PDF - Monotech

PDF - Monotech

PDF - Monotech

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

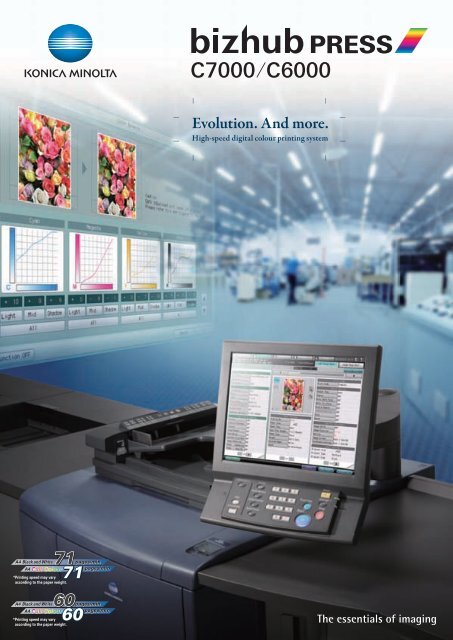

Full colour, on-demand printing systemOne comprehensive system.A total printing solution.Successful digital colour print production requires efficiency, reliability andsuperb results. Introducing new bizhub PRESS C7000/C6000, a scalabledigital printing system that offers versatile media handling, professionalfinishing and simplified workflow integration. A cost effective solution wellsuited to a wide variety of printing operations that demand the best.bizhub PRESS creates new values forprinting businesses by providinginnovations through high-leveltechnologies and a new workflow indigital printing based on high qualityproducts and services that offer highvalue-added total solutions.

Remarkably highimage qualityExceptional modularity,excellent versatilityUnmatched reliabilityfor maximum uptimeFrom start to finish, consistentquality for professional resultsSuperb image quality rivals offset printing.The IDC sensor and new colour controlensure consistent results through theentire print run.Versatile and scalable forany on-demand printing requirementA choice of image controllers and inlinefinishing options (including perfect binding)let you customise the system dependingon requirements.Excellent usability andreliability for peerless efficiencyHighly cost efficient, the system achievessmoother performance with enhanceddurability, long-life consumables and shorterstartup time.

From start to finish, consistent qualityfor professional resultsAdvanced screen technology and 1,200 dpi resolutionproduce crisp text and vivid, smoothly gradatedphotos that are nearly indistinguishable from offsetoutput. From the first page to the last, your print jobswill have a slick, professional look.Stable continuous printing of documents up to 5,000 pages longAdjustment of colour densityand halftonesNew precision IDC sensor for more stable outputKeys to stable, high-quality results are consistent CMYK density andhalftone dot diameters. To maintain optimal settings of both, sensorson the intermediate transfer belt monitor control patches andfeedback on colour density and halftones. By receiving feedback oncolour density and halftone dots, the system can automatically makeadjustments for more stable output.Beautiful gradations that match paper typeEffortless colour density controlIncorporating new colour density control, bizhub PRESS C7000/C6000automatically adjusts gradation depending on paper. A density sensorin the optional RU-509 Relay Unit reads colour patches printed onpaper and relays gamma adjustments to the print engine. Additionally,correction values of up to 15 pre-registered paper types can be appliedto achieve proper gradation for the paper being used. This eliminatesthe need to manually adjust colour density when changing media, acommon time-consuming task.Intermediate transfer beltBelt directionSensor is included in the relay unit (RU-509)SensorIDC sensorPatchDrumBelt direction2nd transfer rollerPaper flow directionEnhanced calibration over the print surfaceImproved density balance adjustmentAdditional density control is provided by a new density balanceadjustment function. A colour chart is printed and read with aspectrophotometer*. Results are then uploaded to the main unit via USBmemory device and stored, significantly improving operation efficiencyduring registration and setup to achieve excellent consistency. And formore precise density balance control, bizhub PRESS C7000/C6000includes a 256-step fine adjustment function and a 32-division densityadjustment width.* Calibration via X-rite Series spectrophotometer (X-rite i1iSis XL or X-rite i1) is available from your localsales representative. Not available in all areas.iliSis XLi1 Pro

Razor-sharp text and breathtaking photos with nearly offset qualityA new level of image quality and definitionS.E.A.D. IICombining leading-edge digital imageprocessing technologies, S.E.A.D. II(Screen-Enhancing Active Digital Process)realises superlative tonal gradations, colourconsistency and text clarity. S.E.A.D. IIfeatures 1,200 dpi 8-bit data processing forhigh precision, dot position control whichsegments each dot into 256 parts andKonica Minolta’s original image stabilisingsystem — all working in tandem to deliveroffset-like quality.High definition polymerised tonerKonica Minolta’s Simitri HDCompared with pulverised toner, Simitri HD toner particles are extremelysmall with a consistent shape and size. This makes for brilliant, lustrouscolour images and razor-sharp text and line drawings. The low fusingtemperature of Simitri HD reduces heat load during printing, deliveringsuperior reproduction on a widerange of papers (including thickstock) and saving on energyconsumption.Pulverised tonerdot line textHigh resolution printingTrue 1,200 dpi x 8-bit resolution colour outputThe impressive resolution, made possible by 8-bit multi-layer dataprocessing and an aluminium die-cast laser unit, reveals all the minutedetails of original data, eliminating the need for offset printing for nearlyany print job. Additionally, bizhub PRESS C7000/C6000 provideshigh-production printouts of RIP-data at 3,600 dpi (equivalent) x 1,200dpi resolution.Outline processing for excellent readabilityThe 1,200 dpi resolution also results in optimised outline processing forbetter reproduction of small text and fine lines as well as jagged-freetext and graphics. Outline processing improves the appearance ofcharacters by thinning them, reducing blur of white characters andimproving contouring.Critical alignment for double-side documentsSuperior back-to-front registrationThe highly accurate back-to-front registration of bizhub PRESSC7000/C6000 allows production of high-quality booklets andbrochures. Front edge and skew sensors closely monitor paper positionand alignment shift during printing. Any misalignment detected can beprecisely corrected via the control panel.• Print positioning can be preciselycontrolled with image shift (in steps of 0.1 mm)• Front/back/vertical/horizontalindividual scale changes (in steps of 0.01%)Simitri HD tonerdot line textBack pageFront pageHigher fade resistance than offset inkProprietary Simitri HD tonerprevents fading and peeling fordocuments that retain theirbeauty and texture even instorage. The toner containsstrong-bonding colour pigmentthat is highly resistant tochemical changes and canwithstand extended exposureto UV light, making it morefade resistant than ink used inoffset printing.Offset printingSimitri HD toner resists fading forlong-lasting quality.Highly accuratefront/back registration

Impressive performance,intuitive managementA choice of controllers lets you configure thesystem to perfectly match your productionrequirements. Combined with an easy-to-useinterface, you are assured a fast, efficient andoperator-friendly workflow.Excellent multi-purpose performanceKonica Minolta IC-601 Image controller (option; embedded)The new Konica Minolta IC-601 Print Controller offers powerful workflow features including 1,200 dpi printing at speeds up to 71 ppm (A4), fast RIPprocessing/transfer between the controller and print engine as well as improved CMYK accuracy. There are also new colour management functions, improvedjob control, a full complement of editing functions and remote operation capability. The IC-601 supports Postscript, <strong>PDF</strong>1.7 and XPS and other PDLs.Color Centro - Powerful colour managementKonica Minolta’s proprietary colour management utility boasts a highly functionalprofiler with editing functions and support for spot colour. This software is idealfor both advanced and entry-level users.CalibrationCreate and manage calibration tables based onresults obtained from optional spectrometers.Tone curve adjustmentAdjust tone curve while checking a preview ofsample images. Adjusted tone curves can beexported, registered in the controller and/orcomputer, and chosen from the printer driver,allowing easy fine-tuning during any job.Spot colour managementUse the default spot colour table or customiseand register a new one. The ability to makesubtle changes to the default table realises moreprecise reproduction of spot colours in datacreated by any application, including thoseincapable of specifying spot colour.As profile sets areselectable based on thetype of paper used,subtle adjustment ofimage quality is possible.Use the default spotcolour table orcustomised table toreproduce precisespot colours.Profile managementHigh-level production environments benefitgreatly from the ability to register and manageup to five types of profiles with 50 detailedsettings (5 x 50). Color Centro enablesconsolidation of multiple profiles and coloursettings as Profile Sets that can be associatedwith paper types. With colour configurationsthat include multiple Profile Sets, variouscomplex settings can easily be centrallymanaged and optimal colour settings for variousjobs can be achieved with ease and efficiency.RGB source profileCMYK target profilePrinter profileRGB-CMYK device link profileCMYK-CMYK device link profile5-level settings areprovided for UCR/GCR.The pure black functionallows K100% printout.Point colour adjustment functions allowsubtle adjustment of specific coloursfrom colour conversion profiles.Individual profiles can be made forimages, graphics and textregardless of CMYK or RGB mode.

PS Standard printer driver and A3 paper capability487mmFeaturing a feature-rich and intuitive GUI, this driver provides excellent outputand layout control. It lets you manage the entire process, including settingimage quality for different types of paper and selecting print modes. The driveralso supports A3+ paper and crop marks. A maximum paper size of 330mm x487mm allows the creation of two-up A4-size spreads with crop marks andfull-bleed printing.330mmA4A415-inch touch-panel LCD facilitates workflow managementThe bright colour touch-panel LCD and control panel let you easily manage operationsand monitor progress. Help messages are conveniently displayed on the LCD,providing simple instructions to guide you through every step in the productionprocess, from paper selection and colour configuration to finishing. Printing jobmanagement from the control panel enables you to make colour adjustments andpagination changes for RIP-completed jobs. Currently printing jobs and reserved jobscan be displayed for scheduling, and settings can be changed from the control panel.World-renowned flexibility and ease-of-useEFI Fiery IC-306 image controller (option; external)IC-306 Fiery ® Image Controller combines theupgraded functionality of Fiery System 9 andFiery Driver 4.0 for Windows and Mac.Designed to handle a diverse range ofrequirements, this popular external printserver boasts a rich feature set, includingCommand WorkStation 5 and itssophisticated colour management tools.Variable data printing (VDP) for the business edgeCreate timely and targeted marketing collateral for your customerswith VDP, the ideal tool for customer relationship management anddirect mail. Each printed piece can be customised during the print runby automatically adding names, addresses and other data. OptionalSeeQuence Suiteextends VDP capabilityby allowing you toimpose, compose andpreview print runs withone simple procedure.Direct mailContent can be customised to suit each recipient’s taste andpurchasing habits, including changes to page imposition.Leaflets and flyersShop names, logos, special sales and business hours can beautomatically changed during print run.Tickets and couponsChanging event and merchandise descriptions including price, date,time and numbering is easy to do.

Exceptional modularity forflexible scalabilityThe total digital printing solution designed to growas your business grows. A wide variety ofeasy-to-install modules are available, allowing you totailor bizhub PRESS C7000/C6000 to createthe right system for any production application.Customise to fit your needsWide array of inline finishersSelect from a wide range of modular units for high-speed, high-quality inline printing, processing and finishing. Flexible inline finishing optionsminimise labour and costly mistakes during complex jobs, including stapling, punching, folding, creating booklets and perfect binding. Theeasily configured modules enable you to build a right-size system for any print production environment and adapt to changing needs.Staple up to 100 sheetsFS-521 Stapling FinisherSix-way folding capabilityFD-503 Folding UnitMake 200-page bookletsSD-506 Saddle Stitcher2-pointstapling(vertical side)2-pointstapling(horizontal)Cornerstapling(vertical)Staples up to 100 sheets*of paper and has a3,000-sheet capacity.Corner and two-pointstapling capability. In-lineclinch trims long staplesfor a clean finish.Cornerstapling(horizontal)Centre-foldLetterfold-inLetterfold-outDoubleparallelTwo holes Four holesZ-foldPaperinsertionSix-way folding capability: centre-fold,letter fold-out, letter fold-in,double-parallel, gatefold and Z-fold. 2-and 4-hole punching capability withuser-selectable hole positioning. Caninsert cover sheets to separate setsof documents.GatefoldMulti-centre-fold Multi-letter-fold Saddle stitch TrimmingStitches up to 50 sheets*of paper to makeface-trimmed booklets upto 200 pages long withprecisely aligned edges.Default trimming functionproduces small, clean booklets. Includes multicentre- and multi letter-folding function for upto 5 sheets*.Perfect binding ofup to 600 pagesPB-503 Perfect Binder10 A4-size punch patternsGP-501 Multi PunchGeneral purpose multi-functionalityFS-531 Stapling Finisher/FS-612 Stapling and Saddle Stitching FinisherA4-size punch patterns10 different configurationsNote: The die set is required andsold separately.Stapling Centre-fold Saddle stitchLetter fold-inPerfect binderBinds up to 300 sheets* ofpaper or paper stacks less than30 mm thick. Includes in-linegluing function and paperalignment technology thateliminates the need forthree-way trimming.Interchangeable die setprovides 10 differenthole-punchingconfigurations forA4-size paper.(Not available in all areas.)Two holes 1Four holes 1Paperinsertion 2Staples up to 50 sheets* of paper.Compact units can be expanded withoptional PK-512 Punch Kit and/orPI-502 Post Inserter. FS-612 hascentre and letter folding capability andsaddle stitches up to 20 sheets* tomake 80-page booklets. Ideal forproducing marketing collateral andcorporate documents.1With PK-5122With PI-502FS-531FS-612Note: The number of punch holes may vary depending on the market.* 80g/m 2 paper

High speed for increased productivityFast 71 ppm (C7000) and 60 ppm (C6000) printing*The ultra high-speed colour output capability of bizhub PRESSC7000/C6000 makes short work of even long, double-sided documents.From simple leaflets to multi-page booklets, you’ll be assured of fastprint speeds for a more efficient workflow.* A4-size, single-sidedHigh capacity for long print runsMax. 7,500 sheets in less timePF-602 Paper Feed CabinetMinimise downtime spent reloading paper with high-capacity papertrays and optional paper feeders. The main unit comes equipped withthree 500-sheet paper trays for a total of 1,500 sheets. Papercapacity can be increased to 7,500 sheets with the optional two-trayPF-602 Paper Feed Cabinet.* Switching to a different paper source isperformed automatically if the same size paper has been loaded in analternate tray.* 80g/m 2 paper; ejectedBoost to 4,250-sheet paper capacityLU-202 Large Capacity UnitCompact, yet featuring a high-volume capacity, the optional LU-202Large Capacity Unit holds up to 2,500 sheets. When combined withthe optional 250-sheet MB-504 Multi-bypass Tray and 1,500-sheetmain unit, the total capacity becomes 4,250 sheets.Stack up to 10,000 sheetsLS-505 Large Capacity StackersEquipped with two optional LS-505Large Capacity Stackers, each with5,000-sheet capacity, bizhub PRESSC7000/C6000 can stack up to 10,000sheets* of output. Each stackerincludes a dolly for easy transport offinished documents from the work area.* 80g/m 2 paper; ejectedMain Unit500 sheets x 3 traysRU-509 relay unitThe new colour density sensor provides effortless colour densitycontrol and is compatible with two types of optional curl correctionmechanisms. Also with relay unit for connecting paperejection–related finishing option.PF-602 Paper Feed Cabinet3,000 sheets x 2 trays

Robust reliability,maximum uptimePrecise, dependable operation you can count on, jobafter job. Built to withstand the rigours ofhigh-volume use, the assured reliability of bizhubPRESS C7000/C6000 delivers increased uptime,a must for busy printing businesses.Long-life consumablesfor better uptimeLong-life consumables increaseuptime, allowing long print runs withvastly decreased interruptions.Lifecycles of the drum, developingunit and intermediate transfer unithave been appreciably extended.Toner cartridges are shaped formaximum yield and have greatercapacity than those of previousmodels. Cartridges can even bereplaced on the fly without stoppingthe print run. Other user-replaceableparts ensure long-lasting operationand peace of mind.Highly rigid frame bodybizhub PRESS C7000/C6000 utilises a highly rigid frame and box-typedouble-layered chassis to achieve excellent durability even underheavy, continuous usage. The rigid frame body helps prevent vibrationand twisting for steady performance.Toner bottlesRigid frame bodyEasy paper loading and general maintenanceO.R.U.M. (Operator Replaceable Unit Management)*Less time spent waiting for a service representative should problemsarise translates into greater productivity for your business. KonicaMinolta’s O.R.U.M. further maximises system uptime by offering a rangeof user-replaceable parts and preventative maintenance measures thatcan be performed in-house. Moreover, front-access simplifiesmaintenance procedures.* Not available in all areas.Developing unit

Smoother feeding, even with coated paperAir-assisted paper feedingThe optional PF-602 Paper Feed Cabinet and LU-202 Large CapacityUnit are equipped with an air-assisted paper feed mechanism. Thisdramatically reduces mis-feeds by blowing air at constantly changingforce and frequency, effectively separating sheets before they are fedinto the printer — even coated paper in humid conditions when using theoptional HT-503 or HT-504 Dehumidifying Heater. Air flow isautomatically applied when printing on coated stock.Greatly reduce paper curlHybrid decurlingTwo different types of curl correction are available to prevent paper wavingor warping.The optional RU-509 Relay Unit employs a mechanical decurlersuitable for both coated and uncoated papers. Decurl strength isadjustable over five steps and in both directions. The optional HM-102 ICE(Inter-cooler Curl Eliminator) humidifies the paper passage to removeunwanted static electricity and heat from the paper. This reduces thecurling and clinging of paper to realise highly accurate paper delivery.Air-assisted paper mechanismOptional RU-509Mechanical decurler– exit sectionHT-504 Dehumidifying HeaterMechanical decurler– input sectionExcellent paper handling,extensive profilingSupport for a wide variety ofpaper sizes from postcard toA3-wide expands printingpossibilities. The main unitcan handle paper from64g/m 2 to 300 g/m 2 . Inaddition, bizhub PRESSC7000/C6000 can storeprofiles on up to 500 kinds ofpaper that can be recalled as needed, eliminating time-consumingmanual setting operations.Optional HM-102FanWater supplyrollerWaterHumidifyingrollerFanWater* PF-602 Paper Feed Cabinet, LU-202 Large Capacity Unit and Multi-bypass TrayReduce occurrence of blank pagesMulti-feed detection sensorsClear jams fastImproved paper jam controlUltrasonic sensors built into the optional PF-602 detect multi-feeding ofpaper by comparing ultrasonic waves reflecting off the paper. If multi-feedingdoes occur, the C7000 series automatically stops printing. This greatlyreduces printing errors caused by blank pages being mixed in with the output.Jammed paper can be stopped at specific locations for easy removalthanks to an improved paper jam detection mechanism. The position ofthe jam appears on the display, allowing fast hassle-free removal of paper.Sensor detects multi-feed whenultrasonic waves are reflected by the extra sheet.

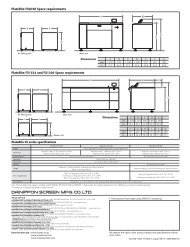

izhub PRESS C7000/C6000 General SpecificationsModel NameTypeColour SupportResolutionMemoryGradationOriginal TypeMax. Original SizePaper SizeImage LossScanPrintDIMMHDDWarm-up TimeFirst Copy Time A4ColourB/WPrint Speed* 1 Colour(A4/Letter)Magnification Fixed Same MagnificationFixed EnlargementFixed ReductionPresetZoomPaper CapacityPaper Weight* 2Multiple PrintAuto DuplexPower RequirementPower ConsumptionDimensions [W] x [D] x [H]* 3Weight* 1 Printing speed may vary according to the paper weight. * 2 Main body trays: 64 to 256g/m 2* 3 Excluding control panel and output tray. Including back side duct.Print Controller SpecificationsModelTypeCPUMemoryHDDPrint SpeedPrint ResolutionPDLProtocolOperating SystemFontsInterfaceDimensionsFiery IC-306ServerCore 2 Quad Q9400 2.66 GHz2GB160GB SATASame as engine print speed1,200 (3,600 equivalent) x 1,200dpiPostScript3 CPSI3017 <strong>PDF</strong>1.7PPML VPSTCP/IP, SNMP, IPP,FTP, SMB,AppleTalk (EtherTalk),BonjourWindows 2000Windows XPWindows Server 2003Windows VistaWindows 7Windows Server 2008MacOS X 10.3.9 or laterAdobe PostScript fonts: 136 fonts10/100/1000Base-T212 x 488 x 482mm(8-1/2" x 19-1/4" x 19")*Hard Disk Kit HD-504 and Preview Kit PH-102 are necessary.bizhub PRESS C7000/C6000ConsoleFull colour600 x 600dpi1,200 (3,600 equivalent) x 1,200dpi512MB x 6160GB x 6 SATA (option)256Sheet, books, 3-dimensional objectsMax. A3 or 11”×17”SRA3, A3, B4, SRA4, A4, SRA4S 1 , A4S 1 ,B5, B5S 1 , A5S 1 , 12" x 18", 11" x 17", 8.5"x 11",irregular sizes (330 x 487 to 140 x 182mm)4mm or less for top edges, 4.5mm or less for bottom edges,3mm or less for right/left edges420 sec. or lessC7000: 7.6 sec. or less, C6000: 7.8 sec. or lessC7000: 5.9 sec. or less, C6000: 6.0 sec. or lessC7000: 71/70ppm, C6000: 60/60ppmC7000: 71/70ppm, C6000: 60/60ppm1: 1±0.5% or less1:1.154/1.224/1.414/2.000,1:0.866/0.816/0.707/0.500,3 types25 to 400% (in 0.1% increments)Standard 1,500 sheets 80 g/m 2 64 -300 g/m 21 to 9,999 sheetsStandard220 -240V 20A (50-60Hz)Less than 4.6kW760 x 992.7 x 1,075.6mm (30" x 39" x 42-1/4")353kg (778-1/2 lb.)1 S: Short edge feedIC-601*EmbeddedCore 2 Duo 2.8GHz4GB250GB x 2 SATASame as engine print speed1,200 (3,600 equivalent) x 1,200dpiPostScript3 CPSI3019 <strong>PDF</strong>1.7TIFF, PPML, PCL5c/6, XPSTCP/IP,IPX/SPX, Net BEUI,AppleTalk (EtherTalk),IPP, WSDWindows 2000Windows XPWindows Server 2003Windows VistaWindows 7Windows Server 2008MacOS X 10.3.9 or laterAdobe PostScript fonts: 136 fontsPCL 81 fonts10/100/1000Base-T412 x 114 x 402mm(16-1/4" x 4-1/2" x 16")System OptionsDF-622 AutomaticDocumentFeederRU-509Relay UnitPaper WeightPF-602 Paper Upper TrayFeeder Unit Lower TrayLS-505 Larger CapacityCapacity Paper SizesStackerFD-503Folding UnitSD-506Saddle StitcherFS-521 StapleFinisherPB-503Perfect BinderLU-202 LargeCapacity UnitFS-612 BookletFinisherFS-531 StapleFinisherCapacityPaper SizesPaper WeightsTypePaper SizePaper WeightsPunch TypesFold TypesPaper SizesPaper WeightsPaper SizesPaper WeightsMax. Sheet CuttingPaper SizesPaper WeightsCapacityStaple ModesTypePaper WeightPaper SizeBound PagesCapacityPaper SizesPaper WeightsPaper SizesPaper WeightsCapacityStaple ModesTypePaper SizePaper WeightStaple CapacityStacking CapacityStaple Modes1 S: Short edge feed50-sheet staple finisherStaple mode A3B4A4A4S 1 B5B5S 1 A5Straight mode SRA3A3B4A4A4S 1 B5B5S 1 A5A5S 1 B6S 1Sub tray mode SRA3, A3, B4, SRA4, SRA4S 1 , A4, A4S 1 , B5, B5S 1 , A5, A5S 1 , B6S 1 , A6S 1Staple mode 64-209g/Straight/shift modeSub tray mode100 sheetsB6 – A3 (128 x 139.7mm – 297 x 431.8mm)Single sided: 35 – 210g/m 2 ; double sided: 50 – 210g/m 2Conveyor unit with decurl functionSRA3, A3, B4, SRA4, SRA4S 1 , A4, A4S, B5, B5S, A5, A5S 1 , B6S 1 , A6S 1 ,wide sizes, tabs,irregular sizes (331 x 488 – 95 x 139 mm)64 – 300g/m 2 (reverse feeding: 64 – 256g/m 2 )3,000 sheets max. (B6 – SRA3, irregular sizes); 64 – 256g/m 23,000 sheets max. (Postcard – SRA3, irregular sizes); 64 – 300g/m 25,000 sheet stacker (main tray), 200 sheet (sub-tray)Straight/shift mode: SRA3, A3, B4, SRA4, SRA4S 1 , A4, A4S 1 , B5Sub-tray mode: SRA3, A3, B4, SRA4, SRA4S 1 , A4, A4S 1 , B5, B5S 1 , A5, A5S 1 , B6S 1 , A6S 1 ,wide sizes,tabs, irregular sizes (331 x 488 – 95 x 139 mm)50 – 244g/m 2 (50 – 300g/m 2 in sub-tray)2-hole punch, 4-hole punchCentre fold, letter fold-in, letter fold out, double parallel, Z-fold, gatefold2-hole punch: SRA3, A3, B4, SRA4, SRA4S 1 , A4, A4S 1 , B5, B5S 1Folding mode: A3, B4, SRA4S 1 , A4S 1Post insertion mode: SRA3, A3, B4, SRA4, SRA4S 1 , A4, A4S 1 , B5, B5S 1Straight mode: SRA3, A3, B4, SRA4, SRA4S 1 , A4, A4S 1 , B5, B5S 1 , A5, A5S 1 , B6S 1Sub tray mode: SRA3, A3, B4, SRA4, SRA4S 1 , A4, A4S 1 , B5, B5S 1 , A5, A5S 1 , B6S 1 , A6S 1Punch mode: 64 – 216g/m 2Folding mode: 64 – 130g/m 2 (Centre fold/Internal three-fold/External three-fold/Z-fold)64 – 91gm 2 (Double parallel/Gatefold)Post insertion mode: 50-300g/m 2Straight mode/Sub tray mode: 64-300g/m 2Saddle stitching/trimming/multi-centre fold: SRA3,A3, B4, SRA4S 1 , A4S 1 , B5S 1Multi-letter fold: A4S 1Sub-tray: SRA3, A3, B4,SRA4, SRA4S 1 , A4, A4S, B5, B5S 1 , A5, A5S 1 , B6S 1 , A6S 1 , Postcard, irregular sizes, tabsSaddle stitching & trimming: 50 – 244g/m 2Multi-centre fold: 50 – 244g/m 2 Multi-letter fold: 50 – 91g/m 2 Sub-tray: 50 – 300g/m 250 sheets x 2 (80g/m 2 )Staple mode: SRA3, A3, B4, SRA4, SRA4S 1 , A4, A4S 1 , B5Straight mode: SRA3, A3, B4, SRA4, SRA4S 1 , A4, A4S 1 , B5, B5S 1 , A5, A5S 1 , B6S 1Sub tray mode: SRA3, A3, B4, SRA4, SRA4S 1 , A4, A4S 1 , B5, B5S 1 , A5, A5S 1 , B6S 1 , A6S 1Staple mode: 64-244g/m 2 Shift/straight mode: 64-300g/m 2Main tray: Straight/shift mode: 3,000 sheets (B5, B5S 1 , A4, A4S 1 ); 1,500 sheets (B4, A3);750 sheets (A6, B6, A5) Staple mode: 1,000 sheets Sub tray: 200 sheets (same size)Corner stapling: horizontal, vertical 2-point stapling: horizontal, verticalHot-melt glue book binder with trim function64-105g/m 2 , 81-209g/m 2 for cover sheetsA4, B5, A5, A5S 1 , irregular sizes (139 x 210 to 307 x 221mm)Approx. 300 sheets max. (less than 30mm thick)/approx. 10 sheets min.2,500 sheetsSRA3, A3, B4, SRA4, SRA4S 1 , A4, A4S 1 , B564 – 300g/m 2Staple: A3, B4, SRA4S 1 , A4, A4S 1 , B5, B5S 1 , A5Saddle stitching/Folding: A3, B4, SRA4S 1 , A4Straight: A3, B4, SRA4S 1 , A4, A4S 1 , B5, B5S 1 , A5, A5S 1 , B6S 1Sub tray mode:SRA3, A3, B4, SRA4, SRA4S 1 , A4, A4S 1 , B5, B5S 1 , A5, A5S 1 , B6S 1 , A6S 1Staple/saddle stitching/folding: 64-105g/m 2 Straight/shift/Sub tray: 64-300g/m 2Multi-letter fold: 50 books Multi-centre fold: 33 books (300mm or more), 25 books299mm or lessSaddle stitching: 20 books (300mm or more), 15 books299mm or lessStaple: 100 books2-9 sheets, 417mm or less, 50 books2-9 sheets, 418mm or less, 50 books10-20 sheets,30 books21-30 sheets, 25 books31-40 sheets, 20 books41-50 sheetsSaddle stitching: Variable (128-160mm)Staple: corner stapling: optional 2 points, 2-point stapling: centre64-300g/Max. 50 sheets(60-80g/)100 sets 2-9 sheets stapled, 150-417 mm50 sets 2-9 sheets stapled, 148-149mm / 418-458mm50 sets(10-20 sheets stapled)30 sets(21-30 sheets stapled)25 sets(31-40 sheets stapled)20 sets(41-50 sheets staples)Max.3,000 sheets(A4), 1,500 sheets(A3)Corner: 1 point, Center: 2 pointsSystem OverviewPunch Kit PK-512Punch Kit PK-513 (Sweden punch)Post Inserter PI-502AutomaticDocument Feeder DF-622Original CoverOC-506Main body configurationOutput TrayOT-502HumidifierHM-102Working TableWT-508 *2Multi Bypass TrayMB-504 *2* Some products are not available in some areas.DehumidifierHT-504For PF-602DehumidifierHT-503For LU-202Booklet FinisherFS-612Staple FinisherFS-531Relay UnitRU-509bizhub PRESSC7000/C6000Image ControllerIC-601 *1Konica Minota image controllerImage Controller IC-306EFI server type image controllerHard Disk KitHD-514Preview KitPH-102Paper FeederUnit PF-602 *2Large capacityUnit LU-202 *2Staple FinisherFS-521Perfect BinderPB-503Saddle StitcherSD-506For more information pleasevisit the bizhub Web site atLarge CapacityStacker LS-505Product appearance, configuration and/or specificationsare subject to change without notice.The Konica Minolta logo and the symbol mark, and “The essentials ofimaging” are registered trademarks or trademarks of KONICA MINOLTAHOLDINGS, INC.bizhub, bizhub PRESS, magicolor, PagePro, PageScope, Simitri andS.E.A.D. are registered trademarks or trademarks of KONICA MINOLTABUSINESS TECHNOLOGIES, INC.All other Konica Minolta brand and product names are registered trademarksor trademarks of KONICA MINOLTA BUSINESS TECHNOLOGIES, INC.Windows is a registered trademark of Microsoft Corporation in theUnited States and other countries.Adobe and PostScript are registered trademarks or trademarks ofAdobe Systems Incorporated.All other brand and product names are registered trademarks ortrademarks of their respective owners.Folding UnitFD-503Relay UnitRU-506RU-509 isnecessary forthese finishing options.Multi PunchGP-501 *3*1 Hard Disk Kit HD-514 and Preview Kit PH-102 are necessary.*2 When PF-602 is connected. LU-202, WT-508 and MB-504 are unconnectable.*3 RU-506 is necessary.http://www.bizhubpress.comEcology & EnvironmentKONICA MINOLTA products are designed with theenvironment in mind.• Energy Star• RoHS Compliance• WEEE Compliance• Eco-friendly Toners• Production at ISO CertifiedFactoriesRequirements for safe use• Please read and follow the instruction manual to ensure safe operation.• Only operate using appropriate power supply and voltage.• Connecting the earth wire to an inappropriate place may cause explosion orelectric shock. Please connect accordingly (Taiwan and the Philippines only).This catalogue was printedusing soy ink.9251-3192-01 O0000(E)-A1 Printed in Japan