engineering statement of technical requirements (sotr) -m8

engineering statement of technical requirements (sotr) -m8

engineering statement of technical requirements (sotr) -m8

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

E V'00<br />

PE It- Pi SA1<br />

6JA^1^11^ JJ<br />

yam!<br />

"9 O"FCT OF<br />

2100N 0QG^'<br />

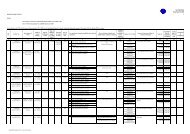

TECHNICAL SPECIFICATION FOR PROCUREMENT<br />

DESIGN - ELECTRICAL<br />

REF: ND,: DRM6A135XX<br />

DATE 31112/2D1D<br />

TS.P.ND.<br />

5107<br />

Y. -„'<br />

YARDS 12701 , 1272 & 1272 REV.ND . DD<br />

SHIP P1 5ACLASS ....`.-<br />

TITLE<br />

DOCUMENTS ATTACI4Ep--.<br />

Q FL<br />

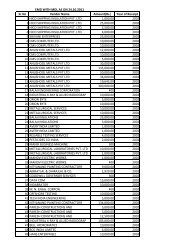

SR,ND. TITLE No <strong>of</strong>Sheeta<br />

Copy<br />

I Part - 0 (Preamble) 1<br />

2 Part - 1Technical ificationfor Procurement )<br />

3 Part - 2 (General uirements for tiectrica ui eturtts) 2<br />

4 SOTR 9<br />

5 PR No. I 110007060 2<br />

PE (P- PIS - ONE SET<br />

it.K.SBRIVASTAVA<br />

DQ4I(#,^cyYNf lZ(U P15A)

M<br />

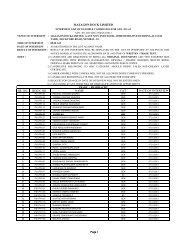

PART C PREAMBLE 1 :<br />

ESRNI6AL DEFMIFICAtION FOii pROCLRFA&Ent<br />

'p$<br />

PART I TECHNICAL 'SPECIFICATIS1 AND SOTR<br />

PART 2 GENERAL. REMENTS OF ELECTRICAL ESwIPMENT<br />

PART 5 PR NO, 1110007060<br />

AQON DOCK UMtE0<br />

MuMe/4i 400010.<br />

OESISN EISCTRICAL<br />

E:-" SPEC IJO..<br />

5107<br />

at)<br />

12/2010

PART OI<br />

01 INTRODUCTION<br />

010 Part 0<br />

This specification is written in two (2) parts:<br />

Preamble<br />

Oil Part I Technical Specification and SOTR<br />

012 Part 2 General Requirements <strong>of</strong> Electrical Equipments<br />

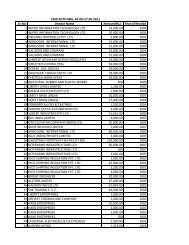

02 DEVIATION<br />

021 The supplier shotdd clearly indicate the clauses in the specification not being complied with. In the a bsence<br />

<strong>of</strong> a clew gaMWIPAC contrary. it will be assumed that the equipment A"WW wilt.nuel the requirement<br />

l<br />

d Inierai ltnquitements <strong>of</strong><br />

sin full, in case th a is Comotbetweenclause m roc unea s<br />

$lecvical Bgsuutnessft clause i Technical Specification shall cake pretence=<br />

022 T e supplier should not after the binding drawings or the scope <strong>of</strong> supply or any other aspect governed by<br />

this ponoct ' requis Lion as mall} agreed, without specific concurrence, f mm Ml3L , eves if any<br />

Clause<br />

Ir resident ' inspectors snacattaBCw^a a' uiG iii,w.<br />

Mecds the re9uirea<br />

Yes / No

1'<br />

, <strong>of</strong> Gam,<br />

tf<br />

-<br />

15 its" f,is; ^ 50 tt<br />

mw

Y^ 12701.127021 12703<br />

" acem?c Mft as1071ttv4<br />

Mumma<br />

(Part-1 ) S.ist 3 <strong>of</strong> 3<br />

8. GUARANTEE<br />

The manufacturer should give guarantee against poor pelforrrrarrcelbad<br />

workman ship<br />

for the period <strong>of</strong> 48 months from the date <strong>of</strong> delivery are 12 months from the date <strong>of</strong><br />

commissioning <strong>of</strong> the ship.<br />

PRODUCT SUPPORT<br />

The supplier should confirm product support for 10 years.<br />

10. ^f • °° •0 h. elial by a vendor with trehnkkat-hiler_<br />

a. A brief speeificationldescription <strong>of</strong> the equipment being <strong>of</strong>fered including a <strong>statement</strong><br />

showing anyway in which the equipment deviated from this TSP.<br />

b Operating supply voltage and frequency<br />

c. Wattage <strong>of</strong> lamp and lux<br />

d. Power factor<br />

e. Part number<br />

f Dirnentional details <strong>of</strong> CFL and weight<br />

g. Type <strong>of</strong> CFL ie. electronic or magnetic -ballast<br />

h. Colour ie. Daylight<br />

I<br />

PART - a<br />

(Psfl. t 1012<br />

ragNIERALI<br />

REDUtREMENTB OE ELECTRICAL EQUIPMENTS<br />

e / Item is generally required to withstand following . maritte conditions:<br />

Th<br />

Attdntatt termsera u Of-50 °C for Machinery Space and 45 °C at other places.<br />

t re<br />

h umid ty loo % at 35 °C, Seawater temperature 35 °C, Rol{.+1- 300P& S, pitch 0+/- 15°, list 20 °.<br />

2. All items must strictly conform to relevant drawings / specifications mentioned. in therequisitim<br />

3. General arrangement dr<br />

Gravity is to be supplied along with the <strong>of</strong>fer, for non-pattermseu ira<br />

awing &I 8 overall dimensions and approximate weight <strong>of</strong> the unit and center <strong>of</strong><br />

Wherever applicable, the production drawings are to be approvedby DQA / Statutory & regulatory agency- The<br />

manufacture <strong>of</strong>tbe itemsls tote started only on approval <strong>of</strong> the drawings. A ad <strong>of</strong> approvedprodwCtton<br />

.<br />

drawings is to be made avmleble to MDL for dimensions , faring details etc<br />

Whenever a pilot sample is required to be. manufactured, the lankproduction is to start only alter approval <strong>of</strong> the<br />

sample by inspecting Agarucy f MDL•<br />

6. No Component will be supplied by MDL<br />

7. The items an to be <strong>of</strong> robust construction so as to withstand adverse marine conditions. Similar parts are to be<br />

interchangeable The castings are to be fix from blowholes, sharp edges to be rounded <strong>of</strong>t the threads are to be<br />

oven and sharp . The switches, lamps, fuses, internal wires etc. used in 1te eg njnnent are to be either patternised<br />

ortype approved by'DQAI classification societies, as applicable. The details regarding this can be obtained from<br />

respective agencies. The indicating lamps should be easily accessible by unscrewing the lull's eye from the front.<br />

Fuses are to be clearly marked:<br />

8.<br />

,<br />

.shock /<br />

d) Lilting arrmtgememis to beprovided for heavy items.<br />

vibration<br />

a) The holes for mounting the equipment should be on hip outside the casing <strong>of</strong>the equipment<br />

b) :T a equipment lets be suitable forbulkhead! deck movnting.If equipment contains movableparts<br />

cowactaus or electronics assemblies etc. the equipment is m be antable for mounting on<br />

such as relaym<br />

Mw mounts we to be supplied Along with the equipment.<br />

c) Suitable earthingarrangement is to beprovided on the equipment.<br />

For Ship'<br />

s cables, the entries are to be through glands, unless otherwise stated The glands are to be as per<br />

specification DGS/EEDM/I5351K6, (For Naval Ships) I Standard Siemen's gland for Merchant Ships The<br />

gland mu and washers are to be left un chilled, unless specified.<br />

9. For connection <strong>of</strong> the ship's cables the terminals are to be easily accessible, For cables <strong>of</strong> sizes <strong>of</strong> 7/0,044 and<br />

higher, crimped sockets and clamp type terminals are to be provided for incoming & outgoing cable connection.<br />

block,<br />

the<br />

eating<br />

<strong>of</strong> n the equpment<br />

and the<br />

Aa apace should bemaw between terminals, tarannal<br />

cable entry glands:<br />

a. Internal wiring inthe panels to be <strong>of</strong> Low Fire Hazard cables.<br />

b The install n material , viz. free end connectors, cable ;maps, special tools if any,`mounts arc. to<br />

complete installation is to be supplied by you along with the equipment.<br />

10. The Part No. /The Pats. No. <strong>of</strong> each item is to beprominently and indelibly cast/ embossed ! tallied.

11. The following engraved tallies <strong>of</strong> brass I anodized aluminum are to be screwed on each equipment<br />

a. ManufCture's tally indicating name, description <strong>of</strong> the item, partlpatt. No,., rating, Sr. No., Year <strong>of</strong><br />

manufacture, weight etc.<br />

b. Functional tallies for switches, lamps, pushes etc.<br />

c. Danger tallies for equipment operating on 220 V andabove, the tally should have white letter on red<br />

d. Whore applicable 'MODWICfION STATE' <strong>of</strong> the equipment tally.<br />

e. Special tal Ies-to be provided as applicable viz. Circuit diagram tallies, operating instructions motor<br />

direction <strong>of</strong> rotation etc.<br />

12. The item is to be painted with admiralty ship's gray paint as per approved pang spec fication*ocedure.<br />

13. Minor modifications required by Owner/Inspecting Agencies / MUL are to be incorporated.<br />

14. For any deviations, however minor, prior approval is to be obtained from DQA (Navy) MDL Deviations<br />

once granted will not be icesaa&y applicable for repeat manufacture.<br />

15. Net weight <strong>of</strong> each item is to be recorded in the presence <strong>of</strong> the mapectorani a certificate to that effect is to be<br />

submittad-along with supplies:<br />

16. The equipment supplied by you will be installed on board the ship byMDL. The services <strong>of</strong> your engineers, if<br />

required during mstallatim setting to work, harbour trials, we trials, etc. to prove your eft to NAVY, be<br />

provided Your service engineers are to bring their own test equipments/toolsand spares for this purpose.<br />

- End Of Part 2

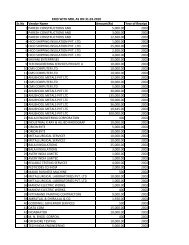

DIRECTORATE OF ELECTRICAL ENGINEERING<br />

STATEMENT OF TECHNICAL REQUIREMENTS (SOTR)<br />

-M8<br />

COMPACT FLUORESCENT LAMPS (CFCs)<br />

SUZTABLEFOR 23OVSUPPLV<br />

BPB<br />

P-17AND LSTR)<br />

SOTR NO. DEE101/04<br />

DATEOFISSUE: OCT O4<br />

IRtJ_°_ 68

a<br />

- 4<br />

STATEMENT OF TECHNICAL REOLOREMENTSISOTR)<br />

Mg<br />

P-17AND LSTIL)<br />

1. Scope. The <strong>statement</strong> <strong>of</strong> <strong>requirements</strong> covers the design , construction , testing<br />

methods and conditions for lighting system luminaries including CFLs with integrated<br />

means for controlling, starting and stable operation (Self Ballasted Lamps) to be fitted<br />

onboard Naval ships . The design, shape & size <strong>of</strong> the CFIs should be compatible to<br />

existing GLS luminaries (with B22/PP) fitted onboard ships and catered for trouble free<br />

operation under the most adverse environmental and marine conditions . The CFLs<br />

should conform to IS 15111 (Part I &II)- 2002 for safety and performance<br />

<strong>requirements</strong>.<br />

2. Pgrom. The purpose <strong>of</strong> CFLs is to provide lighting <strong>of</strong> requisite luminosity<br />

onboard Naval ships. The CFIs will be used in lieu <strong>of</strong> incandescent lamps in non-CAT<br />

`N compartments onboard ships.<br />

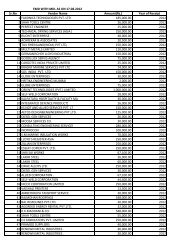

3. wattage <strong>of</strong> CFLs. The CFLs <strong>of</strong> following ratings equivalent to incandescent<br />

lamps will be used onboard IN ships . The wattage should be marked on the lamps.<br />

Wattage <strong>of</strong> Incandescent Lamps Eauivalent Wattage <strong>of</strong> CFLs<br />

40 W 11W<br />

60 W 15-1.91=.<br />

100W 20W<br />

4. Supply Voltage. The CFLs should be designed for 230V 50Hz Ph supply. The<br />

voltage or the voltage range should be marked on the lamp deary.<br />

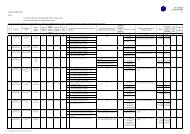

4.1 Input AC Supply Characteristics. The input AC supply characteristics shall be as<br />

per table given below:-<br />

CHARACTERISiIC DESCRIPTION VALUE<br />

Nominal Voltage 230V<br />

Load range tolerance Line to Line ±5%<br />

Constant Load Tolerance + 1%<br />

Maximum Modulation Transients 2%<br />

(Excluding Spikes)<br />

Frequent Transients -10% to + 6%<br />

Voltage Recovery Time 0.5 Sec<br />

Infrequent Transients -16% to + 10%<br />

Recovery Time 1 Sec<br />

Frequency Nominal Frequency 50 Hz

I<br />

5. Technical Reauireme ts.<br />

5.1 Qnstrixtion. The CFL casing shall be made <strong>of</strong> cast aluminum alloy (A6M) with<br />

suitable glass covering . The enclosure <strong>of</strong> CFI- should be <strong>of</strong> splash pro<strong>of</strong> (IP 55)<br />

construction providing adequate protection against ingress <strong>of</strong> moisture and dust.<br />

All electronic components , lamp holder and reflector etc. should be <strong>of</strong> standard<br />

manufacturer and be mounted on single PCB . However the transformer should<br />

be secured Inside the casing. The panel cover should be secured with captive<br />

screws with lock-in-nuts.<br />

5.2 r mq lity <strong>of</strong> CFL vis-h-vis Lamp Fitinos. The details are as follows:-<br />

CFLs (EL Type) CFI- Length in mm Compatible Lamp Fittings<br />

which are already<br />

Remarks<br />

Min Max<br />

Pattemised<br />

20 W 140 155 Patt No . 0581/923-7422<br />

Patt No. 0581/923-5751<br />

Patt No . 0581/923-5752<br />

To be used with<br />

large type lamp<br />

fittings as per BR<br />

320 D<br />

15 W 106 125 Patt No . 0581/923-5758 To be used with<br />

small type lamp<br />

fittings as per BR<br />

320 D<br />

11 W 120 142 Patt No. 0581/923-7421 To be used only<br />

for lighting<br />

bathroom/cabin<br />

mirrors.<br />

5.3 Mane urerer's Technical S flcation. The manufacturer 's <strong>technical</strong><br />

specification <strong>of</strong> the above CFLs Is shown In Appendix 'A'

I<br />

6. Tests.<br />

6.1 Classification <strong>of</strong> Tests<br />

6.2 TYce Test. The type tests to be carried out on selected samples <strong>of</strong> self ballasted<br />

lamps would be as per IS 15111 Part I and II . The details are given in<br />

succeeding paragraphs:-<br />

As per IS 15111 Part I<br />

6.2.1 Marking . The lamps shall be clearly and durably marked with the following<br />

mandatory markings:-<br />

(a) Mark <strong>of</strong> origin (this may take the form <strong>of</strong> a trade-mark, the manufacturers<br />

name or the name <strong>of</strong> the responsible vendor);<br />

(b) Rated voltage or the voltage range (marked 'V' or 'Volts);<br />

(c) Rated wattage (marked 'W' or 'Watts');<br />

(d) Rated Frequency (marked in 'Hz');<br />

(e) Rated luminous flux;<br />

(f) Rated colour temperature; and<br />

(g) Country <strong>of</strong> manufacture.<br />

6.2.1.1 The durability <strong>of</strong> the marking Is checked by trying to remove it by rubbing lightly<br />

for 15 seconds with a piece <strong>of</strong> loth soaked with water and, after drying, for a<br />

further 15 seconds with a piece <strong>of</strong> dotty soaked with hexane. The marking shall<br />

be legible after the test.<br />

6.2.2 Interchangeability. Compliance <strong>of</strong> combination <strong>of</strong> cap and bulb Is checked by<br />

the use <strong>of</strong> gauges for checking the dimensions controlling interchangeability in<br />

accordance with IS 9206:<br />

6.2.3 . Test finger shall not touch live parts in normal<br />

use when applied In all directions with force <strong>of</strong> 10 N.<br />

6.2.4 Insulation -Resistance and Electric Strength after Humidly Treatment. The<br />

lamps shall be conditioned for 48 hours in a cabinet containing air with a relative<br />

humidity between 91 % and 95%. The tempe rature <strong>of</strong> the air Is maintained<br />

within 1°C <strong>of</strong> any convenient value between 20t and 30°C.

6.2.4.1 Insulation resistance shall be measured in the humidity cabinet with a dc<br />

voltage <strong>of</strong> approximately 500V . One minute after application <strong>of</strong> the voltage, the<br />

insulation resistance between current-carrying metal parts <strong>of</strong> the cap and<br />

accessible parts <strong>of</strong> the lamp (assessable parts <strong>of</strong> the insulating material are<br />

covered with metal foil) shall be not less than 4 MO.<br />

6.2.4.2 The insulation resistance <strong>of</strong> B 22 caps between shell and contact shall be not<br />

less than 5 Mfg.<br />

6.2.5 Mechanical Strength. The cap shall be subjected to the torque by means <strong>of</strong> the<br />

torsion test holder. The torque shall not apply suddenly, but shall be increased<br />

continuously from 0 to the specified value . The Lamp should withstand minimum<br />

3.0 Nm <strong>of</strong> mechanical strength.<br />

6.2.6 Cap Temperature Rise. The cap temperature rise tests <strong>of</strong> the complete lamp<br />

during run-up, stabilization period and after stabilization shall not exceed the<br />

value mentioned below:-<br />

For B 22d ........................ 125 K<br />

6.2.7 Resistance to Heat . External part <strong>of</strong> insulating material <strong>of</strong> self ballasted lamp<br />

shall be sufficiently resistant to heat . The test is made in a heating cabinet for a<br />

sufficient time to ensure that they have attained the stabilized testing<br />

temperature before the test commences . The surface <strong>of</strong> the part to be tested is<br />

placed in the horizontal position and a steel ball <strong>of</strong> 5 mm diameter pressed<br />

against this surface with a force <strong>of</strong> 20 N . After ball pressure test the diameter <strong>of</strong><br />

impression shall not exceed 2 mm.<br />

6.2.8 Resistance to Rame Ignition . External parts <strong>of</strong> the insulating material retaining<br />

n live parts in position and external parts <strong>of</strong> insulating material providing protection<br />

against electric shock are subjected to the glow wire test at 650°C.<br />

6.2.9 Fault Condition . Lamps shall not impair safety when operating under following<br />

fault conditions:<br />

(a) Short circuit in starter.<br />

(b) Short circuit across capacitors.<br />

(c) Broken cathode.<br />

(d) De-activated lamp.

OPN<br />

/1^<br />

(e) open circuit<br />

LOAD Part_II<br />

The lamp dimension shall comply with the <strong>requirements</strong> as<br />

6.2.10 rement agency.<br />

indicated by the procu<br />

6.2.11 c+°, and Run-up. The lamp shall fully light up and remain alight within 4.0<br />

seconds at 92% <strong>of</strong> rated voltage. The time to reach 80% <strong>of</strong> the Initial lumen<br />

characteristics shall not exceed 120 sec.<br />

6.2.12 yamo Wati• The initial wattage dissipated by the lamp shall not differ by<br />

mote than + 15% and -10%.<br />

1I uMMULElux. Initial lumen flux after the ageing time shall not be less than<br />

and the<br />

6.2.13 90% <strong>of</strong> the rated luminousthe colour P specified in the standard).<br />

efficacy corresponding<br />

6.2.14 I r• The colour Coordinated <strong>of</strong> a lamp shall be within the tolerance area on<br />

the chromaticity chart<br />

wer Factor. The power factor <strong>of</strong> the combination <strong>of</strong> the ballast and the lamp<br />

6.2.15 Po<br />

shall not be less than 0.80.<br />

Lift.<br />

The average life <strong>of</strong> lamp shall not be less than 6000 hrs.<br />

6.2.17 Lamp Effic W. The efficacy <strong>of</strong> the lamp will be as given in the table 2 <strong>of</strong> IS<br />

15111 (Part II).<br />

After 2000 h <strong>of</strong> operation inducting the aging period, the<br />

6.2.18 Lumen Maintenance .<br />

shall be not less than 90% <strong>of</strong> the initial luminous<br />

iumen m<br />

characteristics.<br />

6.3 ^+nta^ Test The acceptance tests would include the above<br />

tests at<br />

6.2.1 to 6 .2.6 and 6S<br />

1 tox6 2.1 . In addition, CFLs will be subjected<br />

vibration test as per<br />

The CFLs should meet EMI/EMC <strong>requirements</strong> onboard ships as per IEC<br />

7. FWIEM<br />

OEM will provide EMI/EMC Test report The CFLs have been cleared to be used<br />

1547. dth i hail room storage spy.<br />

in non-CAT' A' com r i.e. i, n n<br />

a ys etc-onboard ships.<br />

8. Nnsoe Linn<br />

A oritY. DQA(N) would be the inspection authority.

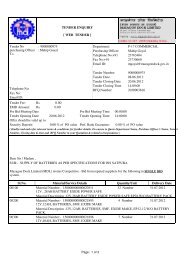

9. Procurement. The following information be provided to the<br />

manufacturer/vendor at the time <strong>of</strong> the procurement <strong>of</strong> CFL: -<br />

(a) Operating Supply (in terms <strong>of</strong> voltage and frequency)<br />

(b) Wattage <strong>of</strong> lamp<br />

(c) Power factor<br />

(d) Part No.<br />

(e) Dimensional details <strong>of</strong> CFL.<br />

(f) Type <strong>of</strong> CFL (with electronic or magnetic ballast)<br />

(g) Colour (Day light/Warm white/Blue/Red)<br />

10. Related Documents and Acceptable Standards.<br />

SOCICWWAMOFIS Titles<br />

IS 15111 (Part I &II ) (2002) - Self ballasted lamps for general lighting<br />

services.<br />

Part I - Safety <strong>requirements</strong>.<br />

Part II- Performance <strong>requirements</strong>.<br />

IS 1258 (1987) - Bayonet lamp holders.<br />

IS 8913 (1978) - Methods <strong>of</strong> measurement <strong>of</strong> lamp cap<br />

temperature rise.<br />

IS 9206 (1979) - Dimensions <strong>of</strong> caps for tungsten filament GLS<br />

lamps.<br />

IS 11000 (Part II/Sec 1x1988) - Fire hazard testing.<br />

Part H - Test methods<br />

Section 1- Glow wire test and guidance<br />

IS 6873 (Part 5)(1999) - Methods <strong>of</strong> measurement <strong>of</strong> electromagnetic<br />

interference<br />

Part 5 - Florescent lamps and luminaries.

IS 2592 (1980) - Vibration tests.<br />

NES 587 - Requirements for lighting system.<br />

EED-Q- 261 - Specification for light fittings<br />

BR 320 D - Catalogue <strong>of</strong> Naval Stores (pass Group 0581)

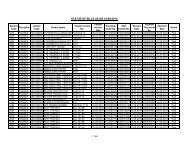

APPENDDC `A'<br />

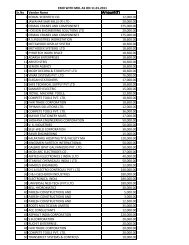

Lamp Related Data ELD-11WI ED-15W ELT-20W Remarks<br />

Working Voltage 230V Voltage to<br />

(V)<br />

Working Frequency 50 Hz<br />

(HZ)<br />

Rated light output 2700 K 600 900 1200<br />

(Base up) (Im) 4000 K 600 900 1200<br />

6500 K 565 850 - 1 1120<br />

Colour Temperature 2700, 4000,6500<br />

2700 K 55 55 60<br />

Efficacy (Im/W) 4000 K 54 54 59<br />

6500 K 51 51 56<br />

Lamps caps B-22d<br />

Lamp current(A): 0.080 0.100 0.140<br />

(Input)<br />

Maximum starting < 4 Second<br />

time mS<br />

Starting Voltage 170<br />

Nominal Power 11 1 15 20<br />

Lamp Power (W) + 15% - 10% (As per BIS)<br />

(Tolerance)<br />

Lumen Maintenance 85 (As per BIS)<br />

(100 + 2000h ) %<br />

Lumen Maintenance 70 (As per OG)<br />

(2000 + 6000h) (%)<br />

Frequemy (kHz) >20<br />

We (with-W 6000 hrs (As per BIS)<br />

operation) 165 min<br />

ON AS Min <strong>of</strong>f Hrs<br />

Burning Position Universal<br />

Applicable Torque 3.0 NM<br />

cap (8-22d/E-27)<br />

Warm-up time after<br />

switch ON<br />

-80% <strong>of</strong> light output 120 Max<br />

(S)<br />

-100%<strong>of</strong> light output 300<br />

S<br />

Max cap 129C<br />

temperature rise °C<br />

Min Starting 140V<br />

V Pnwar Fartnr n Rn<br />

be<br />

spedflecl