SURVEYOR® WS-Series - Laser Design | GKS

SURVEYOR® WS-Series - Laser Design | GKS

SURVEYOR® WS-Series - Laser Design | GKS

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

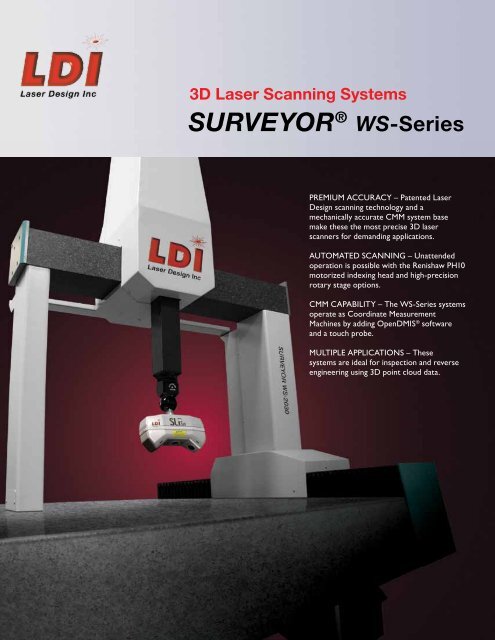

3D <strong>Laser</strong> Scanning SystemsSURVEYOR ® <strong>WS</strong>-<strong>Series</strong>PREMIUM ACCURACY – Patented <strong>Laser</strong><strong>Design</strong> scanning technology and amechanically accurate CMM system basemake these the most precise 3D laserscanners for demanding applications.AUTOMATED SCANNING – Unattendedoperation is possible with the Renishaw PH10motorized indexing head and high-precisionrotary stage options.CMM CAPABILITY – The <strong>WS</strong>-<strong>Series</strong> systemsoperate as Coordinate MeasurementMachines by adding OpenDMIS ® softwareand a touch probe.MULTIPLE APPLICATIONS – Thesesystems are ideal for inspection and reverseengineering using 3D point cloud data.

SURVEYOR ® <strong>WS</strong>-<strong>Series</strong>Machine SpecificationsINCLUDED WITH SYSTEMSYSTEM OPTIONSChoice of <strong>Laser</strong> Probe<strong>Laser</strong> Scanning SoftwareComputerManual <strong>Laser</strong> MountTest ArtifactMEASURING RANGE (MM)<strong>WS</strong>-2030 <strong>WS</strong>-2040 <strong>WS</strong>-3040 <strong>WS</strong>-3060 <strong>WS</strong>-4060 <strong>WS</strong>-4080X 500 500 800 800 1000 1000Y 700 1000 1000 1500 1500 2000Z 500 500 700 700 700 700VOLUMETRIC ACCURACY CMM BASE-ISO 10360-2ModelSLP250, SLP400, SLP500, or SLP2000Surveyor Scan Control SoftwareHigh-end Windows-based PC and monitorAdjustable mounts allow for 2 axes of rotationSpecially designed artifact for validating systemaccuracy. Includes CMM inspection report andQualify inspection templateRenishaw TP20 ProbeStandard AccuracyMPEEMPEP<strong>WS</strong>-2030 <strong>WS</strong>-2040 2.6 + L/300 2.6 2.5 + L/300 2.5<strong>WS</strong>-3040 <strong>WS</strong>-3060 3.0 + L/300 3.0 2.7 + L/300 2.7<strong>WS</strong>-4060 <strong>WS</strong>-4080 3.1 + L/300 3.1 2.8 + L/300 2.8ELECTRICAL NETWORK SPECIFICATIONSRenishaw TP200 ProbeStandard Accuracy• Machines supplied with 1663 SM panel plug (16A/6h 2P+TCEE rules).• Customer will provide the free socket or the panel socketaccording to its requirements.• Mains voltage: 220 V 50 Hz ± 10%.• Max absorption: 15 A., cable section 4 mm 2 .• A CEE-compliant plug is recommended: 1663 SV free plug (16A/6h 2P+T CEE rules).• Wall-type switch dedicated to the machine is recommended.MPEEMPEPRotary StageRenishaw PH107th AxisManual FixturesTouch Probe SoftwareReverse EngineeringSoftwareInspection SoftwareADRS 150 high accuracy rotary stage2-axis Renishaw PH10T or PH10MLDI automated flip fixtureManual flip fixture and extra framesOpenDMIS touch probe softwareGeomagic Studio, Polyworks/Modeler, orRapidform XORGeomagic Qualify, Polyworks/Inspector, orRapidform XOVChoose from the various system options shown below:Renishaw PH10Add 2 axes ofprogrammablehead motion<strong>Laser</strong> ProbesSelect from ourentire line of SLPlaser probesAutomated FlipFixtureChoose an integratedADRS rotary for fullyautomated scanning.Add an automatedflip fixture to holdparts, allowing foreasy part flipping anddata matching.Other recommendations:• Avoid connections near or in common with large-usage equipment (engines, compressors, etc.) that cause strong voltagedrops when started.• Avoid multiple connection points (for example between several machine tools or with several computers).• Do not use multiple sockets, shoddy sockets, or sockets not in conformity with CEE rules.• Always provide grounded sockets.COMPRESSED AIR NETWORK SPECIFICATIONSDew point drying set to at least 3°C and oil separation set: 0.01 parts per million of oil. Required pressure: 6 bar ± 0.5 bar.Rate of flow: 300 Nl./min.LASER DESIGN ACCEPTS NO RESPONSIBILITY FOR DAMAGES OR ACCIDENTS TO PEOPLE, THINGS, ETC. CAUSEDBY NON-OBSERVANCE OF ABOVE REQUIREMENTS.laserdesign.com • 952-884-9648 • info@laserdesign.com

ABOUT LASER DESIGN INC.<strong>Laser</strong> <strong>Design</strong>’s Surveyor line of automated and portable scanning systems are ideal for applicationsinvolving inspection and reverse engineering of complex-shaped parts of virtually any size, color,complexity, or material. The company’s patented laser-line probe technology dramatically reducesscanning time by collecting data substantially faster than conventional metrology methods.<strong>Laser</strong> <strong>Design</strong> operates <strong>GKS</strong> Global Services, a service bureau division offering complete 3D laserscanning, reverse engineering, and dimensional inspection services for 30 years. <strong>Laser</strong> <strong>Design</strong> and<strong>GKS</strong> have headquarters in Georgia, Michigan, and Minnesota plus satellite offices that provideon-site services in the United States and countries around the world.9401 James Ave S., Suite 132, Minneapolis, MN 55431 USAlaserdesign.com • 952-884-9648 • info@laserdesign.com© 1987-2012 <strong>Laser</strong> <strong>Design</strong> Inc. All rights reserved. Specifications subject to machine installation by authorized LDI technician only.