Caldie eng-04 - Uddeholm

Caldie eng-04 - Uddeholm

Caldie eng-04 - Uddeholm

- No tags were found...

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

CALDIETool steel

CALDIEThe information in this brochure is based on our present state of knowledgeand is intended to provide general notes on our products and theiruses. It should not therefore be construed as a warranty of specificproperties of the products described or a warranty for fitness for a particularpurpose.2

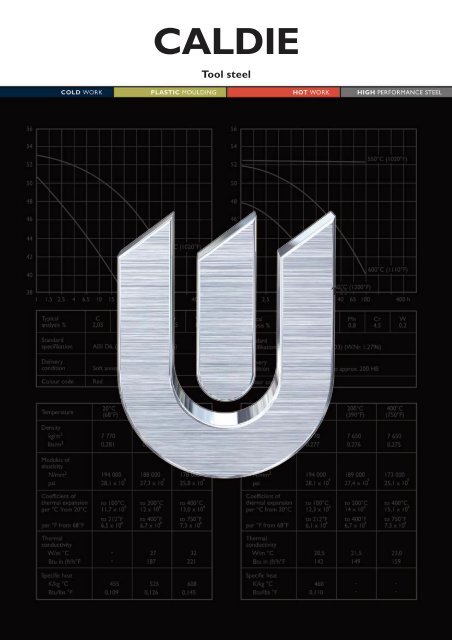

CALDIETTT-graphAustenitizing temperature 1020°C (1870°F). Holding time 30 minutes.°F20001800°C11001000Austenitizing temperature 1025°CHolding time 30 min1600900A c 1f= 870°C140012001000800700600500CarbidesPearliteA c 1 s= 805°CTemp.°C750700650Timehours8,23,923,1Hardn.HV 1024333339080060<strong>04</strong>0<strong>04</strong>00300200Bainite60035030025014,314,68,223,2824835542606200100Martensite2001508,123,58358241 10 100 1 000 10 000 100 000 Seconds1 10 100 1 000 Minutes1 10 100 HoursTEMPERINGChoose the tempering temperature according to thehardness required by reference to the temperinggraph below. Temper at least twice with intermediatecooling to room temperature. The lowesttempering temperature which should be used is525°C (980°F). The minimum holding time attemperature is 2 hours.Tempering graphHardness, HRC6664Austenitizing temperature 1020°C (1870°F)Retained austenite %206260Hardness155810565452Retained austenite5500 520 540 560 580 600°C932 968 10<strong>04</strong> 1<strong>04</strong>0 1076 1112°FTempering temperature5

CALDIEHardness, grain size and retained austenite as afunction of austenitizing temperatureGrainsizeASTM Hardness, HRCRetained austenite %10 66509Grain sizeHardness8644076 6330Retained austenite54 6220326110160990 1000 1010 1020 1030 1<strong>04</strong>0 1050 1060°C1814 1832 1850 1868 1886 19<strong>04</strong> 1922 1940°FAustenitizing temperature, 30 minutesDIMENSIONAL CHANGESThe dimensional changes have been measured afteraustenitizing at 1020°C (1870°F)/30 minutesfollowed by gas quenching in N 2 at a cooling rate of1,1°C/s between 800–500°C (1470–930°F) in a coldchamber vacuum furnace.Specimen size: 100 x 100 x 100 mm (3,9"x 3,9"x3,9")Dimensional changes (%)0,180,160,140,120,100,080,060,<strong>04</strong>0,020-0,02-0,<strong>04</strong>-0,06-0,08500 520 540 560 580 600°C932 968 10<strong>04</strong> 1<strong>04</strong>0 1076 1112°FTempering temperature 2 x 2hSurface treatmentsTool steels may be given a surface treatment inorder to reduce friction and increase wear resistance.The most commonly used treatments arenitriding and surface coating with wear resistantlayers produced via PVD or CVD.The high hardness and toughness together with agood dimensional stability makes <strong>Caldie</strong> suitable asa substrate steel for various surface coatings.NITRIDING AND NITROCARBURIZINGNitriding and nitrocarburizing result in a hardsurface layer which is very resistant to wear andgalling.The surface hardness after nitriding is approximately1000–1200 HV 0,2kg . The thickness of the layershould be chosen to suit the application in question.PVDPhysical vapour deposition, PVD, is a method ofapplying a wear-resistant coating at temperaturesbetween 200–500°C (390–930°F).CVDChemical vapour deposition, CVD, is used forapplying wear-resistant surface coatings at atemperature of around 1000°C (1830°F).WeldingGood results when welding tool steel can beachieved if proper precautions are taken during thewelding operation.•The joints should be prepared properly.• Repair welds should be made at elevated temperature.Make the two first layers with thesame electrode diameter and/or current.• Always keep the arc l<strong>eng</strong>th as short as possible.The electrode should be angled at 90° to thejoint sides to minimize undercut. In addition,the electrode should be held at an angle of75–80° to the direction of forward travel.•For large repairs, weld the initial layers with asoft filler material (buffering layer).6

CALDIERelative comparisonof <strong>Uddeholm</strong> cold work tool steelMATERIAL PROPERTIES AND RESISTANCE TO FAILURE MECHANISMSHardness/ Fatigue cracking resistanceResistance Resistance to Ductility/ Toughness/<strong>Uddeholm</strong> to plastic Machin- Grind- Dimension Abrasive Adhesive resistance to grossgrade deformation ability ability stability wear wear chipping crackingARNECALMAXCALDIERIGORSLEIPNERSVERKER 21SVERKER 3VANADIS 4 ExtraVANADIS 6VANADIS 10VANADIS 23Further informationPlease contact your local <strong>Uddeholm</strong> office forfurther information on the selection, heat treatment,application and availability of <strong>Uddeholm</strong> tool steels.9