You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

www.emseal.<strong>com</strong><br />

1234567890123456789012<br />

1234567890123456789012<br />

1234567890123456789012<br />

1234567890123456789012<br />

1234567890123456789012<br />

1234567890123456789012<br />

1234567890123456789012<br />

1234567890123456789012<br />

1234567890123456789012<br />

1234567890123456789012<br />

1234567890123456789012<br />

<strong>EMSEAL</strong><br />

<strong>EMSEAL</strong><br />

1234567890123456789012<br />

1234567890123456789012<br />

1234567890123456789012<br />

1234567890123456789012<br />

1234567890123456789012<br />

1234567890123456789012<br />

1234567890123456789012<br />

1234567890123456789012<br />

1234567890123456789012<br />

1234567890123456789012<br />

1234567890123456789012<br />

1234567890123456789012<br />

®<br />

Manufacturer:<br />

Product Description<br />

• IST is a preformed expanding foam<br />

tape sealant. It is made by<br />

impregnating a resilient, high-density,<br />

open-cell polyurethane foam with<br />

water-based, stabilized acrylics. It<br />

is supplied factory pre<strong>com</strong>pressed<br />

and packaged in reel form with<br />

self-adhesive backing for use in<br />

preformed joints subject to expansion<br />

and contraction movement, and<br />

also as gaskets in tightly squeezed,<br />

non-moving joints.<br />

After removal of packaging, material<br />

begins gradual expansion-slowly<br />

in cold weather, faster in<br />

hot.<br />

Sealing ability is a function of the<br />

characteristics of the open cell foam<br />

structure, the level of impregnation,<br />

and the degree of <strong>com</strong>pression or<br />

density which can be varied to suit<br />

specific applications. For example,<br />

lower <strong>com</strong>pression serves for dust,<br />

driving snow, etc., while progressively<br />

greater <strong>com</strong>pression is required for<br />

vertical run-off water, ponding water,<br />

etc.<br />

IST is supplied pre<strong>com</strong>pressed to<br />

less than the nominal material size<br />

for easy insertion into a preformed<br />

joint of the same opening width.<br />

Sealing between the foam and<br />

substrate is achieved through a<br />

<strong>com</strong>bination of the pressure-sensitive<br />

adhesive impregnation and the<br />

back pressure of the expanding<br />

foam.<br />

IST SEALANT TAPES<br />

<strong>EMSEAL</strong> JOINT SYSTEMS, LTD.<br />

23 Bridle Lane, Suite 3<br />

Westborough, MA 01581-2603<br />

Toll Free: 800-837-3331 PH: 860-677-7386 FX: 860-677-1408<br />

Uses, Applications<br />

As a water, vapor, air, sound and<br />

dust seal between metal surfaces,<br />

as well as between concrete and<br />

other substrates.<br />

For applications requiring high temperature<br />

stability.<br />

Ideal as a gasket tightly squeezed<br />

between joint faces that are<br />

mechanically fastened together<br />

such as lap seams.<br />

Its resilience makes it also suitable<br />

for use in a partly expanded<br />

condition for filling preformed<br />

openings between <strong>com</strong>ponents and<br />

where joint opening size varies due<br />

to seasonal temperature changes.<br />

In applications where damping vibration<br />

and noise is as important as<br />

weather sealing.<br />

As a secondary seal behind caulk.<br />

IST TECH DATA<br />

JANUARY 2001, PAGE 1 OF 2<br />

TECHD<br />

ATA<br />

<strong>EMSEAL</strong> CORPORATION<br />

84 Brydon Drive<br />

Rexdale, ON, Canada M9W 4N6<br />

Toll Free: 866-436-7325 PH: 416-740-2090 FX: 416-740-0233<br />

Advantages<br />

Does not dry out.<br />

Durable, resilient, therefore suitable<br />

for moving joints.<br />

Tolerant of joint face irregularities.<br />

Ideal as a secondary seal to wet<br />

sealants (caulk).<br />

Compatible with and adheres to<br />

most wet sealants.<br />

Does not bleed.<br />

Back pressure of foam maintains<br />

seal, minimizes tension on substrate,<br />

and reduces possibility of failure<br />

due to weak or improperly prepared<br />

substrates.<br />

Exposed face remains virtually flat<br />

regardless of variation and changes<br />

in joint width and <strong>com</strong>pression.<br />

User friendly—no masking, mixing,<br />

priming, tooling, curing or cleanup<br />

required.<br />

Polyester scrim embedded in selfadhesive<br />

resists stretching of<br />

material during installation.<br />

Good thermal and sound insulating<br />

properties.<br />

Difficult to vandalize.<br />

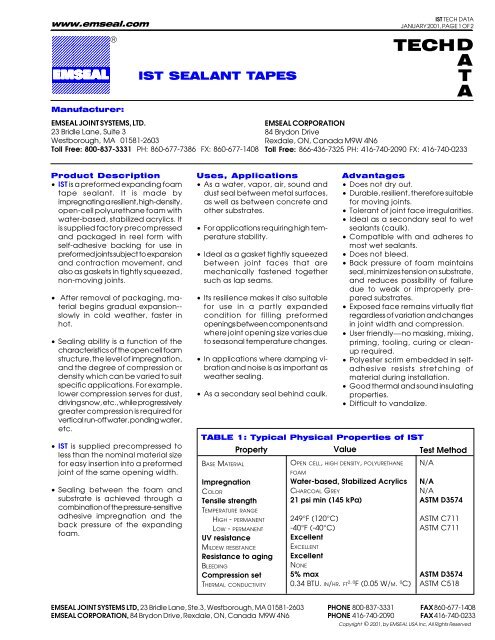

TABLE 1: Typical Physical Properties of IST<br />

BASE MATERIAL<br />

Impregnation<br />

COLOR<br />

Tensile strength<br />

TEMPERATURE RANGE<br />

HIGH - PERMANENT<br />

LOW - PERMANENT<br />

UV resistance<br />

MILDEW RESISTANCE<br />

Resistance to aging<br />

BLEEDING<br />

Compression set<br />

THERMAL CONDUCTIVITY<br />

Property Value Test Method<br />

OPEN CELL, HIGH DENSITY, POLYURETHANE<br />

FOAM<br />

Water-based, Stabilized Acrylics<br />

CHARCOAL GREY<br />

21 psi min (145 kPa)<br />

249°F (120°C)<br />

-40°F (-40°C)<br />

Excellent<br />

EXCELLENT<br />

Excellent<br />

NONE<br />

5% max<br />

0.34 BTU. IN/HR. FT 2, 0 F (0.05 W/M. 0 C)<br />

<strong>EMSEAL</strong> JOINT SYSTEMS LTD, 23 Bridle Lane, Ste.3, Westborough, MA 01581-2603 PHONE 800-837-3331 FAX 860-677-1408<br />

<strong>EMSEAL</strong> CORPORATION, 84 Brydon Drive, Rexdale, ON, Canada M9W 4N6 PHONE 416-740-2090 FAX 416-740-0233<br />

N/A<br />

N/A<br />

N/A<br />

ASTM D3574<br />

ASTM C711<br />

ASTM C711<br />

ASTM D3574<br />

ASTM C518<br />

Copyright © 2001, by <strong>EMSEAL</strong> USA Inc, All Rights Reserved

http://www.emseal.<strong>com</strong><br />

Minimizes tension on substrate<br />

and reduces possibility of failure<br />

due to weak or improperly prepared<br />

substrates.<br />

Vermin resistant.<br />

Limitations<br />

IST will not adhere to joints that are<br />

dirty or dust-covered or to surfaces<br />

coated with oils or release agents.<br />

IST service temperature range is<br />

-40°F to 249°F (-40°C to 120°C).<br />

Joint Seal<br />

Characteristics<br />

Table 1 gives the physical properties<br />

of IST.<br />

Table 2 illustrates standard sizing<br />

of IST.<br />

Joint Design<br />

Substrate faces must be parallel<br />

and have sufficient clear depth to<br />

fully support IST.<br />

Substrate must be capable of resisting,<br />

without deflection, approximately<br />

1.5 to 2.5 lb/in 2 (10 to 17<br />

kPa) back pressure from the IST.<br />

Installation<br />

Surface Preparation: Joint surfaces<br />

must be free from gross irregularities,<br />

loose particles, foreign matter<br />

such as dirt, dust, ice, snow, water,<br />

etc., and coatings such as grease,<br />

oil, release agents, lacquers, etc.,<br />

that may be detrimental to the<br />

adhesion of the sealant.<br />

IST should be stored indoors at room<br />

temperature. Recovery is quicker<br />

when warm and slower when cold.<br />

Remove IST from protective packaging.<br />

Expose self-adhesive side by<br />

removing release liner.<br />

Join consecutive lengths of material<br />

with a 45° miter.<br />

Warranty<br />

Standard or project-specific warranties<br />

are available from <strong>EMSEAL</strong> on request.<br />

IST TECH DATA<br />

FEBRUARY 1998, PAGE 2 OF 2<br />

TABLE 2: Standard Sizes<br />

The following are the most popular sizes, but material of<br />

virtually any size can be provided to suit your specific requirements.<br />

Nominal Expanded Box Rolls Roll Product<br />

Size Size Quantity Per Box Length Code<br />

1/16x3/8" 1/4x3/8" 1968' 60 32.8' 1010<br />

(1.6x10mm) (10x10mm) (300m)<br />

1/16x1" 1/4x1" 511.68' 26 32.8' 1025<br />

(1.6x25mm) (10x25mm) (156m)<br />

1/10x1/2" 3/8x1/2" 1640' 50 32.8' 1012<br />

(2.5x12mm) (10x12mm) (500m)<br />

1/10x3/4" 3/8x3/4" 1049.6' 32 32.8' 1020<br />

(2.5x20mm) (10x20mm) (320m)<br />

1/8x1/2" 1/2x1/2" 820' 50 26.24' 1512<br />

(3.2x12mm) (12x12mm) (250)<br />

1/8x3/4" 1/2x20" 524.8' 32 26.24' 1520<br />

(3.2x20mm) (12x20mm) (160m)<br />

1/4x1/2" 1/2x1/2" 984' 50 19.68' 2512<br />

(6x12mm) (24x12mm) (300m)<br />

1/4x3/4" 1x3/4" 629.76' 32 19.68' 2520<br />

(6x20mm) (24x20mm) (192mm)<br />

1/4x1-1/2" 1x1-1/2" 314.88' 20 19.68' 2537<br />

(6x37mm) (24x37mm) (96m)<br />

For technical service, samples,<br />

and pricing contact:<br />

<strong>EMSEAL</strong> JOINT SYSTEMS LTD.<br />

23 Bridle Lane, Suite 3<br />

Westborough, MA 01581-2603<br />

PH: 800-837-3331 FX: 860-677-1408<br />

Availability and Price<br />

<strong>EMSEAL</strong> products are available internationally.<br />

The product range is<br />

continually being developed, and<br />

<strong>EMSEAL</strong> reserves the right to modify<br />

or withdraw any product without prior<br />

notice.<br />

Printed with soy-based inks on acid-free, recycled, chlorine-free paper.<br />

<strong>EMSEAL</strong> USA INC. 23 Bridle Lane, Ste.3, Westborough, MA 01581-2603 PHONE 800-837-3331 FAX 860-677-1408<br />

<strong>EMSEAL</strong> CORPORATION, 84 Brydon Drive, Rexdale, ON, Canada M9W 4N6 PHONE 416-740-2090 FAX 416-740-0233<br />

Copyright © 1998, by <strong>EMSEAL</strong> USA Inc, All Rights Reserved