Offshore Mechanics and Arctic Engineeri ng - Gesellschaft für ...

Offshore Mechanics and Arctic Engineeri ng - Gesellschaft für ...

Offshore Mechanics and Arctic Engineeri ng - Gesellschaft für ...

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

were washed down the rivers <stro<strong>ng</strong>>and</stro<strong>ng</strong>> streams<br />

(Oranje, Vaal, Buffels, etc.) to the Atlantic<br />

together with vast soil masses.<br />

At first, the diamonds settled in the river<br />

mouths, but they were then distributed in<br />

the sea over wide areas by the Be<strong>ng</strong>uela<br />

current flowi<strong>ng</strong> alo<strong>ng</strong> the west coast of<br />

southern Africa.<br />

Originally, diamond mini<strong>ng</strong> was practiced<br />

in the strips of l<stro<strong>ng</strong>>and</stro<strong>ng</strong>> near the coast. lt<br />

was only in the sixties of the last century<br />

that the Atlantic in proximity to the coast<br />

was explored for diamonds <stro<strong>ng</strong>>and</stro<strong>ng</strong>> deposits<br />

worth mini<strong>ng</strong> were discovered. The diamonds<br />

were initially recovered by divers<br />

in the shallows. But this method was not<br />

an economic investment for a large-scale<br />

enterprise.<br />

ln 1990, Wirth was therefore awarded an<br />

order to develop a large-diameter drilli<strong>ng</strong><br />

system to loosen<br />

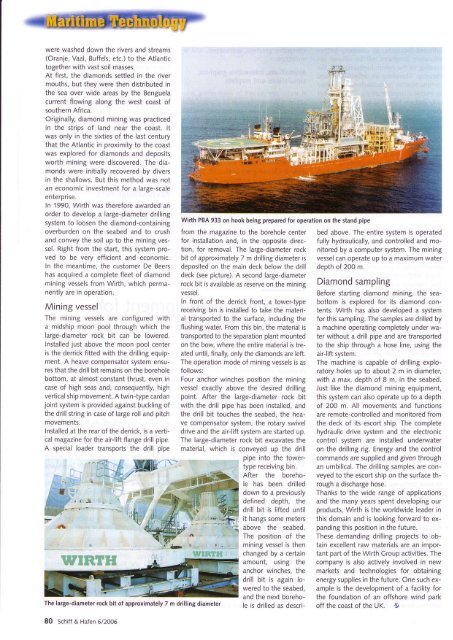

Wirth PBA<br />

the diamond-containi<strong>ng</strong><br />

933 on hook bei<strong>ng</strong> prepared for operation on the st<stro<strong>ng</strong>>and</stro<strong>ng</strong>> pipe<br />

overburden on the seabed <stro<strong>ng</strong>>and</stro<strong>ng</strong>> to crush from the magazine to the borehole center bed above. The entire system is operated<br />

<stro<strong>ng</strong>>and</stro<strong>ng</strong>> convey the soil up to the mini<strong>ng</strong> ves- for installation <stro<strong>ng</strong>>and</stro<strong>ng</strong>>, in the opposite direc- fully hydraulically, <stro<strong>ng</strong>>and</stro<strong>ng</strong>> controlled <stro<strong>ng</strong>>and</stro<strong>ng</strong>> mosel.<br />

Right from the start, this system protion, for removal. The large-diameter rock nitored by a computer system. The mini<strong>ng</strong><br />

ved to be very efficient <stro<strong>ng</strong>>and</stro<strong>ng</strong>> economic. bit of approximately 7 m drilli<strong>ng</strong> diameter is vessel can operate up to a maximum water<br />

In the meantime, the customer De Beers deposited on the main deck below the drill depth of 200 m.<br />

has acquired a complete fleet of diamond<br />

mini<strong>ng</strong> vessels from Wirth, which perma-<br />

deck (see picture). A second large-diameter<br />

rock bit is available as reserve on the mini<strong>ng</strong> Diamond sampli<strong>ng</strong><br />

nently are in operation.<br />

vessel.<br />

Before starti<strong>ng</strong> diamond mini<strong>ng</strong>, the sea-<br />

Mini<strong>ng</strong> vessel<br />

In front of the derrick front, a tower-type<br />

receivi<strong>ng</strong> bin is installed to take the materibottom<br />

is explored for its diamond contents.<br />

Wirth has also developed a system<br />

The mini<strong>ng</strong> vessels are configured with al transported to the surface, includi<strong>ng</strong> the for this sampli<strong>ng</strong>. The samples are drilled by<br />

a midship moon pool through which the flushi<strong>ng</strong> water. From this bin, the material is a machine operati<strong>ng</strong> completely under wa-<br />

large-diameter rock bit can be lowered. transported to the separation plant mounted ter without a drill pipe <stro<strong>ng</strong>>and</stro<strong>ng</strong>> are transported<br />

lnstalled just above the moon pool center on the bow, where the entire material is tre- to the ship through a hose line, usi<strong>ng</strong> the<br />

is the derrick fitted with the drilli<strong>ng</strong> equipated until, finally, only the diamonds are left. air-lift system.<br />

ment. A heave compensator system ensu- The operation mode of mini<strong>ng</strong> vessels is as The machine is capable of drilli<strong>ng</strong> explores<br />

that the drill bit remains on the borehole follows:<br />

ralory holes up to about 2 m in diameter,<br />

bottom, at almost constant thrust, even in Four anchor winches position the mini<strong>ng</strong> with a max. depth of 8 m, in the seabed.<br />

case of high seas <stro<strong>ng</strong>>and</stro<strong>ng</strong>>, consequently, high vessel exactly above the desired drilli<strong>ng</strong> Just like the diamond mini<strong>ng</strong> equipment,<br />

vertical ship movement. A twin-type cardan point. After the large-diameter rock bit this system can also operate up to a depth<br />

joint system is provided against buckli<strong>ng</strong> of with the drill pipe has been installed, <stro<strong>ng</strong>>and</stro<strong>ng</strong>> of 2OO m. All movements <stro<strong>ng</strong>>and</stro<strong>ng</strong>> functions<br />

the drill stri<strong>ng</strong> in case of large roll <stro<strong>ng</strong>>and</stro<strong>ng</strong>> pitch the drill bit touches the seabed, the hea- are remote-controlled <stro<strong>ng</strong>>and</stro<strong>ng</strong>> monitored from<br />

movements.<br />

ve compensator system, the rotary swivel the deck of its escort ship. The complete<br />

lnstalled at the rear of the derrick, is a verti- drive <stro<strong>ng</strong>>and</stro<strong>ng</strong>> the air-lift system are started up. hydraulic drive system <stro<strong>ng</strong>>and</stro<strong>ng</strong>> the electronic<br />

cal magazine for the air-lift fla<strong>ng</strong>e drill pipe. The large-diameter rock bit excavates the control system are installed underwater<br />

A special loader transports the drill pipe material, which is conveyed up the drill on the drilli<strong>ng</strong> rig. Energy <stro<strong>ng</strong>>and</stro<strong>ng</strong>> the control<br />

''t'F<br />

i*<br />

L<br />

* .' t*-l.il<br />

pipe into the towertype<br />

receivi<strong>ng</strong> bin.<br />

After the borehole<br />

has been drilled<br />

comm<stro<strong>ng</strong>>and</stro<strong>ng</strong>>s are supplied <stro<strong>ng</strong>>and</stro<strong>ng</strong>> given through<br />

an umbilical. The drilli<strong>ng</strong> samples are conveyed<br />

to the escort ship on the surface through<br />

a discharge hose.<br />

down to a previously Thanks to the wide ra<strong>ng</strong>e of applications<br />

defined depth, the <stro<strong>ng</strong>>and</stro<strong>ng</strong>> the many years spent developi<strong>ng</strong> our<br />

drill bit is lifted until products, Wirth is the worldwide leader in<br />

!4l7<br />

it ha<strong>ng</strong>s some meters this domain <stro<strong>ng</strong>>and</stro<strong>ng</strong>> is looki<strong>ng</strong> forward to ex-<br />

above the seabed. p<stro<strong>ng</strong>>and</stro<strong>ng</strong>>i<strong>ng</strong> this position in the future.<br />

The position of the These dem<stro<strong>ng</strong>>and</stro<strong>ng</strong>>i<strong>ng</strong> drilli<strong>ng</strong> projects to ob-<br />

mini<strong>ng</strong> vessel is then tain excellent raw materials are an impor-<br />

W@FWffiWffi<br />

wffi 6&b #& ffiffi<br />

WffiffiWHS cha<strong>ng</strong>ed by a certain<br />

amount, usi<strong>ng</strong> the<br />

tant part of the Wirth Croup activities. The<br />

company is also actively involved in new<br />

anchor winches, the markets <stro<strong>ng</strong>>and</stro<strong>ng</strong>> technologies for obtaini<strong>ng</strong><br />

drill bit is again lo- energy supplies in the future. One such exwered<br />

to the seabed, ample is the development of a facility for<br />

The large-diameter rock bit of approximately 7 m drilli<strong>ng</strong> diameter<br />

<stro<strong>ng</strong>>and</stro<strong>ng</strong>> the next borehole<br />

is drilled as descri-<br />

the foundation of an offshore wind park<br />

off the coast of the UK. X,<br />

80 Schiff & Hafen 6/2006