LOCTITE 242

LOCTITE 242

LOCTITE 242

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

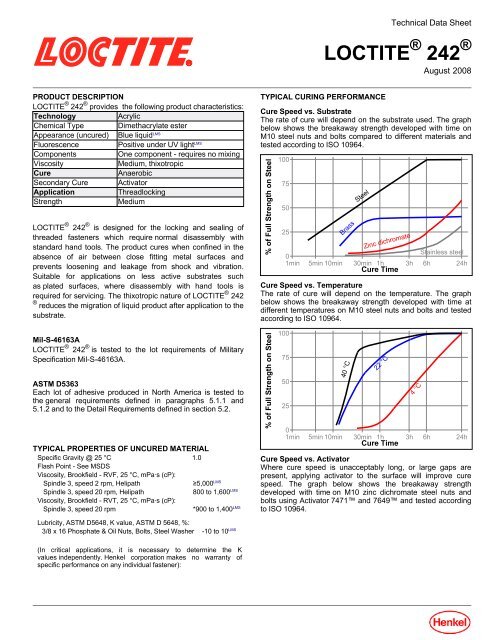

Technical Data Sheet<strong>LOCTITE</strong> ® <strong>242</strong> ®August-2008PRODUCT DESCRIPTION<strong>LOCTITE</strong> ® <strong>242</strong> ® provides the following product characteristics:TechnologyAcrylicChemical Type Dimethacrylate esterAppearance (uncured) Blue liquid LMSFluorescencePositive under UV light LMSComponentsOne component - requires no mixingViscosityMedium, thixotropicCureAnaerobicSecondary Cure ActivatorApplicationThreadlockingStrengthMedium<strong>LOCTITE</strong> ® <strong>242</strong> ® is designed for the locking and sealing ofthreaded fasteners which require normal disassembly withstandard hand tools. The product cures when confined in theabsence of air between close fitting metal surfaces andprevents loosening and leakage from shock and vibration.Suitable for applications on less active substrates suchas plated surfaces, where disassembly with hand tools isrequired for servicing. The thixotropic nature of <strong>LOCTITE</strong> ® <strong>242</strong>® reduces the migration of liquid product after application to thesubstrate.Mil-S-46163A<strong>LOCTITE</strong> ® <strong>242</strong> ® is tested to the lot requirements of MilitarySpecification Mil-S-46163A.ASTM D5363Each lot of adhesive produced in North America is tested tothe general requirements defined in paragraphs 5.1.1 and5.1.2 and to the Detail Requirements defined in section 5.2.TYPICAL PROPERTIES OF UNCURED MATERIALSpecific Gravity @ 25 °C 1.0Flash Point - See MSDSViscosity, Brookfield - RVF, 25 °C, mPa·s (cP):Spindle 3, speed 2 rpm, Helipath≥5,000 LMSSpindle 3, speed 20 rpm, Helipath800 to 1,600 LMSViscosity, Brookfield - RVT, 25 °C, mPa·s (cP):Spindle 3, speed 20 rpm*900 to 1,400 LMSLubricity, ASTM D5648, K value, ASTM D 5648, %:3/8 x 16 Phosphate & Oil Nuts, Bolts, Steel Washer -10 to 10 LMSTYPICAL CURING PERFORMANCECure Speed vs. SubstrateThe rate of cure will depend on the substrate used. The graphbelow shows the breakaway strength developed with time onM10 steel nuts and bolts compared to different materials andtested according to ISO 10964.% of Full Strength on Steel100755025BrassSteelZinc dichromateStainless steel01min 5min 10min 30min 1h 3h 6h 24hCure TimeCure Speed vs. TemperatureThe rate of cure will depend on the temperature. The graphbelow shows the breakaway strength developed with time atdifferent temperatures on M10 steel nuts and bolts and testedaccording to ISO 10964.% of Full Strength on Steel10075502540 °C22 °C01min 5min 10min 30min 1h 3h 6h 24hCure TimeCure Speed vs. ActivatorWhere cure speed is unacceptably long, or large gaps arepresent, applying activator to the surface will improve curespeed. The graph below shows the breakaway strengthdeveloped with time on M10 zinc dichromate steel nuts andbolts using Activator 7471 and 7649 and tested accordingto ISO 10964.4 °C(In critical applications, it is necessary to determine the Kvalues independently. Henkel corporation makes no warranty ofspecific performance on any individual fastener):

TDS <strong>LOCTITE</strong> ® <strong>242</strong> ® , August-2008% of Full Strength on Steel100755025Activator 764901min 5min 10min 30min 1h 3h 6h 24hCure TimeActivator 7471No activatorTYPICAL PERFORMANCE OF CURED MATERIALAdhesive PropertiesAfter 1 hour @ 22 °CBreakaway Torque, ISO 10964:3/8 x 16 steel nuts (grade2) and bolts (grade 5)Prevail Torque, ISO 10964:3/8 x 16 steel nuts (grade2) and bolts (grade 5)N·m 5.6 to 17 LMS(lb.in.) (50 to 150)N·m 1.7 to 6.8 LMS(lb.in.) (15 to 60)After 24 hours @ 22 °CBreakaway Torque, ISO 10964:3/8 x 16 steel nuts (grade N·m 7.9 to 17 LMS2) and bolts (grade 5)(lb.in.) (70 to 150)3/8 x 16 cadmium nuts and bolts N·m 1.1 to 6.8 LMS(lb.in.) (10 to 60)3/8 x 16 zinc nuts and bolts N·m 2.3 to 6.8 LMS(lb.in.) (20 to 60)M10 black oxide steel N·m *8 to 19 LMSnuts and bolts(lb.in.) (71 to 168)Prevail Torque, ISO 10964:3/8 x 16 steel nuts (grade N·m 2.8 to 6.8 LMS2) and bolts (grade 5)(lb.in.) (25 to 60)3/8 x 16 cadmium nuts and bolts N·m 0.5 to 4.5 LMS(lb.in.) (4 to 40)3/8 x 16 zinc nuts and bolts N·m 1.1 to 4.5 LMS(lb.in.) (10 to 40)TYPICAL ENVIRONMENTAL RESISTANCECured for 24 hours @ 22 °CBreakloose Torque, ISO 10964:M10 steel nuts and boltsHot StrengthTested at temperature100% Strength @ 22 °C75502500 100 120 150Temperature, °CHeat AgingAged at temperature indicated and tested @ 22 °C% Initial Strength @ 22 °C125100755025100 °C120 °C00 100 500 1000 3000 5000Exposure Time, hours150 °CChemical/Solvent ResistanceAged under conditions indicated and tested @ 22 °C.% of initial strengthEnvironment °C 100 h 500 h 1000 hMotor oil (MIL-L-46152) 125 100 100 100Unleaded gasoline 22 100 100 95Leaded Gasoline I 22 100 100 100Brake fluid 22 100 100 100Ethanol 22 100 100 95Acetone 22 100 100 851,1,1 Trichloroethane 22 100 100 90Water/glycol 50/50 87 80 75 70GENERAL INFORMATIONThis product is not recommended for use in pure oxygenand/or oxygen rich systems and should not be selected asa sealant for chlorine or other strong oxidizing materialsFor safe handling information on this product, consult theMaterial Safety Data Sheet (MSDS).Where aqueous washing systems are used to clean thesurfaces before bonding, it is important to check forcompatibility of the washing solution with the adhesive. Insome cases these aqueous washes can affect the cure andperformance of the adhesive.This product is not normally recommended for use on plastics(particularly thermoplastic materials where stress cracking ofthe plastic could result). Users are recommended to confirmcompatibility of the product with such substrates.Directions for use:For Assembly1. For best results, clean all surfaces (external and internal)with a <strong>LOCTITE</strong> ® cleaning solvent and allow to dry.2. If the material is an inactive metal or the cure speed is tooslow, spray all threads with and allow to dry.3. Shake the product thoroughly before use.4. To prevent the product from clogging in the nozzle, do notallow the tip to touch metal surfaces during application.5. For Thru Holes, apply several drops of the product ontothe bolt at the nut engagement area.6. For Blind Holes, apply several drops of the product downthe internal threads to the bottom of the hole.Henkel Americas+860.571.5100Henkel Europe+49.89.320800.1800Henkel Asia Pacific+86.21.2891.8863For the most direct access to local sales and technical support visit: www.henkel.com/industrial

TDS <strong>LOCTITE</strong> ® <strong>242</strong> ® , August-20087. For Sealing Applications, apply a 360° bead of productto the leading threads of the male fitting, leaving the firstthread free. Force the material into the threads tothouroughly fill the voids. For bigger threads and voids,adjust product amount accordingly and apply a 360° beadof product on the female threads also.8. Assemble and tighten as required.For Disassembly1. Remove with standard hand tools.2. In rare instances where hand tools do not work becauseof excessive engagement length, apply localized heat tonut or bolt to approximately 250 °C. Disassemble whilehot.For Cleanup1. Cured product can be removed with a combination ofsoaking in a Loctite solvent and mechanical abrasionsuch as a wire brush.Loctite Material Specification LMSLMS dated October-16, 1995 (*October 7, 1999). Test reportsfor each batch are available for the indicated properties. LMStest reports include selected QC test parameters consideredappropriate to specifications for customer use. Additionally,comprehensive controls are in place to assure product qualityand consistency. Special customer specification requirementsmay be coordinated through Henkel Quality.StorageStore product in the unopened container in a dry location.Storage information may be indicated on the product containerlabeling.Optimal Storage: 8 °C to 21 °C. Storage below 8 °C orgreater than 28 °C can adversely affect product properties.Material removed from containers may be contaminated duringuse. Do not return product to the original container. HenkelCorporation cannot assume responsibility for product whichhas been contaminated or stored under conditions other thanthose previously indicated. If additional information is required,please contact your local Technical Service Center orCustomer Service Representative.Conversions(°C x 1.8) + 32 = °FkV/mm x 25.4 = V/milmm / 25.4 = inchesµm / 25.4 = milN x 0.225 = lbN/mm x 5.71 = lb/inN/mm² x 145 = psiMPa x 145 = psiN·m x 8.851 = lb·inN·m x 0.738 = lb·ftN·mm x 0.142 = oz·inmPa·s = cPNoteThe data contained herein are furnished for information onlyand are believed to be reliable. We cannot assumeresponsibility for the results obtained by others over whosemethods we have no control. It is the user's responsibility todetermine suitability for the user's purpose of any productionmethods mentioned herein and to adopt such precautions asmay be advisable for the protection of property and of personsagainst any hazards that may be involved in the handling anduse thereof. In light of the foregoing, Henkel Corporationspecifically disclaims all warranties expressed or implied,including warranties of merchantability or fitness for aparticular purpose, arising from sale or use of HenkelCorporation’s products. Henkel Corporation specificallydisclaims any liability for consequential or incidentaldamages of any kind, including lost profits. The discussionherein of various processes or compositions is not to beinterpreted as representation that they are free fromdomination of patents owned by others or as a license underany Henkel Corporation patents that may cover suchprocesses or compositions. We recommend that eachprospective user test his proposed application before repetitiveuse, using this data as a guide. This product may be coveredby one or more United States or foreign patents or patentapplications.Trademark usageExcept as otherwise noted, all trademarks in this documentare trademarks of Henkel Corporation in the U.S. andelsewhere.® denotes a trademark registered in the U.S.Patent and Trademark Office.Reference 1.2Henkel Americas+860.571.5100Henkel Europe+49.89.320800.1800Henkel Asia Pacific+86.21.2891.8863For the most direct access to local sales and technical support visit: www.henkel.com/industrial