You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

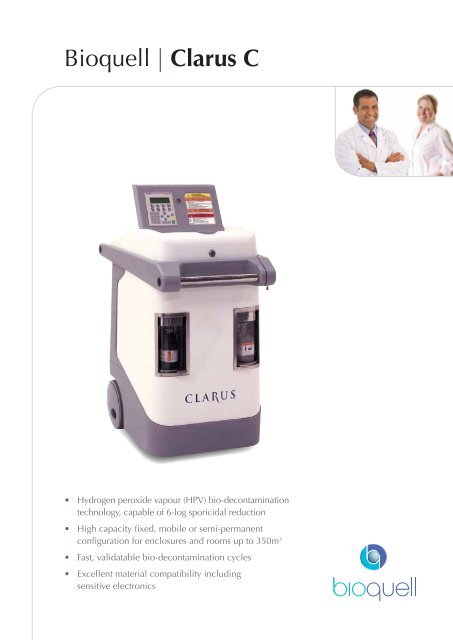

Bioquell | <strong>Clarus</strong> C• Hydrogen peroxide vapour (HPV) bio-decontaminationtechnology, capable of 6-log sporicidal reduction• High capacity fixed, mobile or semi-permanentconfiguration for enclosures and rooms up to 350m 3• Fast, validatable bio-decontamination cycles• Excellent material compatibility includingsensitive electronics

Bioquell <strong>Clarus</strong> C hydrogen peroxide vapour generatorThe Bioquell <strong>Clarus</strong> C hydrogen peroxide vapour generator is anadvanced solution for low temperature, residue free bio-decontamination.<strong>Clarus</strong> units have been installed worldwide giving reliable, continuousbio-decontamination of pharmaceutical isolators, clean rooms,pass-through devices and many other applications.• Multi-purpose generator capable of bio-decontaminatingequipment (e.g. isolators, RABS, transfer chambers) ormulti-room facilities• Fully compliant with the requirements of GMP• Bioquell dual circuit technology for fast and efficientbio-decontamination cycles• Capable of storing multiple gas cycle parameters formultiple applications• Remote operation available and connection to buildingmanagement system (BMS) capability• No requirement for room dehumidification prior to cyclesBioquell hydrogen peroxide solution• Bioquell hydrogen peroxide is specifiedand approved for use with BioquellHPV generators• Approved for use as a biocide byregulatory bodies (BPD, EPA)• Selected for optimal biocidal effectiveness

Common room configurationsHVAC aerationCeiling fans distributethe vapour throughoutthe entire roomRecirculatingvapourVapour distributioninto roomSemi-permanent configuration:• For room bio-decontamination without the needto enter the affected area• Ideal for locations which require biodecontaminationor emergency bio-decontaminationafter a bio-spillage• A single HPV generator can be used tobio-decontaminate multiple discrete areas• HPV introduced, recirculated and monitored viaproprietory gassing interface platePermanent configuration:Rotating gasdistributionnozzles• For frequent and regular bio-decontamination of aroom or suite of multiple rooms• Highly efficient distribution of HPV usingrotating nozzles• <strong>Clarus</strong> C HPV generator can be located in technicalspace remote from area to be bio-decontaminated• System can be integrated with building managementsystem (BMS)• <strong>Clarus</strong> C dedicated to area to bebio-decontaminated• Fully validatable for GMP facilitiesHVAC or mobile aerationMobile configuration• For infrequent or periodic bio-decontamination• No need for modification of room/facilityinfrastructure• Operated via a remote control panel locatedoutside of the area to be bio-decontaminated• Mobile aeration/distribution system forenhanced distribution and faster cycle times

External materials of constructionGlass reinforced polyesterTemperatureOperating 15°C to 30°CStorage -15°C to 50°CRelative humidityOperatingStoragePower requirementOperating positionDimensions (WxHxD)OpenClosedShipping cartonWeightMaximum H 2O 2liquid volumeWaste liquid bottle sizeH 2O 2liquid concentrationGas hosesGas hose connectionsControl systemAirflow rateGassingConditioning/aerationTemperature of supply gas at outlet 60°CH 2O 2liquid injection rateDouble HEPA filtration from room inletNoise level80% RH maximum80% RH at 38°C maximumAC 230V, single phase, 50Hz, 6 ampsAC 120V, single phase, 60Hz, 11.5 ampsAC 200V, three phase, 50/60Hz, 9.2 ampsUpright only680 x 1260 x 900mm680 x 1060 x 900mm780 x 1350 x 1100mm140 kg, Gross shipping weight 170 kg500 ml or external 4 litre option500 ml, or external run-off, or external 4 litre option30-35% w/w Bioquell hydrogen peroxide (stored at 2-8°C)38mm I/D x 2m long (optional extra)38mm (1.5 inch) male/female Camlock fittingsSiemens ® S7 PLC(software compliant with GAMP)Greater than 30 m 3 /hrGreater than 30 m 3 /hrApproximate 1 – 8 g/min99.997% efficiencyLess than 60dBA at 1 metreEnclosure decontamination capacity For enclosures and rooms up to 350m 3(subject to configuration and loading)Data printerI/O communication portLocking brakeStandard instrumentation• Wide range H 2O 2sensor (0-1000ppm)• Auxiliary test port for Dräger tube /hand pump sampler• Relative humidity sensor• Return and delivery gas temperaturesensors (PT100)• Pre-heater temperature and safety cut-out• Re-heater temperature and safety cut-out• Vaporiser temperature and safety tripThermal print recordRS-485 D-typeIntegral foot pedal on/off• Cooling coil gas outlet temperaturesensor (PT100)• Dosing system pressure / weight transducer• Air flow measurement transducer• Waste bottle full sensor• Bottle position sensors (internal bottles only)• Enclosure low/high pressure safety switches• Enclosure pressure transducer• Dual circuit valve position sensorsFeatures in brief• Dual circuit technology for optimum cycle times• Closed circuit operation – no externalvent required• GAMP compliant software• Compact and highly portable design• Easily cleanable external surface• Volt-free contacts for external signals• Integral thermal paper printer• Remote start/stop• Simple connection, flexible supply/return hosesand pressure monitoring• Cycle edit and store facility for new applications• Effective against a wide range of micro-organisms• Utilises 30-35% w/w Bioquell hydrogenperoxide solution• Enclosures up to 350m 3