enhanced cutting and finishing of handglass using a co2 laser

enhanced cutting and finishing of handglass using a co2 laser

enhanced cutting and finishing of handglass using a co2 laser

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

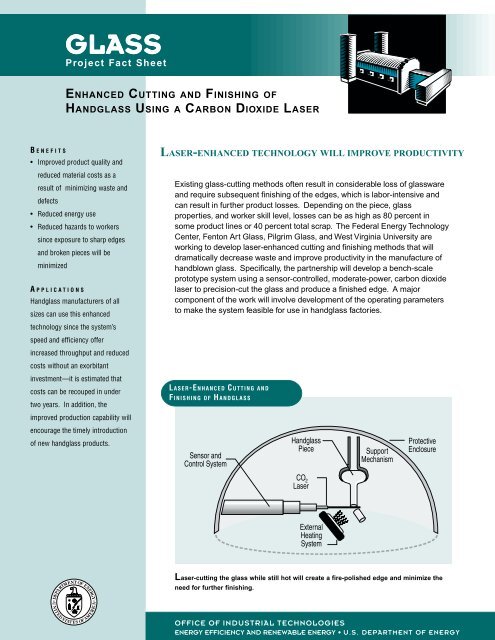

GLASSProject Fact SheetENHANCED CUTTING AND FINISHING OFHANDGLASS USING A CARBON DIOXIDE LASERB ENEFITS• Improved product quality <strong>and</strong>reduced material costs as aresult <strong>of</strong> minimizing waste <strong>and</strong>defects• Reduced energy use• Reduced hazards to workerssince exposure to sharp edges<strong>and</strong> broken pieces will beminimizedA PPLICATIONSH<strong>and</strong>glass manufacturers <strong>of</strong> allsizes can use this <strong>enhanced</strong>technology since the system’sspeed <strong>and</strong> efficiency <strong>of</strong>ferincreased throughput <strong>and</strong> reducedcosts without an exorbitantinvestment—it is estimated thatcosts can be recouped in undertwo years. In addition, theimproved production capability willencourage the timely introduction<strong>of</strong> new h<strong>and</strong>glass products.LASER-ENHANCED TECHNOLOGY WILL IMPROVE PRODUCTIVITYExisting glass-<strong>cutting</strong> methods <strong>of</strong>ten result in considerable loss <strong>of</strong> glassware<strong>and</strong> require subsequent <strong>finishing</strong> <strong>of</strong> the edges, which is labor-intensive <strong>and</strong>can result in further product losses. Depending on the piece, glassproperties, <strong>and</strong> worker skill level, losses can be as high as 80 percent insome product lines or 40 percent total scrap. The Federal Energy TechnologyCenter, Fenton Art Glass, Pilgrim Glass, <strong>and</strong> West Virginia University areworking to develop <strong>laser</strong>-<strong>enhanced</strong> <strong>cutting</strong> <strong>and</strong> <strong>finishing</strong> methods that willdramatically decrease waste <strong>and</strong> improve productivity in the manufacture <strong>of</strong>h<strong>and</strong>blown glass. Specifically, the partnership will develop a bench-scaleprototype system <strong>using</strong> a sensor-controlled, moderate-power, carbon dioxide<strong>laser</strong> to precision-cut the glass <strong>and</strong> produce a finished edge. A majorcomponent <strong>of</strong> the work will involve development <strong>of</strong> the operating parametersto make the system feasible for use in h<strong>and</strong>glass factories.L ASER-ENHANCED CUTTING ANDF INISHING OF HANDGLASSLaser-<strong>cutting</strong> the glass while still hot will create a fire-polished edge <strong>and</strong> minimize theneed for further <strong>finishing</strong>.OFFICE OF INDUSTRIAL TECHNOLOGIESENERGY EFFICIENCY AND RENEWABLE ENERGY • U.S. DEPARTMENT OF ENERGY

Project DescriptionGoal: Use a carbon dioxide <strong>laser</strong> to enhance the <strong>cutting</strong> <strong>and</strong> <strong>finishing</strong> process <strong>of</strong>h<strong>and</strong>glass, thereby improving energy efficiency <strong>and</strong> product quality.The <strong>laser</strong> will cut the glass while it is still hot, producing a fire-polished edge that willminimize the need for further grinding or polishing. Throughout the process, the <strong>laser</strong> willnot generate any photochemical by-products that could discolor the glass. Researcherswill also develop a heating system to keep the glass hot while the <strong>laser</strong> is in use. Asensor system will control the entire process; it will turn the <strong>laser</strong> on, monitor the <strong>cutting</strong>,<strong>and</strong> disengage when the <strong>cutting</strong> is complete. The process will be portable, will use readilyavailable electrical power <strong>and</strong> cooling water, <strong>and</strong> will be designed for use on a variety <strong>of</strong>glass products.Progress <strong>and</strong> MilestonesAfter extensive laboratory studies <strong>and</strong> a prototype design phase in which test partnerswill have input to ensure compatibility with factory practices, the prototype system will betested at several industry factories.Prototype testing has dictated a <strong>laser</strong> power <strong>of</strong> 1000 watts is required to cut glassefficiently in a reasonable time interval. A robotic glass h<strong>and</strong>ling system is beingdeveloped by Umbrella, Inc. for use in the factory prototype. The robot is easilyprogrammed to h<strong>and</strong>le any glassware <strong>and</strong> will include a vision system for piecerecognition. The factory prototype system will include the robot glass h<strong>and</strong>ler <strong>and</strong>computer control system from Umbrella, Inc., <strong>and</strong> a 1300 watt CO 2<strong>laser</strong> from ContinentalLaser Energy.PROJECT PARTNERSNational Energy Technology LaboratoryMorgantown, WVFenton Art Glass CompanySutton, WVPilgrim Glass CorporationCeredo, WVWest Virginia UniversityMorgantown, WVFOR ADDITIONAL INFORMATION,PLEASE CONTACT:Elliott LevineOffice <strong>of</strong> Industrial TechnologiesPhone: (202) 586-1476Fax: (202) 586-3180elliott.levine@ee.doe.govhttp://www.oit.doe.gov/glassPlease send any comments,questions, or suggestions towebmaster.oit@ee.doe.govVisit our home page athttp://www.oit.doe.govOffice <strong>of</strong> Industrial TechnologiesEnergy Efficiency<strong>and</strong> Renewable EnergyU.S. Department <strong>of</strong> EnergyWashington, D.C. 20585December 2000