dC13 070a. 294 kW (400 hp) - Kraft Power

dC13 070a. 294 kW (400 hp) - Kraft Power

dC13 070a. 294 kW (400 hp) - Kraft Power

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

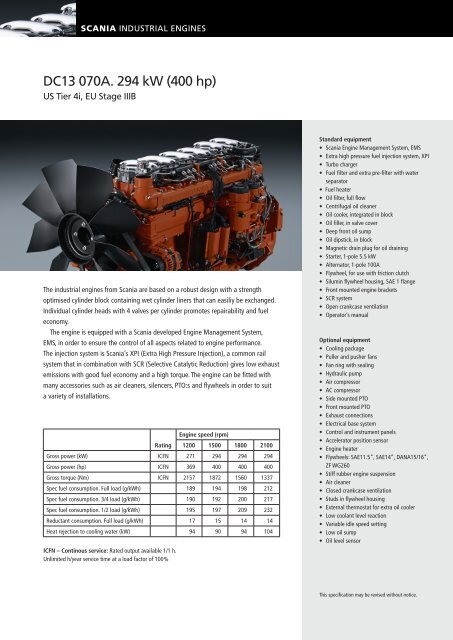

SCANIA industrial enginesDC13 070A. <strong>294</strong> <strong>kW</strong> (<strong>400</strong> <strong>hp</strong>)US Tier 4i, EU Stage IIIBThe industrial engines from Scania are based on a robust design with a strengthoptimised cylinder block containing wet cylinder liners that can easiliy be exchanged.Individual cylinder heads with 4 valves per cylinder promotes repairability and fueleconomy.The engine is equipped with a Scania developed Engine Management System,EMS, in order to ensure the control of all aspects related to engine performance.The injection system is Scania’s XPI (Extra High Pressure Injection), a common railsystem that in combination with SCR (Selective Catalytic Reduction) gives low exhaustemissions with good fuel economy and a high torque. The engine can be fitted withmany accessories such as air cleaners, silencers, PTO:s and flywheels in order to suita variety of installations.Engine speed (rpm)Rating 1200 1500 1800 2100Gross power (<strong>kW</strong>) ICFN 271 <strong>294</strong> <strong>294</strong> <strong>294</strong>Gross power (<strong>hp</strong>) ICFN 369 <strong>400</strong> <strong>400</strong> <strong>400</strong>Gross torque (Nm) ICFN 2157 1872 1560 1337Spec fuel consumption. Full load (g/<strong>kW</strong>h) 189 194 198 212Spec fuel consumption. 3/4 load (g/<strong>kW</strong>h) 190 192 200 217Spec fuel consumption. 1/2 load (g/<strong>kW</strong>h) 195 197 209 232Reductant consumption. Full load (g/<strong>kW</strong>h) 17 15 14 14Heat rejection to cooling water (<strong>kW</strong>) 94 90 94 104ICFN – Continous service: Rated output available 1/1 h.Unlimited h/year service time at a load factor of 100%Standard equipment• Scania Engine Management System, EMS• Extra high pressure fuel injection system, XPI• Turbo charger• Fuel filter and extra pre-filter with waterseparator• Fuel heater• Oil filter, full flow• Centrifugal oil cleaner• Oil cooler, integrated in block• Oil filler, in valve cover• Deep front oil sump• Oil dipstick, in block• Magnetic drain plug for oil draining• Starter, 1-pole 5.5 <strong>kW</strong>• Alternator, 1-pole 100A• Flywheel, for use with friction clutch• Silumin flywheel housing, SAE 1 flange• Front mounted engine brackets• SCR system• Open crankcase ventilation• Operator’s manualOptional equipment• Cooling package• Puller and pusher fans• Fan ring with sealing• Hydraulic pump• Air compressor• AC compressor• Side mounted PTO• Front mounted PTO• Exhaust connections• Electrical base system• Control and instrument panels• Accelerator position sensor• Engine heater• Flywheels: SAE11.5”, SAE14”, DANA15/16”,ZF WG260• Stiff rubber engine suspension• Air cleaner• Closed crankcase ventilation• Studs in flywheel housing• External thermostat for extra oil cooler• Low coolant level reaction• Variable idle speed setting• Low oil sump• Oil level sensorThis specification may be revised without notice.

SCANIA industrial enginesDC13 070A. <strong>294</strong> <strong>kW</strong> (<strong>400</strong> <strong>hp</strong>)US Tier 4i, EU Stage IIIBEdition 01 © Scania CV AB, SE-151 87 Södertälje, SwedenEngine descriptionNo of cylinders6 in-lineWorking principle 4-strokeFiring order 1 - 5 - 3 - 6 - 2 - 4Displacement12.7 litresBore x stroke130 x 160 mmCompression ratio 17.3:1Weight1050 kg (excl oil and coolant)Piston speed at 1500 rpm 8.0 m/sPiston speed at 1800 rpm 9.6 m/sCamshaftHigh position alloy steelPistonsSteel pistonsConnection rodsI-section press forgings of alloy steelCrankshaftAlloy steel with hardenedand polished bearing surfacesOil capacity 34-45 dm 3Electrical system 1-pole 24V6744341406442 4471:69701:6969Output<strong>kW</strong> 300290<strong>hp</strong><strong>400</strong>280<strong>kW</strong> 300380 <strong>hp</strong>270<strong>400</strong>290360260<strong>kW</strong> 280300380 <strong>hp</strong>250340270<strong>400</strong>290240360260280320 380230250270340220300 360240260320210230250280 340200220300240260190320210230280180200220240 300170260190210220 280160180200240150170190200 260140220160180180 240130150170200120160140220160180Nm2170 130150220 kpm2002070120160210Torque 1401970200180Nm 1870 2170 130190220 kpm1770 2070 120180160 2101670 1970170 200Nm 1570 1870 2170160190 220 kpm1470 1770 2070150180 2101370 1670 1970140170 2001270 1570 1870130160 1901470 1770g/<strong>kW</strong>h 215150 18030 g/<strong>kW</strong>hFuel 1370 1670140 170 Reductant2101270 1570130 160 252051470150g/<strong>kW</strong>h2020021530 g/<strong>kW</strong>h1370Reductant140FuelReductant2101270 195130 15 25Spec205fuel and Reductant consumption190g/<strong>kW</strong>h 215100 20 g/<strong>kW</strong>h200185ReductantFuelFuel21090 Reductant5180195801520517519070010200185800 1000 1200 1<strong>400</strong> Fuel 1600 1800 2000 60Fuelrpm19518050 519040175300185800 1000 1200 1<strong>400</strong> 1600 1800 2000Reductantrpm20180101750800 1000 1200 1<strong>400</strong> 1600 1800 2000 rpmTest conditions Air temperature +25°C. Barometric pressure 100 kPa (750 mmHg). Humidity 30%. Diesel fuelacc. to ECE R 24 Annex 6. Density of fuel 0.840 kg/dm 3 . Viscosity of fuel 3.0 cSt at 40°C. Energy value 42700 kJ/kg.<strong>Power</strong> test code ISO 3046. <strong>Power</strong> and fuel values +/-3%.SE 151 87 Södertälje, SwedenTelephone +46 8 553 810 00Telefax +46 8 553 829 93www.scania.comengines@scania.com

SCANIA industrial enginessCr systemus tier 4i, eu stage iiiBSCR (Selective Catalytic Reduction) technology is used on Scania’s enginesfor Stage IIIB and Tier 4i to reduce the NO Xcontent in the exhaust gases.A chemical process is started by injecting reductant, a urea and watermixture, into the exhaust gas stream. During injection the water evaporatesand the urea breaks down to form ammonia. The ammonia then reactswith the nitrogen gases in the catalytic converter and forms harmlessproducts such as nitrogen gas and water. Through the use of SCR theexhaust gases are purged of poisonous levels of NO Xin the best possibleway. Scania is making use of a system that is carefully developed andtested in our own laboratory.The principle for Scania SCR systemThe reductant tank holds 38 or 60 litres and is heated by the engine’scooling system in order to avoid freezing of the urea solution, ureafreezes at -11°C. The reductant tank and a pump module are deliveredas a unit which is fitted to brackets for an easy installation. The Scaniasystem contains all mechanical and electrical parts needed except fromthe exhaust piping which is to be adapted according to the customersinstallation.Mechanical systemElectric system234455312766189101:70581:7059Mechanical system Standard Optional1 Reductant tank and pump module 38 l 60 l2 Reductant fluid return line 2 m 3.5 m3 Coolant valve –4 Reductant pressure line 2 m 3.5 m5 Coolant hose for tank and pumpheating6 Hydrolysis catalyst with reductantdoser– – –7 NO Xsensor with control unit –8 SCR catalyst –9 Temperature sensor –10 Coolant hose, return from tank andpump heating– –Electric system Standard Optional1 Customer interface, SCR system –2 Pipe network between engine andSCR control unit3 m 6 m3 Electrical interface, SCR system –4 Temperature sensor electrical cable 3 m 6 m5 Reductant doser electrical cable 3 m 6 m6 NO Xsensor electrical cable 3 m 6 mThis specification may be revised without notice.

SCANIA industrial enginesSCR systemUS Tier 4i, EU Stage IIIBReductant tank - 38 litresTotal volume: 50 litresFilling volume: 38 litres675 280SCR catalyst1:7060570Reductant tank - 60 litresTotal volume: 70 litresFilling volume: 60 litres675 280Engine <strong>Power</strong> (kw) Volume (litres) Measure A (mm)DC09 202-<strong>294</strong> 24 765DC13 257-405 33 857DC16 405-515 48 1060SCR catalyst with silencer700768Edition 01 © Scania CV AB, SE-151 87 Södertälje, Sweden1:7061Hydrolysis catalystwith reductant doserø 185450ø 1901:7062ø 597Engine <strong>Power</strong> (kw) Volume (litres)DC09 202-<strong>294</strong> 33DC13 257-405 33DC16 Not available1:7064This specification may be revised without notice.SE 151 87 Södertälje, SwedenTelephone +46 8 553 810 00Telefax +46 8 553 829 93www.scania.comengines@scania.com