Pasteurization Technology

Pasteurization Technology

Pasteurization Technology

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

March 10, 2011<br />

District Michigan<br />

MBAA<br />

Technical Meeting<br />

Grand Ledge, MI

Presentation Agenda<br />

� <strong>Pasteurization</strong> Basics<br />

� Tunnel <strong>Pasteurization</strong> <strong>Technology</strong><br />

� Flash <strong>Pasteurization</strong> <strong>Technology</strong><br />

� <strong>Technology</strong> Comparison<br />

� Questions and Discussion

Theory and Objective of <strong>Pasteurization</strong><br />

� Elevated levels of heat will kill organisms<br />

� Heat beer to arrest biological contamination<br />

� Destroy viability of yeast<br />

� Prevent post fermentation<br />

� Brewers want Pasteurize not Sterilize<br />

� Minimum temperature for target organisms<br />

� Limited <strong>Pasteurization</strong> units

Time and Temperature<br />

Curve<br />

Maintaining the<br />

time/temperature<br />

profile is key to<br />

preserving the<br />

process or<br />

protecting against<br />

under and over<br />

pasteurization

<strong>Pasteurization</strong> – Lethal Effect<br />

� A lethal effect of 1 PU (<strong>Pasteurization</strong> Unit) is<br />

obtained when product can be held at 140F for 1<br />

minute<br />

� Brewers typically target 10PU’s to 15PU’s<br />

� Control of PU’s is essential<br />

� Elevated PU’s can affect flavor degradation

Measuring <strong>Pasteurization</strong> Units<br />

� Measure at “Cold Spot” of container<br />

� Probe position in container<br />

� Pasteurizer internal calculation<br />

� Using sensing devices and programming<br />

� Calculate PU’s<br />

� Time above 120F<br />

� Time in holding tube at <strong>Pasteurization</strong> temperature

Measuring Heat Transmission<br />

Cold Spot is<br />

usually<br />

located at<br />

¼” to 1”<br />

above the<br />

center of the<br />

bottom of<br />

the container<br />

TEMPERATURE °F<br />

140<br />

135<br />

130<br />

125<br />

120<br />

115<br />

110<br />

105<br />

100<br />

95<br />

90<br />

85<br />

80<br />

75<br />

70<br />

65<br />

TIME IN MINUTES<br />

2 4 6 8 10 12 14 16 18 20 22 24 26 28<br />

AVE. TEMP.<br />

COLD SPOT TEMP.<br />

INITIAL BEER TEMP. 40 °F (4.4 °C)<br />

SPRAY AT 140 °F (60 °C)<br />

T00384<br />

60.0<br />

57.2<br />

54.4<br />

51.7<br />

48.9<br />

46.1<br />

43.3<br />

40.6<br />

37.8<br />

35.0<br />

32.2<br />

29.4<br />

26.7<br />

23.9<br />

21.1<br />

18.3<br />

TEMPERATURE °C

Lethal Rate Curve<br />

PRODUCT TEMPERATURE<br />

°C<br />

62.2<br />

61.7<br />

61.1<br />

60.6<br />

60.0<br />

59.4<br />

58.9<br />

58.3<br />

57.8<br />

57.2<br />

56.1<br />

48.9<br />

°F<br />

144<br />

143<br />

142<br />

141<br />

140<br />

139<br />

138<br />

137<br />

136<br />

135<br />

133<br />

Average 12.35 P.U.'s<br />

Cold Spot 8.60 P.U.'s<br />

120 0.025<br />

0 5 10 15<br />

MINUTES<br />

2.09<br />

1.74<br />

1.45<br />

1.20<br />

1.00<br />

0.83<br />

0.69<br />

0.57<br />

0.48<br />

0.39<br />

0.27<br />

LETHAL RATE P. U. 'S / MINUTE<br />

PU’s calculated for<br />

product temperature<br />

above 120ºF.<br />

Area under the curve<br />

equals the number of<br />

PU’s achieved.<br />

Cold spot PU’s less<br />

than Average.

<strong>Pasteurization</strong> Unit Graph<br />

PU / MINUTE =<br />

1<br />

-1<br />

LOG<br />

140 - °F<br />

12.5<br />

(°F - 140)<br />

= 1.20226<br />

PU / MINUTE =<br />

-1<br />

LOG<br />

(°C - 60)<br />

1<br />

60 - °C<br />

6.94<br />

= 1.393<br />

PU / MINUTE<br />

40.0<br />

30.0<br />

20.0<br />

10.0<br />

7.0<br />

5.0<br />

3.0<br />

2.0<br />

1.0<br />

0.7<br />

0.5<br />

0.3<br />

0.2<br />

0.1<br />

TEMPERATURE °C<br />

50 52 54 56 58 60 62 64 66 68 70<br />

0.03<br />

120 130 140 150 160<br />

TEMPERATURE °F<br />

10 PU’s<br />

30 sec<br />

= 157F<br />

10 PU’s<br />

10 min<br />

= 140F

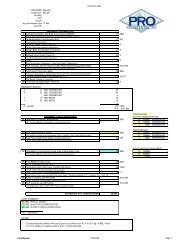

Barry-Wehmiller Advanced PU Limit<br />

System<br />

PU Accumulation<br />

PU Accumulation Rate<br />

120<br />

125<br />

130<br />

135<br />

140<br />

145<br />

150<br />

Product Temperature [deg F]<br />

155<br />

160<br />

165<br />

170<br />

175<br />

1000.00<br />

100.00<br />

10.00<br />

1.00<br />

0.10<br />

0.01<br />

PU / minute

Validating Measurement<br />

� Independent validation for tunnel<br />

� Several manufacturers of independent PU<br />

measuring devices<br />

� Measure time and temperature<br />

� Calculate and report PU values<br />

� Machine internal validation for flash<br />

� Redundancy on sensors<br />

� Micro analysis

Verifying <strong>Pasteurization</strong><br />

Independent<br />

measurement is<br />

capable with tunnel<br />

technology only.<br />

Redundancy can<br />

help reliability

Types of Beer <strong>Pasteurization</strong> <strong>Technology</strong><br />

Two basic types of beer pasteurization<br />

1. Tunnel <strong>Pasteurization</strong><br />

2. Flash <strong>Pasteurization</strong>

Tunnel Pasteurizer

Tunnel Pasteurizer Overview<br />

� General Description<br />

� Pasteurizer Features<br />

� Pasteurizer Systems<br />

� Operational Controls<br />

� Reporting/Recording

Pasteurizer – General Description<br />

� Length - Width<br />

� # of Decks<br />

� Features<br />

� Systems

Pasteurizer Features<br />

� End Casings<br />

� Removable<br />

Top Covers<br />

� Container<br />

Water Blow-<br />

Off<br />

� Condensate<br />

Return System

Pasteurizer Process Systems<br />

� Regeneration Capability<br />

� Heating System<br />

� Belt and Drive System<br />

� Spray System<br />

� Pump Systems<br />

� PU Control<br />

� Controls, Alarms

Tunnel Pasteurizer Regeneration<br />

Cold containers<br />

entering require heat<br />

Hot containers exiting<br />

require cooling<br />

Zoning<br />

Set Point Balance<br />

Maximum Regen<br />

Compensation<br />

Exit Temperature

Single Heat Exchanger System<br />

Single Heat Exchanger with plate Heat Exchanger.<br />

Closed Loop System with hot water available on<br />

demand.

Basic Concepts<br />

Single Heat Exchanger System<br />

� Benefits of the Single Heat<br />

Exchanger System<br />

� Low Maintenance<br />

� Only one heat exchanger<br />

� Plate Heat exchanger<br />

� Efficient use of energy<br />

� Condensate return<br />

� Less Pump<br />

Horsepower required

Typical Heat Exchanger Skid – Large<br />

Machine

Pasteurizer Main Belt<br />

� Intralox 400 and 1900 with<br />

Enduralox<br />

� Twentebelt Combinox and<br />

Eyelink<br />

� Regina 3120<br />

� Rexnord 5997 with DTS-C

UHMW Wear Strip Attachment<br />

Allow for UHMW expansion<br />

Easy install and replacement

Main Drive SEW Motor/gearbox

Spray and Pump System<br />

� Pressurized water flow rate<br />

designed to optimize thermal<br />

heat transfer rates<br />

� Up to 6.8gpm/ft²<br />

� Thermal Dynamic Models<br />

� Manual Blow Downs<br />

� Even flow across the deck<br />

� Predictable Heat Transfer<br />

� Removable spray headers<br />

� 3 1/2” header, 3/8” nozzles

Spray System Filter<br />

Screens<br />

Redundancies for Maintaining Spray Consistency<br />

� Belt side guides<br />

� Belt mesh pattern<br />

� Dual pump inlet screens<br />

� Spray header design<br />

� Spray header blow down

Filter Screen External Access Doors

Spray System Blow Down

PU Limiting<br />

� Hot Zones<br />

� Add cold water<br />

to zone reservoir<br />

� Re-heat on start<br />

up

Advanced PU Control System<br />

� Advanced PU Control System controls the<br />

pasteurization process:<br />

� Guarantee very tight PU control<br />

� Preserve the process curve in stop/start<br />

conditions<br />

� Move process to container if container can not<br />

get to process

Possible to have hot water on<br />

one header and cold water on<br />

another header from the same<br />

manifold

Utility Control <strong>Technology</strong> ‘IntelliFlow’<br />

� The IntelliFlow System:<br />

� Used in conjunction with Advanced PU Control<br />

� Water temperature separation technology<br />

� Eliminates requirement for water re-heating<br />

� Provides benefits of PU control without added<br />

utility consumption

Pasteurizer Control Items<br />

� Sensors, proximity switches, instruments<br />

� Safeties and Alarms

Pasteurizer Safety and Alarms<br />

� Hot zone pumps 2º below set point for 30 seconds<br />

will stop belt<br />

� Pressure sensors all zones below 2psi for 15<br />

seconds stops pasteurizer<br />

� All levels satisfied before pasteurizer will start<br />

� Belt speed monitored by checking starwheel pulse<br />

duration to time set in recipe<br />

� Drive overloads – spring and proximity

Pasteurizer Recording Capability<br />

� Data collected from Sensors:<br />

� Temperature of all zone sprays<br />

� Speed of belt<br />

� Levels<br />

� Data collected in the pasteurizer PLC<br />

� Data sent to remote storage<br />

� Data can be extracted to workable files<br />

� Reports can be generated

Flash Pasteurizer<br />

Volutherm Series<br />

Flash Pasteurizer

Flash <strong>Pasteurization</strong><br />

� <strong>Pasteurization</strong> occurs prior to filling<br />

� Short Time High Temperature (HTST)<br />

� Heat Exchanger (plate or tube)<br />

� Fixed or Variable flow rates<br />

� <strong>Pasteurization</strong> calculated by Holding Time and<br />

Temperature<br />

� High Efficiency (90% regeneration)<br />

� Controls are Key!

Flash Pasteurizer 180 Hl/Hr

Flash Pasteurizer 320 Hl/Hr

Flash Pasteurizer 360 Hl/Hr<br />

Flexibility to design<br />

units to fit various<br />

applications<br />

Juice unit with Heat<br />

Exchanger mounted<br />

on the floor for<br />

accessibility on<br />

larger pasteurizers<br />

Often times machines<br />

can be designed to<br />

handle different<br />

products on the same<br />

unit

Flash Pasteurizer – 250 Hl/Hr

Flash Pasteurizer Features<br />

� Constant PU Variable Flow rate Unit.<br />

� Pressure Balance System.<br />

� 90% Energy Recovery.<br />

� Status and Process Alarms.<br />

� Digital Paperless Chart Recorder.<br />

� Fully Automatic Operation.

Flash Pasteurizer Design

Flash Pasteurizer<br />

Components

Product Flow Meter<br />

An Electromagnetic flow measuring system is used to monitor the flow of the<br />

product at the discharge of the pasteurizer.

Product Flow Control Valve<br />

(Detail View)<br />

4-20mA Electrical Input Signal.<br />

Resulting in a 0-100% Valve opening.

Product Temperature Measurement<br />

PT100 Temperature probes monitor the temperature of the fluids<br />

Within the pasteurizer.<br />

As the temperature changes the resistance measured by a<br />

Transmitter fitted inside the temperature probe changes.<br />

The input signal to the pasteurizer control system is electronic<br />

4 – 20mA.

Product Temperature Control<br />

Pressure Reducing Valve<br />

A pressure reducing valve is designed for<br />

maintaining the pressure downstream of the steam<br />

supply valve to an adjusted set point value.<br />

Set point approximately 2.0bar<br />

The valve closes when the downstream<br />

pressure rises.<br />

Pneumatic Control Valve<br />

The hot water that is used to raise the beer to the<br />

required pasteurization temperature is heated using<br />

steam controlled by the pneumatic controlled valve.<br />

This valve uses a pneumatic control signal to adjust<br />

The amount to which it opens and so the amount of<br />

steam that can flow into the plate pack

Process Recording<br />

� Touch Screen HMI<br />

� Select recipes<br />

� Operational functions<br />

� Adjust parameters<br />

� Alarm displays<br />

� Digital Paperless Process Logger<br />

� Records temperatures<br />

� Records flow rates<br />

� Records pressures<br />

� CIP and Run modes

Process Recording<br />

�Temperatures<br />

�Pressures<br />

�Calculated PU’s<br />

�Production / CIP Flow rate<br />

�Production / CIP / SIP Mode<br />

�Product In Machine

Central System Operation

Central System Operation

Flash Pasteurizer – Benefits and Features<br />

� Performance tolerance to with in 1PU<br />

� Variable flow, variable temperature<br />

� Maximum regeneration<br />

� Quality monitoring, alarms, reports, archiving<br />

� Machine self-diagnostics<br />

� Operation safe-guards for PU protection<br />

� Gentle product handling (HTST)<br />

� Compact footprint, Low energy use

PROCESS COMPARISONS

Process Comparison Factors<br />

� Application Issues<br />

� Operational Issues<br />

� Quality Issues<br />

� Economic Issues<br />

� Equipment Issues

Application Issues<br />

� Tunnel<br />

� Wide range of products<br />

� Carbonated or non-carbonated<br />

� Container limitations<br />

� Flash<br />

� Wider range of products<br />

� Product limits for plate and frame<br />

� Carbonated or non-carbonated

Operational Issues<br />

� Tunnel<br />

� Controls and Complexity can be less<br />

� More forgiving<br />

� Reduced requirement for micro control<br />

� Manual machine cleaning<br />

� PU Control required for line conditions<br />

� Flash<br />

� Cleaning and Sanitation Increased<br />

� Line availability reduced<br />

� Enhanced microbiological testing<br />

� CIP systems are critical<br />

� Buffer systems for handling line conditions

Quality Issues<br />

� Tunnel<br />

� Taste affects possible with prolonged stops<br />

� Validation using independent device<br />

� Reduced requirement for micro control<br />

� Exit temperatures<br />

� Flash<br />

� Minimal taste affects<br />

� Potential for recontamination<br />

� Validation – trust sensors, redundancy<br />

� Ability to re-circulate<br />

� Disinfecting caps and containers – filler contact points

Economic Issues<br />

� Tunnel<br />

� High capital costs for new equipment and installation<br />

� Operating costs can be high<br />

� Reduced costs for monitoring quality<br />

� Increased line utilization<br />

� Flash<br />

� Capital cost can include warmer, filling room upgrades<br />

� High efficiency reduces utility cost (warmer?)<br />

� Less floor space required

Example Comparison for Flash and Tunnel<br />

� Example Selection:<br />

� Brewery<br />

� Bottle production line operating at 800bpm<br />

� Target PU’s at 10 +/- 2<br />

� Target BOT at 75°F

Example Comparison for Flash and<br />

Tunnel<br />

� Equipment Cost<br />

Flash Process Tunnel Process<br />

Volutherm 200B –<br />

$300,000<br />

Buffer Tank - $50,000<br />

Warmer - $375,000<br />

Clean Room – $275,000<br />

Total equipment -<br />

$1,000,000<br />

New Double Deck sized<br />

correctly to optimize utility<br />

consumption and provide low<br />

product exit temperatures<br />

- $1,500,000

Example Comparison for Flash and<br />

Tunnel<br />

� Utility Consumption<br />

Flash Process Tunnel Process<br />

Volutherm 200B<br />

New Double Deck Tunnel<br />

Water - 140 gal/chase out Water - 0gpm, running mode<br />

Steam – 8,000 btu/min<br />

- 100gpm run-out<br />

BWCo Warmer<br />

24mins<br />

Water – 0gpm normal Steam – 20,000 normal run<br />

Steam - 31,500btu/min<br />

- 72,000 start-up<br />

Total Steam -39,500 Avg. steam - ~<br />

btu/min<br />

35,000btu/min

Example Comparison for Flash and<br />

Tunnel<br />

� Floor space requirement<br />

Flash Process Tunnel Process<br />

Volutherm 200B – 200 sq. ft.<br />

Buffer tank and valves stand<br />

- 80 sq. ft.<br />

Warmer 826 SD<br />

- 280 sq. ft.<br />

Total - 480 sq. ft.<br />

New Double Deck Tunnel<br />

1120 sq. ft.

Summary of Process Comparison<br />

� Capital Cost – Similar when considering clean room<br />

� Utility Consumption – Similar when using warmer<br />

� Process Considerations – Culture change for flash<br />

� Cleaning Materials/Sanitizing Agents and Micro<br />

Control requirements – Higher costs for flash<br />

� Available Packaging Line Time – Higher for tunnel<br />

� Floor Space – Flash has reduced space requirement

Time for a beer….<br />

�Thanks for listening!