pdf - electralloy

pdf - electralloy

pdf - electralloy

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

THE MAKINGOF GREAT ALLOYS.AOD REFINING ––PREDICTABLE METALLURGYAND GREATER YIELDS.Two AOD units, controlled by IRS or tobe more specific, the Intelligent RefiningSystem®, refines liquid metal providedby our 32-ton electric arc furnace.This computerized system provides nodoubt-about-itmetallurgical predictabilityand consistency. This control, coupledwith masterful bottom pouring, gives youcleaner alloys, better surface quality, lowresiduals and, ultimately higher yields.Electroslag RemeltingThis is a consumable electrode remeltingprocess that produces a cleaner, moreuniform alloy with minimum segregation.Vacuum Arc RemeltingA consumable electrode remelting processinside a vacuum chamber. Exposureof molten metal droplets to vacuum pressurereduces the amount of dissolvedgases providing a cleaner product withlittle segregation.AnnealingElectralloy’s annealing furnaces can handleyour toughest thermal treat requirementsfor bar, billet, ingot and electrodes.Temperatures can be specified as high as2200° F and can be held to +/- 25° F. Ourwater quench tank can treat 50,000 lbs.of material up to 25 feet in length whilemeeting the most stringent requirements.Intelligent Refining System® is a trademark of Praxair.

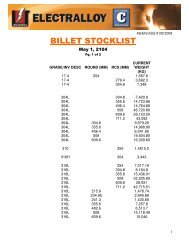

ELECTRALLOY PRODUCTS.MADE TO ORDER.Experience counts. Electralloy’s experiencein melting a variety of alloy families isevident in the end product. When youbuy from Electralloy, you get productsthat consistently perform at or beyondexpectation.Give us your scrap, we’ll giveyou pigs or ingots.Electralloy’s complete custom meltingservice can turn your segregated or mixedscrap into low-carbon, prime melt stockpigs or ingots. We can also combine alloysto meet whatever chemistry specificationsyou need.Forging quality billets.Electralloy can provide a variety of alloysand sizes in both round and round cornersquares. All billets are ultrasonic testedand certified.SPEED-E-MAC ® free machining bars &billets.For significant increased tool life,productivity and reduced turning costs,switch to SPEED-E-MAC®. These calciumtreated, sulfur-injected type 303, 304, 316and 416 stainless products offer fewerinclusions, increased metal fluidity andminimal stringers.Nitronic ® stainless steels.For a performance beyond 300 or 400 seriesstainless, Nitronic® steels offer higherstrength, excellent cryogenic propertiesand good workability. Licensed by AKSteel, Electralloy uses standard Nitronic®melting and processing practices to ensureconsistently superior product.Master alloy pigs.Our AOD refined 15 lb. pigs are produced ina variety of alloys and many are available forimmediate shipment.G.O. CARLSON plate and plate products.Electralloy specialty plate products areproduced and marketed with the experienceand expertise of G.O. CARLSON. Specialtygrades include Stainless, Nickel Alloys andNitronic® Alloys.

175 MAIN STREET • OIL CITY, PA 163011-800-458-7273 ELECTRALLOY.COMPH: 814-678-4100 FAX: 814-678-4172E-MAIL: SALES@ELECTRALLOY.COMGet Electralloy quality, Electralloyresponse in specialty steels andcustom melting.Ingots – Bottom or top poured from 13”to 70”, 1,900 to 63,000 lbs.Master Alloy Pigs – Guaranteed analysis,proven reproducibility.Forging Quality Billets – Wide variety ofalloys, sizes and grades.Stainless, Nickel Alloy and Specialty BarsSlabsForged BlocksWeld WireNitronic® 50W (AWS A5.9-93 ER209)Nitronic® 60W (AWS A5.9-93 ER218)Coil Rod350 MARSHALLTON - THORNDALEROAD DOWINGTOWN, PA 19335-2063800-338-5622 - GOCARLSON.COMPH: 610-384-2800 FAX 610-383-3429E-MAIL: SALES@GOCARLSON.COMG.O. Carlson Plate – Discrete Plate InStainless, Nickel Alloys And Nitronic®Alloys