Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

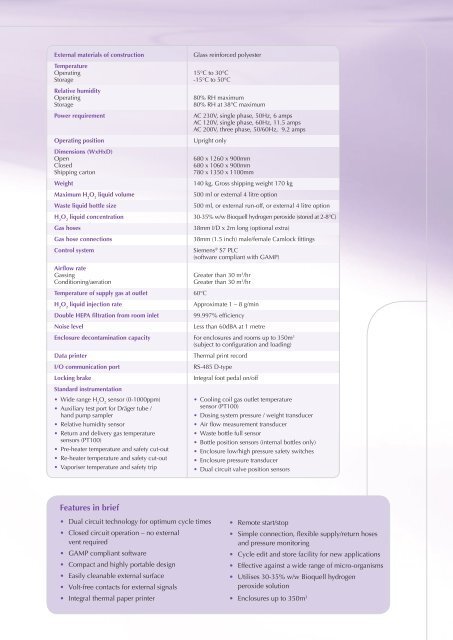

External materials of constructionGlass reinforced polyesterTemperatureOperating 15°C to 30°CStorage -15°C to 50°CRelative humidityOperatingStoragePower requirementOperating positionDimensions (WxHxD)OpenClosedShipping cartonWeightMaximum H 2O 2liquid volumeWaste liquid bottle sizeH 2O 2liquid concentrationGas hosesGas hose connectionsControl systemAirflow rateGassingConditioning/aerationTemperature of supply gas at outlet 60°CH 2O 2liquid injection rateDouble HEPA filtration from room inletNoise level80% RH maximum80% RH at 38°C maximumAC 230V, single phase, 50Hz, 6 ampsAC 120V, single phase, 60Hz, 11.5 ampsAC 200V, three phase, 50/60Hz, 9.2 ampsUpright only680 x 1260 x 900mm680 x 1060 x 900mm780 x 1350 x 1100mm140 kg, Gross shipping weight 170 kg500 ml or external 4 litre option500 ml, or external run-off, or external 4 litre option30-35% w/w Bioquell hydrogen peroxide (stored at 2-8°C)38mm I/D x 2m long (optional extra)38mm (1.5 inch) male/female Camlock fittingsSiemens ® S7 PLC(software compliant with GAMP)Greater than 30 m 3 /hrGreater than 30 m 3 /hrApproximate 1 – 8 g/min99.997% efficiencyLess than 60dBA at 1 metreEnclosure decontamination capacity For enclosures and rooms up to 350m 3(subject to configuration and loading)Data printerI/O communication portLocking brakeStandard instrumentation• Wide range H 2O 2sensor (0-1000ppm)• Auxiliary test port for Dräger tube /hand pump sampler• Relative humidity sensor• Return and delivery gas temperaturesensors (PT100)• Pre-heater temperature and safety cut-out• Re-heater temperature and safety cut-out• Vaporiser temperature and safety tripThermal print recordRS-485 D-typeIntegral foot pedal on/off• Cooling coil gas outlet temperaturesensor (PT100)• Dosing system pressure / weight transducer• Air flow measurement transducer• Waste bottle full sensor• Bottle position sensors (internal bottles only)• Enclosure low/high pressure safety switches• Enclosure pressure transducer• Dual circuit valve position sensorsFeatures in brief• Dual circuit technology for optimum cycle times• Closed circuit operation – no externalvent required• GAMP compliant software• Compact and highly portable design• Easily cleanable external surface• Volt-free contacts for external signals• Integral thermal paper printer• Remote start/stop• Simple connection, flexible supply/return hosesand pressure monitoring• Cycle edit and store facility for new applications• Effective against a wide range of micro-organisms• Utilises 30-35% w/w Bioquell hydrogenperoxide solution• Enclosures up to 350m 3