View - Pacific Grinding Wheel Co.

View - Pacific Grinding Wheel Co.

View - Pacific Grinding Wheel Co.

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

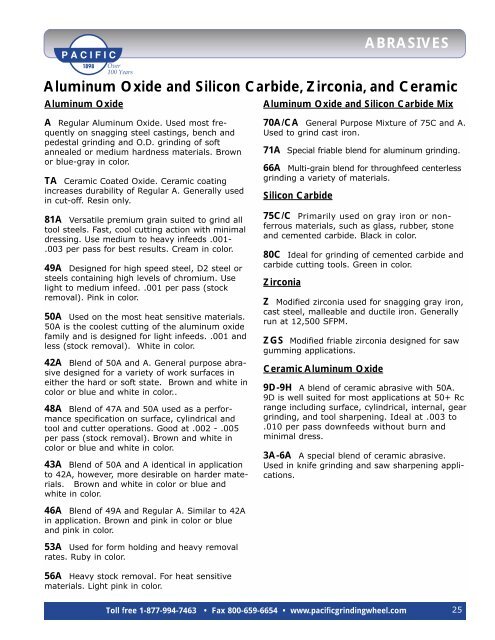

Over100 YearsAluminum OxideABRASIVESAluminum Oxide and Silicon Carbide, Zirconia, and CeramicAluminum Oxide and Silicon Carbide MixA Regular Aluminum Oxide. Used most frequentlyon snagging steel castings, bench andpedestal grinding and O.D. grinding of softannealed or medium hardness materials. Brownor blue-gray in color.TA Ceramic <strong>Co</strong>ated Oxide. Ceramic coatingincreases durability of Regular A. Generally usedin cut-off. Resin only.81A Versatile premium grain suited to grind alltool steels. Fast, cool cutting action with minimaldressing. Use medium to heavy infeeds .001-.003 per pass for best results. Cream in color.49A Designed for high speed steel, D2 steel orsteels containing high levels of chromium. Uselight to medium infeed. .001 per pass (stockremoval). Pink in color.50A Used on the most heat sensitive materials.50A is the coolest cutting of the aluminum oxidefamily and is designed for light infeeds. .001 andless (stock removal). White in color.42A Blend of 50A and A. General purpose abrasivedesigned for a variety of work surfaces ineither the hard or soft state. Brown and white incolor or blue and white in color..48A Blend of 47A and 50A used as a performancespecification on surface, cylindrical andtool and cutter operations. Good at .002 - .005per pass (stock removal). Brown and white incolor or blue and white in color.43A Blend of 50A and A identical in applicationto 42A, however, more desirable on harder materials.Brown and white in color or blue andwhite in color.70A/CA General Purpose Mixture of 75C and A.Used to grind cast iron.71A Special friable blend for aluminum grinding.66A Multi-grain blend for throughfeed centerlessgrinding a variety of materials.Silicon Carbide75C/C Primarily used on gray iron or nonferrousmaterials, such as glass, rubber, stoneand cemented carbide. Black in color.80C Ideal for grinding of cemented carbide andcarbide cutting tools. Green in color.ZirconiaZ Modified zirconia used for snagging gray iron,cast steel, malleable and ductile iron. Generallyrun at 12,500 SFPM.ZGS Modified friable zirconia designed for sawgumming applications.Ceramic Aluminum Oxide9D-9H A blend of ceramic abrasive with 50A.9D is well suited for most applications at 50+ Rcrange including surface, cylindrical, internal, geargrinding, and tool sharpening. Ideal at .003 to.010 per pass downfeeds without burn andminimal dress.3A-6A A special blend of ceramic abrasive.Used in knife grinding and saw sharpening applications.46A Blend of 49A and Regular A. Similar to 42Ain application. Brown and pink in color or blueand pink in color.53A Used for form holding and heavy removalrates. Ruby in color.56A Heavy stock removal. For heat sensitivematerials. Light pink in color.Toll free 1-877-994-7463 • Fax 800-659-6654 • www.pacificgrindingwheel.com 25