ElEctron BEam crosslinking of WirE and caBlE ... - IBA Industrial

ElEctron BEam crosslinking of WirE and caBlE ... - IBA Industrial

ElEctron BEam crosslinking of WirE and caBlE ... - IBA Industrial

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

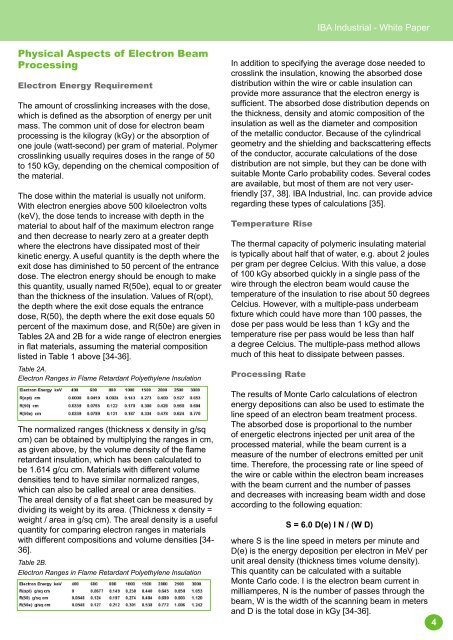

<strong>IBA</strong> <strong>Industrial</strong> - White PaperPhysical Aspects <strong>of</strong> Electron BeamProcessingElectron Energy RequirementThe amount <strong>of</strong> <strong>crosslinking</strong> increases with the dose,which is defined as the absorption <strong>of</strong> energy per unitmass. The common unit <strong>of</strong> dose for electron beamprocessing is the kilogray (kGy) or the absorption <strong>of</strong>one joule (watt-second) per gram <strong>of</strong> material. Polymer<strong>crosslinking</strong> usually requires doses in the range <strong>of</strong> 50to 150 kGy, depending on the chemical composition <strong>of</strong>the material.The dose within the material is usually not uniform.With electron energies above 500 kiloelectron volts(keV), the dose tends to increase with depth in thematerial to about half <strong>of</strong> the maximum electron range<strong>and</strong> then decrease to nearly zero at a greater depthwhere the electrons have dissipated most <strong>of</strong> theirkinetic energy. A useful quantity is the depth where theexit dose has diminished to 50 percent <strong>of</strong> the entrancedose. The electron energy should be enough to makethis quantity, usually named R(50e), equal to or greaterthan the thickness <strong>of</strong> the insulation. Values <strong>of</strong> R(opt),the depth where the exit dose equals the entrancedose, R(50), the depth where the exit dose equals 50percent <strong>of</strong> the maximum dose, <strong>and</strong> R(50e) are given inTables 2A <strong>and</strong> 2B for a wide range <strong>of</strong> electron energiesin flat materials, assuming the material compositionlisted in Table 1 above [34-36].Table 2A.Electron Ranges in Flame Retardant Polyethylene InsulationThe normalized ranges (thickness x density in g/sqcm) can be obtained by multiplying the ranges in cm,as given above, by the volume density <strong>of</strong> the flameretardant insulation, which has been calculated tobe 1.614 g/cu cm. Materials with different volumedensities tend to have similar normalized ranges,which can also be called areal or area densities.The areal density <strong>of</strong> a flat sheet can be measured bydividing its weight by its area. (Thickness x density =weight / area in g/sq cm). The areal density is a usefulquantity for comparing electron ranges in materialswith different compositions <strong>and</strong> volume densities [34-36].Table 2B.Electron Ranges in Flame Retardant Polyethylene InsulationIn addition to specifying the average dose needed tocrosslink the insulation, knowing the absorbed dosedistribution within the wire or cable insulation canprovide more assurance that the electron energy issufficient. The absorbed dose distribution depends onthe thickness, density <strong>and</strong> atomic composition <strong>of</strong> theinsulation as well as the diameter <strong>and</strong> composition<strong>of</strong> the metallic conductor. Because <strong>of</strong> the cylindricalgeometry <strong>and</strong> the shielding <strong>and</strong> backscattering effects<strong>of</strong> the conductor, accurate calculations <strong>of</strong> the dosedistribution are not simple, but they can be done withsuitable Monte Carlo probability codes. Several codesare available, but most <strong>of</strong> them are not very userfriendly[37, 38]. <strong>IBA</strong> <strong>Industrial</strong>, Inc. can provide adviceregarding these types <strong>of</strong> calculations [35].Temperature RiseThe thermal capacity <strong>of</strong> polymeric insulating materialis typically about half that <strong>of</strong> water, e.g. about 2 joulesper gram per degree Celcius. With this value, a dose<strong>of</strong> 100 kGy absorbed quickly in a single pass <strong>of</strong> thewire through the electron beam would cause thetemperature <strong>of</strong> the insulation to rise about 50 degreesCelcius. However, with a multiple-pass underbeamfixture which could have more than 100 passes, thedose per pass would be less than 1 kGy <strong>and</strong> thetemperature rise per pass would be less than halfa degree Celcius. The multiple-pass method allowsmuch <strong>of</strong> this heat to dissipate between passes.Processing RateThe results <strong>of</strong> Monte Carlo calculations <strong>of</strong> electronenergy depositions can also be used to estimate theline speed <strong>of</strong> an electron beam treatment process.The absorbed dose is proportional to the number<strong>of</strong> energetic electrons injected per unit area <strong>of</strong> theprocessed material, while the beam current is ameasure <strong>of</strong> the number <strong>of</strong> electrons emitted per unittime. Therefore, the processing rate or line speed <strong>of</strong>the wire or cable within the electron beam increaseswith the beam current <strong>and</strong> the number <strong>of</strong> passes<strong>and</strong> decreases with increasing beam width <strong>and</strong> doseaccording to the following equation:S = 6.0 D(e) I N / (W D)where S is the line speed in meters per minute <strong>and</strong>D(e) is the energy deposition per electron in MeV perunit areal density (thickness times volume density).This quantity can be calculated with a suitableMonte Carlo code. I is the electron beam current inmilliamperes, N is the number <strong>of</strong> passes through thebeam, W is the width <strong>of</strong> the scanning beam in meters<strong>and</strong> D is the total dose in kGy [34-36].4