AME.IM.3000 LCX Install Guide - Earthsafe Systems, Inc.

AME.IM.3000 LCX Install Guide - Earthsafe Systems, Inc.

AME.IM.3000 LCX Install Guide - Earthsafe Systems, Inc.

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

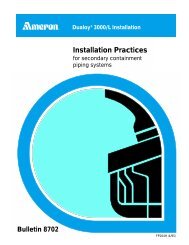

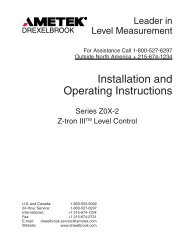

6Piping system layout(cont'd.)• Grade the trench bottom with at least 6 inches of select backfill to provide firm, evensupport for the pipe. Compact the subgrade well to prevent differential settling.• Protect the pipe from impact during backfilling and abrasion during operation bysurrounding it with four to six inches of select backfill such as washed sand, peagravel ( 3 ⁄4-inch maximum) or crushed stone ( 1 ⁄2-inch maximum).• Wrap pipe lying near concrete with rubber or foam padding to avoid direct contactwith the concrete.None4 (min)ConcreteAsphalt2 (min)18 (min)Fig. 6-1. During layout, bonding andinspection, support the piping on2x4 “batter boards” to keep thejoints clean and to keep beddingout of the pipe.4 (min)8 (min)Fig. 6-2. Use only select materials forbedding and backfilling Dualoy3000/<strong>LCX</strong> fuel handling systems. Nativematerials are rarely suitable and shouldnot be used.NativesoilSelect backfill4 (min)6 (min)6 (min)Supporting valves, accessories and vent linesDo not use fiberglass pipe to support the weight of heavy items in a line such as valves,strainers and steel vent riser pipes. Provide separate supports for valves andaccessories.PermanentstructureFig. 6-3. Support risers by attachingthem directly to structure walls.Steel pipe clampSteel nippleSteel riserSteelcouplingSteel elbowBell x maleadapterDualoy 3000/L fiberglass pipe7