STAVAX ESR - Uddeholm

STAVAX ESR - Uddeholm

STAVAX ESR - Uddeholm

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

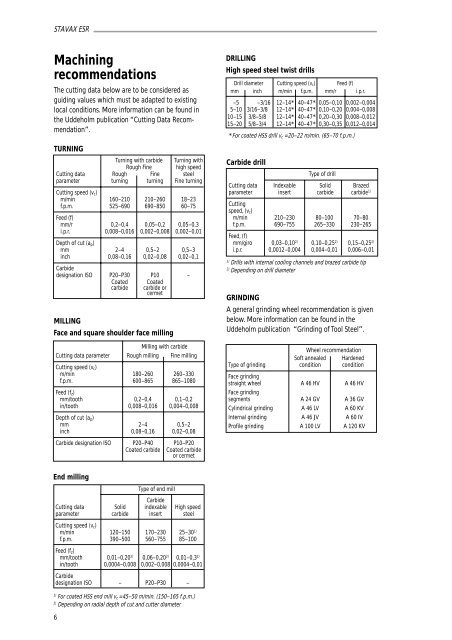

<strong>STAVAX</strong> <strong>ESR</strong>MachiningrecommendationsThe cutting data below are to be considered asguiding values which must be adapted to existinglocal conditions. More information can be found inthe <strong>Uddeholm</strong> publication “Cutting Data Recommendation”.TURNINGTurning with carbide Turning withRough Fine high speedCutting data Rough Fine steelparameter turning turning Fine turningCutting speed (v c )m/min 160–210 210–260 18–23f.p.m. 525–690 690–850 60–75Feed (f)mm/r 0,2–0,4 0,05–0,2 0,05–0,3i.p.r. 0,008–0,016 0,002–0,008 0,002–0,01Depth of cut (a p )mm 2–4 0,5–2 0,5–3inch 0,08–0,16 0,02–0,08 0,02–0,1Carbidedesignation ISO P20–P30 P10 –Coated Coatedcarbide carbide orcermetMILLINGFace and square shoulder face millingMilling with carbideCutting data parameter Rough milling Fine millingCutting speed (v c )m/min 180–260 260–330f.p.m. 600–865 865–1080Feed (f z )mm/tooth 0,2–0,4 0,1–0,2in/tooth 0,008–0,016 0,004–0,008Depth of cut (a p )mm 2–4 0,5–2inch 0,08–0,16 0,02–0,08Carbide designation ISO P20–P40 P10–P20Coated carbide Coated carbideor cermetDRILLINGHigh speed steel twist drillsDrill diameter Cutting speed (v c ) Feed (f)mm inch m/min f.p.m. mm/r i.p.r.–5 –3/16 12–14* 40–47* 0,05–0,10 0,002–0,0045–10 3/16–3/8 12–14* 40–47* 0,10–0,20 0,004–0,00810–15 3/8–5/8 12–14* 40–47* 0,20–0,30 0,008–0,01215–20 5/8–3/4 12–14* 40–47* 0,30–0,35 0,012–0,014* For coated HSS drill v c =20–22 m/min. (65–70 f.p.m.)Carbide drillType of drillCutting data Indexable Solid Brazedparameter insert carbide carbide 1)Cuttingspeed, (v c )m/min 210–230 80–100 70–80f.p.m. 690–755 265–330 230–265Feed, (f)mm/giro 0,03–0,10 2) 0,10–0,25 2) 0,15–0,25 2)i.p.r. 0,0012–0,004 0,004–0,01 0,006–0,011)Drills with internal cooling channels and brazed carbide tip2)Depending on drill diameterGRINDINGA general grinding wheel recommendation is givenbelow. More information can be found in the<strong>Uddeholm</strong> publication “Grinding of Tool Steel”.Wheel recommendationSoft annealed HardenedType of grinding condition conditionFace grindingstraight wheel A 46 HV A 46 HVFace grindingsegments A 24 GV A 36 GVCylindrical grinding A 46 LV A 60 KVInternal grinding A 46 JV A 60 IVProfile grinding A 100 LV A 120 KVEnd millingType of end millCarbideCutting data Solid indexable High speedparameter carbide insert steelCutting speed (v c )m/min 120–150 170–230 25–30 1)f.p.m. 390–500 560–755 85–100Feed (f z )mm/tooth 0,01–0,20 2) 0,06–0,20 2) 0,01–0,3 2)in/tooth 0,0004–0,008 0,002–0,008 0,0004–0,01Carbidedesignation ISO – P20–P30 –1)For coated HSS end mill v c =45–50 m/min. (150–165 f.p.m.)2)Depending on radial depth of cut and cutter diameter6