Snap Cappers - Accutek Packaging Equipment

Snap Cappers - Accutek Packaging Equipment

Snap Cappers - Accutek Packaging Equipment

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

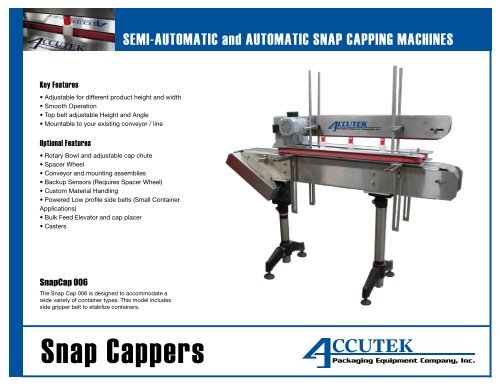

SEMI-AUTOMATIC and AUTOMATIC SNAP CAPPING MACHINESKey Features• Adjustable for different product height and width• Smooth Operation• Top belt adjustable Height and Angle• Mountable to your existing conveyor / lineOptional Features• Rotary Bowl and adjustable cap chute• Spacer Wheel• Conveyor and mounting assemblies• Backup Sensors (Requires Spacer Wheel)• Custom Material Handling• Powered Low profile side belts (Small ContainerApplications)• Bulk Feed Elevator and cap placer• Casters<strong>Snap</strong>Cap 006The <strong>Snap</strong> Cap 006 is designed to accommodate awide variety of container types. This model includesside gripper belt to stabilize containers.<strong>Snap</strong> <strong>Cappers</strong><strong>Packaging</strong> <strong>Equipment</strong> Company, Inc.

SEMI-AUTOMATIC and AUTOMATIC SNAP CAPPING MACHINES<strong>Accutek</strong> <strong>Snap</strong> <strong>Cappers</strong> are continuous motion machinesthat replace the tedious work of manually pressing and/or placing snap caps. <strong>Accutek</strong> <strong>Snap</strong> <strong>Cappers</strong> preventcostly spills by removing human error from this process.This machine can also help prevent repetitious motioninjuries and strains to your work force that can resultwhen manually placing snap caps.<strong>Accutek</strong> <strong>Snap</strong> Capping systems offer solutions to avariety of snap cap types. Milk jugs, dropper inserts,lip balm caps, over caps, “top hat” seals, twist capwith ratcheted rip seal, and a variety of other capapplications are all within the capability of the <strong>Accutek</strong><strong>Snap</strong> <strong>Cappers</strong>.These capping systems are available in a number ofdifferent models each covering wide range of productsand delivery speeds.The <strong>Snap</strong> Cap 006 can be fully automated by the additionof an <strong>Accutek</strong> centrifical bowl or cap elevator orientator.With an automated delievery device the <strong>Accutek</strong><strong>Snap</strong> Capper can reach speeds up to 200 CPM.1 Dimension are for the SC 006 Centrifugal bowl and cap elevator dimensions vary. Call for details.2 Capping speed is dependent on several things: Model, Operator, container dimensions, and cap characteristics.<strong>Packaging</strong> <strong>Equipment</strong> Company, Inc.<strong>Snap</strong> Cap 007The <strong>Snap</strong> Cap 006 combines <strong>Accutek</strong>’sCentrifugal bowl cap applicator (picturedabove) for Automatic Cap placement.SpecificationsDimensions: 1Height: Conveyor DependantLength: 36” (91.4 cm)Depth: Conveyor DependantWeight:Approx. 200 lbs. (90.7 kg)Capping Speed:Up to 200 CPM 2Cap Size:Min: 10mm / Max: 60mmElectrical:110 VAC 20 Amp(Hazardous Location or220 VAC upgrades available)Air Requirements:90 PSI @ 2 CFM1399 Specialty Dr., Vista CA 92081 • 760.734.4177 • Fax 760.734.4188Email: sales@accutekpackaging.com • www.accutekpackaging.com<strong>Snap</strong> <strong>Cappers</strong>