Increase Efficiency and Organization with Akro-Mils and 5S Lean

Increase Efficiency and Organization with Akro-Mils and 5S Lean

Increase Efficiency and Organization with Akro-Mils and 5S Lean

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

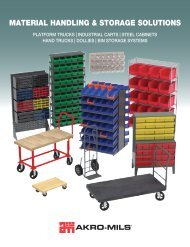

sort •<strong>5S</strong> <strong>Lean</strong> <strong>and</strong> <strong>Akro</strong>-<strong>Mils</strong><strong>5S</strong> <strong>Lean</strong> is a methodology to improve efficiencies<strong>and</strong> enhance operational performance. By incorporatingindustry-leading products from <strong>Akro</strong>-<strong>Mils</strong>, you can easily:• Improve inventory levels• Reduce inventory cost• Create extra workspace• Improve safety• Decrease downtime• Develop controlthrough visual cuesset in order •• Boost employee moralethrough empowerment<strong>and</strong> accountability• Identify problems faster• Promote strongercommunicationamong teamsshine •stBeforeAfter

<strong>and</strong>ardize • sustain +safetyConverting your workplace to <strong>5S</strong> <strong>Lean</strong> <strong>with</strong><strong>Akro</strong>-<strong>Mils</strong> ® products is smart business!<strong>Organization</strong>s that invest in a <strong>5S</strong> process gainproductivity, create higher quality products <strong>and</strong>lower operating costs by simply implementing asystem of waste removal, visual identifi cation<strong>and</strong> effi cient use of space.Whether choosing bins, containers or carts fromour extensive selection, or creating a customsystem, <strong>Akro</strong>-<strong>Mils</strong> innovative products <strong>and</strong> servicesadd value at every stage of your <strong>5S</strong> operation– improving your productivity <strong>and</strong> performance!

sortReduce-Remove-RenewSort it out! The first stepis to organize the workareas, leaving only thosetools <strong>and</strong> materialsnecessary to performdaily activities.Sort• Use <strong>Akro</strong>-<strong>Mils</strong> bins to sort <strong>and</strong> separatelike parts in small or large work spaces• Bins feature large hopper front foreasy access <strong>and</strong> faster picking• <strong>Akro</strong>Bins ® are available in 14 sizes<strong>and</strong> 7 colors for total visualization• InSight Ultra-Clear Bins provide maximumvisibility <strong>and</strong> easy identifi cation of items<strong>5S</strong> Red-Tagging• Identify items that are not necessaryor used infrequently• Use <strong>Akro</strong>-<strong>Mils</strong> mobile carts <strong>and</strong> dolliesto temporarily hold <strong>and</strong> transportred-tagged items for removal

Eliminate• Remove unnecessary itemsfrom the work area• Relocate items that do not belong<strong>Akro</strong>-<strong>Mils</strong> offers a variety ofproducts to assist during thesort stage. Organizing the itemsthat you have will help to determinewhat is needed <strong>and</strong> lay thefoundation for your <strong>5S</strong> program.800-253-2467 • www.akro-mils.com

setEverything Has Its Placeet orderinFrequently used work stationmaterials <strong>and</strong> tools shouldbe arranged so that allneeded items are easy toget to <strong>and</strong> accessiblefor anyone to find.Organize• Work areas should be organized in a way thatmakes the most effi cient uses of shelving,racks, counter areas <strong>and</strong> fl oor space, keepingfrequently used items <strong>with</strong>in reach• <strong>Akro</strong>Bins ® , Shelf Bins <strong>and</strong> InSight Bins let youstore items used together close to each other• Orderliness eliminates waste in production<strong>and</strong> clerical activitiesCreate Space• Louvered Hanging Systems from <strong>Akro</strong>-<strong>Mils</strong>create vertical storage <strong>and</strong> help to make themost of an area• Wire <strong>and</strong> steel shelving systems createcustomized storage systems to fi t any workspace

• <strong>Akro</strong>-<strong>Mils</strong> mobile systems are versatilecenters that keep items organized <strong>and</strong><strong>with</strong>in reach at all timesDesignated Areas• Use bar codes, <strong>Akro</strong>-<strong>Mils</strong> adhesive labels or<strong>Akro</strong>-<strong>Mils</strong> card holders on bins or shelvingunits for accurate inventory control• Use parking spots for mobile wastereceptacles, carts, h<strong>and</strong> trucks <strong>and</strong> dolliesCreate a clutter free workspace by using<strong>Akro</strong>-<strong>Mils</strong> products. <strong>Akro</strong>Bins ® <strong>and</strong> Shelf Binsgive you the flexibility to customize storageareas through color coding. We also offer anumber of panel <strong>and</strong> rail hanging systems,steel shelving or rack systems for sortedinventory <strong>and</strong> materials.800-253-2467 • www.akro-mils.com

shinePolish-Protect-PreventPrevent dirt fromaccumulating <strong>and</strong> developa cleaning maintenanceschedule to help protectparts <strong>and</strong> equipmentfrom dirt, dust<strong>and</strong> debris.Cleaning• Checking the condition of equipmentshould be included as a cleaning taskto help identify early warning signs ofunplanned breakdownsProtect• Store materials securely <strong>with</strong> lidsto keep items clean <strong>and</strong> protected• Easy to clean Totes <strong>and</strong> Attached LidContainers nest when empty for effi cientorganization <strong>and</strong> storage• <strong>Akro</strong>-Grids have divider options tocreate individual compartments forparts, plus optional lids• Many <strong>Akro</strong>-<strong>Mils</strong> plastic products areresistant to oils, chemicals <strong>and</strong> weak acids

• <strong>Akro</strong>Drawers ® are designed for usein a variety of environments <strong>and</strong>applications. <strong>Akro</strong>Drawers <strong>with</strong>enclosed shelving systems help keepsupplies, parts <strong>and</strong> tools secure <strong>and</strong>dust-free. Cover, store, protect <strong>and</strong>more <strong>with</strong> <strong>Akro</strong>DrawersMany <strong>Akro</strong>-<strong>Mils</strong> products have lidsavailable to prevent dust <strong>and</strong> dirt fromaccumulating on supplies. Items suchas Attached Lid Containers, Totes,<strong>Akro</strong>-Grids, InSight <strong>and</strong> <strong>Akro</strong>Bins ® <strong>with</strong>optional lids help protect your products<strong>and</strong> keep items clean.800-253-2467 • www.akro-mils.com

st<strong>and</strong>ardizeBest Practice MethodsBenchmarking <strong>and</strong> evaluationtactics should be utilizedto maintain a consistentapproach for carryingout tasks <strong>and</strong>procedures.Systematic Approach• Now that you have created anorganizational system, develop proceduresto keep your <strong>5S</strong> method in operationWorkflow• Indicator Bins simplify visual recognitionwhen supplies need to be replenished –never run out again!• Super-Size <strong>Akro</strong>Bins ® securely stack atopeach other, ensuring items stay in theirproper places• Portable work centers allow for easymobility <strong>and</strong> integration of <strong>5S</strong> dutiesinto regular work responsibilities

• Easy Flow Gravity Hopper bins <strong>and</strong> racksare designed <strong>with</strong> an angled top openingfor easy, consistent fi lling every time• The 31620 smaller size option includesFIFO sliding shelf divider to help eliminatewaste <strong>and</strong> expiration of productConsistency• By st<strong>and</strong>ardizing operator work stations,non-value added tasks are removed orcorrected, which reduces downtime <strong>and</strong>increases output <strong>and</strong> effi ciency<strong>Akro</strong>-<strong>Mils</strong> bins, carts <strong>and</strong> hoppers helpcreate universal st<strong>and</strong>ards for each processsuch as color coding, labeling <strong>and</strong> uniformsizes. Consistent <strong>and</strong> clear st<strong>and</strong>ards willmake the 5th S, sustain, easier to maintain.800-253-2467 • www.akro-mils.com

sustainTrain-Reinforce-MeasuresustainA disciplined <strong>and</strong> committedworkflow process empowersworkers to improve <strong>and</strong> maintainthe workplace. When employeestake pride in their work,it leads to greater jobsatisfaction <strong>and</strong> higherproductivity.Continue• Reinforcing <strong>and</strong> evaluating best practiceswill keep waste out of the process <strong>and</strong>provide a solid foundation for which tobuild improvements in the future<strong>Akro</strong>-<strong>Mils</strong> products help sustain any<strong>5S</strong> <strong>Lean</strong> process – sort <strong>and</strong> shine, removeunnecessary h<strong>and</strong>ling steps <strong>and</strong> createstreamlined practices <strong>and</strong> workflow.Our plastic <strong>and</strong> steel material h<strong>and</strong>lingproducts promote effective storage,organization <strong>and</strong> transport systems toboost efficiency <strong>and</strong> reduce costs inany work environment.+

safety<strong>5S</strong> Equals a Safe WorkplacesafetyPrevention• In addition to a cleaner, higher quality <strong>and</strong>better functioning workspace, incorporating<strong>5S</strong> techniques will also reduce the risk ofpotential hazardsQuality• Manufactured under rigorousISO 9001 st<strong>and</strong>ards• Products are quality tested to ensureperformance expectations• Products optimize productivity<strong>and</strong> customer satisfaction• Enhance effi ciencies <strong>and</strong> minimize confusionReduce the risk by removing clutter <strong>and</strong>unnecessary waste in the workplace.800-253-2467 • www.akro-mils.com

sort •<strong>5S</strong> <strong>Lean</strong> <strong>and</strong> <strong>Akro</strong>-<strong>Mils</strong>set in order •The focus of a lean environment is to remove unnecessary wastes fromthe process <strong>and</strong> create an effi cient workplace. Identifying whatwasteful actions exist helps companies discover ineffi cienciesthat increase cost <strong>and</strong> provide little value to the customer. Thereare typically 8 wastes that can exist in current practices <strong>and</strong> theidea is to evaluate <strong>and</strong> focus on those areas that need corrected.1. Overproduction: Producingmore than what is needed for ajob or schedule.2. Waiting: Idle time that can bespent doing something productive.3. Transportation: H<strong>and</strong>ling morethan once, delays in movingmaterials or unnecessary h<strong>and</strong>lingduring the completion of tasks.4. Overprocessing: Extra actions oroperations that are performed outsidethe scope of the customers’ needs.THE 8 WASTES:5. Excessive Stock: Any surplussupplies or tools that areunnecessary to the job at h<strong>and</strong>.6. Unnecessary Motion:Any action or movement thatadds no value to the fi nal product.7. Producing Defects: Anyrework that results in scrapor is subst<strong>and</strong>ard to qualityperformance.8. Untapped Creativity:Not utilizing all knowledge, ideas,skills <strong>and</strong> available resourcesemployees have to offer.shine •s8wasthetransportationoverproductionmotionoverprodefe

t<strong>and</strong>ardize • sustain +safetytescessingwaitingunnecessarystock orinventoryThe <strong>5S</strong> model <strong>and</strong> <strong>Akro</strong>-<strong>Mils</strong> products can transform your organizationinto an effi cient machine – one that can thrive even in the most diffi cultof times. For a list of <strong>Akro</strong>-<strong>Mils</strong> distributors, please visit our website:www.akro-mils.com/industrial/locator.asp.Contact <strong>Akro</strong>-<strong>Mils</strong> to requestyour <strong>5S</strong> Kit to get started today!800.253.2467 • www.akro-mils.comuntappedcreativitycts

st<strong>and</strong>ardizeBest Practice MethodsEvaluate <strong>and</strong> improve organizationalefficiencies. St<strong>and</strong>ardize these methodsthroughout the healthcare facility.shinePolish <strong>and</strong> ProtectAn organized area is easy to keepclean <strong>and</strong> identify when items areout of place. Daily housekeepingshould be conducted.Once an area is clean, keep it clean.Employees should inspect for items thatare out of place, expired or damaged duringthe daily cleaning routine.<strong>Akro</strong>-<strong>Mils</strong> products, such as <strong>Akro</strong>Bins ® –used in a 2 bin system – <strong>and</strong> the Easy FlowGravity Hopper, will protect product <strong>and</strong>initiate a FIFO retrieval of supplies.St<strong>and</strong>ardize by using a color coding systemthroughout the facility <strong>and</strong> organize supplyrooms in a like manner – this will help allstaff fi nd patient supplies quicker.

sustainTrain-Reinforce-MeasureContinuous training <strong>and</strong> involvement will helpto obtain commitment from staff members.Sustaining your <strong>5S</strong> model can be challenging.Commitment from the entire organization isessential to the long-term success of yourprogram. Designated time to maintain,committed staff <strong>and</strong> <strong>Akro</strong>-<strong>Mils</strong> productsare vital to this step.+ safety<strong>5S</strong> Equals a Safe WorkplacesafetyA <strong>5S</strong> area is a safe environment foremployees <strong>and</strong> helps to create apositive image.BeforeAfter800-253-2467 • www.akro-mils.com

<strong>5S</strong>Healthcare Solutions<strong>5S</strong><strong>Lean</strong><strong>5S</strong> <strong>Lean</strong> is a methodology toimprove efficiencies <strong>and</strong> enhanceoperational performance.<strong>Increase</strong> <strong>Efficiency</strong> <strong>and</strong> <strong>Organization</strong><strong>with</strong> <strong>Akro</strong>-<strong>Mils</strong> <strong>and</strong> <strong>5S</strong> <strong>Lean</strong>!A well-organized supply room is critical inhealthcare <strong>and</strong> medical settings. Extra time spentby physicians, ancillary staff, <strong>and</strong> nursing staffsearching for supplies can affect the quality ofcare <strong>and</strong> timeliness being given to your patients.By incorporating industry-leading productsfrom <strong>Akro</strong>-<strong>Mils</strong>, you can easily:• Improve workfl ow <strong>and</strong> productivity• Reduce PAR levels• Develop a cleaner, more effi cient environment• Create extra workspace• <strong>Increase</strong> safety• Reduce wasted time <strong>and</strong> effort• Boost employee morale• Ensure improvements remain intact

sortReduce-Remove-RenewSort <strong>and</strong> group medical supplies <strong>and</strong>remove infrequently used items.There are a variety of <strong>Akro</strong>-<strong>Mils</strong> productsavailable to assist <strong>with</strong> these steps.<strong>Akro</strong>Bins ® are available in an assortmentof colors <strong>and</strong> sizes. InSight Bins providevisibility to your supplies to speed upretrieval of patient items.setEverything Has Its Placeet orderinDevelop an effective identification system,color coding supplies by category to organize<strong>and</strong> decrease time spent searching for items.800-253-2467 • www.akro-mils.com

sort •set in order •shine •<strong>Increase</strong> Healthcare <strong>Efficiency</strong> <strong>and</strong> <strong>Organization</strong><strong>with</strong> <strong>Akro</strong>-<strong>Mils</strong> <strong>and</strong> <strong>5S</strong> <strong>Lean</strong>st<strong>and</strong>ardize •sustain +safety©2011 <strong>Akro</strong>-<strong>Mils</strong>/Myers Industries, Inc. #AKM69 07/11