SaniMagnum - Csidesigns.com

SaniMagnum - Csidesigns.com

SaniMagnum - Csidesigns.com

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

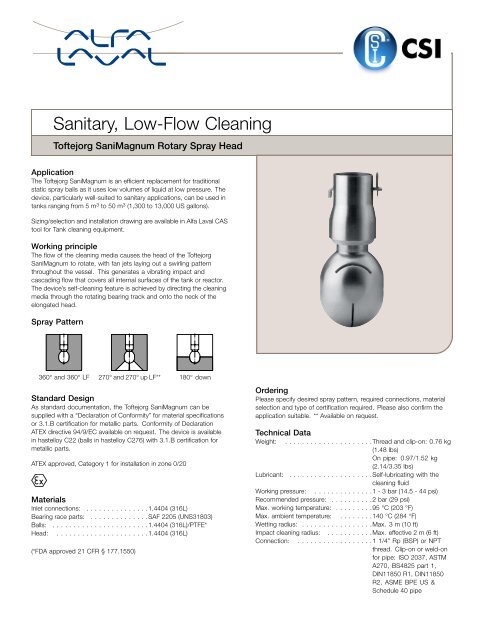

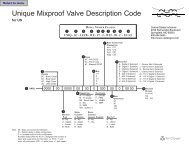

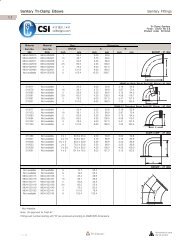

.kySanitary, Low-Flow CleaningkyToftejorg <strong>SaniMagnum</strong> Rotary Spray HeadApplicationThe Toftejorg <strong>SaniMagnum</strong> is an efficient replacement for traditionalstatic spray balls as it uses low volumes of liquid at low pressure. Thedevice, particularly well-suited to sanitary applications, can be used intanks ranging from 5 m 3 to 50 m 3 (1,300 to 13,000 US gallons).Sizing/selection and installation drawing are available in Alfa Laval CAStool for Tank cleaning equipment.Working principleThe flow of the cleaning media causes the head of the Toftejorg<strong>SaniMagnum</strong> to rotate, with fan jets laying out a swirling patternthroughout the vessel. This generates a vibrating impact andcascading flow that covers all internal surfaces of the tank or reactor.The device’s self-cleaning feature is achieved by directing the cleaningmedia through the rotating bearing track and onto the neck of theelongated head.Spray Pattern360° and 360° LF 270° and 270° up LF** 180° down.Standard DesignAs standard documentation, the Toftejorg <strong>SaniMagnum</strong> can besupplied with a “Declaration of Conformity” for material specificationsor 3.1.B certification for metallic parts. Conformity of DeclarationATEX directive 94/9/EC available on request. The device is availablein hastelloy C22 (balls in hastelloy C276) with 3.1.B certification formetallic parts.ATEX approved, Category 1 for installation in zone 0/20MaterialsInlet connections: ...............1.4404 (316L)Bearing raceparts: ..............SAF 2205 (UNS31803)Balls: .......................1.4404 (316L)/PTFE*Head: ......................1.4404 (316L)(*FDA approved 21 CFR § 177.1550)OrderingPlease specify desired spray pattern, required connections, materialselection and type of certification required. Please also confirm theapplication suitable. ** Available on request.Technical DataWeight: .....................Threadandclip-on:0.76kg(1.48 lbs)On pipe: 0.97/1.52 kg(2.14/3.35 lbs)Lubricant: ....................Self-lubricatingwiththecleaning fluidWorkingpressure: ..............1-3bar(14.5-44psi)Re<strong>com</strong>mendedpressure: ..........2bar(29psi)Max.workingtemperature: .........95°C(203°F)Max.ambienttemperature: ........140°C(284°F)Wettingradius: .................Max.3m(10ft)Impactcleaningradius: ...........Max.effective2m(6ft)Connection: ..................11/4”Rp(BSP)orNPTthread. Clip-on or weld-onfor pipe: ISO 2037, ASTMA270, BS4825 part 1,DIN11850 R1, DIN11850R2, ASME BPE US &Schedule 40 pipe

Certificate:2.2 - 3.1.B - ATEXOptions- Downpipes with Tri-Clamp and flange connectionsFlow RateCleaning radiusWettingImpact cleaningDimensions (mm)Welded on pipeThreadClip-onTH ID OD x tISO : ø38 x 1.211/4”BSPBPE / ISO 1½” : ø38.4BPE US / ISO : ø38,1 x 1.6511/4”NPTBPE / ISO 2” : ø51.3BPE US / ISO : ø50,8 x 1.651½" BSPDIN, Range 1 : ø40.4DIN, Range 1 : ø40 x 11½" NPTDIN, Range 2 : ø41.4DIN ,Range 2 : ø41 x 1.5

.ESE00332ENUS 0705The information contained herein is correct at the time of issue,but may be subject to change without prior notice.How to contact Alfa LavalContact details for all countriesare continually updated on our website.Please visit www.alfalaval.<strong>com</strong> toaccess the information direct.