robots_ Minimum load-bearing capacity of robot 200 kgWN 980457 Stand 04/11 AD / Technical changes reserved