25) milking procedure - Babcock Institute - University of Wisconsin ...

25) milking procedure - Babcock Institute - University of Wisconsin ...

25) milking procedure - Babcock Institute - University of Wisconsin ...

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

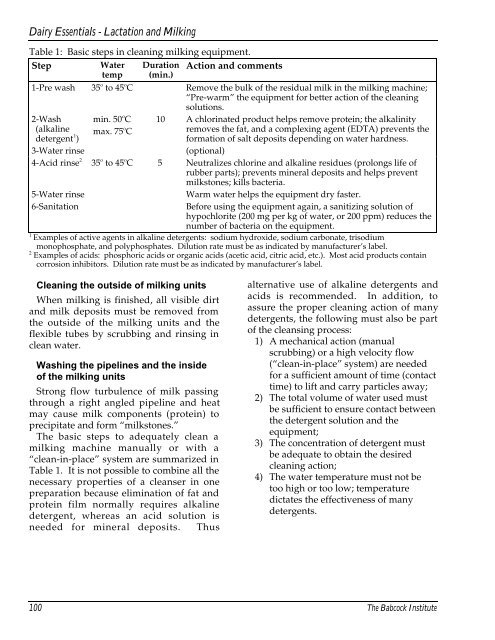

Dairy Essentials - Lactation and MilkingTable 1: Basic steps in cleaning <strong>milking</strong> equipment.StepWater Durationtemp (min.)Action and comments1-Pre wash 35 o to 45 o C Remove the bulk <strong>of</strong> the residual milk in the <strong>milking</strong> machine;“Pre-warm” the equipment for better action <strong>of</strong> the cleaningsolutions.2-Wash(alkalinedetergent 1 )3-Water rinsemin. 50 o Cmax. 75 o C10 A chlorinated product helps remove protein; the alkalinityremoves the fat, and a complexing agent (EDTA) prevents theformation <strong>of</strong> salt deposits depending on water hardness.(optional)4-Acid rinse 2 35 o to 45 o C 5 Neutralizes chlorine and alkaline residues (prolongs life <strong>of</strong>rubber parts); prevents mineral deposits and helps preventmilkstones; kills bacteria.5-Water rinseWarm water helps the equipment dry faster.6-SanitationBefore using the equipment again, a sanitizing solution <strong>of</strong>hypochlorite (200 mg per kg <strong>of</strong> water, or 200 ppm) reduces thenumber <strong>of</strong> bacteria on the equipment.1Examples <strong>of</strong> active agents in alkaline detergents: sodium hydroxide, sodium carbonate, trisodiummonophosphate, and polyphosphates. Dilution rate must be as indicated by manufacturer’s label.2Examples <strong>of</strong> acids: phosphoric acids or organic acids (acetic acid, citric acid, etc.). Most acid products containcorrosion inhibitors. Dilution rate must be as indicated by manufacturer’s label.Cleaning the outside <strong>of</strong> <strong>milking</strong> unitsWhen <strong>milking</strong> is finished, all visible dirtand milk deposits must be removed fromthe outside <strong>of</strong> the <strong>milking</strong> units and theflexible tubes by scrubbing and rinsing inclean water.Washing the pipelines and the inside<strong>of</strong> the <strong>milking</strong> unitsStrong flow turbulence <strong>of</strong> milk passingthrough a right angled pipeline and heatmay cause milk components (protein) toprecipitate and form “milkstones.”The basic steps to adequately clean a<strong>milking</strong> machine manually or with a“clean-in-place” system are summarized inTable 1. It is not possible to combine all thenecessary properties <strong>of</strong> a cleanser in onepreparation because elimination <strong>of</strong> fat andprotein film normally requires alkalinedetergent, whereas an acid solution isneeded for mineral deposits. Thusalternative use <strong>of</strong> alkaline detergents andacids is recommended. In addition, toassure the proper cleaning action <strong>of</strong> manydetergents, the following must also be part<strong>of</strong> the cleansing process:1) A mechanical action (manualscrubbing) or a high velocity flow(“clean-in-place” system) are neededfor a sufficient amount <strong>of</strong> time (contacttime) to lift and carry particles away;2) The total volume <strong>of</strong> water used mustbe sufficient to ensure contact betweenthe detergent solution and theequipment;3) The concentration <strong>of</strong> detergent mustbe adequate to obtain the desiredcleaning action;4) The water temperature must not betoo high or too low; temperaturedictates the effectiveness <strong>of</strong> manydetergents.100 The <strong>Babcock</strong> <strong>Institute</strong>