Identifying and Sourcing Stone for Historic Building Repair

Identifying and Sourcing Stone for Historic Building Repair

Identifying and Sourcing Stone for Historic Building Repair

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

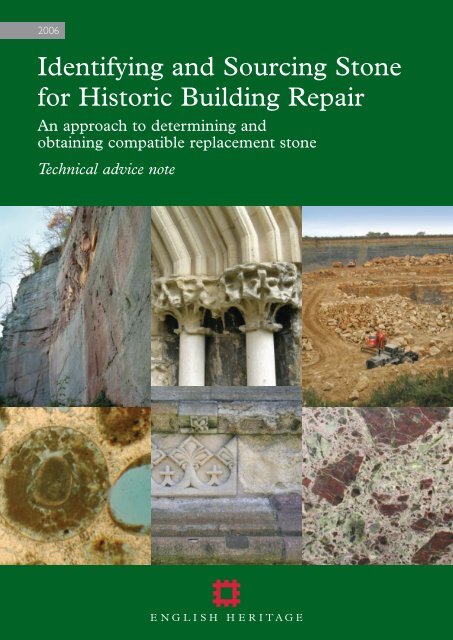

2006<strong>Identifying</strong> <strong>and</strong> <strong>Sourcing</strong> <strong>Stone</strong><strong>for</strong> <strong>Historic</strong> <strong>Building</strong> <strong>Repair</strong>An approach to determining <strong>and</strong>obtaining compatible replacement stoneTechnical advice note

SummaryThis Technical Advice Note providesguidance <strong>for</strong> architects, surveyors,engineers, building managers, contractors,conservation officers <strong>and</strong> owners on thebest way of identifying <strong>and</strong> sourcing stone<strong>for</strong> the repair of historic buildings <strong>and</strong>monuments.<strong>Stone</strong> repair must be planned <strong>and</strong> carriedout with care <strong>and</strong> sensitivity, <strong>and</strong> requiresa sound knowledge of the characteristicsof the stone involved. The choice ofreplacement stone must be bothsympathetic <strong>and</strong> cost-effective. Whereverpossible compatible materials should beused – stone that closely replicates theoriginal in its appearance, chemical,physical <strong>and</strong> mineralogical properties,strength <strong>and</strong> durability.The aim should be to retain the maximumamount of original stone, wherever thisdoes not compromise the integrity of thebuilding. Maximum retention is often thepreferred option, but <strong>for</strong> inaccessiblestructures – such as spires, where thenecessary scaffolding is expensive – it maynot be the most cost-effective in the longterm.It is there<strong>for</strong>e acceptable to replacestone selectively to ensure structuralstability, or when it has decayed beyondrepair. Replacement may also beappropriate when the purity of thebuilding design is considered equallyvaluable, or more valuable, than theoriginal construction material – <strong>for</strong>example, a 19th-century classical building.Successful repair also relies on a thoroughunderst<strong>and</strong>ing of the historical context ofthe building <strong>and</strong> its surroundings.The selection process involves severalsteps:1 Establishing the historical <strong>and</strong> physicalsignificance of the building, <strong>and</strong> thelikely impact of any proposedintervention2 Assessing <strong>and</strong> underst<strong>and</strong>ingweathering <strong>and</strong> other decay processesaffecting the stone3 Undertaking an initial fabric/masonrysurvey to determine the need <strong>for</strong> stonereplacement4 Defining the types of stone used, byvisual examination in situ5 Answering any technical questions insteps 1–4 above, by using the mostappropriate analytical techniques onsamples taken from the site6 Obtaining samples of potentialreplacement stone, <strong>and</strong> testing thesewhere necessary7 <strong>Sourcing</strong> <strong>and</strong> securing replacementstone from existing quarries or (incertain cases) from quarries temporarilyre-opened <strong>for</strong> the purposeIn all but the smallest of projects, stoneselection <strong>for</strong> historic building repairdem<strong>and</strong>s the combined skills <strong>and</strong>knowledge of a team of people experiencedin working with stone. Ideally theteam should be led by a stone consultant(usually a geologist or petrographer), whocan both identify the stone <strong>and</strong> find eitherthe most compatible petrographic matchfrom existing or new sources, or the mostclosely related alternatives. When stone isbeing sourced from a temporary quarry orfrom a new quarry, the stone consultantshould also be experienced in mineralplanning procedures.English Heritage supports the need <strong>for</strong>strategic <strong>and</strong> sustainable sources of stone<strong>for</strong> the conservation, repair, maintenance<strong>and</strong> improvement (CRMI) of historicbuildings, <strong>and</strong> so is working with otherpartners to ensure that the environmentalimpact of quarrying is minimised.Addressing the wider issues arising fromsourcing <strong>and</strong> quarrying stone willcontribute as much to the long-termpreservation of our rich <strong>and</strong> diverseheritage as the building repair itself.Contents1 Introduction . . . . . . . . . . . . . . . . . 32 Evaluation <strong>and</strong> characterisationof the existing stonework . . . . . . 32.1 Visual <strong>and</strong> physical properties . . 32.2 Preliminary surveys . . . . . . . . . . . 43 Sampling <strong>and</strong> identification . . . . 43.1 Sampling . . . . . . . . . . . . . . . . . . . . 4Background in<strong>for</strong>mationrequired <strong>for</strong> sampling . . . . . . . . . . . 5Choosing sample locations . . . . . . . 5Preparing to take samples . . . . . . . 5Sampling fragile stone . . . . . . . . . . 6Planning stone sampling . . . . . . . . 6Photography . . . . . . . . . . . . . . . . . . 6Labelling samples . . . . . . . . . . . . . . 6Useful additional in<strong>for</strong>mation . . . . 73.2 Examination <strong>and</strong> analysisof stone . . . . . . . . . . . . . . . . . . . . . 7H<strong>and</strong> samples . . . . . . . . . . . . . . . . . 7Petrographic analysis . . . . . . . . . . . 7Physical parameters . . . . . . . . . . . . 8Other analytical techniques . . . . . . 84 Criteria <strong>for</strong> selectingreplacement stone . . . . . . . . . . . . 9Petrography . . . . . . . . . . . . . . . . . . 9Chemical characteristics . . . . . . . . . 9Appearance . . . . . . . . . . . . . . . . . . 9Geological age . . . . . . . . . . . . . . . . 9Porosity . . . . . . . . . . . . . . . . . . . . . . 9Compressive strength . . . . . . . . . . . 95 Sources of stone . . . . . . . . . . . . . . 95.1 Active quarries . . . . . . . . . . . . . . . 95.2 Disused quarries . . . . . . . . . . . . . 95.3 Recycled stone . . . . . . . . . . . . . . 106 Obtaining stone <strong>for</strong> historicbuilding repair . . . . . . . . . . . . . . 106.1 Specifying stone . . . . . . . . . . . . . 106.2 Samples of new stone . . . . . . . . 116.3 Testing replacement stone . . . . 116.4 Obtaining stone fromnew or temporary sources . . . . . 117 Sources of further in<strong>for</strong>mation<strong>and</strong> assistance . . . . . . . . . . . . . . . 117.1 <strong>Stone</strong> collections . . . . . . . . . . . . 117.2 Other sources of help . . . . . . . . 12Bibliography . . . . . . . . . . . . . . . . . . . . 12Useful contacts . . . . . . . . . . . . . . . . . 13Annex: A system <strong>for</strong> the fieldidentification of the morecommon building stonesused in Engl<strong>and</strong> . . . . . . . . . . . . . 14Acknowledgements . . . . . . . . . . . . . . 152

1 Introduction<strong>Stone</strong> – abundant, readily available,workable <strong>and</strong> strong – has historicallybeen the most widely used naturalmaterial <strong>for</strong> constructing buildings,monuments, sculpture <strong>and</strong> carveddecoration. Throughout the world,cultural stature is closely related to thenumber of large stone buildings <strong>and</strong>public monuments, <strong>and</strong> through themillennia the extraction, transportation<strong>and</strong> working of basic rock <strong>for</strong>ms hasbeen refined, often with considerableingenuity. On a local scale, use oflocally available stone <strong>and</strong> local masonshas produced distinctive vernacularbuilding styles.Although stone is something of ametaphor <strong>for</strong> permanence <strong>and</strong> durability,this can prove far from the truth.Composition varies, even within a singlesource, <strong>and</strong> a building stone may proveunstable, brittle or soft. Many limestones,<strong>for</strong> example, are particularly prone todecay. To preserve an historic building, itis often necessary to replace some of itsstone <strong>and</strong> regeneration, repair <strong>and</strong>maintenance all help the building’ssustainability. For intervention to besuccessful, however, it is imperative thatthe historic <strong>and</strong> physical significance ofthe building <strong>and</strong> its current condition bedetermined be<strong>for</strong>e the repair programmeis designed.<strong>Stone</strong> sourcing <strong>for</strong>ms part of the design<strong>and</strong> specification stage of repair work,enabling the work programme to remainon course <strong>and</strong> within budget. <strong>Stone</strong>sourcing <strong>for</strong> historic building repair musttake the following factors into account:● the matching stone should be similarin colour, texture <strong>and</strong> physicalproperties to the original● any intervention must not harm theoriginal building fabric● the roles <strong>and</strong> responsibilities of thosewithin the design team must be wellunderstood● all work must comply with the Listed<strong>Building</strong> Consent framework <strong>and</strong>British <strong>and</strong> European St<strong>and</strong>ardsMatching stone is often notstraight<strong>for</strong>ward. Although it may bepossible to distinguish common stonetypes on the basis of colour <strong>and</strong> texture –s<strong>and</strong>stone from slate, Bath limestonefrom Ketton limestone – there will bemany subtle colour differences, texturalchanges <strong>and</strong> variations: striations <strong>and</strong>sedimentary structures, grain sizes,porosities <strong>and</strong> cementation, <strong>and</strong>mineralogical incompatibilities withingeneric stone types. It is exactly thesefine details that may be critical to asuccessful repair, but their recognitionrequires expertise <strong>and</strong> experience.<strong>Historic</strong> building architects, stone-tradeconsultants <strong>and</strong> masonry contractorswill often be able to undertake basicvisual identification <strong>and</strong> sourcing,especially with common stones suchas Portl<strong>and</strong> limestone, or wherebackground in<strong>for</strong>mation is available.However, specialist advice will beneeded to identify more complex stonetypes or to diagnose unusual problems.<strong>Stone</strong> consultants – geologists orpetrographers – can be useful guides <strong>for</strong>client <strong>and</strong> contractor throughout theprocurement process.<strong>Stone</strong> sourcing should be part of thesub-contracted masonry package. If itis left out of the procurement process,there will be insufficient time <strong>for</strong> selecting<strong>and</strong> ordering, expediency will replaceplanning <strong>and</strong> unsuitable stones or stonesupplies may be selected. This couldhave a drastic visual <strong>and</strong> physicalimpact, <strong>and</strong> as the replacement stonecannot usually be remedied withoutgreat expense, it may remain as anuncom<strong>for</strong>table example of bad design,or have a possible long-term disfiguring<strong>and</strong> damaging effect on the historicbuilding’s fabric.Expensive errors can be avoided byincluding a stone consultant in the basicproject team. Operating as a link betweenthe project architect or consultant,<strong>and</strong> the contractor <strong>and</strong> masonry subcontractors,the stone consultant canalso control quality when large amountsof stone are being supplied. On occasionsthey may work in conjunction with amasonry trade consultant.Common stone procurement routesOwner – Architect – (Planner) – Architect –Contractor – QuarryOwner – Architect – (Planner) – Architect –Contractor – Masonry Contractor – QuarryOwner – Architect – (Planner) – Architect –Project Management Company – MasonryPackage – Quarry2 Evaluation <strong>and</strong> characterisationof the existing stonework2.1 Visual <strong>and</strong> physical propertiesMost old buildings have a history ofalterations <strong>and</strong> additions. Often theoriginal fabric incorporated severaldifferent kinds of stone, <strong>and</strong> others mayhave been introduced during subsequentrepairs <strong>and</strong> restorations.In most cases the dominant stone is oflocal origin, but other stone types mayhave been needed <strong>for</strong> different elements ofthe construction – stone suitable <strong>for</strong>walling may not be sufficiently durable <strong>for</strong>exposed areas, such as quoins or parapets.The flextural strength required <strong>for</strong> loadbearingelements such as lintels, <strong>and</strong> theneed <strong>for</strong> large block sizes <strong>for</strong> certaindesign requirements may also havedem<strong>and</strong>ed different varieties. Somechoices may have been purely aesthetic.At times it may have proved necessary toimport suitable stone from outside thelocal area. The stone used at an earlierstage of building may no longer have beenavailable in subsequent phases: often theremaining stone in the original quarry wasnot suitable <strong>for</strong> construction purposes.It is also not unusual to find that stonehas been salvaged <strong>and</strong> re-used (Fig 1).Fig 1 Anadolu Kavagi, near Istanbul, Roman stone, restored<strong>and</strong> rein<strong>for</strong>ced by the Genoans c 1350. (David Heath)Every type of stone has unique properties,<strong>and</strong> a distinct manner of weathering <strong>and</strong>decay. The rate <strong>and</strong> manner ofdeterioration is dependent upon notonly on the stone’s composition, but alsoon the manner in which it was quarried<strong>and</strong> worked, its final use <strong>and</strong> theenvironment in which it is placed. Theremay be faults in the building design <strong>and</strong>construction that cause local decay.Even sound stone elements will be subjectto the various chemical processes <strong>and</strong>mechanical stresses that can, over time,lead to internal <strong>and</strong> superficialdeterioration, <strong>and</strong> eventually may causecomplete disintegration.3

The rate of decay will vary, especially <strong>for</strong>exposed stone, depending on theconditions around <strong>and</strong> within thebuilding: <strong>for</strong> example, wind, rain, thermalvariations, frost action, atmosphericpollution <strong>and</strong> biological activity. Theremay be a delicate balance between thestonework <strong>and</strong> the prevailing climate; ifthis is destabilised deterioration canaccelerate.Changes to the fabric, such as theinsertion of a different type of stone or theenclosure of an external wall (especially ina heated area), can have a harmful effecton the existing stonework. Thejuxtaposition of two incompatible stonescan lead to adverse chemical reactions: <strong>for</strong>example, placing limestone above certains<strong>and</strong>stones can lead to decay as alkalinemoisture leaching out of the limestonereacts with clay or reactive silica bindersin the s<strong>and</strong>stone.Natural decay processes will beaccelerated by poor design <strong>and</strong>construction, such as incorrect orientationof bedding planes (so that blocks areedge- or face-bedded), or permeable stonebeing used <strong>for</strong> rain-shedding features suchas copings <strong>and</strong> parapets. The resultingingress of moisture can lead todeterioration elsewhere in the building.Studying the construction of the originalbuilding <strong>and</strong> the current condition of thestonework <strong>and</strong> its surroundings isthere<strong>for</strong>e essential to determine the need<strong>for</strong> repair, <strong>and</strong> <strong>for</strong> choosing the bestmanner of replacing severely decayedelements.2.2 Preliminary surveysThe initial step is to survey the fabric ofthe building in detail, recording thelocation of the different types of stone,identifying <strong>and</strong> distinguishing the stonesused, <strong>and</strong> determining whether these areoriginal or later additions.Condition surveys by architects <strong>and</strong>surveyors can help identify the factorsgoverning the choices of stone. If possiblearchival sources should be studied, tocollect as much in<strong>for</strong>mation as possibleabout the building’s history, from originalconstruction to the present day. Suchresearch often provides useful insights intothe design, the sources of original <strong>and</strong>added materials, the methods ofconstruction <strong>and</strong> the originalworkmanship <strong>and</strong> that of subsequentalterations.Fig 2 Shap granite showing the scattered large sedimentaryphenocrysts of feldspar (field of view 60mm wide).(David Jefferson)The fundamental fabric/masonry survey<strong>and</strong> visual inspection must also determinethe need <strong>for</strong>, <strong>and</strong> extent of, any requiredrepair, identify the most suitable stonetypes <strong>for</strong> replacement <strong>and</strong> decide on whatskills <strong>and</strong> personnel the project will require.During the initial survey it is notnecessary to identify each stone type in astrict geological sense, although variationswithin a general lithological type – thatmay have resulted from similar stonesbeing obtained from different sources –should be recorded.Features to document include: b<strong>and</strong>ing,inclusions of different coloured materialwithin igneous or metamorphic rocksFig 3 Whitby Abbey, North Yorkshire: various large-scalefeatures, such as grain size variations <strong>and</strong> cross-bedding, on250mm high column drums. (David Jefferson)(Fig 2) <strong>and</strong> the orientation of bedding <strong>and</strong>changes in grain size between layers insedimentary rocks (Fig 3).For sedimentary stones, the height ofthe masonry courses should be recorded.Unless the blocks have been used edgebedded,course height usually reflectsthe thickness of the beds in the quarry.The relative proportions of course heightscan be invaluable, helping a stoneconsultant or geologist to identify theoriginal source.Recordings should be drawn by h<strong>and</strong> onsite as accurate line drawings, <strong>for</strong> exampleproduced from a photogrammetric surveyof the building or documented on toenlarged digital photographs.3 Sampling <strong>and</strong> identificationReasons <strong>for</strong> professional analysis● to identify the type <strong>and</strong> source ofstone so as to obtain an acceptablereplacement● to underst<strong>and</strong> the manner in which astone is weathering or decaying, toestablish measures to slow the rate ofdeterioration● to determine the nature <strong>and</strong> distributionof contaminants within the pores ofthe stone, <strong>and</strong> their possible effect onthe stone <strong>and</strong> on the surrounding fabricof the buildingIn<strong>for</strong>mation required by the analyst● the aim of the petrographic analysis,<strong>and</strong> how the in<strong>for</strong>mation will be used● the history, age <strong>and</strong> condition of thebuilding● the nature <strong>and</strong> extent of visible decaymechanisms● the context <strong>and</strong> location of specificstones or areas of the building beingstudied3.1 SamplingSamples can be used to investigate severalaspects of the stone <strong>and</strong> its deterioration.The type of sample preparation, theanalysis undertaken <strong>and</strong> the resultingrecommendations will depend on theproblem being investigated. Sampling isinvasive, <strong>and</strong> should not be considered aroutine procedure.The following is a guide to the type ofin<strong>for</strong>mation needed <strong>for</strong> differentinvestigations.4

Background in<strong>for</strong>mation required<strong>for</strong> samplingThe nature of the problem being studiedmay make it necessary to sample in aspecific manner, so the analyst’s adviceshould always be sought be<strong>for</strong>e samplingbegins. In many cases – such as studiesof rates of weathering or deterioration,the effects of previous treatments or saltcontamination – it is imperative toexplain the precise nature of the problemwhen submitting the samples, as thismay influence the sample preparation.If previous treatments are being assessed,it is necessary to gather backgroundin<strong>for</strong>mation, particularly about thematerials used. This should includechemical, physical <strong>and</strong> ageing properties,weathering <strong>and</strong> deteriorationcharacteristics of the treatments <strong>and</strong>potentially harmful effects on both thetreated stone <strong>and</strong> on any surroundinguntreated stone.Choosing sample locationsIt is essential to obtain representativesamples of the stone to address therelevant problem. For instance, samplingweathered material can lead tomisinterpretations of the original natureof the stone. As an example, s<strong>and</strong>stonecemented with calcite will have completelydifferent properties from s<strong>and</strong>stonecemented with clay minerals. Whenweathering occurs, both will eventuallyconsist of s<strong>and</strong> grains separated by voidsfrom which the cement has been leached<strong>and</strong> appear remarkably similar.Misinterpretation can lead to incorrectchoices of replacement stone, or toinappropriate conservation strategies <strong>for</strong>the surviving stonework. Similarly,sampling only the non-decayed portionsof blocks is of little use if the problembeing investigated involves any interactionbetween the stone <strong>and</strong> the bedding orpointing mortar.The sample taken must be truly typical.If there are apparent variations in thestone – <strong>for</strong> example in colour, textureor type of weathering – wherever possiblesamples should be collected of eachvariation.Samples should always be taken directlyfrom the building <strong>and</strong> not by collectingfallen stone as its history <strong>and</strong> whether ornot it is representative will always be indoubt. If a piece of stone has detachednaturally from the fabric of the building,its weathering may well bemore advanced, <strong>and</strong> so thepetrographic characteristicsmay not be the same asthe stone still in situ.Preparing to take samplesSampling the stonework of animportant historic building orancient monument isdestructive, but the damageincurred by taking arepresentative sample must beassessed against the potentialdeterioration <strong>and</strong> loss ifunrepresentative samplingshould lead to inappropriatetreatment. Large samples canoften be sub-sampled <strong>for</strong> thelaboratory analysis <strong>and</strong> thenrepaired <strong>and</strong> placed backin situ during the repair work.Samples should be selected to have oneweathered face, with the remaindernon-weathered. The sample’s orientationmust be recorded (Fig 4): this caneither be indicated in the in<strong>for</strong>mationsupplied with the sample, or if thesample is sufficiently large, <strong>and</strong> where itwould not obscure any useful surfacedetail, marked directly on the outer faceof the stone.The optimum sample size will dependon the homogeneity <strong>and</strong> grain size of thestone. For uni<strong>for</strong>m fine-grained stone,samples measuring 75mm 75mm 40mm are generally adequate, whereasa coarse-grained stone will requiresamples 150mm 150mm 80mm.Where a sample must be taken from thecorner of a block with two weatheredfaces, it must be large enough to includesome of the non-weathered inner core.If samples are required from carveddetail, a small-diameter core drill canbe used to collect material fromconcealed surfaces. The resulting holescan then be surface-filled by a specialistconservator.The site <strong>for</strong> a sample must be carefullychosen so as not to disfigure the building,although this must not result in thesample being unrepresentative.Permission to sample must be secured from therelevant authority: a faculty <strong>for</strong> Church ofEngl<strong>and</strong> buildings, the equivalent <strong>for</strong>other religious authorities or ScheduledMonument Consent from the Department<strong>for</strong> Culture, Media <strong>and</strong> Sports throughOrienting a sample.Having knocked the sample off the selected portion ofthe fabric, replace it in the block <strong>and</strong> mark the top <strong>and</strong>the orientation of at least one face. If the top is not aflat surface, an upwards pointing arrow on one of theside faces can be used to indicate the top of the piece.Fig 4 Marking the orientation on a removed stone sample. (David Jefferson)English Heritage <strong>for</strong> ScheduledMonuments. For listed buildings, theLocal Authority Conservation Officermust be consulted. Ideally an officialobserver such as a Local AuthorityConservation Officer or an EnglishHeritage <strong>Historic</strong> <strong>Building</strong>s Architector Inspector should be present duringsampling, to agree on sample locations<strong>and</strong> sizes.It is always preferable that sampling becarried out by an experienced specialist.Be<strong>for</strong>e sampling, the area should bephotographed (see below). If large-scalecolour b<strong>and</strong>ing or grain size variationsexist, this should be captured withclose-up photographs, <strong>and</strong> separatesamples should be taken of each of thedifferent b<strong>and</strong>s.European st<strong>and</strong>ards <strong>for</strong> samplingAlthough harmonised European St<strong>and</strong>ards(BS ENs) exist to govern <strong>and</strong> provideuni<strong>for</strong>mity <strong>and</strong> consistency in sampling,these are designed <strong>for</strong> quality <strong>and</strong> processcontrol.The number of samples requiredto achieve the confidence levels necessary<strong>for</strong> control purposes would not normallybe acceptable <strong>for</strong> underst<strong>and</strong>ing thestone from a historic building, <strong>for</strong> whichinvasive investigations must be minimisedas far as possible. Where a constructionmaterial must be identified or a weatheringproblem investigated, choosing the number<strong>and</strong> location of the samples will dem<strong>and</strong>experienced professional judgement.5

Sampling fragile stoneIf the area to be sampled is deeplyfractured or has shear cracks, it may benecessary to apply a temporary facinglayer to it to prevent detachment, lossof loose surface material or furtherfracturing during sampling <strong>and</strong> removal.Acid-free tissue should be adhered to thesurface with a diluted solution of asuitable reversible consolidant (such aspolyvinyl alcohol, or an acrylic emulsion),applied by a qualified conservatorengaged by the client or stone specialist.If necessary, fragile samples can beprotected in polythene bubble wrap <strong>for</strong>transportation; the protective layers <strong>and</strong>consolidant should then be removed priorto the laboratory analysis.Planning stone samplingThe sampling strategy must be fullyplanned in advance. Ensure that allsampling locations have been identified,<strong>and</strong> that each location has been providedwith safe access. A range of tools <strong>and</strong>other equipment should be available,including:● small hammers● chisels● a range of sample bags● felt-tip permanent markers <strong>and</strong> pencils● tape measures● core-drilling equipment to obtain25–75mm solid diameter cores(Figs 5 <strong>and</strong> 6)Fig 5 Core-drilling rig with 75mm diameter core samplingmagnesian limestone, Howden Minster, East Yorkshire.Fig 6 Core drill (75mm diameter) <strong>and</strong> extracted core inprotective polyethylene tube <strong>for</strong> safe transportation.Checklist prior to samplingPhotography Have photographs been taken ofthe building or monument, <strong>and</strong>of all the sample areas?Sampling Is the sample truly representativeof the stone being studied? Is the sample being taken directlyfrom the st<strong>and</strong>ing structure? Does the sample include both aweathered <strong>and</strong> a non-weathered side? Is the sample approximately 75mm2 75mm 2 40mm? Has the orientation been markedon the sample?PhotographyAll locations must be photographedbe<strong>for</strong>e sampling, preferably in colour.A general view of the building is alsorequired, also a context shot of thegeneral location of each sample, as wellas several close-up shots of the samplesite itself. A colour calibration chart<strong>and</strong> a scale should be included in theclose-up photographs.Direct lighting, from sunlight or flash, cansubdue the surface features, which mayassist in the interpretation of the sample.There<strong>for</strong>e wherever possible, obliquelighting should be used, creating shadowsthat can emphasise subtle surface features.The surface of the sampling area maybe soiled, or covered with biologicalgrowth. If possible a small sample area ina concealed location should be lightlycleaned to reveal the true colour <strong>and</strong>texture of the underlying stone. If not, thevisible condition of the stone should berecorded in addition to the photography.Labelling samplesEach sample must be given a uniqueidentifier, <strong>and</strong> all in<strong>for</strong>mation regardingthe sample <strong>and</strong> its location must berecorded in a systematic manner. Toprevent error, samples should be labelledas soon as they are collected.Where only a few samples are taken,the identifier can be the name of thebuilding or site, <strong>and</strong> a sample number.However, where samples will be analysedby an organisation that deals withmaterial from many different sites, theidentifying system must be site-specific,<strong>and</strong> even organisation-specific. WhateverAfter samplingPhotography Have the sample locations beenphotographed after sampling? Has the sample been photographed?Labelling <strong>and</strong> packaging Is the sample clearly labelled with aunique identifier? Is the sample accompanied by astatement showing the building orsite name, street, town, county, thelocation on the building ormonument <strong>and</strong> the date of sampling? Is the sample securely wrapped <strong>and</strong>secured in an appropriate bag, withadequate labelling both inside <strong>and</strong> out?system is used, the identifier should bemarked not only on the sample, butalso on any accompanying in<strong>for</strong>mation,<strong>and</strong> on all photographs taken of thesample location. The date of samplingmust be included.Samples should be placed immediately ina sealable polythene sample bag, with theidentifier marked either directly on thesample, or where this is impossible on amanila tag placed inside the sample bag.If there is any concern over chemicalpollutants, a non-plastic container shouldbe used instead. When the identifier iswritten directly on the sample, take carenot to damage any features or any surfacecontamination that may be pertinent tothe investigation <strong>for</strong> which the sample wascollected. The outside of the sample bagor container should also be labelled, usinga permanent marker.As most stone is abrasive, if the sample issent <strong>for</strong> analysis by post or carrier, it mustbe packed in a manner that prevents itfrom moving around within the packaging– especially when more than one sample isincluded. The detachment of even a smallfragment during transit may result in theentire sample being damaged. This risk isparticularly high with samples ofweathered stone. In this case samplesshould be tightly bubble-wrapped, be<strong>for</strong>ebeing packed into a padded postalenvelope, either with additional softpadding to stop the sample moving aroundwithin the envelope, or with the sampletaped securely to the inside of the bag.For samples too large to fit safely into apadded envelope, a card postal pack ora box may be required; any spare space6

should be filled with polystyrene chips,vermiculite or bubble-wrap.Useful additional in<strong>for</strong>mationFor cost-effective <strong>and</strong> efficient analysisit is best to provide as much in<strong>for</strong>mationas possible about the stone <strong>and</strong> thebuilding to the analyst along with thesample. Where something is known aboutthe original sources of stone fromgeographical regions, or better still thespecific building, this can be readilycompared with the results of the analysis.This in<strong>for</strong>mation can help to identifypotential sources of replacement stoneas quickly as possible.In the study of deterioration mechanisms,it is important to record the preciselocations of samples, <strong>and</strong> the degree towhich the original stone was exposed.3.2 Examination <strong>and</strong> analysis of stoneH<strong>and</strong> samplesThe characteristics of many buildingstones can be readily identified in situ:this is especially true of the coarsergrainedvarieties such as granite, <strong>and</strong>many of the s<strong>and</strong>stones <strong>and</strong> limestones.Preliminary determination of the generalstone type <strong>and</strong> mineralogy of a stonecan often be obtained in situ using ah<strong>and</strong> lens of about 8 magnification.However, the characterisation of certainother stones – <strong>for</strong> example basalts, slates,siltstones <strong>and</strong> fine-grained limestones –will require specialised laboratorytechniques. Detailed studies requirestereomicroscopy, using magnificationsof up to 40. This helps to interpret thestructure <strong>and</strong> composition of the stone<strong>and</strong> any physical breakdown.Petrographic analysisPetrographic analysis precisely identifiesthe mineralogical composition of a stone,<strong>and</strong> the conditions under which it was<strong>for</strong>med. This allows some assessment ofthe likely decay processes, especiallyas the manner in which stone weathersvaries according to its petrographiccharacteristics.A thin section of the stone is made bymounting a fragment of stone onto amicroscope slide <strong>and</strong> grinding it down toa thickness of 30 microns (1 micron =1 /1000 mm) <strong>and</strong> is viewed through apolarizing microscope. This enablescrystals <strong>and</strong> grains as small as one micronto be viewed in plane-polarized <strong>and</strong> crosspolarizedlight <strong>and</strong> so determine the typeof minerals present <strong>and</strong> any changes intheir composition (Fig 7).Fig 7 Left side: sample of Devonian s<strong>and</strong>stone from a medieval corbel, Kilpeck Church, Here<strong>for</strong>dshire, studied under ordinary. Right side: polarized light microscopy.,The width of each picture is0.72mm. (David Jefferson)The photomicrograph on the left was taken using ordinary light <strong>and</strong> shows that most of the mineral grains are transparent, although some can be speckled or slightly cloudy. In the same imageon the right viewed under polarized light, the nature of the s<strong>and</strong> grains is clearly visible.The quartz grains range from clear to black depending upon their crystal orientation relative to the angle ofthe polarized light. A grain of microcline feldspar, distinguished by its tartan twinning, is located on the bottom left <strong>and</strong> fragments of rock composed of a number of small grains of quartz arepresent in the centre, just above the central quartz grain, <strong>and</strong> in the bottom centre.The bright colours of the elongated grain in the centre top indicate it is muscovite or white mica.Fig 8 Left side: an oöidal limestone with a coarsely crystalline cement, the oöids have been partially dissolved away to leave a strong, sponge-like stone of high porosity, which is highlighted by theuse of blue-coloured resin within the sample. Right side: Ooidal Portl<strong>and</strong> Whitbed under ordinary polarized light with, in this case, the intergranular pore distribution again shown by the bluecolouredresin in the sample. Width of both pictures is 1.4mm. (David Jefferson)7

This type of thin section analysis canalso provide an assessment of the porosityof a stone, which is not visible to thenaked eye (Fig 8). The identification ofporosity is important because the size<strong>and</strong> shape of the pores <strong>and</strong> whether theseare connected to <strong>for</strong>m continuouschannels can markedly affect thedurability of the stone.The British St<strong>and</strong>ard BS EN 12407:2000Natural stone test methods – Petrographicexamination is unnecessarily exhaustive<strong>for</strong> characterising historic building repairstone, <strong>and</strong> its procedures are not suitable<strong>for</strong> studies of weathering <strong>and</strong> soiling.Moreover, the thickness it recommends<strong>for</strong> limestone could be inappropriate <strong>for</strong>some studies.Thin sections should there<strong>for</strong>ebe prepared in the context of the studybeing undertaken, <strong>and</strong> there should be norequirement that sections be prepared<strong>and</strong> analysed in the manner described inBS EN 12407:2000.Physical parametersAlthough petrographic study c<strong>and</strong>etermine the composition <strong>and</strong> physicalproperties of stone, very subtle changes inmineralogy can considerably alter itsappearance. This is especially true ofcolour, which is often controlled by thequantity <strong>and</strong> variety of iron mineralswithin the rock. In s<strong>and</strong>stones, <strong>for</strong>example, the grains are often coated with athin layer of an iron mineral. This coatingcan be less than 1 micron thick, <strong>and</strong> maygive the stone a slight pinkish tinge.Should the iron-rich coating be slightlythicker – even by only 1or 2 microns –the colour may be a deep reddish-brown.There are several common iron mineralsthat produce colour variations.The colour of the stone being studiedshould be recorded using the Munsell ®colour code (an internationally recognisedst<strong>and</strong>ard system used <strong>for</strong> describing thecolour of all types of materials).Geologists <strong>and</strong> archaeologists use theMunsell system to describe rocks, soils<strong>and</strong> ceramics, while architects, buildingsurveyors <strong>and</strong> general contractors will befamiliar with its use <strong>for</strong> classifying <strong>and</strong>specifying paint colours. Colour isarranged into classes or categoriesaccording to three variables: hue, value<strong>and</strong> chroma. It should be noted that moststones lighten or darken to some extentwhen wet. The colour of the stone shouldthere<strong>for</strong>e be recorded both wet <strong>and</strong> dry.Many stones that superficially look veryalike, such as s<strong>and</strong>stones, can be seenunder high magnification to besignificantly different. The microscopemay disclose that the natural cement inone sample is calcite, in another a claymineral, <strong>and</strong> in a third silica. Theweathering properties of all three stoneswould be very different, no matter howsimilar they appeared to the naked eye.Petrography can also identify mineralsknown to be unstable in the builtenvironment, or likely to react with othermaterials, such as mortars. For example,cryptocrystalline silica in a s<strong>and</strong>stone mayreact with highly alkaline lime mortar,resulting in the degradation of the stone.Such features are important not onlywhen determining the reasons <strong>for</strong> thebreakdown of a historic stone, but alsowhen selecting its replacement.The geology of the British Isles is wellcharacterised, so petrographic study canbe very useful <strong>for</strong> locating quarries <strong>and</strong>sources of compatible stone within theUnited Kingdom. Matching historic stoneimported from Europe <strong>and</strong> other parts ofthe world, however, dem<strong>and</strong>s both specificknowledge of the stone <strong>and</strong> carefulreference to st<strong>and</strong>ard samples.Petrographic analysis is essential whenusing commercially available stone, as thetrade names can be misleading. Forexample, Rosso Levanto Marble (Fig 9)is not a marble but a hard polishableserpentinised stone. Purbeck marble isjust one of the many so-called marblesavailable that are not in fact truemetamorphic marble, but are hardpolishable limestone. Similarly, someslates are actually highly compactedmudstones <strong>and</strong> siltstones that have notbeen subjected to the metamorphic <strong>for</strong>cesnecessary to produce true slate.Fig 9 Rosso Levanto Marble (field of view 95mm).(David Jefferson)Other analytical techniquesX-ray diffraction analysisThe diffraction of x-rays passing througha crystalline material produces patternscharacteristic of the crystal, <strong>and</strong> determinesthe mineralogy of a particular stone.Scanning electron microscopyMany of the reactions that damagebuilding stone occur at sub-microscopiclevel. A scanning electron microscopepermits magnifications well in excess of1000, <strong>and</strong> with the addition of an EDX(Energy-Dispersive X-ray Spectrometer)can determine aspects of chemicalcomposition (Fig 10).Fig 10 Environmental Scanning Electron Microscope (ESEM)images: top, pure gypsum on the surface of dolomitic s<strong>and</strong>stone(White Mansfield stone); bottom, individual oöids (roundedshapes) have developed a crust of gypsum within the surroundingpore spaces of Portl<strong>and</strong> limestone. (David Jefferson)A simple chemical test <strong>for</strong> carbonatesLimestone <strong>and</strong> calcareous s<strong>and</strong>stone canbe distinguished from other <strong>for</strong>ms ofs<strong>and</strong>stone <strong>and</strong> from other stone types byapplying a 5% solution of dilute hydrochloricacid to a small area of surface.Any calcium carbonate present withinthe stone will vigorously effervesce ascarbon dioxide is liberated by reactionwith the acid.S<strong>and</strong>stones are commonly composedof quartz s<strong>and</strong> grains, but the cementbinding these together can vary incomposition. If effervescence is observedbetween the grains, the cement is likely tobe calcite. If there is no reaction, the binder8

is probably silica, iron oxide or a claymineral. Granite <strong>and</strong> most other igneousrocks will not effervesce in the presenceof the dilute acid, as they do not containcarbonates.The majority of metamorphicslate is siliceous, but certain slates (<strong>for</strong>example some from the Lake District) docontain some calcium carbonate, <strong>and</strong> willthere<strong>for</strong>e effervesce slightly.Testing stone with hydrochloric acidThe acid should be diluted to an approximately5% solution by volume (1 partconcentrated hydrochloric acid to 19 partswater).To avoid the acid spitting violently,the acid must always be added to thewater rather than the water to the acid.To con<strong>for</strong>m with the 1988 COSHHRegulations (Care of Substances Harmfulto Health), a proper risk assessment mustbe made <strong>and</strong> there should be adequatesafety measures <strong>and</strong> sufficient personalprotection available. Safety spectacles <strong>and</strong>disposable nitrile gloves should be usedwhen decanting <strong>and</strong> diluting the acid.To test, the stone is viewed through abinocular microscope as a small amount ofthe dilute solution is dropped on thesurface with a pipette.Effervescence indicates that calciumcarbonate is present in the stone.4 Criteria <strong>for</strong> selectingreplacement stoneThe following criteria – in descendingorder of importance – should be used <strong>for</strong>finding replacement stone:PetrographyThe constituent grains should be of thesame type, size, angularity <strong>and</strong>proportions as in the original stone.The binding material must also be similar.The ratio of binding material toconstituent fragments or mineral grains<strong>and</strong> the porosity must also be alike.If the mineralogy of the replacement stoneis similar to the original, then the chemistryof the stone will effectively be the same.Chemical characteristicsThe chemistry of the replacement stonemust be similar to that of the original,particularly the concentrations of silica,magnesium <strong>and</strong> iron. The iron content<strong>and</strong> the <strong>for</strong>m in which iron occurs areparticularly important, as this willlargely determine the final colour ofthe exterior surface, especially afterweathering.The composition of the fluids travellingthrough the building fabric will beconditioned by the chemistry of thestone through which they are passing.Different stones will contain pore fluidsof different composition <strong>and</strong> whenpassing into a dissimilar type of stonethese can generate adverse reactions.AppearanceThe appearance of the stone viewed inblock <strong>for</strong>m must be close to the original.If the petrography <strong>and</strong> chemistry aresimilar, then the small-scale appearanceshould also be the same, but large-scalefeatures such as bedding <strong>and</strong> veiningmust also be considered. The bed-depthwithin the quarry must permit theextraction of suitably sized blocks <strong>for</strong> theintended purpose.Geological ageIn the case of sedimentary rocks, thereplacement <strong>and</strong> the original stoneshould be of a similar age, <strong>and</strong> from asimilar sedimentary environment.Metamorphic building stones shouldbe of a grade corresponding to theoriginal, <strong>and</strong> igneous rocks should befrom the same family.PorosityBoth the overall value of the porosity <strong>and</strong>the pore-size distribution should be asclose as possible to those of the originalstone. If a stone with the same porosity<strong>and</strong> permeability cannot be found, useone with a higher rather than lowerporosity. Any subsequent degradation isthen more likely to occur in the new stonerather than in the original fabric.Compressive strengthWhere it is not possible to match thecompressive strength of the replacementwith the original stone, the replacementstone should be weaker rather thanstronger, so that it is the more likelyto fail.Satisfying all these criteria would ideallyrequire the replacement stone to befrom the original quarry, or at least asource in very close proximity to theoriginal quarry. Failing this, the new stoneshould meet as many of the above criteriaas possible, with the first three being themost critical.5 Sources of stone5.1 Active quarriesThere are approximately 220 quarriesproducing building stone in Engl<strong>and</strong>listed in a biennial publication TheNatural <strong>Stone</strong> Directory. Other quarriessupplying building stone can be found inthe Directory of Quarries & QuarryEquipment <strong>and</strong> in the Directory of Mines<strong>and</strong> Quarries. The British GeologicalSurvey <strong>and</strong> freelance stone consultantscan also help locate appropriate currentsources of stone.Some quarries have been working thesame strata in the same location <strong>for</strong>centuries, <strong>for</strong> example, the Portl<strong>and</strong>quarries have been producing relativelyconsistent limestone since the 18thcentury. Some smaller quarries are alsoworking long-established building-stonebeds, but <strong>for</strong> others the output haschanged over the years. The modernstone available from a particular quarrymay retain the identifiable visual featuresof the original, but be petrographicallydifferent from the stone extracted in thepast. Such differences could provesignificant when a stone is inserted inthe existing fabric of an historic building(Fig 11).5.2 Disused quarriesIf the source of stone has been tracedto a particular quarry but the quarryis now closed, it may be possible toobtain the stone by reopening theworkings <strong>for</strong> a short time. L<strong>and</strong> <strong>and</strong>mineral-rights owners are frequentlyamenable to extracting stone from anold quarry on their l<strong>and</strong>, especially ifthe building or monument beingconserved is a local feature. MineralPlanning Authorities are also normallysympathetic to proposals to obtainsupplies of the correct stone fromoriginal sources, especially <strong>for</strong> therepair of historic buildings.To determine whether the stone from aclosed quarry can be economicallyextracted, it must be thoroughly sampledin situ. If any lithological variation issuspected, representative samples mustbe obtained from all the beds of rock,<strong>and</strong> from different parts of every bed.The thickness of the different beds,any lateral variation in thickness, <strong>and</strong>the distribution <strong>and</strong> angle of jointpatterns within the rock must berecorded, as these features determinethe sizes of the blocks that can be9

Fig 11 Grinshill Quarry, Shropshire: left side, old disused quarry; right side, modern working quarry. (Don Cameron, British Geological Survey. © NERC. All rights reserved IPR/74-54C)extracted. Possible block sizes must becarefully compared to the masonrysizes required <strong>for</strong> the repair.Most building stone tends to berectangular, but if the joints in the naturalblock of stone are not at right anglesthere will be a high level of wastage whenthe stone is cut, <strong>and</strong> the resulting blockswill be considerably smaller blocksthan those extracted from the quarry(Figs 12 <strong>and</strong> 13).5.3 Recycled stoneWhere no suitable replacement stone iscommercially available, but only smallquantities of material are required, <strong>for</strong>example, minor repairs to window mullions,it may be acceptable to recycle stone.The provenance of stone being re-usedmust be established <strong>and</strong> must have beenobtained from a lawful dismantling of abuilding or other structure to preventunlisted vernacular buildings being robbed<strong>for</strong> their stone.Great care must be taken when selectingstone <strong>for</strong> re-use. Avoid weathered ordamaged material, <strong>and</strong> ensure that theblocks are large enough to accommodatethe dressing-back necessary to remove theoriginal exposed surfaces.Fig 13 Grinshill, Shropshire, waste stone after cutting, <strong>and</strong>the range of colours within one quarry source.(Don Cameron, British Geological Survey. © NERC.All rights reserved IPR/74-54C)6 Obtaining stone <strong>for</strong> historicbuilding repair6.1 Specifying stoneReplacement stone should be specified tomeet the criteria defined in Section 4,with samples of potential replacementscarefully matching the original material.Fig 12 Clipsham, Lincolnshire, irregular-shaped stone prior to being sawn into rectangular blocks. (David Jefferson)All stone varies to some extent, but thevariation in the replacement stone shouldnot be greater than the variation in theoriginal fabric of the building, to avoiddifferences in petrography, porosity <strong>and</strong>colour of the repair stone. For example,limestone taken from a single quarry canrange from very fine-grained to coarse <strong>and</strong>shelly, depending on which beds are beingworked. If some of the stone produced bythe quarry is not suitable, the exact stone10

equired must be clearly specified. Thegrain size of s<strong>and</strong>stones can also varywidely, so the acceptable range should bespecified, along with the acceptableporosity. This is especially important if thestone is to be inserted into the existingfabric of a building. Experienced quarrymanagers <strong>and</strong> their staff can assist thespecifier with these aspects.Finding blocks of the correct size <strong>for</strong> aparticular purpose may require contractorsto pre-order <strong>and</strong> pay a deposit, as it maytake the quarry some time to locate <strong>and</strong>earmark the appropriate blocks. Thelead-in time the quarry requires to source<strong>and</strong> supply blocks must be taken intoaccount when designing the repairprogramme. The logistics should beplanned well in advance of when the stonewill be needed on site.BS EN 1469:2004 (E), Section 4.2Requirements of natural stone <strong>for</strong> cladding(pp 10–11) suggests that the minimum sizeof reference samples should be at least100mm 2 – 250mm 2 in face area, <strong>and</strong> shouldindicate typical appearance.The <strong>Stone</strong>Federation Great Britain can supply theirin<strong>for</strong>mation sheet (entitled <strong>Stone</strong> Samples),which provides useful guidance on samplesizes, finishes <strong>and</strong> labelling. Labelling is inaccordance with BS EN 12440:2001 Naturalmaterial – denomination criteria: thetraditional name, followed by thepetrographical family, the typical colour, <strong>and</strong>the place of origin (BS EN 12440Introduction clauses 3.1, 3.2, 3.3 <strong>and</strong> 3.4).6.2 Samples of new stoneAll quarries producing building stone willsupply samples on request. These typicallymeasure 100mm by 100mm, <strong>and</strong> areabout 10mm thick.As stone is a natural <strong>and</strong> variable material,a single sample cannot completely representthe variations that probably occur withinthe stone. This is often indicated in thesupplier’s literature, but it should beremembered that stone naturally changescolour as it weathers. New or replacementstone should there<strong>for</strong>e never be selected onthe basis of supplier’s samples alone, <strong>and</strong>these samples should not be sent <strong>for</strong>analytical comparison with samples ofexisting stonework.If a supplier’s sample appears suitable <strong>for</strong>a particular project, the quarry itselfshould be visited. There the likelyvariation in the stone can be determinedby examining the quarry faces, <strong>and</strong> blocksextracted <strong>and</strong> stored at the quarry.Samples from varying blocks can becollected in the same manner as <strong>for</strong> in situsampling (Section 3.1), <strong>and</strong> these shouldbe analysed to determine the suitability ofthe stone <strong>for</strong> its intended purpose.6.3 Testing replacement stoneMany of the established tests <strong>for</strong> buildingstone are designed to investigate theirper<strong>for</strong>mance in the context of modernbuilding practices, <strong>for</strong> example, the breakingload of a fixing used in stone cladding.Other tests – salt crystallisation, saturationcoefficient, porosity, <strong>and</strong> freeze/thawcycles – were originally designed to givean indication of durability. As these teststend to be carried out on small cubes ofstone within a laboratory, they take intoaccount neither the environment within<strong>and</strong> around the building, nor the effectof the mortar between the blocks. Thusit can be difficult to relate the test resultsto the behaviour of stone in situ. Suchtests may, however, be useful <strong>for</strong>comparing the behaviour of the potentialreplacement with that of the originalstone, or with that of a stone whoseproperties in a similar environment arewell understood.Fig14 <strong>Stone</strong> testing chamber, Sheffield Hallam University:top, stone wall being built; bottom, testing in progress.(Chris Wood)Large-scale environmental testingWhere major repairs are required, <strong>and</strong>the replacement stone chosen is notpetrographically identical to the original,large-scale environmental testing can beuseful, if costs permit.Walls constructed in a test chamber can beexposed to simulated weathering conditions,based upon real meteoro-logical data,including wetting, drying, <strong>and</strong> driving rain.Large chambers can accommodate mortarbondedmasonry units up to 2m or 3mlong <strong>and</strong> 2m high.The smaller freeze-thawchambers used <strong>for</strong> testing bricks can also beuseful <strong>for</strong> testing stone. Environmental testingis relatively expensive, but <strong>for</strong> major repairor replacement projects it can prove costeffective(Fig 14).6.4 Obtaining stone from new ortemporary sourcesIn recent years a number of small, disusedquarries have been temporarily re-openedto supply walling stone, stone roofingslates <strong>and</strong> even stone <strong>for</strong> crushing (to helpreplicate medieval mortar mixes). Openingup quarries requires professionalassistance from a stone consultant or anexisting quarrying company.The first step is to identify the l<strong>and</strong>owner<strong>and</strong>, if they are not the same, the mineralrightsowner. The Mineral PlanningAuthority (MPA) should be approached todetermine whether planning consent isrequired. This may be dependent upon thescale of the proposed operation; if thequantity of stone required is relatively small,the MPA will frequently waive planningconsent <strong>and</strong> permit temporary works in amanner agreed in detail with them.Once the necessary consent has beenobtained, the overburden <strong>and</strong> topsoil iscarefully removed <strong>and</strong> stockpiled. Afterstone extraction is completed, theexcavation is backfilled with any wastestone, <strong>and</strong> the stored overburden <strong>and</strong>topsoil is used to restore the site. Thevegetation usually regenerates rapidlyfrom the natural seed bank in the soil.7 Sources of further in<strong>for</strong>mation<strong>and</strong> assistance7.1 <strong>Stone</strong> collectionsThere are a number of sample collectionsof historical <strong>and</strong> contemporary buildingstone, which are useful <strong>for</strong> underst<strong>and</strong>ing11

different stone types or <strong>for</strong> comparingstones. Some collections are open to thepublic, although admission may be charged.The National Collection of <strong>Building</strong><strong>and</strong> Decorative <strong>Stone</strong>s, Natural HistoryMuseum, London: reference collectionsmay be inspected by appointment.The John Watson <strong>Building</strong> <strong>Stone</strong>Collection, Sedgwick Museum <strong>Building</strong>,University of Cambridge: assembled atthe beginning of the 20th century, thiscollection includes building stone, stoneroofing slates, flagstones <strong>and</strong> road stone.The British Geological Survey (BGS),Keyworth, Nottinghamshire: thiscollection of more than 50,000 stones isavailable <strong>for</strong> public consultation, <strong>and</strong>details of the collection are accessiblethrough a computer database.Contact details can be found below underUseful contacts.7.2 Other sources of helpLocal Planning Authorities <strong>and</strong> theirConservation Officers can often helpwith technical advice on local naturalbuilding materials.The BGS can also provide in<strong>for</strong>mationon the geology of building stones,including the location of both active <strong>and</strong>disused quarries.Independent consultants who specialisein the identification, selection <strong>and</strong>assessment of stone <strong>for</strong> the repair ofhistoric buildings can be located throughthe Natural <strong>Stone</strong> Directory, theGeological Society or the Institute ofQuarrying (see Useful contacts).BibliographyAshurst, J <strong>and</strong> Dimes, F J 1977 <strong>Stone</strong> in<strong>Building</strong>: Its Use <strong>and</strong> Potential Today.London: Architectural Press— 1990 Conservation of <strong>Building</strong> <strong>and</strong>Decorative <strong>Stone</strong>s. London: ButterworthHeinemannBrereton, C 1995 The <strong>Repair</strong> of <strong>Historic</strong><strong>Building</strong>s: Advice on Principles <strong>and</strong> Methods,2 edn. London: English HeritageBritish Geological Survey <strong>and</strong> NaturalEnvironment Research Council (NERC)2001 <strong>Building</strong> <strong>Stone</strong> Resources Map of Britain.Nottingham: British Geological Survey— 2002 Directory of Mines <strong>and</strong> Quarries.Kingsley Dunham Centre, Keyworth,Nottingham: BGSClifton Taylor, A 1972 The Pattern ofEnglish <strong>Building</strong>, 3 edn. London: Faber<strong>and</strong> FaberGeological Society of America 1991Rock Color Chart. Colorado: BoulderHart, D 1988 The <strong>Building</strong> MagnesiumLimestones of the British Isles. <strong>Building</strong>Research Establishment Report.Wat<strong>for</strong>d: BRE— 1991 The <strong>Building</strong> Slates of the BritishIsles. <strong>Building</strong> Research EstablishmentReport. Wat<strong>for</strong>d: BREHolmes, A (P M D Duff, ed) 1993Principles of Physical Geology, 4 edn.London: Chapman <strong>and</strong> HallHowe, J A 1910 The Geology of <strong>Building</strong><strong>Stone</strong>s. London: Edward Arnold; Shaftsbury:Donhead, reprinted in facsimile 2001Honeyborne, D B 1982 The <strong>Building</strong>Limestones of France. <strong>Building</strong> ResearchEstablishment Report. Wat<strong>for</strong>d: BRELeary, E 1983 The <strong>Building</strong> Limestonesof the British Isles. <strong>Building</strong> ResearchEstablishment Report. Wat<strong>for</strong>d: BRE— 1986 The <strong>Building</strong> S<strong>and</strong>stones ofthe British Isles. <strong>Building</strong> ResearchEstablishment Report. Wat<strong>for</strong>d: BREQMJ Publishing 2005/6 Directory ofQuarries & Quarry Equipment.Nottingham: QMJ Publishing Ltd— 2006 Natural <strong>Stone</strong> Directory.Nottingham: QMJ Publishing LtdSchaffer, R J 1932 The Weathering of Natural<strong>Building</strong> <strong>Stone</strong>s. Department of Scientific <strong>and</strong>Industrial Research, <strong>Building</strong> ResearchSpecial Report 18. London: HMSO;Shaftsbury: Donhead, reprinted 2004Shore, B C G 1957 <strong>Stone</strong>s of Britain.London: Leonard Hill (Books) LimitedSmith, M R (ed) 1999 <strong>Stone</strong>: <strong>Building</strong><strong>Stone</strong>, Rock Fill <strong>and</strong> Armourstone inConstruction. Geological SocietyEngineering Geology Special Publication16. London: Geological SocietyWarnes, A R 1926 <strong>Building</strong> <strong>Stone</strong>s:Their Properties, Decay, <strong>and</strong> Preservation.London: Ernest Benn LimitedWatson, J 1911 British <strong>and</strong> Foreign <strong>Building</strong><strong>Stone</strong>s. Cambridge: University PressWhitten, D G A, <strong>and</strong> Brooks, J R V 1972 ThePenguin Dictionary of Geology. London: PenguinWinkler, E M 1977 <strong>Stone</strong> in Architecture,Properties, Durability, 3 edn. Hamburg:Springer-VerlagWood, C (ed) 2003 ‘<strong>Stone</strong> roofing: conservingthe materials <strong>and</strong> practice of traditional stoneslate roofing in Engl<strong>and</strong>’. English HeritageResearch Transactions 9. London: James <strong>and</strong>JamesWoolf, D O, 1960 The Identification ofRock Types, rev edn. Washington, DC:United States Government Printing Office12

Useful contactsBritish Geological Survey (BGS)Kingsley Dunham CentreKeyworthNottingham NG12 5GGtel: 0115 936 3100fax: 0115 936 3200e-mail: enquiries@bgs.ac.ukwebsite: www.bgs.ac.ukBritish St<strong>and</strong>ards Institution (BSI)389 Chiswick High RoadLondon W4 4ALtel: 020 8996 9001fax: 020 8996 7001e-mail: orders@bsi-global.comwebsite: www.bsi-global.com<strong>Building</strong> Research Establishment(BRE)Bucknalls LaneGarstonWat<strong>for</strong>d WD25 9XXtel: 01923 664000e-mail: enquiries@bre.co.ukwebsite: www.bre.co.ukDirectory of Quarries <strong>and</strong> QuarryEquipmentQMJ Publishing Limited7 Regent StreetNottingham NG1 5BStel: 0115 941 1315fax: 0115 948 4035e-mail: mail@qmj.co.ukwebsite: www.qmj.co.ukEnglish HeritageCustomer ServicesPO Box 569Swindon SN2 2YPtel: 0870 333 1181fax: 01793 414926e-mail: customers@english-heritage.org.ukwebsite: www.english-heritage.org.ukGeologist’s Directoryavailable from The Geological Society,address belowGeological Society of America RockColour ChartGeo Supplies, Limited49 Station RoadChapeltownSheffield S35 2XEtel: 0114 245 5746fax: 0114 240 3405e-mail: sales@geosupplies.co.ukwebsite: www.geosupplies.co.ukInstitute of Quarrying7 Regent StreetNottingham NG1 5BStel: 0115 945 3880fax: 0115 948 4035e-mail: mail@quarrying.orgwebsite: www.quarrying.orgJohn Watson <strong>Building</strong> <strong>Stone</strong>CollectionSedgwick Museum of Earth SciencesUniversity of CambridgeDowning StreetCambridge CB2 3EQtel: 01223 333456fax: 01223 333450e-mail: sedgwickmuseum@esc.cam.ac.ukwebsite: www.sedgwickmuseum.orgNational <strong>Stone</strong> CentrePorter LaneMiddelton by WirksworthDerbyshire DE4 4LStel/fax: 01629 824833e-mail: nsc@nationalstonecentre.org.ukwebsite: www.nationalstonecentre.org.ukNatural History MuseumCromwell RoadLondon SW7 5BDtel: 020 7942 5839 (Customer Services)website: www.nhm.ac.ukNatural <strong>Stone</strong> DirectoryQMJ Publishing Limited7 Regent StreetNottingham NG1 5BStel: 0115 941 1315fax: 0115 948 4035e-mail: mail@qmj.co.ukwebsite: www.qmj.co.ukThe Geological SocietyBurlington HousePiccadillyLondon W1J 0BGtel: 020 7434 9944fax: 020 7439 8975e-mail: enquiries@geolsoc.org.ukwebsite: www.geolsoc.org.uk13

Annex: A system <strong>for</strong> the field identification of the more common building stones used in Engl<strong>and</strong> (based on a scheme developedby the Division of Physical Research, Bureau of Public Roads, U.S. Department of Commerce by D O Woolf)Preliminary classification groups1 Glassy (wholly or partially) 2 Not glassy, dull, homogeneous, so fine-grained that the grains cannot be recognised3 Distinctly granular 4 Distinct foliation, no effervescence with dilute acid 5 Clearly fragmental in composition, rounded or angularpieces or grains cemented togetherGroup 1 ● glassy lustre, hard, conchoidal fracture, colourless to white or smoky quartz 1Glassygrey, generally brittlerocks ● cellular or frothy glass pumiceGroup 2 Sub-group 2A ● particles almost imperceptible, dull lustre, homogeneous, clay odour, little shaleVery fine- not scratched by a if any effervescence with dilute acid, laminated structure, breaks into flakesgrained fingernail, but readily ● brisk effervescence with dilute acid, little if any clay odour although a limestonerocks scratched with a knife bituminous odour may be discharged if the stone is struck; may containfossil fragments● brisk effervescence with dilute acid, no clay odour, soft, normally white in chalkcolour, can leave white powder on the h<strong>and</strong>s● little if any clay odour, brisk effervescence with dilute acid only when the magnesianrock is powdered or the acid is hotlimestoneSub-group 2B ● very hard, pale colours to black, no clay odour, conchoidal fracture, waxy chert 2not scratched by a knife, or horn-like appearanceor scratched only with ● heavy, dark colour, may be finely crystalline when viewed with a h<strong>and</strong> basaltdifficulty, no efferv- lens, may contain small cavities which can be open or filled with crystallineescence with dilute acid mineralGroup 3 Sub-group 3A ● brisk effervescence with dilute acid; granular material may be broken fossil limestoneGranular easily scratched with fragments, angular material or small spherical grains, the granular materialrocks a knife may be mixed with fine-grained material● brisk effervescence with dilute acid; grains may be large <strong>and</strong> interlocking, marblecompact, colour may be white, cloudy grey or coloured, often b<strong>and</strong>ed orvariable● grains are deep red or brown, embedded in a similarly coloured material; ironstone 3may be slight effervescence with dilute acid; hard b<strong>and</strong>s or patches of veryfine-grained red or brown mineral may occur;. may stain h<strong>and</strong>s redSub-group 3B ● mainly quartz <strong>and</strong> feldspar in relatively large crystals, although mica granitehard, not scratched commonly present, usually grey, pink or redwith a knife or scratched ● mainly quartz in distinct grains often clearly set in a matrix, can fracture s<strong>and</strong>stonewith difficulty, grains round the grains; no distinct red colouration, can be buff, grey or greenish greynormal of approximately ● mainly quartz in distinct grains often clearly set in a reddish coloured ferruginousequal size matrix, can fracture round the grains; may stain h<strong>and</strong>s red s<strong>and</strong>stone● mainly red-stained quartz, embedded in a relatively large quantity of red or ironstone 3brown coloured material; hard b<strong>and</strong>s or patches of very fine-grained red orbrown mineral may occur; may stain h<strong>and</strong>s red● mainly quartz in distinct grains often clearly set in a pale-coloured matrix calcareouswhich effervesces with dilute acid, can fracture round the grainss<strong>and</strong>stone● mainly quartz in distinct grains in a hard siliceous matrix, stone fractures quartzitethrough an appreciable quantity of the grainsGroup 4 ● medium to coarse grain; roughly foliated gneissFoliated ● very fine grain, splits easily into thin slabs, usually dark grey, green or black slaterocksin colourGroup 5 ● rounded pebbles embedded in a cementing medium which can be reddish conglomerateFragmentalin colour● angular fragments of rock embedded in a cementing medium which can be brecciareddish in colour● fragments of volcanic (fine-grained or glassy) rocks embedded in compacted volcanic tuffvolcanic ashor breccia● quartz grains, possibly together with fragments of rock <strong>and</strong> mica, rounded s<strong>and</strong>stoneor angular, less than about 1mm in diameter, cemented together● quartz grains, possibly together with fragments of rock <strong>and</strong> mica, rounded or gritstoneangular, between about 1mm <strong>and</strong> 4mm in diameter, cemented together14

Notes <strong>for</strong> Annex opposite1 Although quartz is a mineral rather than arock, it is included as a building stone becausequartz cobbles from rivers <strong>and</strong> beaches havebeen used in rubble stone buildings.2 Chert includes flint, which is the traditionalname given to the chert b<strong>and</strong>s <strong>and</strong> nodulesfound in some Cretaceous chalk.3 Ironstone is a term traditionally used <strong>for</strong>both calcareous stones rich in iron minerals,which effervesce with dilute acid, <strong>and</strong>extremely iron-rich s<strong>and</strong>stones that do notreact with acid.AcknowledgementsThis Technical Advice Note was written byDr David Jefferson (Jefferson ConsultingLimited), <strong>and</strong> Seamus Hanna <strong>and</strong> BillMartin (<strong>Building</strong> Conservation <strong>and</strong>Research Team, English Heritage). We areindebted to Sasha Chapman’s previouswork on this publication. The authorswould like to express their thanks toEnglish Heritage colleagues John Fidler(Conservation Director), Robert Gowing,Robyn Pender <strong>and</strong> Chris Wood (SeniorArchitectural Conservators, <strong>Building</strong>Conservation <strong>and</strong> Research Team), GilesProcter (<strong>Historic</strong> <strong>Building</strong>s Architect,Yorkshire Region) <strong>and</strong> Dr David M Jones<strong>for</strong> editing the text <strong>for</strong> press, as well as toJohn Bysouth (Independent <strong>Stone</strong>Consultant), Peter Harrison (HarrisonGoldman), Graham Lott (BritishGeological Survey), <strong>and</strong> Nigel Sunter(Purcell, Miller, Triton) <strong>for</strong> their helpfulcomments on the manuscript.15

English Heritage is the Government’sstatutory adviser on the historicenvironment. English Heritage providesexpert advice to the Government aboutall matters relating to the historicenvironment <strong>and</strong> its conservation.For further in<strong>for</strong>mation (<strong>and</strong> copies of thisleaflet, quoting the product code), pleasecontact:English HeritageCustomer Services DepartmentPO Box 569SwindonSN2 2YPtelephone: 0870 333 1181fax: 01793 414926e-mail: customers@english-heritage.org.ukLONDON23 Savile RowLondon W1S 2ETtel: 020 7973 3000EAST OF ENGLANDBrookl<strong>and</strong>s House24 Brookl<strong>and</strong>s AvenueCambridge CB1 1DJtel: 01223 582700EAST MIDLANDS44 DerngateNorthampton NN1 1UHtel: 01604 735400NORTH EASTBessie Surtees House41–44 S<strong>and</strong>hillNewcastle upon Tyne NE1 3JFtel: 0191 269 1200NORTH WESTSuits 3.3 & 3.4 Canada House3 Chepstow StreetManchester M1 5FWtel: 0161 242 1400SOUTH EASTEastgate Court195–205 High StreetGuild<strong>for</strong>d GU1 3EHtel: 01483 252000WEST MIDLANDS112 Colmore RowBirmingham B3 3AGtel: 0121 625 6820YORKSHIRE37 Tanner RowYork YO1 6WPtel: 01904 601901Cover figure:(top left) Grinshill, Shropshire: disused quarry. (Don Cameron, British Geological Survey. © NERC. All rights reserved IPR/74-54C)(top centre) Howden Minster, East Yorkshire: new magnesian limestone replacement on the south doorway arch. (Seamus Hanna)(top right) Clipsham, Lincolshire: modern working quarry. (David Jefferson)(bottom left) Thin section of an oöidal limestone with blue coloured resin highlighting the porosity. (David Jefferson)(bottom centre) Truro Cathedral, Cornwall: replacement stone in a decayed frieze. (Seamus Hanna)(bottom right) Rosso Levanto marble: a hard polishable serpentinised stone. (David Jefferson)Published March 2006Copyright © English Heritage 2006Edited <strong>and</strong> brought to press by David M Jones,English Heritage PublishingDesigned by Mark SimonsProduced by English Heritage PublicationsPrinted by: The ColourhouseProduct code 50912