DSD Series - Kaeser Compressors

DSD Series - Kaeser Compressors

DSD Series - Kaeser Compressors

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

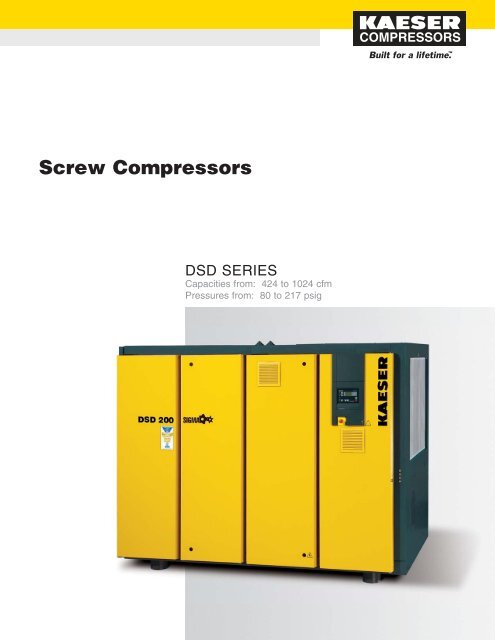

Screw <strong>Compressors</strong><strong>DSD</strong> SERIESCapacities from: 424 to 1024 cfmPressures from: 80 to 217 psig

Built for a lifetimeMaximum efficiency and reliability havelong been synonymous with <strong>Kaeser</strong><strong>Compressors</strong>. Our commitment to excellencedrives us to continually enhanceand optimize our compressed air systemsolutions. With a cutting edge researchand development team committed toproducing industry leading products,<strong>Kaeser</strong> constantly strives to offer lastingsolutions for our customers’ compressedair needs. The <strong>DSD</strong> series rotary screwcompressor delivers on all accounts.<strong>Kaeser</strong>’s unique Sigma Profileairend and intelligent Sigma Control 2system, combined with the latest one-toonedrive technology mean that our <strong>DSD</strong>compressors can guarantee exceptionalenergy savings, without compromisingon durability or ease of maintenance.Our customers expect excellence and wemake it happen.Built to perform. Built to last. <strong>Kaeser</strong>compressors are built for a lifetime.EquipmentMaintenanceElectricity70% of Your Long TermCompressor Cost is ElectricityAnalyze the total cost of a compressedair system and you’ll realize that powercost is significant. In just one year itcould exceed the price of the compressoritself. Over a period of ten years, thiscould consume 70% of your overall airsystem costs. That’s why it is importantto investigate energy efficiency whenconsidering a new compressor or designingan air system.1Sigma Profile AirendOur single-stage, flooded rotary screw airenddelivers pressuresup to 217 psig,and features ourpower saving SigmaProfile design. Ourairends are precisionmachined andoptimized in size and profile to match the airendspeeds with their best specific performance (seeA Perfect Match curve).2True Direct DriveIn our design, the motor is directly connected tothe airend with a one-toonecoupling, providingmaximum transmissionefficiency. This true directdrive eliminates geardrive components, heat and power losses. It isalso maintenance free, increasing reliability anduptime. A cast housing is doweled and pinned toassure perfect alignment.3Premium Efficiency DriveMotorA Perfect MatchSpecific Performance (kW/100 cfm)Airend SpeedOptimum SpeedUnlike the competition, <strong>Kaeser</strong> <strong>Compressors</strong> makes many different airends to that we can applythem at their optimal speed and performance.<strong>Kaeser</strong> uses only premium efficiency TotallyEnclosed Fan Cooled (TEFC) motors with class Finsulation for extra protectionfrom heat and contaminants.Remotegrease fittings makemaintenance abreeze. Each of thethree motor windingsis actively monitoredthrough its own PT100 temperaturesensor. Standard voltages are 460 or 575 V(3-phase, 60 Hz). Other voltages are available.4Reduced Voltage StartingMagnetic Wye-Delta reduced voltage starting isstandard. This energy saving feature ensureslow starting current and smooth acceleration.

<strong>DSD</strong> <strong>Series</strong>451235Inlet FilterFluid Separation SystemWe protect our compressors with a two-stage,1 micron air intake filter.This extends airend lifeand fluid change intervals.The filter may be cleanedseveral times beforereplacement and is easilyserviced with no toolsrequired.Our separator tank has a 3-stage separation system that ensures very low pressuredrop, fluid carry-over (1-3 ppm), and extended filter service life.Our no-leak design features rigid steel piping, flexible connections and vibrationisolators. Each pressure vessel is ASME coded (CRN in Canada) and includes wetside/dry side fittings to check differential pressure, an easy to read fluid levelindicator, and our unique quick drain system.

Unique Air Flow DesignOptimizes CoolingIn <strong>Kaeser</strong>’s “split-cooling” design, twoseparate cooling air inlet zones forthe coolers and drive motor ensureoptimum cooling. Drawing ambient airdirectly across the coolers and motorthrough separate zones eliminates preheatingand results in longer lubricantlife and a cooler running motor. Thisalso results in much lower approachtemperatures, improving moistureseparation and air quality.To increase reliability and reducemaintenance costs, the coolers areconveniently located on the outside ofthe unit, where dust and dirt build-upare easily seen and can be removedwithout dismantling the cooler.Powerful radial fans pull air through thecoolers and create a vacuumwithin the cabinetthat effectively coolsthe motor even undersevere operating conditions.Top exhaust allowsfor convenient ducting and reduces thesystem footprint.Intelligent Control andProtectionTo protect your investment and ensurethe most efficient operation possible,we control this compressor with ourSigma Control 2. This intelligentcontroller comes standard with multiplepre-programmed control profilesso you can select the one that bestfits your application. Sigma Control 2monitors more than 20 critical operatingparameters, shuts the unit down toprevent damage and signals if immediateservice is required. It also trackspreventive maintenance intervals andprovides notice when PMs are due.Sigma Control 2 has superior communicationscapabilities. An Ethernet portand built-in web-server enable remoteaccess. ModBus, Profibus, Devicenet,and other industrial communicationsinterfaces are also available as plugin options for seamless integrationinto plant control/monitoring systems.See our Sigma Control 2 brochure fordetails.Extremely Low Sound andVibrationAll <strong>DSD</strong> models come standard with<strong>Kaeser</strong>’s superior cabinet that featurescomplete metal enclosures with soundproofing liners and heavy-duty vibrationisolation. Using one-to-one direct driveand our unique cooing airflow designwith radial fans greatly reduces internalnoise and vibration.As a result, the <strong>DSD</strong> series runmuch quieter than other compressorsof similar size.Optimized EfficiencyIn <strong>DSD</strong> packages, one-to-one drive reduces thenumber of components needed compared toa gear drive unit thus increasing reliability andservice life.<strong>Kaeser</strong> has selected oversized airends specificallymatched to produce the requiredoutput in flow and pressure. Compared to compressorsusing small, high-speed gear-drivenairends, the <strong>DSD</strong> one-to-one drive provides triplesavings: no-loss power transmission, improvedpower consumption, and reduced maintenanceand related downtime costs.One-to-One Direct DriveAirend RPM = Motor RPM

DimensionsStandard Version<strong>DSD</strong> 125, 150, and 175OptionsVariable frequency control<strong>DSD</strong> compressors are available withSigma Frequency Control (SFC) toprovide superior part load efficiencyand steady pressure in applicationswith widely varying air demands.Standard features include EMI filters,line reactors, and galvanic separationcontactors for extra electrical systemprotection. SFC units also feature drivecabinet cooling fans and the latest inSiemens drive technology for reliabilityand efficiency.Water-cooledUnit with optional SFC. See SFC literaturefor more information.80-1/4”<strong>DSD</strong> compressors are available water-cooled with stainless steel, plate type heatexchangers as standard equipment. Shell and tube heat exchangers are availableon request.Heat Recovery92-3/4”Compressing air converts the electrical energy you buy into heat. <strong>DSD</strong> compressorsare available with a heat recovery option to recover up to 76% of this energy.They can come ready to be connected to an external heat exchanger or withinternal heat exchangers. Options include the plate type, shell and tube, or SWTheat exchangers. The SWT fail-safe heat exchangers provide extra protectionfrom process contamination in sensitive applications such as food, chemical, orpharmaceutical processing.When you consider that a 250 hp compressor running full time at 7 cents/kW uses over $187,500 per year in energy, the potential savings and benefits aresignificant.68”Air Discharge: 2½” ANSI FlangeDimensions are for reference only —please contact <strong>Kaeser</strong> for dimensionaldrawings.

CAGI CertifiedPerformanceOur compressors’ energy efficiencyhas been tested and confirmed byan independent laboratory as partof the Compressed Air and GasInstitute’s Rotary Screw CompressorPerformance Verification Program.<strong>DSD</strong> <strong>Series</strong> - Technical Specifications for Standard Units*Model<strong>DSD</strong> 125<strong>DSD</strong> 150<strong>DSD</strong> 175<strong>DSD</strong> 200PressureRange(psig)Capacity(cfm) (1)125 569175 424125 671175 544125 660175 636217 526125 862175 639217 530125 1003RatedMotorPower(hp)DimensionsL x W x H(in.)Weight(lb.) (2)SoundLevel(dB(A)) (3)125 92¾ x 68 x 80¼ 6283 71150 92¾ x 68 x 80¼ 7055 73175 92¾ x 68 x 80¼ 7496 74200 102½ x 77 7 /8 x 80¼ 8047 73<strong>DSD</strong> 250 175 837 250 102½ x 77 7 /8 x 80¼ 8267 73217 615(1) Performance rated in accordance with CAGI/ISO 1217 test code. (2) Weights may vary slightly depending on airendmodel. (3) Per ISO 2151 using ISO 9614-2.NOTE: Other pressures available from 80 to 217 psig* For units with SFC and/or dryer, please contact your local authorized <strong>Kaeser</strong> distributor.Specifications are subject to change without notice.To find CAGI data sheets forthese compressors, scan thisQR code with your Smartphoneor go to www.kaeser.com/cagi.Compressed AirSystem Design<strong>Kaeser</strong>’s team of engineers are alwaysat your service to help design or optimizeyour compressed air system.Using our Air Demand Analysis(ADA) and <strong>Kaeser</strong> Energy SavingSystem (KESS) we can evaluate yourexisting installation and demonstrate howproposed changes will improve your systemperformance.<strong>Kaeser</strong> can also produce twodimensionaland three-dimensional drawingsof the proposed system. This is ahuge benefit in project planning. It helpsvisualize new equipment and how it willfit into the building along with existingequipment, piping, walls, vents, etc. Thisfacilitates installation planning.From complex installations tochallenging environments to limitedspace, <strong>Kaeser</strong> can design a system tomeet your specific requirements forperformance and reliability.www.kaeser.com<strong>Kaeser</strong> <strong>Compressors</strong>, Inc.511 Sigma DriveFredericksburg, VA 22408 USATelephone: 540-898-5500Toll Free: 800-777-7873info.usa@kaeser.com<strong>Kaeser</strong> <strong>Compressors</strong> Canada Inc.3760 La Verendrye StreetBoisbriand, QC J7H 1R5 CANADATelephone: (450) 971-1414Toll free: (800) 477-1416info.canada@kaeser.com<strong>Kaeser</strong> Compresores de MéxicoS de RL de CVCalle 2 #123Parque Industrial Juríca76100 Querétaro, Qro.Telephone: 01 (442) 218 64 48sales.mexico@kaeser.com<strong>Kaeser</strong> Compresores deGuatemala y Cia. Ltda.Calz. Atanasio Tzul 21-00, zona 12El Cortijo II, Bodega 50101012–Guatemala CityTelephone: +502 2412-6000info.guatemala@kaeser.com© 2012 <strong>Kaeser</strong> <strong>Compressors</strong>, Inc. All rights reserved. 11/12US<strong>DSD</strong>