Section C â Flat Spray Nozzles - Spraying Systems Co.

Section C â Flat Spray Nozzles - Spraying Systems Co.

Section C â Flat Spray Nozzles - Spraying Systems Co.

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

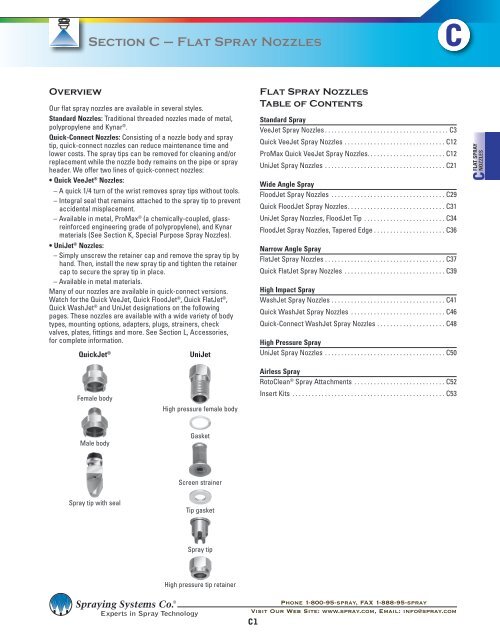

<strong>Section</strong> C – <strong>Flat</strong> <strong>Spray</strong> <strong>Nozzles</strong>OverviewOur flat spray nozzles are available in several styles.Standard <strong>Nozzles</strong>: Traditional threaded nozzles made of metal,polypropylene and Kynar ® .Quick-<strong>Co</strong>nnect <strong>Nozzles</strong>: <strong>Co</strong>nsisting of a nozzle body and spraytip, quick-connect nozzles can reduce maintenance time andlower costs. The spray tips can be removed for cleaning and/orreplacement while the nozzle body remains on the pipe or sprayheader. We offer two lines of quick-connect nozzles:• Quick VeeJet ® <strong>Nozzles</strong>:– A quick 1/4 turn of the wrist removes spray tips without tools.– Integral seal that remains attached to the spray tip to preventaccidental misplacement.– Available in metal, ProMax ® (a chemically-coupled, glassreinforcedengineering grade of polypropylene), and Kynarmaterials (See <strong>Section</strong> K, Special Purpose <strong>Spray</strong> <strong>Nozzles</strong>).• UniJet ® <strong>Nozzles</strong>:– Simply unscrew the retainer cap and remove the spray tip byhand. Then, install the new spray tip and tighten the retainercap to secure the spray tip in place.– Available in metal materials.Many of our nozzles are available in quick-connect versions.Watch for the Quick VeeJet, Quick FloodJet ® , Quick <strong>Flat</strong>Jet ® ,Quick WashJet ® and UniJet designations on the followingpages. These nozzles are available with a wide variety of bodytypes, mounting options, adapters, plugs, strainers, checkvalves, plates, fittings and more. See <strong>Section</strong> L, Accessories,for complete information.QuickJet ®UniJet<strong>Flat</strong> <strong>Spray</strong> <strong>Nozzles</strong>Table of <strong>Co</strong>ntentsStandard <strong>Spray</strong>VeeJet <strong>Spray</strong> <strong>Nozzles</strong> ......................................C3Quick VeeJet <strong>Spray</strong> <strong>Nozzles</strong> . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . C12ProMax Quick VeeJet <strong>Spray</strong> <strong>Nozzles</strong>. . . . . . . . . . . . . . . . . . . . . . . . C12UniJet <strong>Spray</strong> <strong>Nozzles</strong> . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . C21Wide Angle <strong>Spray</strong>FloodJet <strong>Spray</strong> <strong>Nozzles</strong> . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . C29Quick FloodJet <strong>Spray</strong> <strong>Nozzles</strong> ..............................C31UniJet <strong>Spray</strong> <strong>Nozzles</strong>, FloodJet Tip . . . . . . . . . . . . . . . . . . . . . . . . . C34FloodJet <strong>Spray</strong> <strong>Nozzles</strong>, Tapered Edge ......................C36Narrow Angle <strong>Spray</strong><strong>Flat</strong>Jet <strong>Spray</strong> <strong>Nozzles</strong> . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . C37Quick <strong>Flat</strong>Jet <strong>Spray</strong> <strong>Nozzles</strong> . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . C39High Impact <strong>Spray</strong>WashJet <strong>Spray</strong> <strong>Nozzles</strong> . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . C41Quick WashJet <strong>Spray</strong> <strong>Nozzles</strong> . . . . . . . . . . . . . . . . . . . . . . . . . . . . . C46Quick-<strong>Co</strong>nnect WashJet <strong>Spray</strong> <strong>Nozzles</strong> . . . . . . . . . . . . . . . . . . . . . C48High Pressure <strong>Spray</strong>UniJet <strong>Spray</strong> <strong>Nozzles</strong> . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . C50<strong>Flat</strong> <strong>Spray</strong><strong>Nozzles</strong>Female bodyHigh pressure female bodyAirless <strong>Spray</strong>RotoClean ® <strong>Spray</strong> Attachments . . . . . . . . . . . . . . . . . . . . . . . . . . . . C52Insert Kits . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . C53Male bodyGasketScreen strainer<strong>Spray</strong> tip with sealTip gasket<strong>Spray</strong> tipHigh pressure tip retainerPhone 1-800-95-spray, FAX 1-888-95-sprayVisit Our Web Site: www.spray.com, Email: info@spray.comC1

<strong>Flat</strong> <strong>Spray</strong> <strong>Nozzles</strong><strong>Flat</strong> <strong>Spray</strong> <strong>Nozzles</strong>Optimization Tips• Reduce operating costs and maintenance downtime by using quick-connectnozzles. Nozzle bodies remain on the header – only spray tips are replaced.• Use strainers to reduce nozzle clogging and ensure optimum performance.• Use adjustable ball connections for quick, precise nozzle orientation.• Evaluate your specific spraying application and implement a regular nozzlemaintenance plan.Maintenance essentials include:– Visual inspection of spray pattern. In flat spray nozzles, nozzle wearcauses streaks and heavier flows in the center of the pattern. A decreasein the effective spray angle coverage also typifies deterioration.– Monitor flow rate and pressure to detect changes resulting from orificeor vane wear.• Be sure to use the best type of flat spray nozzle for your application.– Tapered-edge flat spray nozzles are designed for use on a spray manifoldor header. These nozzles provide uniform, overall coverage across theimpact area as a result of overlapping distributions.– Even flat spray nozzles produce a thin rectangular pattern and provideuniform coverage. In manifold set-ups, the nozzles are positioned foredge-to-edge pattern contact. The nozzles are used primarily in highimpactapplications.– Deflected-type flat spray nozzles produce a relatively even flat spraypattern of medium-sized drops. The spray pattern is formed by liquidflowing over the deflector surface from a round orifice.– <strong>Flat</strong> spray nozzles with a 0° spray angle produce a solid stream. Thesenozzles typically provide the highest impact per unit area.ProMax ® Miniature QuickVeeJet ® with Replaceable TipsQPPM nozzle bodyOptional Kynar ® tip strainerOptional external O-ring(CP7717-2/13-VI)<strong>Spray</strong> tip<strong>Spray</strong> Pattern InspectionStrainersTapered-edgeflat sprayDeflected-typeflat sprayKynar body strainerEven flat spraySolid streamsprayPhone 1-800-95-spray, FAX 1-888-95-sprayVisit Our Web Site: www.spray.com, Email: info@spray.comC2

<strong>Spray</strong> <strong>Nozzles</strong>, Standard <strong>Spray</strong>Features and Benefits• <strong>Flat</strong> spray pattern distributes the liquid as a flat- or sheet-type spray.• Small- to medium-sized drops.• Uniform distribution over a wide range of flow rates and pressures.• <strong>Spray</strong> angles available from 0° (solid stream) to 110° at 40 psi (2.8 bar).• Specially tapered spray pattern is ideal for use in manifold and header applications.• High impact solid stream provides highest impact per unit area.• Unobstructed flow passages minimize clogging.<strong>Flat</strong> <strong>Spray</strong><strong>Nozzles</strong>H-DTH-DUH-UBelow 1 gpm (3.8 l/min) at40 psi (2.8 bar)1/8" to 1/4" NPT or BSPT (F)H-VV1 gpm (3.9 l/min) and above at40 psi (2.8 bar)1/8" to 1/4" NPT or BSPT (F)H-VVLU1 gpm (3.9 l/min) and above at40 psi (2.8 bar)1/8" to 3/4" NPT or BSPT (M)Below 1 gpm (3.9 l/min) at40 psi (2.8 bar)1/8" to 1/4" NPT or BSPT (M)Integral strainer1/8" to 1/4" NPT or BSPT (M)40 gpm (152 l/min) and above at40 psi (2.8 bar)1" to 2" NPT or BSPT (M)Optimization TipsSee Alsohttp://• See page C2 for optimization tips.Applications• Air washing• Liquor washers• <strong>Co</strong>oling and quenching• Scrubbers• Dust control• Washing/rinsing• Fire suppression/prevention • Water cooling• Gas washing• Accessories– Adjustable ball fittings– Check valves– Jet stabilizers for reducedturbulence– Pressure gauges– Pressure relief valves– Robotic tips for high precisionapplications– Split-eyelet connectors– Strainers for H1/8VV(order strainer 12686)and H1/4VV (orderstrainer 12687)– Strainers for otherVeeJet nozzles– Swivel connectors• For chemical and corrosion resistance, see VeeJet spray nozzlesin Kynar ®Phone 1-800-95-spray, FAX 1-888-95-sprayVisit Our Web Site: www.spray.com, Email: info@spray.comC3

<strong>Spray</strong> <strong>Nozzles</strong>, Standard <strong>Spray</strong><strong>Flat</strong> <strong>Spray</strong> <strong>Nozzles</strong>Performance Data<strong>Spray</strong>Angleat40 psi110°95°80°73°Nozzle Type/Inlet <strong>Co</strong>nn. (in.)H-VV H-VVL H-DTCapacitySizeEquiv.OrificeDia.(in.)Capacity(gallons per minute)**At the stated pressure in psi.1/8 1/4 1/8 1/4 1/8 1/4 5 10 20 30 40 60 80 100 200 300 500 20 40 80 200l l l l 01 .026 .035 .05 .07 .09 .10 .12 .14 .16 .22 .27 .35 94 110 121 124l l l l 015 .032 .05 .08 .11 .13 .15 .18 .21 .24 .34 .41 .53 97 110 121 124l l l l l 02 .035 .07 .10 .14 .17 .20 .24 .28 .32 .45 .55 .71 98 110 120 123l l l l l 03 .043 .11 .15 .21 .26 .30 .37 .42 .47 .67 .82 1.1 99 110 120 123l l l l l l 04 .050 .14 .20 .28 .35 .40 .49 .57 .63 .89 1.1 1.4 100 110 119 122l l l l l 05 .056 .18 .25 .35 .43 .50 .61 .71 .79 1.1 1.4 1.8 100 110 118 122l l l l l l 06 .061 .21 .30 .42 .52 .60 .73 .85 .95 1.3 1.6 2.1 101 110 117 122l l l l l 08 .071 .28 .40 .57 .69 .80 .98 1.1 1.3 1.8 2.2 2.8 102 110 117 121l l l l l l 10 .079 .35 .50 .71 .87 1.0 1.2 1.4 1.6 2.2 2.7 3.5 103 110 117 119l l l l l 15 .094 .53 .75 1.1 1.3 1.5 1.8 2.1 2.4 3.4 4.1 5.3 104 110 117 118l l l 0050 .018 – – .035 .043 .050 .060 .07 .08 .11 .14 .18 81 95 105 113l l l l 01 .026 .035 .05 .07 .09 .10 .12 .14 .16 .22 .27 .35 81 95 105 113l l l 015 .032 .05 .08 .11 .13 .15 .18 .21 .24 .34 .41 .53 82 95 105 113l l l l l l 02 .035 .07 .10 .14 .17 .20 .24 .28 .32 .45 .55 .71 82 95 105 113l l l l l 03 .043 .11 .15 .21 .26 .30 .37 .42 .47 .67 .82 1.1 83 95 104 111l l l l l l 04 .050 .14 .20 .28 .35 .40 .49 .57 .63 .89 1.1 1.4 84 95 103 108l l l l l 05 .056 .18 .25 .35 .43 .50 .61 .71 .79 1.1 1.4 1.8 84 95 102 107l l l l l l 06 .061 .21 .30 .42 .52 .60 .73 .85 .95 1.3 1.6 2.1 86 95 101 106l l 065 .064 .23 .33 .46 .56 .65 .80 .92 1.0 1.5 1.8 2.3 86 95 101 106l l l l l l 08 .071 .28 .40 .57 .69 .80 .98 1.1 1.3 1.8 2.2 2.8 87 95 100 105l l l l 0050 .018 – – .035 .043 .050 .060 .07 .08 .11 .14 .18 61 80 95 101l l l l 0067 .021 – .033 .05 .06 .067 .08 .09 .11 .15 .18 .24 67 80 94 99l l l l l l 01 .026 – .05 .07 .09 .10 .12 .14 .16 .22 .27 .35 68 80 89 92l l l l 015 .032 – .08 .11 .13 .15 .18 .21 .24 .34 .41 .53 68 80 89 92l l l l l l 02 .035 .07 .10 .14 .17 .20 .24 .28 .32 .45 .55 .71 69 80 88 91l l l l l l 03 .043 .11 .15 .21 .26 .30 .37 .42 .47 .67 .82 1.1 70 80 87 90l l l l l l 04 .050 .14 .20 .28 .35 .40 .49 .57 .63 .89 1.1 1.4 71 80 86 89l l l l l l 05 .056 .18 .25 .35 .43 .50 .61 .71 .79 1.1 1.4 1.8 71 80 86 89l l l l l l 06 .061 .21 .30 .42 .52 .60 .73 .85 .95 1.3 1.6 2.1 72 80 85 88l l l 07 .066 .25 .35 .49 .61 .70 .86 .99 1.1 1.6 1.9 2.5 72 80 85 88l l l l l l 08 .071 .28 .40 .57 .69 .80 .98 1.1 1.3 1.8 2.2 2.8 72 80 84 87l l l l 09 .075 .32 .45 .64 .78 .90 1.1 1.3 1.4 2.0 2.5 3.2 73 80 84 87l l l l l 0077 .023 – .039 .055 .067 .077 .09 .11 .12 .17 .21 .27 53 73 86 92l l l l 0154 .032 .054 .077 .11 .13 .15 .19 .22 .24 .34 .42 .54 55 73 84 88l l 0231 .038 .082 .12 .16 .20 .23 .28 .33 .37 .52 .63 .82 56 73 83 87l l l l 0308 .044 .11 .15 .22 .27 .31 .38 .44 .49 .69 .84 1.1 58 73 82 86l l 0462 .054 .16 .23 .33 .40 .46 .57 .65 .73 1.0 1.3 1.6 60 73 80 84l l 0770 .069 .27 .39 .54 .67 .77 .94 1.1 1.2 1.7 2.1 2.7 64 73 77 82<strong>Spray</strong>Angle(°)*Phone 1-800-95-spray, FAX 1-888-95-sprayVisit Our Web Site: www.spray.com, Email: info@spray.comC4

<strong>Spray</strong> <strong>Nozzles</strong>, Standard <strong>Spray</strong>Performance Data*At the stated pressure in psi.<strong>Spray</strong>Angleat40 psi65°50°40°Nozzle Type/Inlet <strong>Co</strong>nn. (in.)H-VV H-VVL H-DTCapacitySizeEquiv.OrificeDia.(in.)Capacity(gallons per minute)*1/8 1/4 1/8 1/4 1/8 1/4 5 10 20 30 40 60 80 100 200 300 500 20 40 80 200l l 0017 .011 – – .012 .015 .017 .021 .024 .027 .038 .047 .06 44 65 77 86l l 0033 .015 – – .023 .029 .033 .040 .045 .052 .07 .09 .12 47 65 76 83l l l l l 0067 .021 – .03 .05 .06 .067 .08 .09 .11 .15 .18 .24 50 65 75 81l l l l l l 01 .026 – .05 .07 .09 .10 .12 .14 .16 .22 .27 .35 51 65 74 80l l l l 015 .032 – .08 .11 .13 .15 .18 .21 .24 .34 .41 .53 51 65 74 80l l l l l l 02 .035 .07 .10 .14 .17 .20 .24 .28 .32 .45 .55 .71 52 65 73 79l l 025 .039 .09 .13 .18 .22 .25 .31 .35 .40 .56 .68 .88 52 65 73 79l l l l l l 03 .043 .11 .15 .21 .26 .30 .37 .42 .47 .67 .82 1.1 53 65 72 78l l l l l l 04 .050 .14 .20 .28 .35 .40 .49 .57 .63 .89 1.1 1.4 53 65 72 76l l l l l l 05 .056 .18 .25 .35 .43 .50 .61 .71 .79 1.1 1.4 1.8 53 65 72 76l l l 055 .059 .19 .28 .39 .48 .55 .67 .78 .87 1.2 1.5 1.9 53 65 72 76l l l l l 06 .061 .21 .30 .42 .52 .60 .73 .85 .95 1.3 1.6 2.1 54 65 72 75l l l 07 .066 .25 .35 .49 .61 .70 .86 .99 1.1 1.6 1.9 2.5 54 65 71 75l l l l l l 08 .071 .28 .40 .57 .69 .80 .98 1.1 1.3 1.8 2.2 2.8 55 65 71 74l l l 09 .075 .32 .45 .64 .78 .90 1.1 1.3 1.4 2.0 2.5 3.2 55 65 71 74l l l l 01 .026 – .05 .07 .09 .10 .12 .14 .16 .22 .27 .35 37 50 59 65l l l l 02 .035 – .10 .14 .17 .20 .24 .28 .32 .45 .55 .71 39 50 57 63l l l l l 03 .043 .11 .15 .21 .26 .30 .37 .42 .47 .67 .82 1.1 40 50 56 62l l l l l 04 .050 .14 .20 .28 .35 .40 .49 .57 .63 .89 1.1 1.4 42 50 56 61l l l l l 05 .056 .18 .25 .35 .43 .50 .61 .71 .79 1.1 1.4 1.8 44 50 56 61l l 055 .059 .19 .28 .39 .48 .55 .67 .78 .87 1.2 1.5 1.9 44 50 56 61l l l l l 06 .061 .21 .30 .42 .52 .60 .73 .85 .95 1.3 1.6 2.1 45 50 56 60l l l 07 .066 .25 .35 .49 .61 .70 .86 .99 1.1 1.6 1.9 2.5 45 50 56 60l l l l l 08 .071 .28 .40 .57 .69 .80 .98 1.1 1.3 1.8 2.2 2.8 45 50 55 60l l l 09 .075 .32 .45 .64 .78 .90 1.1 1.3 1.4 2.0 2.5 3.2 45 50 55 59l l l l l 01 .026 – – .07 .09 .10 .12 .14 .16 .22 .27 .35 26 40 52 59l l l l l 015 .032 – – .11 .13 .15 .18 .21 .24 .34 .41 .53 27 40 52 59l l l l l l 02 .035 – .10 .14 .17 .20 .24 .28 .32 .45 .55 .71 29 40 51 58l l l l l l 03 .043 – .15 .21 .26 .30 .37 .42 .47 .67 .82 1.1 30 40 50 57l l l l l l 04 .050 – .20 .28 .35 .40 .49 .57 .63 .89 1.1 1.4 30 40 50 56l l l l l l 05 .056 – .25 .35 .43 .50 .61 .71 .79 1.1 1.4 1.8 31 40 49 55l l l l 055 .059 – .28 .39 .48 .55 .67 .78 .87 1.2 1.5 1.9 31 40 49 55l l l l l l 06 .061 – .30 .42 .52 .60 .73 .85 .95 1.3 1.6 2.1 31 40 49 55l l l l 065 .064 – .33 .46 .56 .65 .80 .92 1.0 1.5 1.8 2.3 31 40 48 54l l l l 07 .066 – .35 .49 .61 .70 .86 .99 1.1 1.6 1.9 2.5 31 40 48 54l l l l l l 08 .071 .28 .40 .57 .69 .80 .98 1.1 1.3 1.8 2.2 2.8 31 40 47 53l 085 .073 .30 .43 .60 .74 .85 1.0 1.2 1.3 1.9 2.3 3.0 32 40 46 50l l l l 09 .075 .32 .45 .64 .78 .90 1.1 1.3 1.4 2.0 2.5 3.2 32 40 46 50<strong>Spray</strong>Angle(°)*<strong>Flat</strong> <strong>Spray</strong><strong>Nozzles</strong>Phone 1-800-95-spray, FAX 1-888-95-sprayVisit Our Web Site: www.spray.com, Email: info@spray.comC5

<strong>Spray</strong> <strong>Nozzles</strong>, Standard <strong>Spray</strong><strong>Flat</strong> <strong>Spray</strong> <strong>Nozzles</strong>Performance Data<strong>Spray</strong>Angleat40 psi25°15°Nozzle Type/Inlet <strong>Co</strong>nn. (in.)H-VV H-VVL H-DTCapacitySizeEquiv.OrificeDia.(in.)Capacity(gallons per minute)**At the stated pressure in psi.1/8 1/4 1/8 1/4 1/8 1/4 5 10 20 30 40 60 80 100 200 300 500 20 40 80 200l l l l l 01 .026 – – .07 .09 .10 .12 .14 .16 .22 .27 .35 14 25 34 42l l l l l l 02 .035 – – .14 .17 .20 .24 .28 .32 .45 .55 .71 15 25 33 40l l l l l l 03 .043 – – .21 .26 .30 .37 .42 .47 .67 .82 1.1 15 25 33 40l l l l l l 04 .050 – .20 .28 .35 .40 .49 .57 .63 .89 1.1 1.4 16 25 32 39<strong>Spray</strong>Angle(°)*l l l 045 .053 – .23 .32 .39 .45 .55 .64 .71 1.0 1.2 1.6 16 25 32 39l l l l l l 05 .056 – .25 .35 .43 .50 .61 .71 .79 1.1 1.4 1.8 16 25 32 39l l l l 055 .059 – .28 .39 .48 .55 .67 .78 .87 1.2 1.5 1.9 16 25 31 38l l l l l l 06 .061 – .30 .42 .52 .60 .73 .85 .95 1.3 1.6 2.1 17 25 31 38l l l l 065 .064 – .33 .46 .56 .65 .80 .92 1.0 1.5 1.8 2.3 17 25 31 38l l l l l 07 .066 – .35 .49 .61 .70 .86 .99 1.1 1.6 1.9 2.5 17 25 31 38l l 075 .068 – .38 .53 .65 .75 .92 1.1 1.2 1.7 2.1 2.7 17 25 31 38l l l l l l 08 .071 – .40 .57 .69 .80 .98 1.1 1.3 1.8 2.2 2.8 17 25 31 38l 085 .073 – .43 .60 .74 .85 1.0 1.2 1.3 1.9 2.3 3.0 18 25 31 37l l l l 09 .075 – .45 .64 .78 .90 1.1 1.3 1.4 2.0 2.5 3.2 17 25 31 37l 15 .094 – .75 1.1 1.3 1.5 1.8 2.1 2.4 3.4 4.1 5.3 18 25 31 37l l l 01 .026 – – .07 .09 .10 .12 .14 .16 .22 .27 .35 – 15 24 28l l l l 02 .035 – – .14 .17 .20 .24 .28 .32 .45 .55 .71 6 15 22 27l l l l l l 03 .043 – – .21 .26 .30 .37 .42 .47 .67 .82 1.1 6 15 22 27l l l l l l 04 .050 – – .28 .35 .40 .49 .57 .63 .89 1.1 1.4 7 15 21 26l l l l l l 05 .056 – – .35 .43 .50 .61 .71 .79 1.1 1.4 1.8 7 15 21 26l l l l 055 .059 – .28 .39 .48 .55 .67 .78 .87 1.2 1.5 1.9 7 15 21 26l l l l l l 06 .061 – .30 .42 .52 .60 .73 .85 .95 1.3 1.6 2.1 8 15 21 26l l l l 065 .064 – .33 .46 .56 .65 .80 .92 1.0 1.5 1.8 2.3 8 15 20 25l l l 07 .066 – .35 .49 .61 .70 .86 .99 1.1 1.6 1.9 2.5 8 15 20 25l l l l l l 08 .071 – .40 .57 .69 .80 .98 1.1 1.3 1.8 2.2 2.8 9 15 20 25l l l l 085 .073 – .43 .60 .74 .85 1.0 1.2 1.3 1.9 2.3 3.0 9 15 19 24l l l l 09 .075 – .45 .64 .78 .90 1.1 1.3 1.4 2.0 2.5 3.2 9 15 19 24Phone 1-800-95-spray, FAX 1-888-95-sprayVisit Our Web Site: www.spray.com, Email: info@spray.comC6

<strong>Spray</strong> <strong>Nozzles</strong>, Standard <strong>Spray</strong>Performance Data*At the stated pressure in psi.<strong>Spray</strong>Angleat40 psiNozzle Type/Inlet <strong>Co</strong>nn. (in.)H-U H-DU UCapacitySizeEquiv.OrificeDia.(in.)Capacity(gallons per minute)*1/8 1/4 3/8 1/2 3/4 1/8 1/4 1 1-1/4 2 5 10 20 30 40 60 80 100 200 300 500 20 40 80 200110° l 20 .109 .71 1.0 1.4 1.7 2.0 2.4 2.8 3.2 4.5 5.5 7.1 105 110 117 11895°80°65°l l l l l 10 .079 .35 .50 .71 .87 1.0 1.2 1.4 1.6 2.2 2.7 3.5 89 95 100 105l l l l l 15 .094 .53 .75 1.1 1.3 1.5 1.8 2.1 2.4 3.4 4.1 5.3 90 95 100 105l l l l 20 .109 .71 1.0 1.4 1.7 2.0 2.4 2.8 3.2 4.5 5.5 7.1 90 95 100 105l l l l l 30 .133 1.1 1.5 2.1 2.6 3.0 3.7 4.2 4.7 6.7 8.2 10.6 91 95 101 105l l l l 40 .153 1.4 2.0 2.8 3.5 4.0 4.9 5.7 6.3 8.9 11.0 14.1 92 95 100 105l l l 50 .172 1.8 2.5 3.5 4.3 5.0 6.1 7.1 7.9 11.2 13.7 17.7 93 95 99 103l l l 60 .188 2.1 3.0 4.2 5.2 6.0 7.3 8.5 9.5 13.4 16.4 21 93 95 99 103l l l l 70 .203 2.5 3.5 4.9 6.1 7.0 8.6 9.9 11.1 15.7 19.2 25 93 95 99 103<strong>Spray</strong>Angle(°)*l 80 .217 2.8 4.0 5.7 6.9 8.0 9.8 11.3 12.6 17.9 22 28 93 95 99 102l 100 .243 3.5 5.0 7.1 8.7 10.0 12.2 14.1 15.8 22 27 35 93 95 99 102l 150 .297 5.3 7.5 10.6 13.0 15.0 18.4 21 24 34 41 53 93 95 99 102l 400 .472 14.1 20 28 35 40 49 57 63 89 110 141 93 95 99 102l l l l l l 10 .079 .35 .50 .71 .87 1.0 1.2 1.4 1.6 2.2 2.7 3.5 73 80 84 87l l l l l 15 .094 .53 .75 1.1 1.3 1.5 1.8 2.1 2.4 3.4 4.1 5.3 74 80 83 86l l l l l l 20 .109 .71 1.0 1.4 1.7 2.0 2.4 2.8 3.2 4.5 5.5 7.1 74 80 83 86l l l l l l 30 .133 1.1 1.5 2.1 2.6 3.0 3.7 4.2 4.7 6.7 8.2 10.6 74 80 83 86l l l l l l 40 .153 1.4 2.0 2.8 3.5 4.0 4.9 5.7 6.3 8.9 11.0 14.1 74 80 83 86l l l l 50 .172 1.8 2.5 3.5 4.3 5.0 6.1 7.1 7.9 11.2 13.7 17.7 74 80 83 85l l l l 60 .188 2.1 3.0 4.2 5.2 6.0 7.3 8.5 9.5 13.4 16.4 21 75 80 83 85l l l l 70 .203 2.5 3.5 4.9 6.1 7.0 8.6 9.9 11.1 15.7 19.2 25 75 80 83 86l l 100 .243 3.5 5.0 7.1 8.7 10.0 12.2 14.1 15.8 22 27 35 75 80 83 86l l 150 .297 5.3 7.5 10.6 13.0 15.0 18.4 21 24 34 41 53 73 80 84 86l l 200 .343 7.1 10.0 14.1 17.3 20 24 28 32 45 55 71 74 80 82 85l 400 .472 14.1 20 28 35 40 49 57 63 89 110 141 78 80 81 83l 500 .528 17.7 25 35 43 50 61 71 79 112 137 177 78 80 81 83l 580 .569 21 29 41 50 58 71 82 92 130 159 205 78 80 81 83l l l l l 10 .079 .35 .50 .71 .87 1.0 1.2 1.4 1.6 2.2 2.7 3.5 56 65 71 74l l 12 .084 .42 .60 .85 1.0 1.2 1.5 1.7 1.9 2.7 3.3 4.2 56 65 71 73l l l l l l 15 .094 .53 .75 1.1 1.3 1.5 1.8 2.1 2.4 3.4 4.1 5.3 56 65 70 73l l l l l 20 .109 .71 1.0 1.4 1.7 2.0 2.4 2.8 3.2 4.5 5.5 7.1 57 65 70 73l 25 .121 .88 1.3 1.8 2.2 2.5 3.1 3.5 4.0 5.6 6.8 8.8 57 65 69 73l l l l l 30 .133 1.1 1.5 2.1 2.6 3.0 3.7 4.2 4.7 6.7 8.2 10.6 58 65 69 72l l l l l 40 .153 1.4 2.0 2.8 3.5 4.0 4.9 5.7 6.3 8.9 11.0 14.1 59 65 68 72l l l l l 50 .172 1.8 2.5 3.5 4.3 5.0 6.1 7.1 7.9 11.2 13.7 17.7 60 65 68 71l l l l 60 .188 2.1 3.0 4.2 5.2 6.0 7.3 8.5 9.5 13.4 16.4 21 60 65 68 71l l l l l 70 .203 2.5 3.5 4.9 6.1 7.0 8.6 9.9 11.1 15.7 19.2 25 60 65 68 71l l 100 .243 3.5 5.0 7.1 8.7 10.0 12.2 14.1 15.8 22 27 35 58 65 69 70l l 150 .297 5.3 7.5 10.6 13.0 15.0 18.4 21 24 34 41 53 59 65 68 70<strong>Flat</strong> <strong>Spray</strong><strong>Nozzles</strong>Phone 1-800-95-spray, FAX 1-888-95-sprayVisit Our Web Site: www.spray.com, Email: info@spray.comC7

<strong>Spray</strong> <strong>Nozzles</strong>, Standard <strong>Spray</strong><strong>Flat</strong> <strong>Spray</strong> <strong>Nozzles</strong>Performance Data<strong>Spray</strong>Angleat40 psi65°50°Nozzle Type/Inlet <strong>Co</strong>nn. (in.)H-U H-DU UCapacitySizeEquiv.OrificeDia.(in.)Capacity(gallons per minute)**At the stated pressure in psi.1/8 1/4 3/8 1/2 3/4 1/8 1/4 1 1-1/4 2 5 10 20 30 40 60 80 100 200 300 500 20 40 80 200<strong>Spray</strong>Angle(°)*l l 200 .343 7.1 10.0 14.1 17.3 20 24 28 32 45 55 71 60 65 67 69l 250 .373 8.8 12.5 17.7 22 25 31 35 40 56 68 88 60 65 67 69l 300 .409 10.6 15.0 21 26 30 37 42 47 67 82 106 60 65 67 69l 400 .472 14.1 20 28 35 40 49 57 63 89 110 141 60 65 67 69l l 500 .528 17.7 25 35 43 50 61 71 79 112 137 177 60 65 66 68l 580 .569 21 29 41 50 58 71 82 92 130 159 205 61 65 66 68l 02 .035 .07 .10 .14 .17 .20 .24 .28 .32 .45 .55 .71 39 50 57 63l 03 .043 .11 .15 .21 .26 .30 .37 .42 .47 .67 .82 1.1 40 50 56 62l 04 .050 .14 .20 .28 .35 .40 .49 .57 .63 .89 1.1 1.4 42 50 56 61l 05 .056 .18 .25 .35 .43 .50 .61 .71 .79 1.1 1.4 1.8 44 50 56 61l 055 .059 .19 .28 .39 .48 .55 .67 .78 .87 1.2 1.5 1.9 44 50 56 61l 06 .061 .21 .30 .42 .52 .60 .73 .85 .95 1.3 1.6 2.1 45 50 56 60l 07 .066 .25 .35 .49 .61 .70 .86 .99 1.1 1.6 1.9 2.5 45 50 56 60l 08 .071 .28 .40 .57 .69 .80 .98 1.1 1.3 1.8 2.2 2.8 45 50 55 60l l l l l 10 .079 .35 .50 .71 .87 1.0 1.2 1.4 1.6 2.2 2.7 3.5 45 50 55 59l l l l l 15 .094 .53 .75 1.1 1.3 1.5 1.8 2.1 2.4 3.4 4.1 5.3 45 50 55 59l l l l l 20 .109 .71 1.0 1.4 1.7 2.0 2.4 2.8 3.2 4.5 5.5 7.1 45 50 55 59l l l l l 30 .133 1.1 1.5 2.1 2.6 3.0 3.7 4.2 4.7 6.7 8.2 10.6 45 50 55 59l l l l l 40 .153 1.4 2.0 2.8 3.5 4.0 4.9 5.7 6.3 8.9 11.0 14.1 46 50 54 59l l l l 50 .172 1.8 2.5 3.5 4.3 5.0 6.1 7.1 7.9 11.2 13.7 17.7 46 50 54 59l l l 60 .188 2.1 3.0 4.2 5.2 6.0 7.3 8.5 9.5 13.4 16.4 21 46 50 54 59l l l l 70 .203 2.5 3.5 4.9 6.1 7.0 8.6 9.9 11.1 15.7 19.2 25 46 50 54 59l l 80 .217 2.8 4.0 5.7 6.9 8.0 9.8 11.3 12.6 17.9 22 28 45 50 53 58l 85 .224 3.0 4.3 6.0 7.4 8.5 10.4 12.0 13.4 19.0 23 30 45 50 53 57l 90 .230 3.2 4.5 6.4 7.8 9.0 11.0 12.7 14.2 20 25 32 45 50 53 56l l 100 .243 3.5 5.0 7.1 8.7 10.0 12.2 14.1 15.8 22 27 35 44 50 52 54l 110 .255 3.9 5.5 7.8 9.5 11.0 13.5 15.6 17.4 25 30 39 45 50 53 54l 120 .266 4.2 6.0 8.5 10.4 12.0 14.7 17.0 19.0 27 33 42 44 50 53 55l 135 .282 4.8 6.8 9.5 11.7 13.5 16.5 19.1 21 30 37 48 45 50 52 55l l 150 .297 5.3 7.5 10.6 13.0 15.0 18.4 21 24 34 41 53 45 50 52 55l 200 .343 7.1 10.0 14.1 17.3 20 24 28 32 45 55 71 46 50 52 55l 250 .384 8.8 12.5 17.7 22 25 31 35 40 56 68 88 46 50 52 55l 400 .472 14.1 20 28 35 40 49 57 63 89 110 141 46 50 52 55l l 500 .528 17.7 25 35 43 50 61 71 79 112 137 177 49 50 51 54l 580 .569 21 29 41 50 58 71 82 92 130 159 205 49 50 51 53l 750 .647 27 38 53 65 75 92 106 119 168 205 265 49 50 51 53l 1000 .747 35 50 71 87 100 122 141 158 224 274 354 49 50 51 53l 1500 .915 53 75 106 130 150 184 212 237 335 411 530 49 50 51 52l 2000 1.056 71 100 141 173 200 245 283 316 447 548 707 49 50 51 52Phone 1-800-95-spray, FAX 1-888-95-sprayVisit Our Web Site: www.spray.com, Email: info@spray.comC8

<strong>Spray</strong> <strong>Nozzles</strong>, Standard <strong>Spray</strong>Performance Data*At the stated pressure in psi.<strong>Spray</strong>Angleat40 psi40°25°15°Nozzle Type/Inlet <strong>Co</strong>nn. (in.)H-U H-DU UCapacitySizeEquiv.OrificeDia.(in.)Capacity(gallons per minute)*1/8 1/4 3/8 1/2 3/4 1/8 1/4 1 1-1/4 2 5 10 20 30 40 60 80 100 200 300 500 20 40 80 200l l l l l 10 .079 .35 .50 .71 .87 1.0 1.2 1.4 1.6 2.2 2.7 3.5 32 40 45 48l l l l l l 15 .094 .53 .75 1.1 1.3 1.5 1.8 2.1 2.4 3.4 4.1 5.3 32 40 45 48l l l l l l 20 .109 .71 1.0 1.4 1.7 2.0 2.4 2.8 3.2 4.5 5.5 7.1 32 40 45 48l l l l l 30 .133 1.1 1.5 2.1 2.6 3.0 3.7 4.2 4.7 6.7 8.2 10.6 33 40 45 48l l l l l 40 .153 1.4 2.0 2.8 3.5 4.0 4.9 5.7 6.3 8.9 11.0 14.1 34 40 45 48l l l l 50 .172 1.8 2.5 3.5 4.3 5.0 6.1 7.1 7.9 11.2 13.7 17.7 35 40 45 48l l l l 60 .188 2.1 3.0 4.2 5.2 6.0 7.3 8.5 9.5 13.4 16.4 21 35 40 45 48l l l l 70 .203 2.5 3.5 4.9 6.1 7.0 8.6 9.9 11.1 15.7 19.2 25 35 40 45 48l 80 .217 2.8 4.0 5.7 6.9 8.0 9.8 11.3 12.6 17.9 22 28 35 40 44 47l l 100 .243 3.5 5.0 7.1 8.7 10.0 12.2 14.1 15.8 22 27 35 34 40 43 46l l 150 .297 5.3 7.5 10.6 13.0 15.0 18.4 21 24 34 41 53 35 40 43 44<strong>Spray</strong>Angle(°)*l 200 .343 7.1 10.0 14.1 17.3 20 24 28 32 45 55 71 36 40 42 44l 500 .528 17.7 25 35 43 50 61 71 79 112 137 177 38 40 41 45l l l l 10 .079 .35 .50 .71 .87 1.0 1.2 1.4 1.6 2.2 2.7 3.5 18 25 31 37l l l l l 15 .094 .53 .75 1.1 1.3 1.5 1.8 2.1 2.4 3.4 4.1 5.3 18 25 31 37l l l l l 20 .109 .71 1.0 1.4 1.7 2.0 2.4 2.8 3.2 4.5 5.5 7.1 19 25 31 37l l l l l 30 .133 1.1 1.5 2.1 2.6 3.0 3.7 4.2 4.7 6.7 8.2 10.6 20 25 30 36l l l l 40 .153 1.4 2.0 2.8 3.5 4.0 4.9 5.7 6.3 8.9 11.0 14.1 21 25 29 35l l l 50 .172 1.8 2.5 3.5 4.3 5.0 6.1 7.1 7.9 11.2 13.7 17.7 21 25 29 35l l l 60 .188 2.1 3.0 4.2 5.2 6.0 7.3 8.5 9.5 13.4 16.4 21 22 25 29 35l l l l 70 .203 2.5 3.5 4.9 6.1 7.0 8.6 9.9 11.1 15.7 19.2 25 22 25 29 35l l 100 .243 3.5 5.0 7.1 8.7 10.0 12.2 14.1 15.8 22 27 35 23 25 28 32l l 150 .297 5.3 7.5 10.6 13.0 15.0 18.4 21 24 34 41 53 24 25 28 30l 200 .343 7.1 10.0 14.1 17.3 20 24 28 32 45 55 71 24 25 26 29l l 500 .528 17.7 25 35 43 50 61 71 79 112 137 177 24 25 26 29l 750 .647 27 38 53 65 75 92 106 119 168 205 265 24 25 26 28l 1000 .747 35 50 71 87 100 122 141 158 224 274 354 24 25 26 28l l l l 10 .079 .35 .50 .71 .87 1.0 1.2 1.4 1.6 2.2 2.7 3.5 10 15 19 24l l l l l 15 .094 .53 .75 1.1 1.3 1.5 1.8 2.1 2.4 3.4 4.1 5.3 10 15 19 24l l l l l 20 .109 .71 1.0 1.4 1.7 2.0 2.4 2.8 3.2 4.5 5.5 7.1 10 15 19 23l l l l l 30 .133 1.1 1.5 2.1 2.6 3.0 3.7 4.2 4.7 6.7 8.2 10.6 10 15 19 21l l l l l 40 .153 1.4 2.0 2.8 3.5 4.0 4.9 5.7 6.3 8.9 11.0 14.1 10 15 18 21l l l l 50 .172 1.8 2.5 3.5 4.3 5.0 6.1 7.1 7.9 11.2 13.7 17.7 11 15 18 21l l l 60 .188 2.1 3.0 4.2 5.2 6.0 7.3 8.5 9.5 13.4 16.4 21 11 15 18 21l l l l 70 .203 2.5 3.5 4.9 6.1 7.0 8.6 9.9 11.1 15.7 19.2 25 11 15 18 21l l 100 .243 3.5 5.0 7.1 8.7 10.0 12.2 14.1 15.8 22 27 35 13 15 17 18l 120 .266 4.2 6.0 8.5 10.4 12.0 14.7 17.0 19.0 27 33 42 13 15 17 18l 150 .297 5.3 7.5 10.6 13.0 15.0 18.4 21 24 34 41 53 14 15 17 18l 200 .343 7.1 10.0 14.1 17.3 20 24 28 32 45 55 71 14 15 17 18l 500 .528 17.7 25 35 43 50 61 71 79 112 137 177 14 15 16 17l 1000 .747 35 50 71 87 100 122 141 158 224 274 354 14 15 16 17<strong>Flat</strong> <strong>Spray</strong><strong>Nozzles</strong>Phone 1-800-95-spray, FAX 1-888-95-sprayVisit Our Web Site: www.spray.com, Email: info@spray.comC9

<strong>Spray</strong> <strong>Nozzles</strong>, Standard <strong>Spray</strong><strong>Flat</strong> <strong>Spray</strong> <strong>Nozzles</strong>Performance Data<strong>Spray</strong>Angleat40 psi0°Nozzle Type/Inlet <strong>Co</strong>nn. (in.)H-U H-DU UCapacitySizeEquiv.OrificeDia.(in.)Capacity(gallons per minute)**At the stated pressure in psi.1/8 1/4 3/8 1/2 3/4 1/8 1/4 1 1-1/4 2 5 10 20 30 40 60 80 100 200 300 500 20 40 80 200l l l 03 .041 .11 .15 .21 .26 .30 .37 .42 .47 .67 .82 1.1l l l l 04 .047 .14 .20 .28 .35 .40 .49 .57 .63 .89 1.1 1.4l l l l 05 .053 .18 .25 .35 .43 .50 .61 .71 .79 1.1 1.4 1.8l l l l 055 .055 .19 .28 .39 .48 .55 .67 .78 .87 1.2 1.5 1.9l l l l 06 .058 .21 .30 .42 .52 .60 .73 .85 .95 1.3 1.6 2.1l l l l 065 .060 .23 .33 .46 .56 .65 .80 .92 1.0 1.5 1.8 2.3l l l 07 .062 .25 .35 .49 .61 .70 .86 .99 1.1 1.6 1.9 2.5l l l l 08 .067 .28 .40 .57 .69 .80 .98 1.1 1.3 1.8 2.2 2.8l 085 .069 .30 .43 .60 .74 .85 1.0 1.2 1.3 1.9 2.3 3.0l l l l 09 .071 .32 .45 .64 .78 .90 1.1 1.3 1.4 2.0 2.5 3.2l l l l 10 .075 .35 .50 .71 .87 1.0 1.2 1.4 1.6 2.2 2.7 3.5l l 12 .082 .42 .60 .85 1.0 1.2 1.5 1.7 1.9 2.7 3.3 4.2l l l l 15 .091 .53 .75 1.1 1.3 1.5 1.8 2.1 2.4 3.4 4.1 5.3l l l l l 20 .106 .71 1.0 1.4 1.7 2.0 2.4 2.8 3.2 4.5 5.5 7.1l l l l 30 .129 1.1 1.5 2.1 2.6 3.0 3.7 4.2 4.7 6.7 8.2 10.6l l l l 40 .149 1.4 2.0 2.8 3.5 4.0 4.9 5.7 6.3 8.9 11.0 14.1l l 50 .167 1.8 2.5 3.5 4.3 5.0 6.1 7.1 7.9 11.2 13.7 17.7l l 60 .183 2.1 3.0 4.2 5.2 6.0 7.3 8.5 9.5 13.4 16.4 21l l l 70 .198 2.5 3.5 4.9 6.1 7.0 8.6 9.9 11.1 15.7 19.2 25l l 80 .211 2.8 4.0 5.7 6.9 8.0 9.8 11.3 12.6 17.9 22 28l 100 .236 3.5 5.0 7.1 8.7 10.0 12.2 14.1 15.8 22 27 35l 120 .259 4.2 6.0 8.5 10.4 12.0 14.7 17.0 19.0 27 33 42l l 150 .289 5.3 7.5 10.6 13.0 15.0 18.4 21 24 34 41 53l 165 .303 5.8 8.3 11.7 14.3 16.5 20 23 26 37 45 58l 200 .334 7.1 10.0 14.1 17.3 20 24 28 32 45 55 71l l 250 .373 8.8 12.5 17.7 22 25 31 35 40 56 68 88l 350 .437 12.4 17.5 25 30 35 43 49 55 78 96 124l l 570 .558 20 29 40 49 57 70 81 90 127 156 202l 700 .618 25 35 49 61 70 86 99 111 157 192 247l 1000 .739 35 50 71 87 100 122 141 158 224 274 354l 1100 .775 39 55 78 95 110 135 156 174 246 301 389l 1400 .875 49 70 99 121 140 171 198 221 313 383 495l 1800 .992 64 90 127 156 180 220 255 285 402 493 636l 2000 1.045 71 100 141 173 200 245 283 316 447 548 707l 3500 1.383 124 175 247 303 350 429 495 553 783 959 1237<strong>Spray</strong>Angle(°)*0Solid StreamPhone 1-800-95-spray, FAX 1-888-95-sprayVisit Our Web Site: www.spray.com, Email: info@spray.comC10

Quick and ProMax ® Quick VeeJet<strong>Spray</strong> <strong>Nozzles</strong>, Standard <strong>Spray</strong><strong>Flat</strong> <strong>Spray</strong> <strong>Nozzles</strong>Features and Benefits• <strong>Flat</strong> fan spray pattern with uniform distribution.• Small- to medium-sized drops.• <strong>Spray</strong> angles 25° to 110° at 40 psi (2.8 bar).• Fast and easy installation of spray tips without tools.• Automatic alignment.• Lower cost – nozzle body can be reused – only spray tips arereplaced.• Miniature versions are ideal when smaller physical size andlower weight are important.• Standard Quick VeeJet have easy-grip spray tips with a seal thatremains attached to the tip to prevent accidental misplacement.• ProMax Quick VeeJet nozzles provide increased chemicalresistance and less build-up. Internal O-ring seal andoptional external O-ring provide additional protection againstcontaminants in harsh environments. See chart for maximumpressures at various temperatures.• ProMax Quick VeeJet spray tips color-coded for easy flowrate identification.• Standard Quick VeeJet spray nozzle assemblies:– Nozzle body, spray tip with integral seal.– Miniature nozzle body, seal, spray tip.• ProMax Quick VeeJet spray nozzle assemblies:– Nozzle body, spray tip and optional external O-ring.– Miniature nozzle body, optional body strainer, tip strainer,external O-ring, spray tip.MiniatureQuickJet ® Bodies• QJJS male inlet connectionsMiniature Quick VeeJet <strong>Spray</strong> TipsTypical assemblies for Miniature Quick VeeJet nozzles are comprised of a body,seal and spray tip.QSUQSVVQJJS male bodySeal1 gpm (3.9 l/min)or above at 40 psi (2.8 bar)Below1 gpm (3.9 l/min)at 40 psi (2.8 bar)<strong>Spray</strong> tipPhone 1-800-95-spray, FAX 1-888-95-sprayVisit Our Web Site: www.spray.com, Email: info@spray.comC12

Quick and ProMax ® Quick VeeJet<strong>Spray</strong> <strong>Nozzles</strong>, Standard <strong>Spray</strong>StandardQuickJet ® Bodies• QJA female and QJJA maleinlet connections• QJLA female and QJJLA maleinlet connectionsQuick VeeJet <strong>Spray</strong> TipsTypical Quick VeeJet nozzles are comprised of two components, a body and a spray tip.Each of these spray tips is compatible with either the male or female bodies.QLUAQUAQVVA<strong>Flat</strong> <strong>Spray</strong><strong>Nozzles</strong>QJA and QJLA female bodies orQJJA and QJJLA male bodies1 gpm (3.9 l/min)or above at 40 psi (2.8 bar)up to a maximum of25 gpm (99 l/min) at40 psi (2.8 bar)1 gpm (3.9 l/min)or above at 40 psi (2.8 bar)up to a maximum of8 gpm (32 l/min) at40 psi (2.8 bar)Below 1 gpm (3.9 l/min)at 40 psi (2.8 bar)<strong>Spray</strong> tipProMax MiniatureQuickJet Bodies• QPPM male inlet connections• Optional Kynar ® body strainer, 50 meshProMax Miniature Quick VeeJet <strong>Spray</strong> TipsTypical Miniature Quick VeeJet nozzles are comprised of a QPPM nozzle body and aQMVV spray tip. Options include a Kynar body strainer, Kynar tip strainer and externalO-ring (for harsh environments). <strong>Co</strong>nsult your local sales engineer for more informationon the Kynar strainers.QMVVOptional Kynar body strainerRed; .15 gpmGray; .20 gpmBlack; .30 gpmOrange; .40 gpmQPPM nozzle bodyOptional Kynar tip strainerGreen; .50 gpmYellow; .60 gpmBlue; .80 gpmOptional external O-ring (CP7717-2/13-VI)Capacities at 40 psi (2.8 bar)<strong>Spray</strong> tipPhone 1-800-95-spray, FAX 1-888-95-sprayVisit Our Web Site: www.spray.com, Email: info@spray.comC13

Quick and ProMax ® Quick VeeJet<strong>Spray</strong> <strong>Nozzles</strong>, Standard <strong>Spray</strong><strong>Flat</strong> <strong>Spray</strong> <strong>Nozzles</strong>ProMax QuickJet ®Bodies• QPPA male inlet connectionsQPPA nozzle bodyOptional external O-ring (CP7717-2/17-VI)ProMax Quick VeeJet <strong>Spray</strong> TipsTypical Quick VeeJet nozzles are comprised of a QPPA nozzle body and a QPTA spray tip.Options include an external O-ring for harsh environments.QPTAWhite; 1.0 gpmGray; 1.5 gpmBlack; 2.0 gpmOrange; 3.0 gpm<strong>Spray</strong> tipGreen; 4.0 gpmYellow; 5.0 gpmBlue; 6.0 gpmRed; 7.0 gpmCapacities at 40 psi (2.8 bar)Optimization TipsSee Alsohttp://• See page C2 for optimization tips.ApplicationsStandard QuickVeeJet <strong>Nozzles</strong>• Degreasing and rinsing• Metal cleaning and processing• Parts washing/rinsing• Pressure cleaning• Sand, coal and gravel washing• <strong>Spray</strong> coating• <strong>Spray</strong> coolingProMax MiniatureQuick VeeJet <strong>Nozzles</strong>• Carpet cleaning equipment• Printed circuit boardmanufacturingProMax QuickVeeJet <strong>Nozzles</strong>• Chemical manufacturing• <strong>Co</strong>ating• <strong>Co</strong>oling• Food processing• Metal finishing• Parts washing/rinsing• Printed circuit boardmanufacturing• Accessories– ProMax QuickJet nozzle adapters– QuickJet adjustable ball fitting bodies– QuickJet nozzle adapters– QuickJet nozzle plugs– QuickJet nozzle plugs for ProMax bodies– QuickJet split-eyelet bodies– UniJet ® nozzle system adapter for QuickJet nozzlesProMax QuickJet nozzle maximum pressuresat various temperaturesPhone 1-800-95-spray, FAX 1-888-95-sprayVisit Our Web Site: www.spray.com, Email: info@spray.comC14

Quick and ProMax ® Quick VeeJet<strong>Spray</strong> <strong>Nozzles</strong>, Standard <strong>Spray</strong>Performance Data<strong>Spray</strong>Angleat40 psi110°95°80°*At the stated pressure in psi.Quick VeeJet Tip TypeCapacityEquiv.Capacity<strong>Spray</strong> AngleOrifice(gallons per minute)*(°)*Size Dia.QSVV QVVA QSU QUA QLUA QMVV QPTA (in.) 5 10 20 30 40 60 80 100 175† 200†† 300 20 40 80 200l l 01 .026 .035 .05 .07 .09 .10 .12 .14 .16 – .22 .27 94 110 121 124l l l 015 .032 .05 .08 .11 .13 .15 .18 .21 .24 .31 .34 .41 97 110 121 124l l l 02 .036 .07 .10 .14 .17 .20 .24 .28 .32 .42 .45 .55 98 110 120 123l l l 03 .043 .11 .15 .21 .26 .30 .37 .42 .47 .63 .67 .82 99 110 120 123l l 04 .050 .14 .20 .28 .35 .40 .49 .57 .63 .84 .89 1.1 100 110 119 122l l 05 .056 .18 .25 .35 .43 .50 .61 .71 .79 1.0 1.1 1.4 100 110 118 122l l 06 .061 .21 .30 .42 .52 .60 .73 .85 .95 1.3 1.3 1.6 101 110 117 122l l l 08 .071 .28 .40 .57 .69 .80 .98 1.1 1.3 1.7 1.8 2.2 102 110 117 121l 10 .079 .35 .50 .71 .87 1.0 1.2 1.4 1.6 – 2.2 2.7 103 110 117 119l 15 .094 .53 .75 1.1 1.3 1.5 1.8 2.1 2.4 – 3.4 4.1 104 110 117 118l 20 .109 .71 1.0 1.4 1.7 2.0 2.4 2.8 3.2 – 4.5 5.5 105 110 117 118l l 01 .026 .035 .05 .07 .09 .10 .12 .14 .16 – .22 .27 81 95 105 113l l 015 .032 .05 .08 .11 .13 .15 .18 .21 .24 .31 .34 .41 82 95 105 113l l 02 .036 .07 .10 .14 .17 .20 .24 .28 .32 .42 .45 .55 82 95 105 113l l 03 .043 .11 .15 .21 .26 .30 .37 .42 .47 .63 .67 .82 83 95 104 111l l 04 .050 .14 .20 .28 .35 .40 .49 .57 .63 .84 .89 1.1 84 95 103 108l l 05 .056 .18 .25 .35 .43 .50 .61 .71 .79 1.0 1.1 1.4 84 95 102 107l l 06 .061 .21 .30 .42 .52 .60 .73 .85 .95 1.3 1.3 1.6 86 95 101 106l l 08 .071 .28 .40 .57 .69 .80 .98 1.1 1.3 1.7 1.8 2.2 87 95 100 105l l l 10 .079 .35 .50 .71 .87 1.0 1.2 1.4 1.6 – 2.2 2.7 89 95 100 105l l 15 .094 .53 .75 1.1 1.3 1.5 1.8 2.1 2.4 – 3.4 4.1 90 95 100 105l l l 20 .109 .71 1.0 1.4 1.7 2.0 2.4 2.8 3.2 – 4.5 5.5 90 95 100 105l l 30 .133 1.1 1.5 2.1 2.6 3.0 3.7 4.2 4.7 – 6.7 8.2 91 95 101 105l l 40 .153 1.4 2.0 2.8 3.5 4.0 4.9 5.7 6.3 – 8.9 11.0 92 95 100 105l l 50 .172 1.8 2.5 3.5 4.3 5.0 6.1 7.1 7.9 – 11.2 13.7 93 95 99 103l l 60 .188 2.1 3.0 4.2 5.2 6.0 7.3 8.5 9.5 – 13.4 16.4 93 95 99 103l l 70 .203 2.5 3.5 4.9 6.1 7.0 8.6 9.9 11.1 – 15.7 19.2 93 95 99 103l 100 .243 3.5 5.0 7.1 8.7 10.0 12.2 14.1 15.8 – 22 27 93 95 99 102l 150 .297 5.3 7.5 10.6 13.0 15.0 18.4 21 24 – 34 41 93 95 99 102l l 0050 .018 – – .035 .043 .050 .060 .07 .08 – .11 .14 61 80 95 101l l 0067 .021 – .033 .05 .06 .067 .08 .09 .11 – .15 .18 67 80 94 99l l 01 .026 – .05 .07 .09 .10 .12 .14 .16 – .22 .27 68 80 89 92l l 015 .032 – .08 .11 .13 .15 .18 .21 .24 – .34 .41 68 80 89 92l l l 02 .036 .07 .10 .14 .17 .20 .24 .28 .32 .42 .45 .55 69 80 88 91l l l 03 .043 .11 .15 .21 .26 .30 .37 .42 .47 .63 .67 .82 70 80 87 90l l l 04 .050 .14 .20 .28 .35 .40 .49 .57 .63 .84 .89 1.1 71 80 86 89l l 05 .056 .18 .25 .35 .43 .50 .61 .71 .79 1.0 1.1 1.4 71 80 86 89l l l 06 .061 .21 .30 .42 .52 .60 .73 .85 .95 1.3 1.3 1.6 72 80 85 88l l l 08 .071 .28 .40 .57 .69 .80 .98 1.1 1.3 1.7 1.8 2.2 72 80 84 87†Maximum pressure for QMVV is 175 psi.††Maximum pressure for QPTA is 200 psi.l l l 10 .079 .35 .50 .71 .87 1.0 1.2 1.4 1.6 – 2.2 2.7 73 80 84 87l l l 15 .094 .53 .75 1.1 1.3 1.5 1.8 2.1 2.4 – 3.4 4.1 74 80 83 86l l l 20 .109 .71 1.0 1.4 1.7 2.0 2.4 2.8 3.2 – 4.5 5.5 74 80 83 86l l 30 .133 1.1 1.5 2.1 2.6 3.0 3.7 4.2 4.7 – 6.7 8.2 74 80 83 86<strong>Flat</strong> <strong>Spray</strong><strong>Nozzles</strong>Phone 1-800-95-spray, FAX 1-888-95-sprayVisit Our Web Site: www.spray.com, Email: info@spray.comC15

Quick and ProMax ® Quick VeeJet<strong>Spray</strong> <strong>Nozzles</strong>, Standard <strong>Spray</strong><strong>Flat</strong> <strong>Spray</strong> <strong>Nozzles</strong>Performance Data<strong>Spray</strong>Angleat40 psi80°73°65°*At the stated pressure in psi.Quick VeeJet Tip TypeCapacityEquiv.Capacity<strong>Spray</strong> AngleOrifice(gallons per minute)*(°)*Size Dia.QSVV QVVA QSU QUA QLUA QMVV QPTA (in.) 5 10 20 30 40 60 80 100 175† 200†† 300 20 40 80 200l l 40 .153 1.4 2.0 2.8 3.5 4.0 4.9 5.7 6.3 – 8.9 11.0 74 80 83 86l l 50 .172 1.8 2.5 3.5 4.3 5.0 6.1 7.1 7.9 – 11.2 13.7 74 80 83 85l l 60 .188 2.1 3.0 4.2 5.2 6.0 7.3 8.5 9.5 – 13.4 16.4 75 80 83 85l l 70 .203 2.5 3.5 4.9 6.1 7.0 8.6 9.9 11.1 – 15.7 19.2 75 80 83 86l 100 .243 3.5 5.0 7.1 8.7 10.0 12.2 14.1 15.8 – 22 27 75 80 83 86l 150 .297 5.3 7.5 10.6 13.0 15.0 18.4 21 24 – 34 41 73 80 84 86l 200 .343 7.1 10.0 14.1 17.3 20 24 28 32 – 45 55 74 80 82 85l 0023 .012 – – .016 .020 .023 .028 .032 .036 – .051 .063 50 73 89 97l 0039 .016 – .020 .028 .034 .039 .048 .055 .062 – .087 .11 53 73 87 93l 0077 .023 – .039 .055 .067 .077 .09 .11 .12 – .17 .21 53 73 86 92l 0116 .028 .041 .058 .082 .10 .12 .14 .16 .18 – .26 .32 54 73 85 90l 0154 .032 .054 .077 .11 .13 .15 .19 .22 .24 – .34 .42 55 73 84 88l 0231 .038 .082 .12 .16 .20 .23 .28 .33 .37 – .52 .63 56 73 83 87l 0308 .044 .11 .15 .22 .27 .31 .38 .44 .49 – .69 .84 58 73 82 86l 0385 .049 .14 .19 .27 .33 .39 .47 .54 .61 – .86 1.1 59 73 81 85l 0462 .054 .16 .23 .33 .40 .46 .57 .65 .73 – 1.0 1.3 60 73 80 84l 0616 .062 .22 .31 .44 .53 .62 .75 .87 .97 – 1.4 1.7 63 73 79 83l 0770 .069 .27 .39 .54 .67 .77 .94 1.1 1.2 – 1.7 2.1 64 73 77 82l 0924 .076 .33 .46 .65 .80 .92 1.1 1.3 1.5 – 2.1 2.5 65 73 77 80l 0017 .011 – – .012 .015 .017 .021 .024 .027 – .038 .047 44 65 77 86l 0025 .013 – – .018 .022 .025 .031 .035 .040 – .06 .07 45 65 77 84l 0033 .015 – – .023 .029 .033 .040 .047 .052 – .07 .09 47 65 76 83l 0050 .018 – – .035 .043 .050 .060 .07 .08 – .11 .14 48 65 75 82l 0067 .021 – .033 .05 .06 .067 .08 .09 .11 – .15 .18 50 65 75 81l 01 .026 – .05 .07 .09 .10 .12 .14 .16 – .22 .27 51 65 74 80l 015 .032 – .08 .11 .13 .15 .18 .21 .24 – .34 .41 51 65 74 80l l l 02 .036 .07 .10 .14 .17 .20 .24 .28 .32 .42 .45 .55 52 65 73 79l l l 03 .043 .11 .15 .21 .26 .30 .37 .42 .47 .63 .67 .82 53 65 72 78l l 04 .050 .14 .20 .28 .35 .40 .49 .57 .63 .84 .89 1.1 53 65 72 76l l 05 .056 .18 .25 .35 .43 .50 .61 .71 .79 1.0 1.1 1.4 53 65 72 76l l 06 .061 .21 .30 .42 .52 .60 .73 .85 .95 1.3 1.3 1.6 54 65 72 75l l 08 .071 .28 .40 .57 .69 .80 .98 1.1 1.3 1.7 1.8 2.2 55 65 71 74†Maximum pressure for QMVV is 175 psi.††Maximum pressure for QPTA is 200 psi.l l 10 .079 .35 .50 .71 .87 1.0 1.2 1.4 1.6 – 2.2 2.7 56 65 71 74l l 15 .094 .53 .75 1.1 1.3 1.5 1.8 2.1 2.4 – 3.4 4.1 56 65 70 73l l 20 .109 .71 1.0 1.4 1.7 2.0 2.4 2.8 3.2 – 4.5 5.5 57 65 70 73l l 30 .133 1.1 1.5 2.1 2.6 3.0 3.7 4.2 4.7 – 6.7 8.2 58 65 69 72l l 40 .153 1.4 2.0 2.8 3.5 4.0 4.9 5.7 6.3 – 8.9 11.0 59 65 68 72l l 50 .172 1.8 2.5 3.5 4.3 5.0 6.1 7.1 7.9 – 11.2 13.7 60 65 68 71l l 60 .188 2.1 3.0 4.2 5.2 6.0 7.3 8.5 9.5 – 13.4 16.4 60 65 68 71l l 70 .203 2.5 3.5 4.9 6.1 7.0 8.6 9.9 11.1 – 15.7 19.2 60 65 68 71l 100 .243 3.5 5.0 7.1 8.7 10.0 12.2 14.1 15.8 – 22 27 58 65 69 70l 150 .297 5.3 7.5 10.6 13.0 15.0 18.4 21 24 – 34 41 59 65 68 70l 200 .343 7.1 10.0 14.1 17.3 20 24 28 32 – 45 55 60 65 67 69Phone 1-800-95-spray, FAX 1-888-95-sprayVisit Our Web Site: www.spray.com, Email: info@spray.comC16

Quick and ProMax ® Quick VeeJet<strong>Spray</strong> <strong>Nozzles</strong>, Standard <strong>Spray</strong>Performance Data<strong>Spray</strong>Angleat40 psi50°40°*At the stated pressure in psi.Quick VeeJet Tip TypeCapacityEquiv.Capacity<strong>Spray</strong> AngleOrifice(gallons per minute)*(°)*Size Dia.QSVV QVVA QSU QUA QLUA QMVV QPTA (in.) 5 10 20 30 40 60 80 100 175† 200†† 300 20 40 80 200l 0017 .011 – – .012 .015 .017 .021 .024 .027 – .038 .047 27 50 65 74l 0025 .013 – – .018 .022 .025 .031 .035 .040 – .06 .07 29 50 64 71l 0033 .015 – – .023 .029 .033 .040 .047 .052 – .07 .09 30 50 62 68l 0050 .018 – – .035 .043 .050 .060 .07 .08 – .11 .14 32 50 60 66l 0067 .021 – – .05 .06 .067 .08 .09 .11 – .15 .18 35 50 60 66l 01 .026 – .05 .07 .09 .10 .12 .14 .16 – .22 .27 37 50 59 65l 015 .032 – .08 .11 .13 .15 .18 .21 .24 – .34 .41 38 50 58 64l l 02 .036 – .10 .14 .17 .20 .24 .28 .32 .42 .45 .55 39 50 57 63l l 03 .043 .11 .15 .21 .26 .30 .37 .42 .47 .63 .67 .82 40 50 56 62l l 04 .050 .14 .20 .28 .35 .40 .49 .57 .63 .84 .89 1.1 42 50 56 61l l 05 .056 .18 .25 .35 .43 .50 .61 .71 .79 1.0 1.1 1.4 44 50 56 61l l 06 .061 .21 .30 .42 .52 .60 .73 .85 .95 1.3 1.3 1.6 45 50 56 60l l 08 .071 .28 .40 .57 .69 .80 .98 1.1 1.3 1.7 1.8 2.2 45 50 55 60l l 10 .079 .35 .50 .71 .87 1.0 1.2 1.4 1.6 – 2.2 2.7 45 50 55 59l l 15 .094 .53 .75 1.1 1.3 1.5 1.8 2.1 2.4 – 3.4 4.1 45 50 55 59l l 20 .109 .71 1.0 1.4 1.7 2.0 2.4 2.8 3.2 – 4.5 5.5 45 50 55 59l l 30 .133 1.1 1.5 2.1 2.6 3.0 3.7 4.2 4.7 – 6.7 8.2 45 50 55 59l l 40 .153 1.4 2.0 2.8 3.5 4.0 4.9 5.7 6.3 – 8.9 11.0 46 50 54 59l l 50 .172 1.8 2.5 3.5 4.3 5.0 6.1 7.1 7.9 – 11.2 13.7 46 50 54 59l l 60 .188 2.1 3.0 4.2 5.2 6.0 7.3 8.5 9.5 – 13.4 16.4 46 50 54 59l l 70 .203 2.5 3.5 4.9 6.1 7.0 8.6 9.9 11.1 – 15.7 19.2 46 50 54 59l 100 .243 3.5 5.0 7.1 8.7 10.0 12.2 14.1 15.8 – 22 27 44 50 52 54l 120 .266 4.2 6.0 8.5 10.4 12.0 14.7 17.0 19.0 – 27 33 44 50 53 55l 150 .297 5.3 7.5 10.6 13.0 15.0 18.4 21 24 – 34 41 45 50 52 55l 200 .343 7.1 10.0 14.1 17.3 20 24 28 32 – 45 55 46 50 52 55l 0017 .011 – – .012 .015 .017 .021 .024 .027 – .038 .047 21 40 54 61l 0025 .013 – – .018 .022 .025 .031 .035 .040 – .06 .07 22 40 53 60l 0033 .015 – – .023 .029 .033 .040 .047 .052 – .07 .09 22 40 53 60l 0050 .018 – – .035 .043 .050 .060 .07 .08 – .11 .14 22 40 53 60l 0067 .021 – – .05 .06 .067 .08 .09 .11 – .15 .18 24 40 53 60l 01 .026 – – .07 .09 .10 .12 .14 .16 – .22 .27 26 40 52 59l 015 .032 – – .11 .13 .15 .18 .21 .24 – .34 .41 27 40 52 59l l 02 .036 – .10 .14 .17 .20 .24 .28 .32 .42 .45 .55 29 40 51 58l l 03 .043 – .15 .21 .26 .30 .37 .42 .47 .63 .67 .82 30 40 50 57l l 04 .050 – .20 .28 .35 .40 .49 .57 .63 .84 .89 1.1 30 40 50 56l l 05 .056 – .25 .35 .43 .50 .61 .71 .79 1.0 1.1 1.4 31 40 49 55l l 06 .061 – .30 .42 .52 .60 .73 .85 .95 1.3 1.3 1.6 31 40 49 55l l 08 .071 .28 .40 .57 .69 .80 .98 1.1 1.3 1.7 1.8 2.2 31 40 47 53†Maximum pressure for QMVV is 175 psi.††Maximum pressure for QPTA is 200 psi.l l 10 .079 .35 .50 .71 .87 1.0 1.2 1.4 1.6 – 2.2 2.7 32 40 45 48l l 15 .094 .53 .75 1.1 1.3 1.5 1.8 2.1 2.4 – 3.4 4.1 32 40 45 48l l 20 .109 .71 1.0 1.4 1.7 2.0 2.4 2.8 3.2 – 4.5 5.5 32 40 45 48l l 30 .133 1.1 1.5 2.1 2.6 3.0 3.7 4.2 4.7 – 6.7 8.2 33 40 45 48l l 40 .153 1.4 2.0 2.8 3.5 4.0 4.9 5.7 6.3 – 8.9 11.0 34 40 45 48<strong>Flat</strong> <strong>Spray</strong><strong>Nozzles</strong>Phone 1-800-95-spray, FAX 1-888-95-sprayVisit Our Web Site: www.spray.com, Email: info@spray.comC17

Quick and ProMax ® Quick VeeJet<strong>Spray</strong> <strong>Nozzles</strong>, Standard <strong>Spray</strong><strong>Flat</strong> <strong>Spray</strong> <strong>Nozzles</strong>Performance Data<strong>Spray</strong>Angleat40 psi40°25°15°*At the stated pressure in psi.Quick VeeJet Tip TypeCapacityEquiv.Capacity<strong>Spray</strong> AngleOrifice(gallons per minute)*(°)*Size Dia.QSVV QVVA QSU QUA QLUA QMVV QPTA (in.) 5 10 20 30 40 60 80 100 175† 200†† 300 20 40 80 200l l 50 .172 1.8 2.5 3.5 4.3 5.0 6.1 7.1 7.9 – 11.2 13.7 35 40 45 48l l 60 .188 2.1 3.0 4.2 5.2 6.0 7.3 8.5 9.5 – 13.4 16.4 35 40 45 48l l 70 .203 2.5 3.5 4.9 6.1 7.0 8.6 9.9 11.1 – 15.7 19.2 35 40 45 48l 100 .243 3.5 5.0 7.1 8.7 10.0 12.2 14.1 15.8 – 22 27 34 40 43 46l 150 .297 5.3 7.5 10.6 13.0 15.0 18.4 21 24 – 34 41 35 40 43 44l 200 .343 7.1 10.0 14.1 17.3 20 24 28 32 – 45 55 36 40 42 44l 0017 .011 – – – .015 .017 .021 .024 .027 – .038 .047 – 25 35 47l 0025 .013 – – – .022 .025 .031 .035 .040 – .06 .07 – 25 35 45l 0033 .015 – – – .029 .033 .040 .047 .052 – .07 .09 – 25 34 44l 0050 .018 – – – .043 .050 .060 .07 .08 – .11 .14 – 25 34 43l 0067 .021 – – – .06 .067 .08 .09 .11 – .15 .18 – 25 34 42l 01 .026 – – .07 .09 .10 .12 .14 .16 – .22 .27 14 25 34 42l 015 .032 – – .11 .13 .15 .18 .21 .24 – .34 .41 15 25 34 41l l 02 .036 – – .14 .17 .20 .24 .28 .32 .42 .45 .55 15 25 33 40l l 03 .043 – – .21 .26 .30 .37 .42 .47 .63 .67 .82 15 25 33 40l l 04 .050 – .20 .28 .35 .40 .49 .57 .63 .84 .89 1.1 16 25 32 39l l 05 .056 – .25 .35 .43 .50 .61 .71 .79 1.0 1.1 1.4 16 25 32 39l l 06 .061 – .30 .42 .52 .60 .73 .85 .95 1.3 1.3 1.6 17 25 31 38l l 08 .071 – .40 .57 .69 .80 .98 1.1 1.3 1.7 1.8 2.2 17 25 31 38l l 10 .079 – .50 .71 .87 1.0 1.2 1.4 1.6 – 2.2 2.7 18 25 31 37l l 15 .094 – .75 1.1 1.3 1.5 1.8 2.1 2.4 – 3.4 4.1 18 25 31 37l l 20 .109 – 1.0 1.4 1.7 2.0 2.4 2.8 3.2 – 4.5 5.5 19 25 31 37l l 30 .133 1.1 1.5 2.1 2.6 3.0 3.7 4.2 4.7 – 6.7 8.2 20 25 30 36l l 40 .153 1.4 2.0 2.8 3.5 4.0 4.9 5.7 6.3 – 8.9 11.0 21 25 29 35l l 50 .172 1.8 2.5 3.5 4.3 5.0 6.1 7.1 7.9 – 11.2 13.7 21 25 29 35l l 60 .188 2.1 3.0 4.2 5.2 6.0 7.3 8.5 9.5 – 13.4 16.4 22 25 29 35l l 70 .203 2.5 3.5 4.9 6.1 7.0 8.6 9.9 11.1 – 15.7 19.2 22 25 29 35l 100 .243 3.5 5.0 7.1 8.7 10.0 12.2 14.1 15.8 – 22 27 23 25 28 32l 150 .297 5.3 7.5 10.6 13.0 15.0 18.4 21 24 – 34 41 24 25 28 30l 200 .343 7.1 10.0 14.1 17.3 20 24 28 32 – 45 55 24 25 26 29l 0017 .011 – – – .015 .017 .021 .024 .027 – .038 .047 – 15 30 37l 0025 .013 – – – .022 .025 .031 .035 .040 – .06 .07 – 15 28 34l 0033 .015 – – – .029 .033 .040 .047 .052 – .07 .09 – 15 27 32l 0050 .018 – – – .043 .050 .060 .07 .08 – .11 .14 – 15 26 30l 0067 .021 – – – .06 .067 .08 .09 .11 – .15 .18 – 15 25 29l 01 .026 – – – .09 .10 .12 .14 .16 – .22 .27 – 15 24 28l 015 .032 – – – .13 .15 .18 .21 .24 – .34 .41 – 15 23 27l 02 .036 – – .14 .17 .20 .24 .28 .32 – .45 .55 6 15 22 27l 03 .043 – – .21 .26 .30 .37 .42 .47 – .67 .82 6 15 22 27l 04 .050 – – .28 .35 .40 .49 .57 .63 – .89 1.1 7 15 21 26l 05 .055 – – .35 .43 .50 .61 .71 .79 – 1.1 1.4 7 15 21 26l 06 .061 – – .42 .52 .60 .73 .85 .95 – 1.3 1.6 8 15 21 26l 08 .071 – – .57 .69 .80 .98 1.1 1.3 – 1.8 2.2 9 15 20 25†Maximum pressure for QMVV is 175 psi.††Maximum pressure for QPTA is 200 psi.Phone 1-800-95-spray, FAX 1-888-95-sprayVisit Our Web Site: www.spray.com, Email: info@spray.comC18

Quick and ProMax ® Quick VeeJet<strong>Spray</strong> <strong>Nozzles</strong>, Standard <strong>Spray</strong>Performance Data<strong>Spray</strong>Angleat40 psi15°0°*At the stated pressure in psi.Quick VeeJet Tip TypeCapacityEquiv.Capacity<strong>Spray</strong> AngleOrifice(gallons per minute)*(°)*Size Dia.QSVV QVVA QSU QUA QLUA QMVV QPTA (in.) 5 10 20 30 40 60 80 100 175† 200†† 300 20 40 80 200l 10 .079 .35 .50 .71 .87 1.0 1.2 1.4 1.6 2.1 2.2 2.7 10 15 19 24l 15 .094 .53 .75 1.1 1.3 1.5 1.8 2.1 2.4 3.1 3.4 4.1 10 15 19 24l 20 .109 .71 1.0 1.4 1.7 2.0 2.4 2.8 3.2 4.2 4.5 5.5 10 15 19 23l 30 .133 1.1 1.5 2.1 2.6 3.0 3.7 4.2 4.7 6.3 6.7 8.2 10 15 19 21l 40 .153 1.4 2.0 2.8 3.5 4.0 4.9 5.7 6.3 8.4 8.9 11.0 10 15 18 21l 50 .172 1.8 2.5 3.5 4.3 5.0 6.1 7.1 7.9 10.5 11.2 13.7 11 15 18 21l 60 .188 2.1 3.0 4.2 5.2 6.0 7.3 8.5 9.5 12.5 13.4 16.4 11 15 18 21l 70 .203 2.5 3.5 4.9 6.1 7.0 8.6 9.9 11.1 14.6 15.7 19.2 11 15 18 21l 100 .243 3.5 5.0 7.1 8.7 10.0 12.2 14.1 15.8 21 22 27 13 15 17 18l 120 .266 4.2 6.0 8.5 10.4 12.0 14.7 17.0 19.0 25 27 33 13 15 17 18l 150 .297 5.3 7.5 10.6 13.0 15.0 18.4 21 24 31 34 41 14 15 17 18l 200 .343 7.1 10.0 14.1 17.3 20 24 28 32 42 45 55 14 15 17 18l 0009 .008 .003 .003 .005 .008 .009 .011 .013 .014 .020 .020 .025l 0012 .010 .004 .006 .008 .010 .012 .015 .017 .019 .027 .027 .033l 0019 .012 .007 .009 .013 .016 .019 .023 .027 .030 .043 .043 .052l l 0021 .013 .007 .010 .011 .017 .023 .029 .033 .040 .047 .047 .052l 0050 .019 .018 .025 .035 .043 .050 .060 .07 .08 .10 .11 .14l 0067 .023 .024 .033 .05 .06 .067 .08 .09 .11 .14 .15 .18l 01 .028 .035 .05 .07 .09 .10 .12 .14 .16 .21 .22 .27l 015 .034 .05 .08 .11 .13 .15 .18 .21 .24 .31 .34 .41l 02 .039 .07 .10 .14 .17 .20 .24 .28 .32 .42 .45 .55l l 03 .041 .11 .15 .21 .26 .30 .37 .42 .47 .63 .67 .82l l 04 .047 .14 .20 .28 .35 .40 .49 .57 .63 .84 .89 1.1l l 05 .053 .18 .25 .35 .43 .50 .61 .71 .79 1.0 1.1 1.4l l 06 .058 .21 .30 .42 .52 .60 .73 .85 .95 1.3 1.3 1.6l l 08 .067 .28 .40 .57 .69 .80 .98 1.1 1.3 1.7 1.8 2.2†Maximum pressure for QMVV is 175 psi.††Maximum pressure for QPTA is 200 psi.l 10 .075 .35 .50 .71 .87 1.0 1.2 1.4 1.6 2.1 2.2 2.7l 15 .091 .53 .75 1.1 1.3 1.5 1.8 2.1 2.4 3.1 3.4 4.1l 20 .106 .71 1.0 1.4 1.7 2.0 2.4 2.8 3.2 4.2 4.5 5.5l 30 .129 1.1 1.5 2.1 2.6 3.0 3.7 4.2 4.7 6.3 6.7 8.2l 40 .149 1.4 2.0 2.8 3.5 4.0 4.9 5.7 6.3 8.4 8.9 11.0l 50 .167 1.8 2.5 3.5 4.3 5.0 6.1 7.1 7.9 10.5 11.2 13.7l 60 .183 2.1 3.0 4.2 5.2 6.0 7.3 8.5 9.5 12.5 13.4 16.4l 70 .198 2.5 3.5 4.9 6.1 7.0 8.6 9.9 11.1 14.6 15.7 19.2l 80 .211 2.8 4.0 5.7 6.9 8.0 9.8 11.3 12.6 16.7 17.9 22l 100 .236 3.5 5.0 7.1 8.7 10.0 12.2 14.1 15.8 21 22 27l 120 .259 4.2 6.0 8.5 10.4 12.0 14.7 17.0 19.0 25 27 33l 150 .289 5.3 7.5 10.6 13.0 15.0 18.4 21 24 31 34 41l 200 .334 7.1 10.0 14.1 17.3 20 24 28 32 42 45 55l 250 .373 8.8 12.5 17.7 22 25 31 35 40 52 56 680Solid Stream<strong>Flat</strong> <strong>Spray</strong><strong>Nozzles</strong>Phone 1-800-95-spray, FAX 1-888-95-sprayVisit Our Web Site: www.spray.com, Email: info@spray.comC19

Quick and ProMax ® Quick VeeJet<strong>Spray</strong> <strong>Nozzles</strong>, Standard <strong>Spray</strong><strong>Flat</strong> <strong>Spray</strong> <strong>Nozzles</strong>Dimensions and WeightsStandardNozzleTypeLength(in.)Hex.(in.)Width(in.)NetWeight(oz.)QJJS+QSVV 1-3/32 9/16 – 1QJJS+QSU 1-11/64 9/16 – 1QJA+QVVA 2-5/32 1 – 2-1/2QJJA+QVVA 2-1/16 1 – 2QJA+QUA 2 1 – 2-3/4QJJA+QUA 1-29/32 1 – 2-1/4QJLA+QLUA 2-5/16 1-1/8 – 4-3/4QJJLA+QLUA 2-11/32 1-1/8 – 4-3/4Body TypesInlet<strong>Co</strong>nn.(in.)<strong>Co</strong>nn.FStandard Body<strong>Co</strong>nn.MQJA QJLA QJJS QJJA QJJLA QPPM QPPA1/8 l l l l l1/4 l l l l l3/8 l l l l l1/2 l l l lMaterialsQPPM+QMVV 1-3/16 5/8 – 1/8MaterialMaterial<strong>Co</strong>de<strong>Spray</strong> TipQSVV QSU QVVA QUA QLUAQPPA+QPTA 1-3/4 7/8 1-1/4 3/8Based on largest/heaviest version of each type.Brass (none) l l l l l303 Stainless Steel SS l l l l lStandard Quick VeeJet nozzles available in either brass with a Buna-Nseal or stainless steel with a Viton ® seal.ProMax Quick VeeJet nozzles available with a Viton seal.Miniature ProMax spray tips and bodies have an optional Kynar ® bodystrainer, optional tip strainer. See <strong>Section</strong> K, Special Purpose <strong>Spray</strong><strong>Nozzles</strong> for more details or contact your local representative.Ordering InfoStrainer Ordering InfoNozzle BodyQuick VeeJet <strong>Co</strong>mplete Nozzle<strong>Spray</strong> Tip1/4 QJJA – SS + QVVA – SS 110 10I I I I I I IInlet<strong>Co</strong>nn.BodyTypeMaterial<strong>Co</strong>deTipTypeMaterial<strong>Co</strong>de<strong>Spray</strong>AngleCapacitySizeFor NozzleSeriesBodyStrainerOrder No.TipStrainerOrder No.1/8 QPPM+QMVV CP39212-1-KY CP45095-KY1/4 QPPM+QMVV CP39212-2-KY CP45095-KYProMax Quick VeeJet <strong>Co</strong>mplete NozzleNozzle Body<strong>Spray</strong> Tip1/4 QPPM + QMVV 50 02I I I I IInlet<strong>Co</strong>nn.BodyTypeTipType<strong>Spray</strong>AngleAdd “A” to the capacity size for external O-ring. Example: 02ACapacitySizeBSPT connections require the addition of a “B” prior to the nozzle bodyinlet connection.Phone 1-800-95-spray, FAX 1-888-95-sprayVisit Our Web Site: www.spray.com, Email: info@spray.comC20

<strong>Spray</strong> <strong>Nozzles</strong>, Standard <strong>Spray</strong>UniJet Bodies• T female or TT male inletconnectionsT female body orTT male bodyUniJet<strong>Spray</strong> TipsA typical UniJet assemblyconsists of a T female body orTT male body, screen strainer,spray tip and tip retainer.TPUStandard spray tipFeatures and Benefits• <strong>Flat</strong> fan spray pattern with uniform distribution.• <strong>Spray</strong> angles available from 0° (solid stream) to 110° at40 psi (2.8 bar).• Small- to medium-sized drops.• Lower cost – nozzle body can be reused – only spray tipsare replaced.• Recessed orifices to protect against damage.• A large choice of interchangeable spray tips, body types/sizes, materials, spray angles and accessories.• Flow rates – up to 7 gpm (28 l/min) at 40 psi (2.8 bar).• UniJet nozzle assemblies:– Nozzle body, strainer, spray tip, tip retainer.<strong>Flat</strong> <strong>Spray</strong><strong>Nozzles</strong>Screen strainerOptimization Tips• See page C2 for optimization tips.<strong>Spray</strong> tipSee Alsohttp://Tip retainerApplications• Degreasing and rinsing• Metal cleaning and processing• Parts washing/rinsing• Pressure cleaning• Sand, coal, gravel washing• <strong>Spray</strong> coating• <strong>Spray</strong> cooling• Accessories– Adapters– Adjustable mounting clampnozzle bodies– Ball valve nozzle bodies– Check valves– Hose shanks– Jet stabilizers– Metering and plug plates– Plates, tip retainers, adapters– Plug valve nozzle bodies– Rollover nozzle bodies– Split-eyelet bodies– Strainers and filters– Swivel connectorsPhone 1-800-95-spray, FAX 1-888-95-sprayVisit Our Web Site: www.spray.com, Email: info@spray.comC21

<strong>Spray</strong> <strong>Nozzles</strong>, Standard <strong>Spray</strong><strong>Flat</strong> <strong>Spray</strong> <strong>Nozzles</strong>Performance DataTPU<strong>Spray</strong>Angleat40 psi110°95°CapacitySizeEquiv.OrificeDia.(in.)Capacity(gallons per minute)**At the stated pressure in psi.<strong>Spray</strong>Angle(°)*5 10 20 30 40 60 80 100 200 300 500 20 40 80 2000033 .015 – – .023 .029 .033 .040 .047 .052 .07 .09 .12 91 110 116 1210050 .018 – – .035 .043 .050 .060 .07 .08 .11 .14 .18 91 110 118 1240067 .021 – – .05 .06 .067 .08 .09 .11 .15 .18 .24 92 110 118 12401 .026 .035 .05 .07 .09 .10 .12 .14 .16 .22 .27 .35 94 110 121 124015 .032 .05 .08 .11 .13 .15 .18 .21 .24 .34 .41 .53 97 110 121 12402 .035 .07 .10 .14 .17 .20 .24 .28 .32 .45 .55 .71 98 110 120 12303 .043 .11 .15 .21 .26 .30 .37 .42 .47 .67 .82 1.1 99 110 120 12304 .050 .14 .20 .28 .35 .40 .49 .57 .63 .89 1.1 1.4 100 110 119 12205 .056 .18 .25 .35 .43 .50 .61 .71 .79 1.1 1.4 1.8 100 110 118 12206 .061 .21 .30 .42 .52 .60 .73 .85 .95 1.3 1.6 2.1 101 110 117 12207 .066 .25 .35 .49 .61 .70 .86 .99 1.1 1.6 1.9 2.5 102 110 117 12108 .071 .28 .40 .57 .69 .80 .98 1.1 1.3 1.8 2.2 2.8 102 110 117 12110 .079 .35 .50 .71 .87 1.0 1.2 1.4 1.6 2.2 2.7 3.5 103 110 117 11912 .087 .42 .60 .85 1.0 1.2 1.5 1.7 1.9 2.7 3.3 4.2 103 110 117 11915 .097 .53 .75 1.1 1.3 1.5 1.8 2.1 2.4 3.4 4.1 5.3 104 110 117 11820 .112 .71 1.0 1.4 1.7 2.0 2.4 2.8 3.2 4.5 5.5 7.1 105 110 117 11830 .133 1.1 1.5 2.1 2.6 3.0 3.7 4.2 4.7 6.7 8.2 10.6 105 110 117 11801 .026 .035 .05 .07 .09 .10 .12 .14 .16 .22 .27 .35 81 95 105 113015 .032 .05 .08 .11 .13 .15 .18 .21 .24 .34 .41 .53 82 95 105 11302 .035 .07 .10 .14 .17 .20 .24 .28 .32 .45 .55 .71 82 95 105 11303 .043 .11 .15 .21 .26 .30 .37 .42 .47 .67 .82 1.1 83 95 104 11104 .050 .14 .20 .28 .35 .40 .49 .57 .63 .89 1.1 1.4 84 95 103 10805 .056 .18 .25 .35 .43 .50 .61 .71 .79 1.1 1.4 1.8 84 95 102 10706 .061 .21 .30 .42 .52 .60 .73 .85 .95 1.3 1.6 2.1 86 95 101 10607 .066 .25 .35 .49 .61 .70 .86 .99 1.1 1.6 1.9 2.5 86 95 101 10608 .071 .28 .40 .57 .69 .80 .98 1.1 1.3 1.8 2.2 2.8 87 95 100 10509 .075 .32 .45 .64 .78 .90 1.1 1.3 1.4 2.0 2.5 3.2 89 95 100 10510 .079 .35 .50 .71 .87 1.0 1.2 1.4 1.6 2.2 2.7 3.5 89 95 100 10511 .083 .39 .55 .78 .95 1.1 1.3 1.6 1.7 2.5 3.0 3.9 89 95 100 10512 .087 .42 .60 .85 1.0 1.2 1.5 1.7 1.9 2.7 3.3 4.2 89 95 100 10513 .090 .46 .65 .92 1.1 1.3 1.6 1.8 2.1 2.9 3.6 4.6 89 95 100 10514 .093 .49 .70 .99 1.2 1.4 1.7 2.0 2.2 3.1 3.8 4.9 89 95 100 10515 .097 .53 .75 1.1 1.3 1.5 1.8 2.1 2.4 3.4 4.1 5.3 90 95 100 10516 .100 .57 .80 1.1 1.4 1.6 2.0 2.3 2.5 3.6 4.4 5.7 90 95 100 10518 .106 .64 .90 1.3 1.6 1.8 2.2 2.5 2.8 4.0 4.9 6.4 90 95 100 10520 .112 .71 1.0 1.4 1.7 2.0 2.4 2.8 3.2 4.5 5.5 7.1 90 95 100 10530 .133 1.1 1.5 2.1 2.6 3.0 3.7 4.2 4.7 6.7 8.2 10.6 91 95 101 10540 .153 1.4 2.0 2.8 3.5 4.0 4.9 5.7 6.3 8.9 11.0 14.1 92 95 100 10550 .172 1.8 2.5 3.5 4.3 5.0 6.1 7.1 7.9 11.2 13.7 17.7 93 95 99 10360 .188 2.1 3.0 4.2 5.2 6.0 7.3 8.5 9.5 13.4 16.4 21 93 95 99 10370 .203 2.5 3.5 4.9 6.1 7.0 8.6 9.9 11.1 15.7 19.2 25 93 95 99 103Other body types may be available. <strong>Co</strong>ntact representative for further information.Phone 1-800-95-spray, FAX 1-888-95-sprayVisit Our Web Site: www.spray.com, Email: info@spray.comC22

<strong>Spray</strong> <strong>Nozzles</strong>, Standard <strong>Spray</strong>Performance DataTPU*At the stated pressure in psi.<strong>Spray</strong>Angleat40 psi80°73°CapacitySizeEquiv.OrificeDia.(in.)Capacity(gallons per minute)*<strong>Spray</strong>Angle(°)*5 10 20 30 40 60 80 100 200 300 500 20 40 80 2000050 .018 – – .035 .043 .050 .060 .07 .08 .11 .14 .18 61 80 95 1010067 .021 – .033 .05 .06 .067 .08 .09 .11 .15 .18 .24 67 80 94 9901 .026 – .05 .07 .09 .10 .12 .14 .16 .22 .27 .35 68 80 89 92015 .032 – .08 .11 .13 .15 .18 .21 .24 .34 .41 .53 68 80 89 9202 .035 .07 .10 .14 .17 .20 .24 .28 .32 .45 .55 .71 69 80 88 9103 .043 .11 .15 .21 .26 .30 .37 .42 .47 .67 .82 1.1 70 80 87 9004 .050 .14 .20 .28 .35 .40 .49 .57 .63 .89 1.1 1.4 71 80 86 89045 .053 .16 .23 .32 .39 .45 .55 .64 .71 1.0 1.2 1.6 71 80 86 8905 .056 .18 .25 .35 .43 .50 .61 .71 .79 1.1 1.4 1.8 71 80 86 8906 .061 .21 .30 .42 .52 .60 .73 .85 .95 1.3 1.6 2.1 72 80 85 8807 .066 .25 .35 .49 .61 .70 .86 .99 1.1 1.6 1.9 2.5 72 80 85 8808 .071 .28 .40 .57 .69 .80 .98 1.1 1.3 1.8 2.2 2.8 72 80 84 8709 .075 .32 .45 .64 .78 .90 1.1 1.3 1.4 2.0 2.5 3.2 73 73 73 7310 .079 .35 .50 .71 .87 1.0 1.2 1.4 1.6 2.2 2.7 3.5 73 80 84 8711 .083 .39 .55 .78 .95 1.1 1.3 1.6 1.7 2.5 3.0 3.9 73 73 73 7312 .087 .42 .60 .85 1.0 1.2 1.5 1.7 1.9 2.7 3.3 4.2 73 73 73 7313 .090 .46 .65 .92 1.1 1.3 1.6 1.8 2.1 2.9 3.6 4.6 73 73 73 7314 .093 .49 .70 .99 1.2 1.4 1.7 2.0 2.2 3.1 3.8 4.9 73 73 73 7315 .097 .53 .75 1.1 1.3 1.5 1.8 2.1 2.4 3.4 4.1 5.3 74 80 83 8616 .100 .57 .80 1.1 1.4 1.6 2.0 2.3 2.5 3.6 4.4 5.7 74 80 83 8617 .103 .60 .85 1.2 1.5 1.7 2.1 2.4 2.7 3.8 4.7 6.0 74 80 83 8620 .112 .71 1.0 1.4 1.7 2.0 2.4 2.8 3.2 4.5 5.5 7.1 74 80 83 8625 .121 .88 1.3 1.8 2.2 2.5 3.1 3.5 4.0 5.6 6.8 8.8 74 80 83 8630 .133 1.1 1.5 2.1 2.6 3.0 3.7 4.2 4.7 6.7 8.2 10.6 74 80 83 8640 .153 1.4 2.0 2.8 3.5 4.0 4.9 5.7 6.3 8.9 11.0 14.1 74 80 83 8650 .172 1.8 2.5 3.5 4.3 5.0 6.1 7.1 7.9 11.2 13.7 17.7 74 80 83 8560 .188 2.1 3.0 4.2 5.2 6.0 7.3 8.5 9.5 13.4 16.4 21 75 80 83 8570 .203 2.5 3.5 4.9 6.1 7.0 8.6 9.9 11.1 15.7 19.2 25 75 80 83 860023 .012 – – .016 .020 .023 .028 .032 .036 .051 .063 .081 50 73 89 970039 .016 – .020 .028 .034 .039 .048 .055 .062 .087 .11 .14 53 73 87 930077 .023 – .039 .055 .067 .077 .09 .11 .12 .17 .21 .27 53 73 86 920116 .028 .041 .058 .082 .10 .12 .14 .16 .18 .26 .32 .41 54 73 85 900154 .032 .054 .077 .11 .13 .15 .19 .22 .24 .34 .42 .54 55 73 84 880231 .038 .082 .12 .16 .20 .23 .28 .33 .37 .52 .63 .82 56 73 83 870308 .044 .11 .15 .22 .27 .31 .38 .44 .49 .69 .84 1.1 58 73 82 860385 .049 .14 .19 .27 .33 .39 .47 .54 .61 .86 1.1 1.4 59 73 81 850462 .054 .16 .23 .33 .40 .46 .57 .65 .73 1.0 1.3 1.6 60 73 80 840616 .062 .22 .31 .44 .53 .62 .75 .87 .97 1.4 1.7 2.2 63 73 79 830770 .069 .27 .39 .54 .67 .77 .94 1.1 1.2 1.7 2.1 2.7 64 73 77 820924 .076 .33 .46 .65 .80 .92 1.1 1.3 1.5 2.1 2.5 3.3 65 73 77 80<strong>Flat</strong> <strong>Spray</strong><strong>Nozzles</strong>Other body types may be available. <strong>Co</strong>ntact representative for further information.Phone 1-800-95-spray, FAX 1-888-95-sprayVisit Our Web Site: www.spray.com, Email: info@spray.comC23

<strong>Spray</strong> <strong>Nozzles</strong>, Standard <strong>Spray</strong><strong>Flat</strong> <strong>Spray</strong> <strong>Nozzles</strong>Performance DataTPU<strong>Spray</strong>Angleat40 psi65°50°CapacitySizeEquiv.OrificeDia.(in.)Capacity(gallons per minute)**At the stated pressure in psi.<strong>Spray</strong>Angle(°)*5 10 20 30 40 60 80 100 200 300 500 20 40 80 2000017 .011 – – .012 .015 .017 .021 .024 .027 .038 .047 .06 44 65 77 860025 .013 – – .018 .022 .025 .031 .035 .040 .06 .07 .09 45 65 77 840033 .015 – – .023 .029 .033 .040 .047 .052 .07 .09 .12 47 65 76 830050 .018 – – .035 .043 .050 .060 .07 .08 .11 .14 .18 48 65 75 820067 .021 – .033 .05 .06 .067 .08 .09 .11 .15 .18 .24 50 65 75 8101 .026 – .05 .07 .09 .10 .12 .14 .16 .22 .27 .35 51 65 74 80015 .032 – .08 .11 .13 .15 .18 .21 .24 .34 .41 .53 51 65 74 8002 .035 .07 .10 .14 .17 .20 .24 .28 .32 .45 .55 .71 52 65 73 79025 .039 .09 .13 .18 .22 .25 .31 .35 .40 .56 .68 .88 52 65 73 7903 .043 .11 .15 .21 .26 .30 .37 .42 .47 .67 .82 1.1 53 65 72 78035 .047 .12 .18 .25 .30 .35 .43 .49 .55 .78 .96 1.2 53 65 72 7804 .050 .14 .20 .28 .35 .40 .49 .57 .63 .89 1.1 1.4 53 65 72 7605 .056 .18 .25 .35 .43 .50 .61 .71 .79 1.1 1.4 1.8 53 65 72 76055 .059 .19 .28 .39 .48 .55 .67 .78 .87 1.2 1.5 1.9 53 65 72 7606 .061 .21 .30 .42 .52 .60 .73 .85 .95 1.3 1.6 2.1 54 65 72 7507 .066 .25 .35 .49 .61 .70 .86 .99 1.1 1.6 1.9 2.5 54 65 72 7508 .071 .28 .40 .57 .69 .80 .98 1.1 1.3 1.8 2.2 2.8 55 65 71 7409 .075 .32 .45 .64 .78 .90 1.1 1.3 1.4 2.0 2.5 3.2 55 65 71 7410 .079 .35 .50 .71 .87 1.0 1.2 1.4 1.6 2.2 2.7 3.5 56 65 71 7411 .083 .39 .55 .78 .95 1.1 1.3 1.6 1.7 2.5 3.0 3.9 56 65 71 7412 .087 .42 .60 .85 1.0 1.2 1.5 1.7 1.9 2.7 3.3 4.2 56 65 71 7413 .090 .46 .65 .92 1.1 1.3 1.6 1.8 2.1 2.9 3.6 4.6 56 65 71 7414 .093 .49 .70 .99 1.2 1.4 1.7 2.0 2.2 3.1 3.8 4.9 56 65 71 7415 .097 .53 .75 1.1 1.3 1.5 1.8 2.1 2.4 3.4 4.1 5.3 56 65 70 7320 .112 .71 1.0 1.4 1.7 2.0 2.4 2.8 3.2 4.5 5.5 7.1 57 65 70 7330 .133 1.1 1.5 2.1 2.6 3.0 3.7 4.2 4.7 6.7 8.2 10.6 58 65 69 7240 .153 1.4 2.0 2.8 3.5 4.0 4.9 5.7 6.3 8.9 11.0 14.1 59 65 68 7250 .172 1.8 2.5 3.5 4.3 5.0 6.1 7.1 7.9 11.2 13.7 17.7 60 65 68 7160 .188 2.1 3.0 4.2 5.2 6.0 7.3 8.5 9.5 13.4 16.4 21 60 65 68 7170 .203 2.5 3.5 4.9 6.1 7.0 8.6 9.9 11.1 15.7 19.2 25 60 65 68 710017 .011 – – .012 .015 .017 .021 .024 .027 .038 .047 .06 27 50 65 740025 .013 – – .018 .022 .025 .031 .035 .040 .06 .07 .09 29 50 64 710033 .015 – – .023 .029 .033 .040 .047 .052 .07 .09 .12 30 50 62 680050 .018 – – .035 .043 .050 .060 .07 .08 .11 .14 .18 32 50 60 660067 .021 – – .05 .06 .067 .08 .09 .11 .15 .18 .24 35 50 60 6601 .026 – .05 .07 .09 .10 .12 .14 .16 .22 .27 .35 37 50 59 65015 .032 – .08 .11 .13 .15 .18 .21 .24 .34 .41 .53 38 50 58 6402 .035 – .10 .14 .17 .20 .24 .28 .32 .45 .55 .71 39 50 57 63025 .039 .09 .13 .18 .22 .25 .31 .35 .40 .56 .68 .88 40 50 57 6303 .043 .11 .15 .21 .26 .30 .37 .42 .47 .67 .82 1.1 40 50 56 62035 .047 .12 .18 .25 .30 .35 .43 .49 .55 .78 .96 1.2 40 50 56 6104 .050 .14 .20 .28 .35 .40 .49 .57 .63 .89 1.1 1.4 42 50 56 6105 .056 .18 .25 .35 .43 .50 .61 .71 .79 1.1 1.4 1.8 44 50 56 61Other body types may be available. <strong>Co</strong>ntact representative for further information.Phone 1-800-95-spray, FAX 1-888-95-sprayVisit Our Web Site: www.spray.com, Email: info@spray.comC24

<strong>Spray</strong> <strong>Nozzles</strong>, Standard <strong>Spray</strong>Performance DataTPU*At the stated pressure in psi.<strong>Spray</strong>Angleat40 psi50°40°CapacitySizeEquiv.OrificeDia.(in.)Capacity(gallons per minute)*<strong>Spray</strong>Angle(°)*5 10 20 30 40 60 80 100 200 300 500 20 40 80 20006 .061 .21 .30 .42 .52 .60 .73 .85 .95 1.3 1.6 2.1 45 50 56 6007 .066 .25 .35 .49 .61 .70 .86 .99 1.1 1.6 1.9 2.5 45 50 56 60075 .068 .27 .38 .53 .65 .75 .92 1.1 1.2 1.7 2.1 2.7 45 50 55 6008 .071 .28 .40 .57 .69 .80 .98 1.1 1.3 1.8 2.2 2.8 45 50 55 6009 .075 .32 .45 .64 .78 .90 1.1 1.3 1.4 2.0 2.5 3.2 45 50 55 5910 .079 .35 .50 .71 .87 1.0 1.2 1.4 1.6 2.2 2.7 3.5 45 50 55 5913 .090 .46 .65 .92 1.1 1.3 1.6 1.8 2.1 2.9 3.6 4.6 45 50 55 5915 .097 .53 .75 1.1 1.3 1.5 1.8 2.1 2.4 3.4 4.1 5.3 45 50 55 5920 .112 .71 1.0 1.4 1.7 2.0 2.4 2.8 3.2 4.5 5.5 7.1 45 50 55 5930 .133 1.1 1.5 2.1 2.6 3.0 3.7 4.2 4.7 6.7 8.2 10.6 45 50 55 5940 .153 1.4 2.0 2.8 3.5 4.0 4.9 5.7 6.3 8.9 11.0 14.1 46 50 54 5950 .172 1.8 2.5 3.5 4.3 5.0 6.1 7.1 7.9 11.2 13.7 17.7 46 50 54 5960 .188 2.1 3.0 4.2 5.2 6.0 7.3 8.5 9.5 13.4 16.4 21 46 50 54 5970 .203 2.5 3.5 4.9 6.1 7.0 8.6 9.9 11.1 15.7 19.2 25 46 50 54 590017 .011 – – .012 .015 .017 .021 .024 .027 .038 .047 .06 21 40 54 610025 .013 – – .018 .022 .025 .031 .035 .040 .06 .07 .09 22 40 53 600033 .015 – – .023 .029 .033 .040 .047 .052 .07 .09 .12 22 40 53 600050 .018 – – .035 .043 .050 .060 .07 .08 .11 .14 .18 22 40 53 600067 .021 – – .05 .06 .067 .08 .09 .11 .15 .18 .24 24 40 53 6001 .026 – – .07 .09 .10 .12 .14 .16 .22 .27 .35 26 40 52 59015 .032 – – .11 .13 .15 .18 .21 .24 .34 .41 .53 27 40 52 5902 .035 – .10 .14 .17 .20 .24 .28 .32 .45 .55 .71 29 40 51 58025 .039 – .13 .18 .22 .25 .31 .35 .40 .56 .68 .88 29 40 51 5803 .043 – .15 .21 .26 .30 .37 .42 .47 .67 .82 1.1 30 40 50 5704 .050 – .20 .28 .35 .40 .49 .57 .63 .89 1.1 1.4 30 40 50 5605 .056 – .25 .35 .43 .50 .61 .71 .79 1.1 1.4 1.8 31 40 49 55055 .059 – .28 .39 .48 .55 .67 .78 .87 1.2 1.5 1.9 31 40 49 5506 .061 – .30 .42 .52 .60 .73 .85 .95 1.3 1.6 2.1 31 40 49 5507 .066 .25 .35 .49 .61 .70 .86 .99 1.1 1.6 1.9 2.5 31 40 49 5508 .071 .28 .40 .57 .69 .80 .98 1.1 1.3 1.8 2.2 2.8 31 40 47 5309 .075 .32 .45 .64 .78 .90 1.1 1.3 1.4 2.0 2.5 3.2 32 40 45 4810 .079 .35 .50 .71 .87 1.0 1.2 1.4 1.6 2.2 2.7 3.5 32 40 45 4811 .083 .39 .55 .78 .95 1.1 1.3 1.6 1.7 2.5 3.0 3.9 32 40 45 4812 .087 .42 .60 .85 1.0 1.2 1.5 1.7 1.9 2.7 3.3 4.2 32 40 45 4813 .090 .46 .65 .92 1.1 1.3 1.6 1.8 2.1 2.9 3.6 4.6 32 40 45 4815 .097 .53 .75 1.1 1.3 1.5 1.8 2.1 2.4 3.4 4.1 5.3 32 40 45 4820 .112 .71 1.0 1.4 1.7 2.0 2.4 2.8 3.2 4.5 5.5 7.1 32 40 45 4825 .121 .88 1.3 1.8 2.2 2.5 3.1 3.5 4.0 5.6 6.8 8.8 32 40 45 4830 .133 1.1 1.5 2.1 2.6 3.0 3.7 4.2 4.7 6.7 8.2 10.6 33 40 45 4840 .153 1.4 2.0 2.8 3.5 4.0 4.9 5.7 6.3 8.9 11.0 14.1 34 40 45 4850 .172 1.8 2.5 3.5 4.3 5.0 6.1 7.1 7.9 11.2 13.7 17.7 35 40 45 4860 .188 2.1 3.0 4.2 5.2 6.0 7.3 8.5 9.5 13.4 16.4 21 35 40 45 4870 .203 2.5 3.5 4.9 6.1 7.0 8.6 9.9 11.1 15.7 19.2 25 35 40 45 48<strong>Flat</strong> <strong>Spray</strong><strong>Nozzles</strong>Other body types may be available. <strong>Co</strong>ntact representative for further information.Phone 1-800-95-spray, FAX 1-888-95-sprayVisit Our Web Site: www.spray.com, Email: info@spray.comC25

<strong>Spray</strong> <strong>Nozzles</strong>, Standard <strong>Spray</strong><strong>Flat</strong> <strong>Spray</strong> <strong>Nozzles</strong>Performance DataTPU<strong>Spray</strong>Angleat40 psi25°15°CapacitySizeEquiv.OrificeDia.(in.)Capacity(gallons per minute)**At the stated pressure in psi.<strong>Spray</strong>Angle(°)*5 10 20 30 40 60 80 100 200 300 500 20 40 80 2000017 .011 – – – .015 .017 .021 .024 .027 .038 .047 .06 – 25 35 470025 .013 – – – .022 .025 .031 .035 .040 .06 .07 .09 – 25 35 450033 .015 – – – .029 .033 .040 .047 .052 .07 .09 .12 – 25 34 440050 .018 – – – .043 .050 .060 .07 .08 .11 .14 .18 – 25 34 430067 .021 – – – .06 .067 .08 .09 .11 .15 .18 .24 – 25 34 4201 .026 – – .07 .09 .10 .12 .14 .16 .22 .27 .35 14 25 34 42015 .032 – – .11 .13 .15 .18 .21 .24 .34 .41 .53 15 25 34 4102 .035 – – .14 .17 .20 .24 .28 .32 .45 .55 .71 15 25 33 4003 .043 – – .21 .26 .30 .37 .42 .47 .67 .82 1.1 15 25 33 4004 .050 – .20 .28 .35 .40 .49 .57 .63 .89 1.1 1.4 16 25 32 3905 .056 – .25 .35 .43 .50 .61 .71 .79 1.1 1.4 1.8 16 25 32 39055 .059 – .28 .39 .48 .55 .67 .78 .87 1.2 1.5 1.9 16 25 32 3906 .061 – .30 .42 .52 .60 .73 .85 .95 1.3 1.6 2.1 17 25 31 3807 .066 – .35 .49 .61 .70 .86 .99 1.1 1.6 1.9 2.5 17 25 31 3808 .071 – .40 .57 .69 .80 .98 1.1 1.3 1.8 2.2 2.8 17 25 31 3809 .075 – .45 .64 .78 .90 1.1 1.3 1.4 2.0 2.5 3.2 17 25 31 3810 .079 – .50 .71 .87 1.0 1.2 1.4 1.6 2.2 2.7 3.5 18 25 31 3713 .090 – .65 .92 1.1 1.3 1.6 1.8 2.1 2.9 3.6 4.6 18 25 31 3715 .097 – .75 1.1 1.3 1.5 1.8 2.1 2.4 3.4 4.1 5.3 18 25 31 3720 .112 – 1.0 1.4 1.7 2.0 2.4 2.8 3.2 4.5 5.5 7.1 19 25 31 3730 .133 1.1 1.5 2.1 2.6 3.0 3.7 4.2 4.7 6.7 8.2 10.6 20 25 30 3640 .153 1.4 2.0 2.8 3.5 4.0 4.9 5.7 6.3 8.9 11.0 14.1 21 25 29 3550 .172 1.8 2.5 3.5 4.3 5.0 6.1 7.1 7.9 11.2 13.7 17.7 21 25 29 3560 .188 2.1 3.0 4.2 5.2 6.0 7.3 8.5 9.5 13.4 16.4 21 22 25 29 3570 .203 2.5 3.5 4.9 6.1 7.0 8.6 9.9 11.1 15.7 19.2 25 22 25 29 350017 .011 – – – .015 .017 .021 .024 .027 .038 .047 .06 – 15 30 370025 .013 – – – .022 .025 .031 .035 .040 .06 .07 .09 – 15 28 340033 .015 – – – .029 .033 .040 .047 .052 .07 .09 .12 – 15 27 320050 .018 – – – .043 .050 .060 .07 .08 .11 .14 .18 – 15 26 300067 .021 – – – .06 .067 .08 .09 .11 .15 .18 .24 – 15 25 2901 .026 – – – .09 .10 .12 .14 .16 .22 .27 .35 – 15 24 28015 .032 – – – .13 .15 .18 .21 .24 .34 .41 .53 – 15 23 2702 .035 – – .14 .17 .20 .24 .28 .32 .45 .55 .71 6 15 22 2703 .043 – – .21 .26 .30 .37 .42 .47 .67 .82 1.1 6 15 22 2704 .050 – – .28 .35 .40 .49 .57 .63 .89 1.1 1.4 7 15 21 2605 .056 – – .35 .43 .50 .61 .71 .79 1.1 1.4 1.8 7 15 21 26055 .059 – – .39 .48 .55 .67 .78 .87 1.2 1.5 1.9 7 15 21 2606 .061 – – .42 .52 .60 .73 .85 .95 1.3 1.6 2.1 8 15 21 2607 .066 – – .49 .61 .70 .86 .99 1.1 1.6 1.9 2.5 8 15 21 2608 .071 – – .57 .69 .80 .98 1.1 1.3 1.8 2.2 2.8 9 15 20 2509 .075 – – .64 .78 .90 1.1 1.3 1.4 2.0 2.5 3.2 9 15 20 2510 .079 – – .71 .87 1.0 1.2 1.4 1.6 2.2 2.7 3.5 10 15 19 2411 .083 – .55 .78 .95 1.1 1.3 1.6 1.7 2.5 3.0 3.9 10 15 19 24Other body types may be available. <strong>Co</strong>ntact representative for further information.Phone 1-800-95-spray, FAX 1-888-95-sprayVisit Our Web Site: www.spray.com, Email: info@spray.comC26

<strong>Spray</strong> <strong>Nozzles</strong>, Standard <strong>Spray</strong>Performance DataTPU*At the stated pressure in psi.<strong>Spray</strong>Angleat40 psi15°0°CapacitySizeEquiv.OrificeDia.(in.)Capacity(gallons per minute)*<strong>Spray</strong>Angle(°)*5 10 20 30 40 60 80 100 200 300 500 20 40 80 20012 .087 .42 .60 .85 1.0 1.2 1.5 1.7 1.9 2.7 3.3 4.2 10 15 19 2415 .097 .53 .75 1.1 1.3 1.5 1.8 2.1 2.4 3.4 4.1 5.3 10 15 19 2420 .112 .71 1.0 1.4 1.7 2.0 2.4 2.8 3.2 4.5 5.5 7.1 10 15 19 2330 .133 1.1 1.5 2.1 2.6 3.0 3.7 4.2 4.7 6.7 8.2 10.6 10 15 19 2140 .153 1.4 2.0 2.8 3.5 4.0 4.9 5.7 6.3 8.9 11.0 14.1 10 15 18 2150 .172 1.8 2.5 3.5 4.3 5.0 6.1 7.1 7.9 11.2 13.7 17.7 11 15 18 2160 .188 2.1 3.0 4.2 5.2 6.0 7.3 8.5 9.5 13.4 16.4 21 11 15 18 2170 .203 2.5 3.5 4.9 6.1 7.0 8.6 9.9 11.1 15.7 19.2 25 11 15 18 210009 .008 .003 .003 .005 .008 .009 .011 .013 .014 .020 .025 .0320012 .010 .004 .006 .008 .010 .012 .015 .017 .019 .027 .033 .0420019 .012 .007 .009 .013 .016 .019 .023 .027 .030 .043 .052 .0670021 .013 .007 .010 .011 .017 .023 .029 .033 .040 .047 .052 .0740033 .016 .01 .02 .023 .029 .033 .040 .047 .052 .07 .09 .120050 .019 .018 .025 .035 .043 .050 .060 .07 .08 .11 .14 .180067 .023 .024 .033 .05 .06 .067 .08 .09 .11 .15 .18 .2401 .028 .035 .05 .07 .09 .10 .12 .14 .16 .22 .27 .35015 .034 .05 .08 .11 .13 .15 .18 .21 .24 .34 .41 .5302 .039 .07 .10 .14 .17 .20 .24 .28 .32 .45 .55 .7103 .041 .11 .15 .21 .26 .30 .37 .42 .47 .67 .82 1.104 .047 .14 .20 .28 .35 .40 .49 .57 .63 .89 1.1 1.4045 .052 .16 .23 .32 .39 .45 .55 .64 .71 1.0 1.2 1.605 .053 .18 .25 .35 .43 .50 .61 .71 .79 1.1 1.4 1.8055 .055 .19 .28 .39 .48 .55 .67 .78 .87 1.2 1.5 1.906 .058 .21 .30 .42 .52 .60 .73 .85 .95 1.3 1.6 2.1065 .060 .23 .33 .46 .56 .65 .80 .92 1.0 1.5 1.8 2.307 .062 .25 .35 .49 .61 .70 .86 .99 1.1 1.6 1.9 2.508 .067 .28 .40 .57 .69 .80 .98 1.1 1.3 1.8 2.2 2.809 .071 .32 .45 .64 .78 .90 1.1 1.3 1.4 2.0 2.5 3.210 .075 .35 .50 .71 .87 1.0 1.2 1.4 1.6 2.2 2.7 3.511 .079 .39 .55 .78 .95 1.1 1.3 1.6 1.7 2.5 3.0 3.912 .082 .42 .60 .85 1.0 1.2 1.5 1.7 1.9 2.7 3.3 4.215 .091 .53 .75 1.1 1.3 1.5 1.8 2.1 2.4 3.4 4.1 5.320 .106 .71 1.0 1.4 1.7 2.0 2.4 2.8 3.2 4.5 5.5 7.130 .129 1.1 1.5 2.1 2.6 3.0 3.7 4.2 4.7 6.7 8.2 10.640 .149 1.4 2.0 2.8 3.5 4.0 4.9 5.7 6.3 8.9 11.0 14.10Solid Stream<strong>Flat</strong> <strong>Spray</strong><strong>Nozzles</strong>Other body types may be available. <strong>Co</strong>ntact representative for further information.Phone 1-800-95-spray, FAX 1-888-95-sprayVisit Our Web Site: www.spray.com, Email: info@spray.comC27

<strong>Spray</strong> <strong>Nozzles</strong>, Standard <strong>Spray</strong><strong>Flat</strong> <strong>Spray</strong> <strong>Nozzles</strong>Dimensions and WeightsStandardNozzleTypeLength(in.)Hex.(in.)NetWeight(oz.)T+TPU 1-57/64 13/16 2-1/4TT+TPU 1-57/64 13/16 2Based on largest/heaviest version of each type.MaterialsMaterialMaterial<strong>Co</strong>de<strong>Spray</strong> TipTPUBrass (none) l303 Stainless Steel SS lOther materials available upon request.Ordering InfoNozzle BodyUniJet <strong>Co</strong>mplete Nozzle<strong>Spray</strong> Tip1/4 TT – SS + U110 10 – SSl l l l l lInlet<strong>Co</strong>nn.BodyTypeMaterial<strong>Co</strong>de<strong>Spray</strong>AngleCapacitySizeMaterial<strong>Co</strong>deTip OnlyTPU – 110 10 – SSl l l lTipType<strong>Spray</strong>AngleCapacitySizeMaterial<strong>Co</strong>deBSPT connections require the addition of a “B”prior to the nozzle body inlet connection.Mesh Selection GuideOrificeDia.in. (mm)Up through.018 (.46).019 (.47)through.031 (.79).032 (.80)and largerRecommendedScreenMesh20010050UniJet spray nozzles with TPU tipsused in barrel cleaning operation.Phone 1-800-95-spray, FAX 1-888-95-sprayVisit Our Web Site: www.spray.com, Email: info@spray.comC28

<strong>Spray</strong> <strong>Nozzles</strong>, Wide Angle <strong>Spray</strong>KFeatures and Benefits• Wide-angle flat fan spray pattern with uniform distributionand medium impact.• Medium-sized drops.• Unobstructed flow passages minimize clogging.• Precision engineered for dependable, accurate control ofdeflection and spray angle.<strong>Flat</strong> <strong>Spray</strong><strong>Nozzles</strong>1/8" to 1" NPT or BSPT (M)Optimization Tips• See page C2 for optimization tips.Applications• <strong>Co</strong>oling conveyor belts• <strong>Spray</strong> agitation• Film washing• <strong>Spray</strong>ing eliminator plates• Fire suppression/prevention • Water curtain• Foam knockdownSee Also• Accessories– Adjustable ball fittings– Check valves– Jet stabilizers for reducedturbulence– Pressure gaugeshttp://– Pressure relief valves– Split-eyelet connectors– Strainers– Swivel connectorsDimensions and WeightsMaterialsOrdering InfoStandardNozzleTypeK(M)OrificeDia.Nom.(in.)Length(in.)Hex.(in.)NetWeight(oz.)1/8 1 7/16 1/21/4 1-7/32 9/16 13/8 1-3/4 11/16 21/2 2 7/8 43/4 2-9/16 1-1/2 141 3-5/8 1-7/8 32Based on largest/heaviest version of each type.MaterialMaterial<strong>Co</strong>deNozzle TypeBrass (none) l303 Stainless Steel SS l316 Stainless Steel 316SS lPolyvinyl Chloride PVC lOther materials available upon request.KStandard <strong>Spray</strong> Nozzle1/8 K – SS 2l l l lInlet<strong>Co</strong>nn.NozzleTypeMaterial<strong>Co</strong>deCapacitySizeBSPT connections require theaddition of a “B” prior to theinlet connection.Phone 1-800-95-spray, FAX 1-888-95-sprayVisit Our Web Site: www.spray.com, Email: info@spray.comC29