Radial Stiffness of Secugrid - Global Synthetics

Radial Stiffness of Secugrid - Global Synthetics

Radial Stiffness of Secugrid - Global Synthetics

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

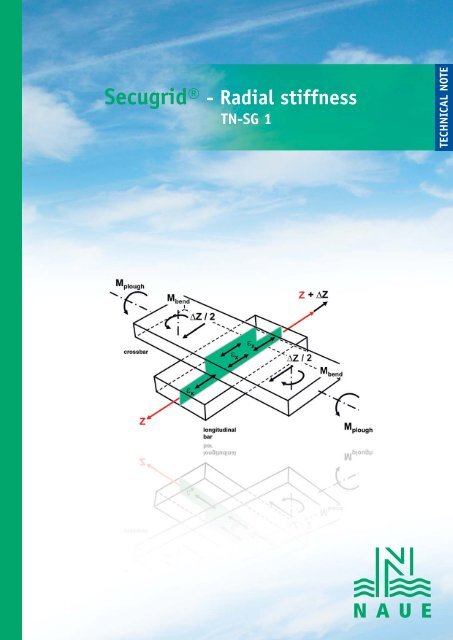

<strong>Secugrid</strong>® - <strong>Radial</strong> stiffnessTN-SG 1TECHNICAL NOTE

Figure 1Shear interactionbetween baseaggregate and<strong>Secugrid</strong>® geogridLoad distribution in geogrid reinforced base coursesThe use <strong>of</strong> geogrids to reinforce s<strong>of</strong>t or compressiblefoundation soils for unpaved aggregateroads is one <strong>of</strong> the major application areas forgeogrids. Traffic loads which are applied to aggregateroad surfaces create lateral movementsinside the base aggregate. When a geogrid is installedbetween the subgrade and the base aggregate,shear interaction develops (Figure 1). This shearinteraction is also known as the "interlocking effect".The interlocking effect restrains the aggregate laterally(Figure 2) and transmits tensile forces from the aggregateto the geogrid. As the geogrid is much stiffer intension than the base aggregate, lateral stresses andstrains in the reinforced base aggregate are reduced andless vertical deformation (rut depth) in the road surfacecan be expected.<strong>Secugrid</strong>® - <strong>Radial</strong> stiffness · TN-SG 1Figure 2Efficiency <strong>of</strong><strong>Secugrid</strong>®geogridsThe interaction betweengeogrid and base aggregateincreases the elasticmodulus and thus thestiffness or load distributioncapacity <strong>of</strong> thebase course. This correlationenables the reduction<strong>of</strong> reinforced aggregatethicknesses in comparisonto un-reinforcedaggregate layers (Figure 3)or longer service lives <strong>of</strong>the reinforced sectionwith comparable basecourse thicknesses.2

Figure 3Increase <strong>of</strong> loaddistribution anglewith geogrids(Giroud et al. 1984)<strong>Secugrid</strong>® - <strong>Radial</strong> stiffness · TN-SG 1Stresses from traffic loads, which are transferred to thebase aggregate, lead to an outward motion <strong>of</strong> the aggregatefrom the wheel, mainly in the direction <strong>of</strong> thetraffic flow and perpendicular to it. Due to the shear interaction(interlocking) that is generated between thebase aggregate and the reinforcement, the geogrid ismainly stressed in longitudinal and transverse directions.This key reinforcement characteristic <strong>of</strong> a geogrid is alsoknown as the "tensile modulus" or "secant stiffness".Biaxial load distribution typically takes place where thetraffic flow is guided in defined directions across the installedgeogrid reinforcement, such as in roads and railwayapplications (Figure 4, bottom).In applications where a defined direction <strong>of</strong> traffic flowdoes not exist, such as in large traffic areas like parkinglots and container terminals (Figure 4, right), thegeogrid reinforcement might also be stressed diagonallyto the longitudinal and transverse (biaxial) direction.Regardless <strong>of</strong> which <strong>of</strong> these two different stress conditionsbecomes decisive, one <strong>of</strong> the main reinforcementfactors is the ability <strong>of</strong> the geogrid to absorb the mobilisedstresses at potentially low deformations.Figure 4Potential stressdirections ingeogrid reinforcementlayers3

Evaluation <strong>of</strong> geogrid stiffnessTo examine the tensile modulus or secant stiffnessvalues <strong>of</strong> <strong>Secugrid</strong>® geogrids in the conventionalbiaxial directions as well as diagonally to the longitudinaland transverse direction, tensile tests accordingto EN ISO 10319 have been carried out at tBU Institutfür textile Bau- und Umwelttechnik, Greven (Germany)that determined the radial geogrid stiffness at verylow deformations <strong>of</strong> 0.5% (Figure 5).Figure 5<strong>Radial</strong> Secant <strong>Stiffness</strong><strong>of</strong> <strong>Secugrid</strong>® geogridsat 0.5% elongation<strong>Secugrid</strong>® - <strong>Radial</strong> stiffness · TN-SG 1The test results show extremely high secant stiffnessvalues <strong>of</strong> ≥ 1,500 kN/m for <strong>Secugrid</strong>® 30/30 Q1and values <strong>of</strong> ≥ 2,000 kN/m for <strong>Secugrid</strong>® 30/30 Q6 inboth biaxial directions. Importantly, high secant stiffnessvalues <strong>of</strong> ≥ 592 kN/m for <strong>Secugrid</strong>® 30/30 Q1and ≥ 828 kN/m for <strong>Secugrid</strong>® 30/30 Q6 have alsobeen achieved diagonally to the longitudinal andtransverse directions.as for a multidirectional extruded polypropylene/PPgeogrid with triangular apertures. All test results <strong>of</strong> themeasured radial secant stiffness values at 0.5% strainfor the tested geogrids are shown in Figure 6. Thevalues show that the tested <strong>Secugrid</strong>® geogrids providethe highest radial stiffness values <strong>of</strong> all materials tested.To be able to compare the performance <strong>of</strong> <strong>Secugrid</strong>®geogrids to other reinforcement products, the same testswere carried out for woven and knitted geogrids as wellFigure 6<strong>Radial</strong> Secant<strong>Stiffness</strong> <strong>of</strong>different geogridsat 0.5% elongation4

In Table 1 the minimum <strong>Radial</strong> Secant <strong>Stiffness</strong> valuesat 0.5% elongation <strong>of</strong> the examined geogrids aresummarized:Geogrid<strong>Secugrid</strong>® 20/20 Q1 (PP)<strong>Secugrid</strong>® 30/30 Q6 (PP)<strong>Secugrid</strong>® 30/30 Q1 (PP)<strong>Radial</strong> <strong>Stiffness</strong> J0.5% [kN/m]≥ 494≥ 828≥ 592<strong>Secugrid</strong>® - <strong>Radial</strong> stiffness · TN-SG 1<strong>Secugrid</strong>® 40/40 Q1 (PP)≥ 802Knitted multifilament geogrid (PP)≥ 394Woven multifilament geogrid (PET)≥ 344Extruded biaxial geogrid (PP)Extruded multidirectional geogrid (PP) –Type 160*≥ 550UK datasheetUS datasheet≥ 505 ≥ 300Extruded multidirectional geogrid (PP) –Type 170** according to manufacturer’s product information≥ 580 ≥ 475Table 1Secant stiffnessvalues J 0.5% <strong>of</strong>different geogridsBased on the special manufacturing technique for <strong>Secugrid</strong>®geogrids, the flat, welded, pre-stressed polymerbars provide the desired high tensile modulus values(high tensile forces are absorbed at low strain levels)in longitudinal, transverse and diagonal directions,especially at the typically low strain rates which developinside geogrid reinforced aggregate base courses.NAUE GmbH & Co. KGGewerbestrasse 232339 Espelkamp-FiestelGermanyPhone +49 5743 41-0Fax +49 5743 41-240E-Mail info@naue.comInternet www.naue.comMemberships <strong>of</strong> the NAUE GroupMemberMember Member Member Member Member Member MemberMemberBent<strong>of</strong>ix® BFG 5000<strong>Secugrid</strong>® Q6 and R6MemberMemberMemberMemberMemberMember Member Member MemberMember®and <strong>Secugrid</strong>® are registered trademarks <strong>of</strong> NAUE GmbH & Co. KG.The information contained herein is to the best <strong>of</strong> our knowledge, true and accurate. There is no implied or expressed warranty.© 2010 by NAUE GmbH & Co. KG, Espelkamp-Fiestel, Germany · All rights reserved. · TN-SG 1 · Status 08.12.2010 · *Patent No.: 6,572,718 B25