(SEI) Formation on Graphene as a Model Li-ion Battery Anode

(SEI) Formation on Graphene as a Model Li-ion Battery Anode

(SEI) Formation on Graphene as a Model Li-ion Battery Anode

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

Articlepubs.acs.org/cmIn Situ X‐ray Study of the Solid Electrolyte Interph<strong>as</strong>e (<str<strong>on</strong>g>SEI</str<strong>on</strong>g>) <str<strong>on</strong>g>Formati<strong>on</strong></str<strong>on</strong>g><strong>on</strong> <strong>Graphene</strong> <strong>as</strong> a <strong>Model</strong> <strong>Li</strong>-i<strong>on</strong> <strong>Battery</strong> <strong>Anode</strong>Sudeshna Chattopadhyay, §,† Albert L. <strong>Li</strong>ps<strong>on</strong>, §,† Hunter J. Karmel, † J<strong>on</strong>athan D. Emery, †Timothy T. Fister, ‡ Paul A. Fenter, ‡ Mark C. Hersam,* ,† and Michael J. Bedzyk* ,†† Department of Materials Science and Engineering, Northwestern University, Evanst<strong>on</strong>, Illinois 60208, United States‡ Chemical Sciences and Engineering Divisi<strong>on</strong>, Arg<strong>on</strong>ne Nati<strong>on</strong>al Laboratory, Lem<strong>on</strong>t, Illinois 60439, United States*S Supporting Informati<strong>on</strong>ABSTRACT: The solid electrolyte interph<strong>as</strong>e (<str<strong>on</strong>g>SEI</str<strong>on</strong>g>) plays a critical role in theperformance and safety of <strong>Li</strong>-i<strong>on</strong> batteries, but the crystal structure of the materialsformed have not been previously studied. We employ the model system of epitaxialgraphene <strong>on</strong> SiC to provide a well-defined graphitic surface to study the crystallinity andtexture formati<strong>on</strong> in the <str<strong>on</strong>g>SEI</str<strong>on</strong>g>. We observe, via in situ synchrotr<strong>on</strong> X-ray scattering, theformati<strong>on</strong> and growth of <strong>Li</strong>F crystallites at the graphene surface, which incre<strong>as</strong>e in size withlithiati<strong>on</strong> dose and are textured such that the <strong>Li</strong>F (002) planes are approximately parallel tothe graphene sheets. Furthermore, X-ray photoelectr<strong>on</strong> spectroscopy (XPS) reveals thecompositi<strong>on</strong> of the <str<strong>on</strong>g>SEI</str<strong>on</strong>g> formed in this system to c<strong>on</strong>sist of <strong>Li</strong>F and organic compoundssimilar to those found previously <strong>on</strong> graphite. <str<strong>on</strong>g>SEI</str<strong>on</strong>g> comp<strong>on</strong>ents, other than <strong>Li</strong>F, do notproduce X-ray diffracti<strong>on</strong> peaks and are categorized <strong>as</strong> amorphous. From high-resoluti<strong>on</strong>transmissi<strong>on</strong> electr<strong>on</strong> microscopy, the <strong>Li</strong>F crystallites are seen in near proximity to thegraphene surface al<strong>on</strong>g with additi<strong>on</strong>al apparently amorphous material, which is likely tobe other <str<strong>on</strong>g>SEI</str<strong>on</strong>g> comp<strong>on</strong>ents detected by XPS and/or misoriented <strong>Li</strong>F. This newunderstanding that <strong>Li</strong>F crystallites grow <strong>on</strong> the graphene surface with str<strong>on</strong>g texturing will <strong>as</strong>sist future efforts to model andengineer the <str<strong>on</strong>g>SEI</str<strong>on</strong>g> formed <strong>on</strong> graphitic materials.KEYWORDS: <strong>Li</strong>-i<strong>on</strong> batteries, solid electrolyte interph<strong>as</strong>e, graphene, graphite, X-ray scattering■ INTRODUCTIONThe performance, lifetime, and safety of batteries need to beenhanced to enable emerging are<strong>as</strong> of technology, such <strong>as</strong>electric vehicles. During cycling, a layer of decomposedelectrolyte, known <strong>as</strong> the solid electrolyte interph<strong>as</strong>e (<str<strong>on</strong>g>SEI</str<strong>on</strong>g>),forms <strong>on</strong> <strong>Li</strong>-i<strong>on</strong> battery electrodes. 1 Since the <str<strong>on</strong>g>SEI</str<strong>on</strong>g> is formedfrom the breakdown of the electrolyte, it reduces the capacity ofthe battery and can be detrimental to cell lifetime. On the otherhand, the stability and p<strong>as</strong>sivating qualities of the <str<strong>on</strong>g>SEI</str<strong>on</strong>g> areimportant to limit unc<strong>on</strong>trolled reacti<strong>on</strong>s, which can pose safetyrisks resulting from cat<strong>as</strong>trophic failure. 2The <str<strong>on</strong>g>SEI</str<strong>on</strong>g> previously h<strong>as</strong> been studied using a variety of in situmethods including atomic force microscopy (AFM), scanningi<strong>on</strong> c<strong>on</strong>ductance microscopy (SICM), Fourier-transform infrared(FTIR) spectroscopy, and ellipsometry. 3−7 Ex situ studies,using X-ray photoelectr<strong>on</strong> spectroscopy (XPS) and scanningelectr<strong>on</strong> microscopy (SEM), have been utilized to probe the<str<strong>on</strong>g>SEI</str<strong>on</strong>g> compositi<strong>on</strong> and morphology. 8−10 These studies show that<str<strong>on</strong>g>SEI</str<strong>on</strong>g> formati<strong>on</strong> <strong>on</strong> the anode surface is more pr<strong>on</strong>ounced thanthat <strong>on</strong> the cathode, 11 and its compositi<strong>on</strong> depends <strong>on</strong> thechoice of electrolyte and electrode materials. 11,12 Although the<str<strong>on</strong>g>SEI</str<strong>on</strong>g> is critical to the operati<strong>on</strong> of <strong>Li</strong>-i<strong>on</strong> batteries, its structureand evoluti<strong>on</strong> are not fully understood.The most comm<strong>on</strong>ly used anode material in commercial <strong>Li</strong>i<strong>on</strong>batteries is graphitic carb<strong>on</strong>. The compositi<strong>on</strong> of the <str<strong>on</strong>g>SEI</str<strong>on</strong>g> <strong>on</strong>graphite with fluorinated electrolytes h<strong>as</strong> been found to includehydrocarb<strong>on</strong>s, lithium alkyl carb<strong>on</strong>ates, <strong>Li</strong>OH, <strong>Li</strong> 2 CO 3 ,<strong>Li</strong> 2 O,and <strong>Li</strong>F. 7,8,10,13−16 <strong>Li</strong>F w<strong>as</strong> shown to grow in the <str<strong>on</strong>g>SEI</str<strong>on</strong>g>, but nostructural study (to our knowledge) w<strong>as</strong> previously performed.10 C<strong>on</strong>sequently, the structural relati<strong>on</strong>ships (if any)between the <strong>Li</strong>F and the electrode surface are not wellestablished.<strong>Li</strong>F is postulated to form from decompositi<strong>on</strong>/reducti<strong>on</strong> of the <strong>Li</strong>PF 6 salt (due to its thermal and chemicalinstabilities), via the reacti<strong>on</strong> <strong>Li</strong>PF 6 ↔ <strong>Li</strong> + F − ↓ +PF 5 and manyother possible reacti<strong>on</strong>s. 12,15,17,18 Furthermore, the <str<strong>on</strong>g>SEI</str<strong>on</strong>g> w<strong>as</strong>found to grow thicker and with different compositi<strong>on</strong> <strong>on</strong> theedge planes of graphite <strong>as</strong> compared to the b<strong>as</strong>al plane. 8,19−21To reduce the total irreversible capacity of the system, whilestill allowing f<strong>as</strong>t <strong>Li</strong> + diffusi<strong>on</strong> into the anode via the edgesurfaces, a combinati<strong>on</strong> of b<strong>as</strong>al and edge surfaces is used. Anunderstanding of the <str<strong>on</strong>g>SEI</str<strong>on</strong>g> <strong>on</strong> both the b<strong>as</strong>al and edge planes ofgraphite is therefore necessary in order to understand how tooptimize anode morphology.X-ray scattering can probe interfacial systems in situ, isn<strong>on</strong>destructive, and can determine the interfacial structure atthe atomic scale. In situ and ex situ X-ray diffracti<strong>on</strong> haveReceived: May 23, 2012Revised: July 10, 2012Published: July 23, 2012© 2012 American Chemical Society 3038 dx.doi.org/10.1021/cm301584r | Chem. Mater. 2012, 24, 3038−3043

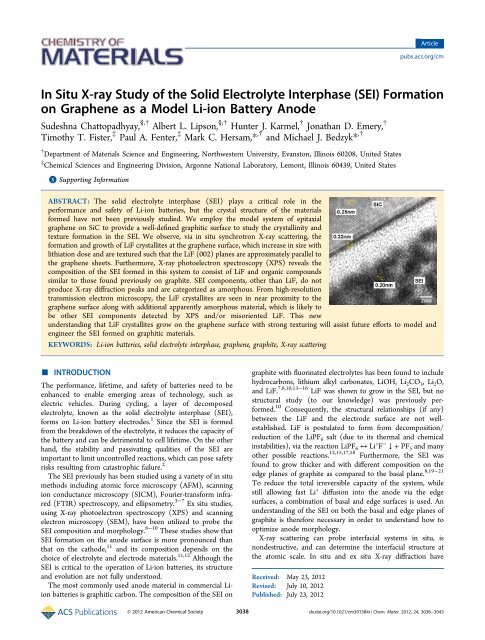

Chemistry of Materialspreviously been used to study the bulk crystal structure of <strong>Li</strong>i<strong>on</strong>battery electrodes during cycling, 22−30 but it h<strong>as</strong> not yetbeen utilized to study the structure of the <str<strong>on</strong>g>SEI</str<strong>on</strong>g>. C<strong>on</strong>sequently,there is little informati<strong>on</strong> about the crystallinity andmorphology of the <str<strong>on</strong>g>SEI</str<strong>on</strong>g>.We have employed a model system of epitaxial graphene <strong>on</strong>6H-SiC (EG/SiC) for these studies. <strong>Graphene</strong> sheets provide awell-defined graphitic surface that is not perturbed duringlithiati<strong>on</strong>. 31 These graphene sheets fully cover the SiC withdomains of ∼200 nm and therefore possess a high percentageof b<strong>as</strong>al plane area and minimal edge plane sites. C<strong>on</strong>sequently,this system provides a model substrate for probing <str<strong>on</strong>g>SEI</str<strong>on</strong>g>formati<strong>on</strong> <strong>on</strong> graphitic b<strong>as</strong>al planes. Furthermore, in thissystem, the graphene sheets are excepti<strong>on</strong>ally parallel to the SiC(0006) b<strong>as</strong>al planes 31 enabling the study of texture formati<strong>on</strong>(i.e., preferential orientati<strong>on</strong> of crystals) in the <str<strong>on</strong>g>SEI</str<strong>on</strong>g> that is notpossible with graphitic substrates having substantial mosaicdisorder and surface roughness. Preferential orientati<strong>on</strong> ofcrystallites in the <str<strong>on</strong>g>SEI</str<strong>on</strong>g> may modify the rate of <strong>Li</strong> + diffusi<strong>on</strong> to theelectrode surface through those crystals, which could changethe rate performance of the battery. 32,33Herein, we report our studies <strong>on</strong> the atomic structure of the<str<strong>on</strong>g>SEI</str<strong>on</strong>g> formed <strong>on</strong> EG/SiC. XPS studies show <str<strong>on</strong>g>SEI</str<strong>on</strong>g> comp<strong>on</strong>ents <strong>on</strong>EG/SiC that are similar to that found previously <strong>on</strong> graphiteanodes. Furthermore, we find that <strong>Li</strong>F crystallites form andgrow <strong>on</strong> the EG/SiC surface with str<strong>on</strong>g texturing duringlithiati<strong>on</strong> via in situ synchrotr<strong>on</strong> X-ray scattering. L<strong>as</strong>tly, usinghigh-resoluti<strong>on</strong> transmissi<strong>on</strong> electr<strong>on</strong> microscopy (HRTEM),we observe the structure and morphology of the <str<strong>on</strong>g>SEI</str<strong>on</strong>g> <strong>on</strong> theEG/SiC surface.■ EXPERIMENTAL SECTIONSiC samples were n-type doped single crystal wafers purch<strong>as</strong>ed fromCREE. As described elsewhere, 31 the SiC(0001) substrates werecleaned with acet<strong>on</strong>e and isopropanol before being graphitized inultrahigh vacuum. Scanning tunneling microscopy (STM) revealedthat the surfaces were covered by a combinati<strong>on</strong> of single and bilayergraphene with minimal 6√3 × 6√3 rec<strong>on</strong>structi<strong>on</strong> exposed. Theelectrolyte w<strong>as</strong> 1 M <strong>Li</strong>PF 6 (99.99%, Sigma-Aldrich) in 1:1 ethylenecarb<strong>on</strong>ate (EC) to dimethyl carb<strong>on</strong>ate (DMC) (anhydrous, Sigma-Aldrich), and the counter electrode w<strong>as</strong> metallic <strong>Li</strong> (Sigma-Aldrich).The samples for the XPS and HRTEM me<strong>as</strong>urements were lithiatedgalvanostatically in a two electrode beaker type cell with a current of21 μA/cm 2 . The sample used for the X-ray scattering experiment w<strong>as</strong>lithiated in a home-built in situ X-ray thin-film 34 cell with a 7.5 μmKapt<strong>on</strong> window (see Supporting Informati<strong>on</strong>, S1). The cell w<strong>as</strong> sealedin an inert atmosphere using a combinati<strong>on</strong> of Kapt<strong>on</strong> film, a Vit<strong>on</strong>g<strong>as</strong>ket, and pipe fittings. The seal w<strong>as</strong> leak tested, and the <strong>Li</strong> metalcounter electrode showed no significant oxidati<strong>on</strong> when examinedafter the X-ray experiments, which is c<strong>on</strong>sistent with an insignificantamount of water inside the cell. The galvanostatic lithiati<strong>on</strong> of thissample started at a current of 0.032 mA/cm 2 until a charge of 0.13mAh/cm 2 , then 0.064 mA/cm 2 until 0.26 mAh/cm 2 , and l<strong>as</strong>t 0.13 mA/cm 2 until 0.51 mAh/cm 2 .XPS me<strong>as</strong>urements were taken using an ESCA Probe (Omicr<strong>on</strong>)after samples were cleaned with isopropanol to remove residualelectrolyte. The spectra were smoothed by using f<strong>as</strong>t Fourier transform(FFT) filtering to remove noise. A peak fitting procedure w<strong>as</strong> used tofind the exact peak positi<strong>on</strong>s listed in Table 1.X-ray scattering experiments were performed at sector 5ID-C(DND-CAT) at the Advanced Phot<strong>on</strong> Source using 17.00 keVphot<strong>on</strong>s in a reflecti<strong>on</strong> geometry (see Supporting Informati<strong>on</strong>, S2).Two detectors were used during these experiments: a charge coupleddevice (CCD) area detector (“Roper CCD”) (Princet<strong>on</strong> Instruments7501-0002) mounted <strong>on</strong> the detector arm of the diffractometer 35 anda MAR165 large area CCD detector (“MAR CCD”) (MAR Research)3039ArticleFigure 1. Ex situ XPS spectra for a 14 mAh/cm 2 lithiated EG/SiCsample using 1 M <strong>Li</strong>PF 6 in 1:1 EC/DMC electrolyte for (a) <strong>Li</strong> 1s, (b)F 1s, (c) C 1s, and (d) O 1s.centered <strong>on</strong> the beam path after the sample. The diffracti<strong>on</strong> data fromthe <str<strong>on</strong>g>SEI</str<strong>on</strong>g> (i.e., intensity vs momentum transfer, q z , me<strong>as</strong>ured near thesurface normal directi<strong>on</strong>) w<strong>as</strong> extracted from the Roper CCD imagesby m<strong>as</strong>king-out the true specularly reflected X-ray beam from theimages, integrating the image al<strong>on</strong>g q x , and plotting the remainingnear-specular scattering intensity vs q z . Using Nika software, the MARCCD images were c<strong>on</strong>verted into reciprocal space maps and ‘polefigures’ were extracted. 36 For the <strong>Li</strong>F (002) pole figure, a combinati<strong>on</strong>of MAR CCD images were taken at incident angles of 5° and 10.384°.10.384° is the local specular positi<strong>on</strong> for <strong>Li</strong>F (002), meaning that <strong>Li</strong>Fcrystals with their (002) planes parallel to the SiC (0006) planessatisfy the Bragg c<strong>on</strong>diti<strong>on</strong> at this incident angle. The pole figure for<strong>Li</strong>F (111) w<strong>as</strong> extracted from those same two images and an imagenear to the local specular from the Roper CCD (see SupportingInformati<strong>on</strong>, S3). The extracted data for both <strong>Li</strong>F (002) and (111)were merged, <strong>as</strong> w<strong>as</strong> proposed by Baker et al. to remove artifactscreated by the geometry. 37The sample for HRTEM w<strong>as</strong> prepared using focused i<strong>on</strong> beammilling procedures, <strong>as</strong> described previously. 31 HRTEM w<strong>as</strong> performed■using a JEM-2100F TEM (JEOL) at 200 kV.RESULTS AND DISCUSSIONEx situ XPS w<strong>as</strong> utilized to investigate the surface compositi<strong>on</strong>of the <str<strong>on</strong>g>SEI</str<strong>on</strong>g> formed <strong>on</strong> EG/SiC. The resulting spectra for a 14mAh/cm 2 lithiated EG/SiC sample using 1 M <strong>Li</strong>PF 6 in 1:1 EC/DMC electrolyte are shown in Figure 1, and peak positi<strong>on</strong>swith proposed <strong>as</strong>signments are given in Table 1. The <strong>Li</strong> 1sTable 1. Binding Energies and Proposed Assignments for theXPS Spectra for a 14 mAh/cm 2 <strong>Li</strong>thiated EG/SiC SampleUsing 1 M <strong>Li</strong>PF 6 in 1:1 EC/DMC Electrolyteelementbindingenergy (eV) proposed <strong>as</strong>signment ref<strong>Li</strong> 56.1 <strong>Li</strong>F 8, 10, 15,16<strong>Li</strong> 54.7 <strong>Li</strong>−O (R-CH 2 OCO 2 <strong>Li</strong>, <strong>Li</strong>OH and <strong>Li</strong>-Ographite)8, 15or polymerF 686.2 <strong>Li</strong>F 8, 10C 286 Polymer (PEO) 10C 288.1 R-CH 2 OCO 2 <strong>Li</strong> 10C 289 R-CH 2 OCO 2 <strong>Li</strong> 10O 533.4 C−O b<strong>on</strong>ds 8, 10P 135 un<strong>as</strong>signed 15dx.doi.org/10.1021/cm301584r | Chem. Mater. 2012, 24, 3038−3043

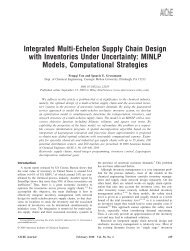

Chemistry of MaterialsArticleFigure 2. X-ray scattering data from an in situ lithiated EG/SiC sample. (a) Diffracti<strong>on</strong> pattern extracted from the images taken using the RoperCCD camera in the specular geometry for the sample at open circuit and at 0.51 mAh/cm 2 lithiati<strong>on</strong>. (b) CCD images around the <strong>Li</strong>F (002) Braggpeak (incidence angle of 10.609°) atdifferent lithiati<strong>on</strong> stages. The <strong>Li</strong>F (002) Bragg peak is observed at q z = 3.11 Å −1 , while the small central spot ineach image (at q z = 3.16 Å −1 ) corresp<strong>on</strong>ds to the scattering intensity from the surface rod of EG/SiC interface. (c) Domain size and integratedintensity of the <strong>Li</strong>F (002) Bragg peak in the window of the Roper CCD at different lithiati<strong>on</strong> states.spectrum shows a str<strong>on</strong>g peak at a binding energy of 56.1 eVindicating the formati<strong>on</strong> of <strong>Li</strong>F. 8,10,15,16 There is also a peak at54.7 eV corresp<strong>on</strong>ding possibly to <strong>Li</strong>−O b<strong>on</strong>ds (e.g., R-CH 2 OCO 2 <strong>Li</strong>, <strong>Li</strong>OH, and <strong>Li</strong>-O-graphite) or a lithiumc<strong>on</strong>taining polymer. 8,15 In Figure 1b, the F 1s spectrumshows a peak at 686.2 eV, further indicating <strong>Li</strong>F. 8,10 Note thatthere is no peak at 688 eV, which would indicate residual<strong>Li</strong>PF 6 . 10,16 In the C 1s spectra, there are three peaks at 286 eV,288.1 eV, and 289 eV. The peak at 286 eV could be a polymersuch <strong>as</strong> polyethylene oxide (PEO) with C−O b<strong>on</strong>ds, which canbe formed via the polymerizati<strong>on</strong> of EC. 10 The other two peakscan be <strong>as</strong>signed to the two carb<strong>on</strong>s in R-CH 2 OCO 2 <strong>Li</strong>. 10 Thereis no evidence for <strong>Li</strong> 2 CO 3 , which h<strong>as</strong> a peak between 290.5 and291.5 eV. The O 1s spectrum is shown in Figure 1d with <strong>as</strong>tr<strong>on</strong>g peak at 533.4 eV, which is c<strong>on</strong>sistent with a variety ofC−O b<strong>on</strong>ds. 8,10 There is also a peak from the P 2p at 135 eV,which is not <strong>Li</strong>PF 6 and cannot be <strong>as</strong>signed. 15 These <str<strong>on</strong>g>SEI</str<strong>on</strong>g>compounds are c<strong>on</strong>sistent with those found previously <strong>on</strong>graphite with similar electrolytes. 8,10,15,16To understand the atomic structure of the <str<strong>on</strong>g>SEI</str<strong>on</strong>g> comp<strong>on</strong>entsduring growth, we utilized in situ synchrotr<strong>on</strong> X-ray scattering.Figure 2 shows the scattering data taken using the Roper CCDnear the specular reflecti<strong>on</strong> c<strong>on</strong>diti<strong>on</strong> for the SiC. Thediffracti<strong>on</strong> pattern (Figure 2a) shows four peaks between 2.2Å −1 and 7 Å −1 that incre<strong>as</strong>e in intensity after lithiati<strong>on</strong> (0.51mAh/cm 2 ). These peaks corresp<strong>on</strong>d to the (111), (002),(220), and (004) 38 for cubic <strong>Li</strong>F in the rock salt structure, <strong>as</strong>indicated in Figure 2a. There appears to be n<strong>on</strong>zero intensity atthe peak locati<strong>on</strong> for <strong>Li</strong>F (222) at open circuit due tointerference from the SiC (0 0 0 13) qu<strong>as</strong>i-Bragg peak. There is,however, a trace of <strong>Li</strong>F present at open circuit voltage <strong>as</strong> can beseen by the n<strong>on</strong>zero (002) and (004) peaks (this intensitycorresp<strong>on</strong>ds to 2° <strong>Li</strong>F mosaic width the intensity andpeak shape for <strong>Li</strong>F (002) do not change appreciably betweenthis positi<strong>on</strong> and the local specular positi<strong>on</strong>, where the peakaligns with the surface reflecti<strong>on</strong>. These scattering patternsshow that the intensity of this peak incre<strong>as</strong>es with lithiati<strong>on</strong>, butwithout any significant change in the mosaic width.Furthermore, the central spot in the images, corresp<strong>on</strong>ding tothe surface specular reflecti<strong>on</strong> of EG/SiC, is unchanged atdifferent lithiati<strong>on</strong> stages (in either intensity or shape),indicating that the graphene structure is not disturbed. 31 Figure2c shows the evoluti<strong>on</strong> of the <strong>Li</strong>F (002) Bragg peak integratedintensity and vertical domain size at various lithiati<strong>on</strong> states.The average crystal size (me<strong>as</strong>ured al<strong>on</strong>g the surface normaldirecti<strong>on</strong>) incre<strong>as</strong>es m<strong>on</strong>ot<strong>on</strong>ically with incre<strong>as</strong>ing lithiati<strong>on</strong>and reaches a value of ∼50 nm at 0.51 mAh/cm 2 . The3040dx.doi.org/10.1021/cm301584r | Chem. Mater. 2012, 24, 3038−3043

Chemistry of MaterialsArticleFigure 3. (a) In situ diffracti<strong>on</strong> pattern of 0.51 mAh/cm 2 lithiated EG/SiC taken with the MAR CCD at an incidence angle of 5°. The arrow in theimage indicates the diffuse SiC (0006) peak. (b) Extracted pole figure for the image shown in part a and images at the specular positi<strong>on</strong>s for the <strong>Li</strong>F(111) (right y-axis) and (002) peaks (left y-axis), with background subtracti<strong>on</strong> and polarizati<strong>on</strong> correcti<strong>on</strong>, stitched near to 90° in χ.integrated intensity of the <strong>Li</strong>F (002) in the window of theRoper CCD incre<strong>as</strong>es nearly linearly with charge.These data also reveal informati<strong>on</strong> c<strong>on</strong>cerning theorientati<strong>on</strong> of the <strong>Li</strong>F crystals. The intensity of the <strong>Li</strong>F (002)peak is more than an order of magnitude larger than that of the<strong>Li</strong>F (111) peak, indicating a preferential orientati<strong>on</strong> of the <strong>Li</strong>F(002) planes approximately parallel to the SiC (0006) planes.Since the intensity ratio calculated for a <strong>Li</strong>F powder is 4:3, 39this suggests that a large fracti<strong>on</strong> of the <strong>Li</strong>F h<strong>as</strong> the (002)orientati<strong>on</strong>. While the <strong>Li</strong>F (002) peak is most intense al<strong>on</strong>g thespecular directi<strong>on</strong> (here, indicated <strong>as</strong> q x =0Å −1 ), we do not seeany c<strong>on</strong>tributi<strong>on</strong> from the <strong>Li</strong>F (002) Bragg peak to the surfacereflectivity, suggesting that while the <strong>Li</strong>F is preferentiallyaligned, it is not epitaxial with the graphene.We have also employed a large area detector to collect thepowder rings of <strong>Li</strong>F (002) and <strong>Li</strong>F (111) to probe the full <strong>Li</strong>Ftexture. 37,40−42 Figure 3a shows the diffracti<strong>on</strong> pattern of EG/SiC lithiated to 0.51 mAh/cm 2 taken using the MAR CCD atan incidence angle of 5°. Atq below 2.3 Å −1 , there is additi<strong>on</strong>aldiffracti<strong>on</strong> intensity from the Kapt<strong>on</strong> window 34 and theelectrolyte (note that the sample holder clips this image forq z < 0.7 Å −1 causing the shadow).Figure 3b shows the complete pole figures (between 20° and160° in χ, see Supporting Informati<strong>on</strong>, S2 for geometry) for the<strong>Li</strong>F (111) and (002) peaks. The pole figure is extracted bymerging both the diffracti<strong>on</strong> pattern at an incidence angle of 5°and the local specular positi<strong>on</strong>s (shown in SupportingInformati<strong>on</strong>, Figure S3), including background subtracti<strong>on</strong>and correcti<strong>on</strong> for the horiz<strong>on</strong>tally polarized X-ray beam. 37Since the <str<strong>on</strong>g>SEI</str<strong>on</strong>g> layer is more than 100 nm thick, 31 an incidenceangle of 5° w<strong>as</strong> chosen instead of grazing incidence to reducethe effects of absorpti<strong>on</strong> and beam footprint, which wouldchange the probed regi<strong>on</strong> for the two me<strong>as</strong>urements. 37 The <strong>Li</strong>F(002) peak is str<strong>on</strong>gest at χ =90°, while the <strong>Li</strong>F (111) is mostintense at 35° and 145°. These peaks are due to str<strong>on</strong>gtexturing with crystals oriented such that the <strong>Li</strong>F (002) planesare parallel to the graphene sheets. The full width at halfmaximumof the <strong>Li</strong>F (002) peak at χ =90° is approximately2.4°, indicating a narrow mosaic distributi<strong>on</strong> of <strong>Li</strong>F orientati<strong>on</strong>sin the <str<strong>on</strong>g>SEI</str<strong>on</strong>g>. It should be noted that the signal from the surfacerod at this momentum transfer (q z ) c<strong>on</strong>tributes less than 1% tothe integrated intensity of the <strong>Li</strong>F (002) peak. We also observea weak peak near 90° in χ for <strong>Li</strong>F (111), indicating that thereare some <strong>Li</strong>F crystals that have their (111) planes parallel withthe graphene planes. Figure 4 shows that the peak at χ=145°incre<strong>as</strong>es more rapidly with lithiati<strong>on</strong> than the other regi<strong>on</strong>s ofthe ring corresp<strong>on</strong>ding to the randomly oriented crystals. ThisFigure 4. Pole figure, with background subtracti<strong>on</strong> and polarizati<strong>on</strong>correcti<strong>on</strong>, for <strong>Li</strong>F (111) at different lithiati<strong>on</strong> stages extracted fromMAR CCD images at an incidence angle of 5°.indicates that the growth of oriented crystals, with (002) planesparallel to the graphene sheets, is favored over randomlyoriented crystals after the initial <strong>Li</strong>F nucleati<strong>on</strong>.HRTEM w<strong>as</strong> used to further elucidate the morphology of the<str<strong>on</strong>g>SEI</str<strong>on</strong>g>. Figure 5 shows a representative ex situ HRTEM image ofthe <str<strong>on</strong>g>SEI</str<strong>on</strong>g> near the EG/SiC surface after 14 mAh/cm 2 lithiati<strong>on</strong>,observed al<strong>on</strong>g the SiC [2 12̅ 0] directi<strong>on</strong>. The SiC (0001)crystal lattice structure is clearly observed in this orientati<strong>on</strong>.The HRTEM image also shows a 0.32 nm spacing of graphenebetween the SiC crystalline regi<strong>on</strong> and <str<strong>on</strong>g>SEI</str<strong>on</strong>g>. The thick <str<strong>on</strong>g>SEI</str<strong>on</strong>g> layerc<strong>on</strong>tains crystallites whose layer spacing closely matches the(002) d-spacing of <strong>Li</strong>F. There is also an approximately 3 nmthick regi<strong>on</strong> between the graphene and <strong>Li</strong>F crystals, <strong>as</strong> well <strong>as</strong>small regi<strong>on</strong>s throughout the rest of the <str<strong>on</strong>g>SEI</str<strong>on</strong>g>, which appearamorphous. The amorphous-like regi<strong>on</strong> at the surface of theEG/SiC indicates that the crystalline <strong>Li</strong>F is not truly epitaxialwith EG/SiC, which is c<strong>on</strong>sistent with the X-ray reflectivity.These apparently amorphous regi<strong>on</strong>s likely c<strong>on</strong>tain randomlyoriented <strong>Li</strong>F and/or other <str<strong>on</strong>g>SEI</str<strong>on</strong>g> comp<strong>on</strong>ents that were detectedwith XPS.■ CONCLUSIONWe find that the <str<strong>on</strong>g>SEI</str<strong>on</strong>g> formed <strong>on</strong> the EG/SiC surface iscomposed of <strong>Li</strong>F and other comm<strong>on</strong> <str<strong>on</strong>g>SEI</str<strong>on</strong>g> products that are alsofound <strong>on</strong> graphite. In situ X-ray scattering shows that <strong>Li</strong>Fformed <strong>on</strong> the graphene sheets is crystalline, whose amountand vertical domain size incre<strong>as</strong>e with lithiati<strong>on</strong> dose.Furthermore, these crystals show texturing, which strengthens3041dx.doi.org/10.1021/cm301584r | Chem. Mater. 2012, 24, 3038−3043

Chemistry of MaterialsFigure 5. Ex situ HRTEM near the EG/SiC surface taken al<strong>on</strong>g theSiC [2 12̅0] for a 14 mAh/cm 2 lithiated EG/SiC sample, showing thestructure of the SiC, the graphene layers, and the solid electrolyteinterph<strong>as</strong>e (<str<strong>on</strong>g>SEI</str<strong>on</strong>g>) with <strong>Li</strong>F crystals.with lithiati<strong>on</strong>, with their (002) planes aligning close to parallelwith the graphene sheets with an orientati<strong>on</strong> distributi<strong>on</strong> widthof 2.4° at 0.51 mAh/cm 2 . However, no other diffracti<strong>on</strong> peakswere found, indicating that the other <str<strong>on</strong>g>SEI</str<strong>on</strong>g> compounds areamorphous. Ex situ HRTEM indicates some apparentlyamorphous material between the graphene surface and theregi<strong>on</strong> with <strong>Li</strong>F crystallites, thus c<strong>on</strong>firming the c<strong>on</strong>clusi<strong>on</strong>from X-ray reflectivity that the crystalline <strong>Li</strong>F does not growdirectly <strong>on</strong> the graphene surface. There is also additi<strong>on</strong>alamorphous material throughout the <str<strong>on</strong>g>SEI</str<strong>on</strong>g> that indicates theformati<strong>on</strong> of other <str<strong>on</strong>g>SEI</str<strong>on</strong>g> comp<strong>on</strong>ents or misoriented <strong>Li</strong>F. Theunderstanding that <strong>Li</strong>F forms textured crystals, al<strong>on</strong>g with otheramorphous <str<strong>on</strong>g>SEI</str<strong>on</strong>g> comp<strong>on</strong>ents, will allow for more accuratemodeling of <strong>Li</strong> + diffusi<strong>on</strong> and stability of the <str<strong>on</strong>g>SEI</str<strong>on</strong>g> <strong>on</strong> graphiticsurfaces. These new models will inform <strong>on</strong>going efforts torealize <strong>Li</strong>-i<strong>on</strong> batteries with improved rate capability, safety, andlifetime.■ ASSOCIATED CONTENT*S Supporting Informati<strong>on</strong>X-ray thin-film cell design, X-ray scattering geometry, X-rayscattering data at the local specular positi<strong>on</strong>s for <strong>Li</strong>F (111)(Roper CCD) and <strong>Li</strong>F (002) (MAR CCD), and pole figurec<strong>on</strong>structi<strong>on</strong>. This material is available free of charge via the■Internet at http://pubs.acs.org.AUTHOR INFORMATIONCorresp<strong>on</strong>ding Author*E-mail: bedzyk@northwestern.edu; m-hersam@northwestern.edu.Author C<strong>on</strong>tributi<strong>on</strong>s§ These authors c<strong>on</strong>tributed equally and are co-first authors.NotesThe authors declare no competing financial interest.Article■ ACKNOWLEDGMENTSThis research w<strong>as</strong> supported by the Center for Electrical EnergyStorage, an Energy Fr<strong>on</strong>tier Research Center funded by theU.S. Department of Energy, Office of Science, Office of B<strong>as</strong>icEnergy Sciences (Award Number DE-AC02-06CH11357). Wealso acknowledge the use of Northwestern University andArg<strong>on</strong>ne Nati<strong>on</strong>al Laboratory user facilities including theNUANCE Center, DND-CAT, and NSF-supported MRSECfacilities. We would further like to acknowledge the help of Dr.Jins<strong>on</strong>g Wu and Benjamin Myers with TEM samplepreparati<strong>on</strong> and imaging.■ REFERENCES(1) Peled, E. J. Electrochem. Soc. 1979, 126, 2047.(2) Vetter, J.; Novak, P.; Wagner, M. R.; Veit, C.; Moller, K. C.;Besenhard, J. O.; Winter, M.; Wohlfahrt-Mehrens, M.; Vogler, C.;Hammouche, A. J. Power Sources 2005, 147, 269.(3) Chu, A. C.; Josefowicz, J. Y.; Farringt<strong>on</strong>, G. C. J. Electrochem. Soc.1997, 144, 4161.(4) Hir<strong>as</strong>awa, K. A.; Sato, T.; Asahina, H.; Yamaguchi, S.; Mori, S. J.Electrochem. Soc. 1997, 144, L81.(5) <strong>Li</strong>ps<strong>on</strong>, A. L.; Ginder, R. S.; Hersam, M. C. Adv. Mater. 2011, 23,5613.(6) Santner, H. J.; Korepp, C.; Winter, M.; Besenhard, J. O.; Moller,K. C. Anal. Bioanal. Chem. 2004, 379, 266.(7) McArthur, M. A.; Trussler, S.; Dahn, J. R. J. Electrochem. Soc.2012, 159, A198.(8) Bar-Tow, D.; Peled, E.; Burstein, L. J. Electrochem. Soc. 1999, 146,824.(9) Blyth, R. I. R.; Buqa, H.; Netzer, F. P.; Ramsey, M. G.; Besenhard,J. O.; Golob, P.; Winter, M. Appl. Surf. Sci. 2000, 167, 99.(10) Anderss<strong>on</strong>, A. M.; Edstrom, K. J. Electrochem. Soc. 2001, 148,A1100.(11) B<strong>as</strong>ic Research Needs for Electrical Energy Storage; Office of B<strong>as</strong>icEnergy Sciences, Department of Energy: W<strong>as</strong>hingt<strong>on</strong>, DC, 2007.(12) Lu, M.; Cheng, H.; Yang, Y. Electrochim. Acta 2008, 53, 3539.(13) Peled, E.; Tow, D. B.; Mers<strong>on</strong>, A.; Gladkich, A.; Burstein, L.;Golodnitsky, D. J. Power Sources 2001, 97−8, 52.(14) Peled, E.; Golodnitsky, D.; Ardel, G. J. Electrochem. Soc. 1997,144, L208.(15) Kanamura, K.; Tamura, H.; Takehara, Z. J. Electroanal. Chem.1992, 333, 127.(16) Leroy, S.; Martinez, H.; Dedryvère, R.; Lemordant, D.;G<strong>on</strong>beau, D. Appl. Surf. Sci. 2007, 253, 4895.(17) Yan, J.; Xia, B.; Su, Y.; Zhou, X.; Zhang, J.; Zhang, X.Electrochim. Acta 2008, 53, 7069.(18) Yan, J.; Zhang, J.; Su, Y.; Zhang, X.; Xia, B. Electrochim. Acta2010, 55, 1785.(19) Winter, M.; Novak, P.; M<strong>on</strong>nier, A. J. Electrochem. Soc. 1998,145, 428.(20) Placke, T.; Siozios, V.; Schmitz, R.; Lux, S. F.; Bieker, P.; Colle,C.; Meyer, H. W.; P<strong>as</strong>serini, S.; Winter, M. J. Power Sources 2012, 200,83.(21) Olivier, J. P.; Winter, M. J. Power Sources 2001, 97−8, 151.(22) Wang, X.-J.; Chen, H.-Y.; Yu, X.; Wu, L.; Nam, K.-W.; Bai, J.; <strong>Li</strong>,H.; Huang, X.; Yang, X.-Q. Chem. Commun. 2011, 47, 7170.(23) Wang, Z. X.; Wu, C. A.; <strong>Li</strong>u, L. J.; Wu, F.; Chen, L. Q.; Huang,X. J. J. Electrochem. Soc. 2002, 149, A466.(24) Nam, K. W.; Wang, X. J.; Yo<strong>on</strong>, W. S.; <strong>Li</strong>, H.; Huang, X. J.;Ha<strong>as</strong>, O.; Bai, J. M.; Yang, X. Q. Electrochem. Commun. 2009, 11, 913.(25) Wang, X. J.; Jaye, C.; Nam, K. W.; Zhang, B.; Chen, H. Y.; Bai, J.M.; <strong>Li</strong>, H.; Huang, X. J.; Fischer, D. A.; Yang, X. Q. J. Mater. Chem.2011, 21, 11406.(26) Zeng, D. L.; Cabana, J.; Yo<strong>on</strong>, W. S.; Grey, C. P. Chem. Mater.2010, 22, 1209.3042dx.doi.org/10.1021/cm301584r | Chem. Mater. 2012, 24, 3038−3043

Chemistry of MaterialsArticle(27) Sharma, N.; Peters<strong>on</strong>, V. K.; Elcombe, M. M.; Avdeev, M.;Studer, A. J.; Blagojevic, N.; Yusoff, R.; Kamarulzaman, N. J. PowerSources 2010, 195, 8258.(28) Adams, S.; Rao, R. P. J. Mater. Chem. 2012, 22, 1426.(29) Choi, D.; Xiao, J.; Choi, Y. J.; Hardy, J. S.; Vijayakumar, M.;Bhuvaneswari, M. S.; <strong>Li</strong>u, J.; Xu, W.; Wang, W.; Yang, Z. G.; Graff, G.L.; Zhang, J. G. Energy Envir<strong>on</strong>. Sci. 2011, 4, 4560.(30) Aurbach, D.; Ein-Eli, Y. J. Electrochem. Soc. 1995, 142, 1746.(31) <strong>Li</strong>ps<strong>on</strong>, A. L.; Chattopadhyay, S.; Karmel, H. J.; Fister, T. T.;Emery, J. D.; Thackeray, M. M.; Fenter, P. A.; Bedzyk, M. J.; Hersam,M. C. J. Phys. Chem. C 2012, submitted.(32) Garcia, M. E.; Garofalini, S. H. J. Electrochem. Soc. 1999, 146,840.(33) Yamada, H.; Suzuki, T. S.; Uchikoshi, T.; Hozumi, M.; Kohama,K.; Sakka, Y. J. Ceram. Soc. Jpn. 2011, 119, 701.(34) Fenter, P. A. Rev. Mineral Geochem. 2002, 49, 149.(35) Fenter, P.; Catalano, J. G.; Park, C.; Zhang, Z. J. Synchrotr<strong>on</strong>Radiat. 2006, 13, 293.(36) Ilavsky, J. J. Appl. Crystallogr. 2012, 45, 324.(37) Baker, J. L.; Jimis<strong>on</strong>, L. H.; Mannsfeld, S.; Volkman, S.; Yin, S.;Subramanian, V.; Salleo, A.; Alivisatos, A. P.; T<strong>on</strong>ey, M. F. Langmuir2010, 26, 9146.(38) Finch, G. I.; Fordham, S. Proc. Phys. Soc. 1936, 48, 85.(39) Internati<strong>on</strong>al Centre for Diffracti<strong>on</strong> Data Card No. 01-071-3743.(40) Sirringhaus, H.; Brown, P. J.; Friend, R. H.; Nielsen, M. M.;Bechgaard, K.; Langeveld-Voss, B. M. W.; Spiering, A. J. H.; Janssen, R.A. J.; Meijer, E. W.; Herwig, P.; de Leeuw, D. M. Nature 1999, 401,685.(41) Jimis<strong>on</strong>, L. H.; Salleo, A.; Chabinyc, M. L.; Bernstein, D. P.;T<strong>on</strong>ey, M. F. Phys. Rev. B 2008, 78.(42) Belman, N.; Acharya, S.; K<strong>on</strong>ovalov, O.; Vorobiev, A.;Israelachvili, J.; Efrima, S.; Golan, Y. Nano Lett. 2008, 8, 3858.3043dx.doi.org/10.1021/cm301584r | Chem. Mater. 2012, 24, 3038−3043