Linear Positioners Catalog_en-US_revA - Kollmorgen

Linear Positioners Catalog_en-US_revA - Kollmorgen

Linear Positioners Catalog_en-US_revA - Kollmorgen

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

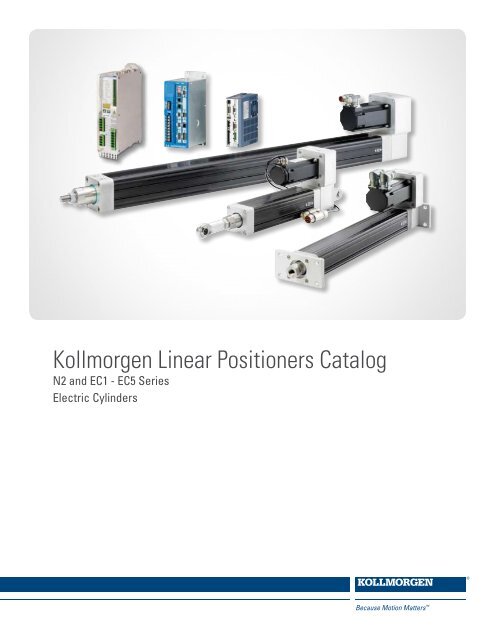

Kollmorg<strong>en</strong> <strong>Linear</strong> <strong>Positioners</strong> <strong>Catalog</strong>N2 and EC1 - EC5 SeriesElectric Cylinders

Kollmorg<strong>en</strong>.Every solution comes from a realunderstanding of OEM chall<strong>en</strong>ges.The ever-escalating demands of the marketplace mean increased pressureon OEMs at every turn. Time constraints. Demands for better performance.Having to think about the next-g<strong>en</strong>eration machine ev<strong>en</strong> before the curr<strong>en</strong>tone is built. While expectations are <strong>en</strong>ormous, budgets are not. Kollmorg<strong>en</strong>’sinnovative motion solutions and quality products help <strong>en</strong>gineers not onlyovercome these chall<strong>en</strong>ges but also build truly differ<strong>en</strong>tiated machines.Because motion matters, it’s our focus. Motion can distinctly differ<strong>en</strong>tiate amachine and deliver a marketplace advantage by improving it’s performance.This translates to overall increased effici<strong>en</strong>cy on the factory floor. Perfectlydeployed machine motion can make your customer’s floor more reliableand effici<strong>en</strong>t, <strong>en</strong>hance accuracy and improve operator safety. Motion alsorepres<strong>en</strong>ts <strong>en</strong>dless possibilities for innovation. We’ve always understood thispot<strong>en</strong>tial, and have kept motion at our core, rel<strong>en</strong>tlessly developing productsthat offer precision control of speed, accuracy and position in machines thatrely on complex motion.K O L L M O R G E N

K O L L M O R G E N L I N E A R P O S I T I O N E R S C A T A L O GTable of Cont<strong>en</strong>tsElectric Cylinder Servo Systems - Overview 4, 5Electric Cylinder - Features 6, 7Electric Cylinder Specifications - Overview 8N2 Series G<strong>en</strong>eral Specifications 9 - 11EC Series G<strong>en</strong>eral Specifications 12 - 19Performance DataQuick Selection Guide 20Performance Summary 21 - 24Thrust Speed CurvesN2 Series 25, 26EC1 Series 27, 28EC2 Series 29, 30EC3 Series 31 - 33EC4 Series 34 - 36EC5 Series 37 - 40Servo System Curr<strong>en</strong>t Calculation 41Outline Drawings - Electric CylindersN2 Series - Outline Drawings 42 - 47N2 Series - Rod-End Adapters 48EC Series - Outline Drawings 49 - 54EC Series - Rod-End Adapters 55Servo Drive Overview - Selection Guide 70S200 Drive 71 - 73S300 Drive 74, 75Smart Drive Drive/IEC 61131 Control 76 - 79Application Engineering Refer<strong>en</strong>ce 80 - 97Engineering Refer<strong>en</strong>ce 98 - 103Application Worksheet 104 - 107Ordering Information N2 Series 108, 109Ordering Information EC Series 110, 111Ordering Information Servo Drive SystemsS200 Drive 112S300 Drive 113Smart Drive Drive/IEC 61131 Control 114, 115AKM motor options for Electric Cylinders 116Outline Drawings - AKM ServomotorsAKM1x frame 117AKM2x frame 118AKM4x frame 119AKM5x frame 120Options and Accessories - Electric Cylinders 56 - 64AKM Brushless Servo - System SummaryAKM1x Servo Systems 65AKM23 Servo Systems 66AKM42 Servo Systems 67AKM52G Servo Systems 68AKM52L Servo Systems 69www.kollmorg<strong>en</strong>.com3

N2 & EC Series Electric Cylinder Servo SystemsL I N E A R P O S I T I O N E R SN2 with AKM23Kollmorg<strong>en</strong>’sElectric Cylinder Servo Systems provide an unpreced<strong>en</strong>ted level of flexibility.EC2 with AKM23º The N2 and EC Series Electric Cylinders offer an unpreced<strong>en</strong>ted degree of flexibility. This flexibility <strong>en</strong>ables solutionto be optimized for the application requirem<strong>en</strong>ts, reducing system cost and minimizing the electric cylinder size.º The flexible design of the N2 and EC Series simplifies <strong>en</strong>gineering design and system integration by providing anintegrated gearing design of both timing belt and helical gearing.º Integrated AKM brushless servomotor provides a system solution reducing application and <strong>en</strong>gineering requirem<strong>en</strong>tsas well as eliminates mechanical interface and interoperability issues. Stepper motors are also available.Standard Configurable Electric Cylinder Designs:N2 SeriesEC SeriesTransport ScrewIntegratedGearingMounting TypesPrecision ballscrew (2 and 5 [rev/in] pitch)Lead screw (5 and 8 [rev/in] pitch)Timing belt (1.0, 1.5, 2.0:1 ratios)Helical gear (2.5, 3.5, 12.0:1 ratios)Inline (direct coupled)7 Parallel Mounts5 Inline MountsPrecision ballscrew (3 to 32 [mm/rev] lead)Lead screw (4 [mm/rev] lead)Timing belt (1.0, 1.5, 2.0:1 ratios)Helical gear (2.0, 2.5, 4.0, 5.0, 7.0, 10.0:1 ratios, model dep<strong>en</strong>d<strong>en</strong>t)Inline (direct coupled)8 Parallel Mounts5 Inline MountsRod-End Adapters 4 Types (English and Metric) 5 Types (English and Metric)Stroke L<strong>en</strong>gthsStandard stroke (2 to 22.5 in)Custom stroke l<strong>en</strong>gths availableStandard stroke l<strong>en</strong>gthsEC1 50 to 200 mm (7.87 in)EC2 50 to 750 mm (29.5 in)EC3 50 to 1000 mm (39.4 in)EC4 & EC5 50 to 1500 mm (59.1 in)Options and AccessoriesElectric Cylinder accessories and time-prov<strong>en</strong> options have be<strong>en</strong> designed for the industrial <strong>en</strong>vironm<strong>en</strong>t to simplify systemintegration. Options include limit switches, dual rod-<strong>en</strong>d bearings, guide bearing, protective boot, and ext<strong>en</strong>ded temperature rangesjust to name a few. See the option and accessory section on pages 56 - 64 for more details.4K O L L M O R G E N

N2 & EC Series Electric Cylinder Servo SystemsThe Electric Cylinders Servo Systems are offered with three Kollmorg<strong>en</strong> brushless servo drive series to provide system flexibility.Let your application and system requirem<strong>en</strong>ts determine what solution integrates the best.• Single v<strong>en</strong>dor solution for the complete electro-mechanicalsystem <strong>en</strong>sures system interoperability and a single dedicatedworldwide motion-control supplier for support.• The Electric Cylinder Servo Systems are available in drive andcontrol technologies ranging form simple and intuitive positioningdrives to fully programmable IEC 61131 based control systems:• The Electric Cylinder Servo Systems leverage multiple Kollmorg<strong>en</strong>Servo Drive/Controllers and the AKM brushless servomotors forcomplete system flexibility and industry leading servo responseand precision.L I N E A R P O S I T I O N E R SS200 115 / 230 VacCompact DriveHigh-Performance• Base Unit: Analog torque-and-velocity, step and direction, <strong>en</strong>coder following• Network Option Cards (SynqNet, D-Link ® Network for IEC 61131 Control)• Indexer Option Card, Simple Positioning System– 180 motion tasks, increm<strong>en</strong>tal absolute positioning, Jog mode– Simple intuitive Graphical User Interface (GUI), no programming experi<strong>en</strong>ce requiredS300 115 / 230 / 400 / 460 VacFlexible DriveUniversal ControlOptions &Power Range• Base Unit: Analog torque and velocity, CanOp<strong>en</strong> ® , step and direction, <strong>en</strong>coder following• Network Option Card solutions• DeviceNet, Profibus DP, SynqNet, Ethercat ® , SERCOS II, SERCOS III• Simple Positioning System– 256 motion tasks, link motion tasks, ACCEL/DECEL control, S-curve– Increm<strong>en</strong>tal, absolute positioning, Jog mode and moreMachine and motionControl IEC 61131IntegratedController/DriveSmart Drive (SD) 115 / 230 / 400 / 460 Vac• Fully Programmable IEC 61131 based Integrated Controller/Drive (1-16 axes)• Ethernet network interface for motion that simplifies wiring, increases performance, reliability, andprovides local and remote diagnostic capability• Ext<strong>en</strong>sive library of motion control function blocks to reduce developm<strong>en</strong>t timewww.kollmorg<strong>en</strong>.com5

Electric Cylinder FeaturesL I N E A R P O S I T I O N E R SElectric cylinders are direct desc<strong>en</strong>d<strong>en</strong>ts of hydraulic and pneumaticcylinders. Possessing many of the same unique design characteristicsthat made hydraulic and pneumatic cylinders popular, electric cylindersb<strong>en</strong>efit from a cleaner and simpler power transmission. Decades of electriccylinder research and developm<strong>en</strong>t has provided machine designerswith a flexible, simple and unique approach to solving rigid or pivotinglinear motion applications.Electrically Powered, Maint<strong>en</strong>ance FreeToday nearly all machines incorporate panel switches, s<strong>en</strong>sors, lights, displays, PLCs or PCs. Electric power is nearly always available on themachine. Compressed air or hydraulic pumps are not always available or desirable. So why not simplify the machine by using the same control forall the axes of motion? A multi-axis programmable motor control can give you command of both rotary and linear motion. Lastly, the maint<strong>en</strong>ancefreedesign provides another strong reason to consider electric cylinders in your next application.Straight-Line Thrust Transmission Use All Available PowerWh<strong>en</strong> high thrust is required, rod type cylinders have the advantage over other actuationmeans in that all the thrust transmitting compon<strong>en</strong>ts are in-line. This provides thesimplest and most effici<strong>en</strong>t means of transmitting thrust to the load.Straight Line Force PathNon-Intrusive: Thrust Rod Can Clear Out of the Way.A primary advantage of rod-type electric cylinders is the capability to ext<strong>en</strong>dinto a work area during an operation and th<strong>en</strong> retract to clear the area forsubsequ<strong>en</strong>t operations. Another b<strong>en</strong>efit of the rod-type design is that the motorand main body of the electric cylinder can be isolated from the work area.This is very useful wh<strong>en</strong> dealing with such hostile <strong>en</strong>vironm<strong>en</strong>ts as vacuum,high temperature, or wash down applications.Mounting examples…Above: Rigid (side lug mounts)Right: Pivot (clevis)PayloadBearing Slide335°Mounting FlexibilityAs in most aspects of design, a little creativity goes a long way wh<strong>en</strong> attachinga cylinder to a machine. Two g<strong>en</strong>eral types of mounting styles areavailable, rigid and pivoting. Rigid mounting options include side-tappedholes, front and rear flanges, side lugs and side angle brackets. Thesetypically restrict motion to straight-line travel paths. Pivoting mounts suchas the clevis or trunnion allow the cylinder to move as a link in a dynamicassembly. There are many applications for this “arc-motion” – conveyordiverter gates, pivoting rollers, lid lifters for chemical chambers, “scissorsclamps” and so on.60°6K O L L M O R G E N

Electric Cylinders Are Preferred Wh<strong>en</strong>:• Positioning an externally guided and supported load.• Moving a load that pivots.• There is a high conc<strong>en</strong>tration of airborne contaminants (rodless positionersare inher<strong>en</strong>tly less well protected).• Replacing a hydraulic or pneumatic cylinder with an electro-mechanicalsolution.Kollmorg<strong>en</strong> offers electric cylinder drive mechanisms designed aroundeither lead screws or ballscrews. Ballscrews, being the more effici<strong>en</strong>tof the two, utilize ballnuts riding on recirculating ball bearings resultingin higher speeds, loads and cycle rates. However, the more effici<strong>en</strong>tdesign of ballscrew technology l<strong>en</strong>ds it to being backdriv<strong>en</strong> wh<strong>en</strong>power is removed if precautions are not tak<strong>en</strong> (e.g., electric brakes orcounter loading).Lead screws are capable of holding the load in position wh<strong>en</strong> power isremoved, but are less effici<strong>en</strong>t in operation.Kollmorg<strong>en</strong>’s guide system prev<strong>en</strong>ts rotation of the ball / lead nut, thuseliminating any torque loading to machine linkage.EC Servo <strong>Linear</strong> <strong>Positioners</strong>• Designed for performance• Highest quality precision rolled ballscrews and leadscrews – for quiet, long-life operation• Brushless Servo with <strong>en</strong>coder, resolver or SFD feedback• Stepper motors are also available• Sealed for IP54 protection and IP65 option available• Thrust up to 25000 N [5620 lb]• Speed up to 1.3 m/s [52.5 in/s]• Metric design (ISO 6431)• Available in 5 power ranges – EC1, 2, 3, 4 & 5N2 Servo <strong>Linear</strong> <strong>Positioners</strong>• Smallest Package Size• Time-Prov<strong>en</strong> Design• Improved Durability Over Previous Designs• Thrust up to 2670 N [600 lb]• Speed up to 0.76 m/s [30 in/sec]• English dim<strong>en</strong>sions (to NFPA standards)• Brushless Servo with <strong>en</strong>coder, resolver or SFD feedbackL I N E A R P O S I T I O N E R STypical Construction (EC2 cut-away shown)Brushless servomotors(not shown) with quickdisconnect cabling anda variety of feedbackoptions.Wiper seal on polished stainlesssteel output tube keeps contaminantsout and lubricants in.Metric (ISO 6431) and Englishrod <strong>en</strong>ds available.Ground stainless steelthrust tube for long wearand corrosion resistance.Timing belt and geareddrives providelong life with a wide varietyof drive ratios.Angular contact bearings<strong>en</strong>sure long life with minimalbacklash.Recirculating ballscrews andlead screws provide smooth, highthrust drive. Lead screws hold loadwithout power.Front sleeve bearingsupports side loads andminimizes runout.Housing is hard-coat dized and teflon coated foranolonglife, perman<strong>en</strong>t lubrication,resistant to corrosion,and protection of all internalcompon<strong>en</strong>ts.www.kollmorg<strong>en</strong>.com7

Electric Cylinder Servo System: Specification OverviewFeature N2 EC1 EC2 EC3 EC4 EC5L I N E A R P O S I T I O N E R SStd. Maximum StrokeL<strong>en</strong>gth [in (mm)]* 22.5 (571.5) 7.87 (200) 29.53 (750) 39.37 (1000) 59.06 (1500) 59.06 (1500)Type of Screw Lead Ball Ball Lead Ball Lead Ball Ball BallLead[displacem<strong>en</strong>t / rev]Nom. Lead ScrewDiameter0.2 in, 0.5 in 0.2 in, 0.5 in 0.125 in 4 mm 16, 5 mm 4 mm16, 10,5 mm25, 10 mm 32, 10 mm0.625 in 0.625 in 0.375 in 16 mm 16 mm 20 mm 20 mm 25 mm 32 mmBacklash [in (mm)] 0.016 (0.40) 0.015 (0.38) 0.015 (0.38) 0.016 (0.40) 0.010 (0.25) 0.016 (0.40) 0.010 (0.25) 0.12 (0.30) 0.12 (0.30)Dim<strong>en</strong>sion Std. English NFPA Std. Metric ISO6431 Std.Bore size 30 mm 50 mm 63 mm 80 mm 100 mmBrushlessServomotorAKM23, NEMA 23 AKM1x, NEMA 17 AKM23, NEMA 23AKM23, NEMA 23AKM42, NEMA 34AKM52, NEMA 42 **AKM42, NEMA 34AKM52, NEMA 42 **AKM42, NEMA 34AKM52, NEMA 42 **Stepper Motor Contact Factory CTP12, NEMA 17 Contact FactoryMax. Thrust [lb (N)] 600 (2670) 150 (667) 810 (3600) 1620 (7200) 2700 (12,000) 5620 (25,000)Max. Velocity[in/sec (m/s)]Max. Rated Duty Cycle(load, speeddep<strong>en</strong>d<strong>en</strong>t) [% ]12 (0.3) 30 (0.76) 13 (0.33) 9.2 (0.23) 50 (1.27) 8.0 (0.20) 50 (1.28) 52.5 (1.33) 52.5 (1.33)50 100 100 50 100 50 100 100 100Limit Switches OptionalStd. OperatingTemperature Range[C (F)]0 to 60 (32 to 140) -30 to 70 (-22 to 158)Moisture/ContaminantsHumid, but Not DirectContactIP54 Std. IP65 Opt.Notes* Requires dual rod-<strong>en</strong>d bearing option for l<strong>en</strong>gth over 12".** NEMA 42 mount, shaft does not follow a NEMA std.EC38K O L L M O R G E N

N2 Series Electric Cylinders: G<strong>en</strong>eral SpecificationsTravel L<strong>en</strong>gthsCylinder Stroke Designator/Effective Travel L<strong>en</strong>gthsStroke l<strong>en</strong>gth designator [in] 2.0 4.0 6.0 8.0 12.0 *18.0 *24.0Effective Travel L<strong>en</strong>gth [in] 2.0 4.0 6.0 8.0 12.0 16.5 22.5* Dual rod-<strong>en</strong>d bearing required for 18 inch and 24 inch stroke units.* Effective travel reduced by 1.5 inches respectively with dual rod-<strong>en</strong>d bearing.Custom travel l<strong>en</strong>gths are available.Construction MaterialsBearing HousingsCylinder HousingThrust TubeWiper sealSpeed Reducer VersionsBelt/PulleyHelical GearingSupport BearingsTransport Screw VersionsBallscrewBallnutLead screwLead nutType 380 die cast aluminum, epoxy coated6063-T6 aluminum, hard-coated anodized and Teflon ® coated304 Series Stainless Steel, 1/4 hard, ground and polishedPolyurethaneAT-5, polyurethane with steel t<strong>en</strong>sile cordsAlloy steel, case hard<strong>en</strong>edBall bearingsCarbon steel screwAlloy steel, heat-treated ballnutCarbon steel screwBronze lead nut (standard, recomm<strong>en</strong>ded for servo system)(Lubricated polyacetal plastic drive nut also available but notrecomm<strong>en</strong>ded for use with servomotor based systems.)L I N E A R P O S I T I O N E R SSystem SpecificationsElectricCylinderScrew-NutTypePitch[revs/in]ScrewDiameter[in]Effici<strong>en</strong>cy[%]MinimumBackdriveLoad [lb]MaximumThrust[lb]MaximumSpeed[in/s]Backlash[mm (in)]Repeatability[mm/300mm (in/ft)]N2-2B Ballscrew 2.0 0.625 90 10 * 552 ** 30 0.38 (0.015) +/-0.15 (+/-0.006)N2-5B Ballscrew 5.0 0.625 90 20 600 12 0.38 (0.015) +/-0.15 (+/-0.006)N2-5A-BZ Bronze 5.0 0.625 40 400 600 ** 12 0.40 (0.016) +/-0.75 (+/-0.003)* Thrust limited by AKM23 motor/drive T peak limit.** Maximum speed and Maximum Thrust specification define range of N2 series; not available on the same unit.See Thrust Speed curves (pages 25, 26) for compreh<strong>en</strong>sive details.Weight (approximate, without options)Cylinder- Motor Weight [ kg ] Weight [ lbs ]N2-AKM23 = 2.28 + 0.11 x [in stroke] = 5.0 + 0.25 x [in stroke]Brushless ServomotorForce Speed Cuves See pages 25, 26Servo System Specifications See page 66Dim<strong>en</strong>sions See page 118www.kollmorg<strong>en</strong>.com9

N2 Series Electric Cylinders: PropertiesElectricCylinderScrew TypePitch[revs/in]ScrewEffici<strong>en</strong>cy [%]TransmissionRatio Type Effici<strong>en</strong>cy [%]OverallEffici<strong>en</strong>cy [%]L I N E A R P O S I T I O N E R SN2-...-10L-2B Ballscrew 2.0 90 Inline/direct coupled N/A N/A 90N2-...-10-2B Ballscrew 2.0 90 1:1 Timing belt 90 81N2-...-15-2B Ballscrew 2.0 90 1.5:1 Timing belt 90 81N2-...-20-2B Ballscrew 2.0 90 2.0:1 Timing belt 90 81N2-...-25-2B Ballscrew 2.0 90 2.5:1 Helical gear 70 63N2-...-10L-5B Ballscrew 5.0 90 Inline/direct coupled N/A 90 90N2-...-10-5B Ballscrew 5.0 90 1:1 Timing belt 90 81N2-...-15-5B Ballscrew 5.0 90 1.5:1 Timing belt 90 81N2-...-20-5B Ballscrew 5.0 90 2.0:1 Timing belt 90 81N2-...-25-5B Ballscrew 5.0 90 2.5:1 Helical gear 70 63N2-...-10L-5A Lead 5.0 40 Inline/direct coupled N/A 40 16N2-...-10-5A Lead 5.0 40 1:1 Timing belt 90 36N2-...-15-5A Lead 5.0 40 1.5:1 Timing belt 90 36N2-...-20-5A Lead 5.0 40 2.0:1 Timing belt 90 36N2-...-25-5A Lead 5.0 40 2.5:1 Helical gear 70 28N2 Series Electric Cylinders - G<strong>en</strong>eral SpecificationsN2 Series Electric Cylinder InertiaRotary Inertia (Reflected to Motor) = A + B* (Stroke, in) + C * (Load weight, lb)ModelN2 SeriesRatio Reduction type ScrewA B Coz-in 2 oz-in 2 / in oz-in 2 / lbN2-…-10-5B 1:10.5702 0.0685 0.0162N2-…-15-5B 1.5:1 Belt/pulleyPitch 5 revs/inDia 0.625 in0.2756 0.03045 0.0072BallscrewN2-…-20-5B 2:1 0.1689 0.0171 0.0041N2-…-10-2B 1:10.6532 0.07555 0.1013N2-…-15-2B 1.5:1 Belt/pulleyPitch 2 revs/inDia 0.625 in0.3126 0.03355 0.0450BallscrewN2-…-20-2B 2:1 0.1895 0.01899 0.0253N2-…-10-5A 1:10.06845 0.06845 0.0162N2-…-15-5A 1.5:1 Belt/pulleyPitch 5 revs/inDia 0.625 in0.0304 0.0304 0.0072Lead ScrewN2-…-20-5A 2:1 0.0171 0.0171 0.0041To convert inertia units from oz-in 2 to oz-in-sec 2 divide by 386.10K O L L M O R G E N

N2 Series Electric Cylinders: G<strong>en</strong>eral SpecificationsBallscrew LifeBallscrew life is rated in inches of travel at a giv<strong>en</strong> load. The values in the chart below indicates the travel life where 90% of allunits in a sample will continue to work, while 10% have failed. This is similar to the B10 rating of a roller bearing mechanism.Be sure to consider acceleration loads as well as thrust, gravity and friction loads.Load(lb)8007006005004003002001005B/2BBallscrew Life: Load vs. Travel Life ChartL I N E A R P O S I T I O N E R S1 2 3 4 6 8 10 20 30 40 60 80 100 2006Travel Life (x 10 inches)Environm<strong>en</strong>tal Operation (see Options and Accessories section, page 60-61)TemperatureMoistureContaminants32° to 140°F, [0° to 60°C]H High temperature option allows 32° to 160°F, [0° to 70°C]F Sub-freezing temperature option allows -20° to 105°F, [-29° to 40°C]Humid, but not direct moisture contactW Water resistant option allows some direct moisture contactNon-corrosive, non-abrasive.PB Protective Boot option prev<strong>en</strong>ts moisture and dry contaminants from <strong>en</strong>teringthe cylinder through the wiper ring on the rodN2 with AKM23www.kollmorg<strong>en</strong>.com11

EC Series Electric Cylinders: G<strong>en</strong>eral SpecificationsTravel L<strong>en</strong>gthsL I N E A R P O S I T I O N E R SCylinder Travel L<strong>en</strong>gths [ mm ]EC1 50 100 150 200EC2 50 100 150 200 250 300 450 600 750EC3 50 100 150 200 250 300 450 600 750 1000EC4 50 100 150 200 250 300 450 600 750 1000 1250 1500EC5 50 100 150 200 250 300 450 600 750 1000 1250 1500Custom strokes available in increm<strong>en</strong>ts of 1 mm.Construction MaterialsBearing & Drive Housing6063-T6 aluminum, anodizedGuide Cylinder6063-T6 aluminum, hard anodizedMounting Plates6061-T6 aluminum and cast aluminum plate, anodizedThrust Tube300 Series Stainless Steel, 1/4 hard and groundThrust BearingsAngular contact, high thrust ball bearingsSpeed Reducer VersionsBelt/PulleyAT-5, polyurethane with steel t<strong>en</strong>sile cordsHelical GearingAlloy steel, case hard<strong>en</strong>edTransport Screw VersionsBallscrew/BallnutHeat treated carbon steel alloyLead screw/Lead nutBronze; carbon steel alloy lead screwCylinderNominalDiameter [mm (in)]Screw PropertiesLead ScrewEC1 (0.375) 3.175 (0.125)Lead [mm (in)] / rev.BallscrewEC2 16 4 (0.157) 5 (0.197) 16 (0.630 )EC3 20 4 (0.157) 5 (0.197) 10 (0.395 ) 16 (0.630)EC4 25 10 (0.394) 25 (0.984)EC5 32 10 (0.394) 32 (1.259)Weight (approximate, without options)Cylinder- Motor Weight [kg] Weight [lbs]EC1-AKM11 = 0.864 + 0.162 x [mm stroke] = 1.9 + 0.356 x [in stroke]EC1-AKM13 = 1.136 + 0.162 x [mm stroke] = 2.5 + 0.356 x [in stroke]EC1-CTP12 = 0.764 + 0.162 x [mm stroke] = 1.88 + 0.356 x [in stroke]EC2-AKM23 = 4.18 + 0.006 x [mm stroke] = 9.2 + 0.33 x [in stroke]EC3-AKM23 = 5.75 + 0.008 x [mm stroke] = 12.6 + 0.46 x [in stroke]EC3-AKM42 = 6.70 + 0.008 x [mm stroke] = 14.7 + 0.46 x [in stroke]EC4-AKM42 = 14.7 + 0.0188 x [mm stroke] = 32.2 + 1.05 x [in stroke]EC4-AKM52 = 17.1 + 0.0188 x [mm stroke] = 37.7 + 1.05 x [in stroke]EC5-AKM42 = 14.7 + 0.0188 x [mm stroke] = 32.2 + 1.05 x [in stroke]EC5-AKM52 = 17.1 + 0.0188 x [mm stroke] = 37.7 + 1.05 x [in stroke]Brushless ServomotorForce Speed CuvesSee pages EC1 (p.27),EC2 (p. 29, 30),EC3 (p. 31-33), EC4 (p. 34-36),EC5 (p. 37-39)Servo System SpecificationsSee page 65-69Dim<strong>en</strong>sionsSee page 117-120Stepper MotorForce Speed Cuves (p.28)System Specifications and dim<strong>en</strong>sionsSee P7000 Selection GuideSee CT Series Selection Guide12K O L L M O R G E N

EC Series Electric Cylinders: G<strong>en</strong>eral SpecificationsSystem Specifications - Backlash, Lead AccuracyCylinderLead[mm (in)]TypeBacklash[mm (in)] /rev.Lead Accuracy[mm/300mm (in/ft)]Repeatability[mm (in)]EC1 (0.125) Ball 0.381 (0.015) +/-0.10 (+/-0.004) +/-0.013 (+/-0.0005)EC2EC316, 5 Ball 0.25 (0.010) +/-0.05 (+/-0.002) +/-0.013 (+/-0.0005)4 Lead 0.40 (0.016) +/-0.10 (+/-0.004) +/-0.013 (+/-0.0005)16, 10, 5 Ball 0.25 (0.010) +/-0.05 (+/-0.002) +/-0.013 (+/-0.0005)4 Lead 0.40 (0.016) +/-0.10 (+/-0.004) +/-0.013 (+/-0.0005)EC4 25, 10 Ball 0.30 (0.012) +/-0.05 (+/-0.002) +/-0.013 (+/-0.0005)L I N E A R P O S I T I O N E R SEC5 32, 10 Ball 0.30 (0.012) +/-0.05 (+/-0.002) +/-0.013 (+/-0.0005)EC2 and EC3 with AKM23www.kollmorg<strong>en</strong>.com13

EC Series Electric Cylinders: G<strong>en</strong>eral SpecificationsEnvironm<strong>en</strong>tal OperationL I N E A R P O S I T I O N E R STemperatureMoisture/Contaminants-30° to 70°C [-22° to 158°F]Wh<strong>en</strong> operating below 2°C [35°F] v<strong>en</strong>t tubing fitting must be installed.Consult the factory for more information.IP 54 rated: Polyurethane thrust tube wiper seal.Mating surfaces gasket sealed. Protected against dust and splashing water (non-corrosive, non-abrasive).Limited ingress permitted.V<strong>en</strong>t Tube Fitting: A v<strong>en</strong>t tube fitting is included, which can be installed to permit the <strong>Linear</strong> Positioner tobreathe from a non-contaminated area, or receive a positive pressure continuous purge (14-20 kPa [2-3 psi]).Maint<strong>en</strong>anceLube PortPB Protective Boot (IP65) Option: An optional thrust tube boot prev<strong>en</strong>ts moisture and dry contaminantsfrom bypassing the thrust tube wiper seal, providing IP65 protection wh<strong>en</strong> used with included v<strong>en</strong>t tubefitting. The boot also prev<strong>en</strong>ts contaminant buildup on the thrust tube.Clean Room & Vacuum Applications: Kollmorg<strong>en</strong> has designed special positioners for clean room andvacuum applications. Please consult the factory if your application requires special <strong>en</strong>vironm<strong>en</strong>talcompatibility.The EC Series <strong>Linear</strong> Positioner design eliminates the need for most routine maint<strong>en</strong>ance. Re-lubrication isrequired in high cycle applications. See the EC Series Operator’s Manual for replacem<strong>en</strong>t parts.EC2 - EC5 models include a lube port and adapter for a standard grease gun.EC4 with AKM4214K O L L M O R G E N

EC Series Electric Cylinders: G<strong>en</strong>eral SpecificationsThrust Tube Torque CapacityThrust tube does not rotate during operation.Maximum allowable torque during operation and installation is shown in the following table:Torque Capacity [lb-in (N-m)]EC1 18 (2.0)EC2 45 (5.0)EC3 67 (7.5)EC4 90 (10)EC5 90 (10)Side Load Mom<strong>en</strong>t(lb-in)Top or Side ofCylinder HousingExt<strong>en</strong>d Distance(inches)Side Load (lb)SideplayL I N E A R P O S I T I O N E R SThrust Tube Side Load Capacity vs. Ext<strong>en</strong>sionEC1* Side loading is not recom<strong>en</strong>ded with the EC1.Side loading will reduce the EC1 life.Side Load (kg)20151050050100 mm150 mm200 mmEC2300 mm 450 mm600 mm750 mm100 200 300 400 500 600750Thrust Tube Ext<strong>en</strong>sion (mm)EC3EC43030Side Load (kg)20100050 mm100 mm200 mm1000 mm300 mm750 mm450 mm 600 mm200 400 600800 1000Thrust Tube Ext<strong>en</strong>sion [mm]Side Load (kg)20100050 mm100 mm200 mm1000 mm300 mm750 mm450 mm 600 mm200 400 600800 1000Thrust Tube Ext<strong>en</strong>sion [mm]EC530Side Load (kg)20100050 mm100 mm200 mm1000 mm300 mm750 mm450 mm 600 mm200 400 600800 1000Thrust Tube Ext<strong>en</strong>sion [mm]www.kollmorg<strong>en</strong>.com15

EC Series Electric Cylinders: G<strong>en</strong>eral SpecificationsLifeL I N E A R P O S I T I O N E R SBallscrewBallscrew life is rated in inches of travel at a giv<strong>en</strong> load. Thevalues in the chart indicate the travel life where 90% of allunits in a sample will continue to work, while 10% have failed.This is similar to the B10 rating of a roller bearing mechanism.Be sure to consider acceleration loads as well as thrust, gravityand friction loads.Lead ScrewUsable life for a lead screw is defined as the l<strong>en</strong>gth of travelcompleted before backlash (of lead screw/nut) exceeds 0.020”[0.5 mm]. A travel life of 25 km [1 million inches] under themaximum rated load can be used as a g<strong>en</strong>eral approximation.However, since directly dep<strong>en</strong>d<strong>en</strong>t on application conditions(load, duty cycle, move profiles, and <strong>en</strong>vironm<strong>en</strong>t), it is difficultto predict a statistical travel life.EC1-03B Ballscrew LifeEC1 Ballscrew Life CurveEC2 Ballscrew LifeLoad (lb)7006005004003002001000EC1-03BBallscrew0.01 0.1 1 10 100Travel Life (x 10 6 inches)Load (lb)80070060050040030020010001EC2-05BBallscrewEC2-16BBallscrew10 100Travel Life (x 10 6 inches)1000Load (lb)80070060050040030020010001EC3 Ballscrew LifeEC3-05BBallscrewEC3-16BBallscrew10 100Travel Life (x 10 6 inches)1000Load (lb)3000250020001500100050000.1EC4 Ballscrew LifeEC4-25BBallscrewEC4-10BBallscrew1 10 100Travel Life (x 10 6 inches)1000Load (lb)EC5 Ballscrew Life60005000 EC5-10BBallscrew40003000EC5-32BBallscrew2000100000.1 1 10 100 1000Travel Life (x 10 6 inches)16K O L L M O R G E N

EC Series Electric Cylinders: G<strong>en</strong>eral SpecificationsEC Series <strong>Linear</strong> Positioner InertiaModelEC SeriesRatioEC1-...-10(L)-03B 1:1Rotary Inertia (Reflected to Motor) = A + B* (Stroke, in) + C * (Load, lb)Reduction typeScrew A B CDia x Lead [mm (in)] lb-in-s 2 lb-in-s 2 / in lb-in-s 2 / lb1.74 E-04 4.98 E-06 1.53 E-06EC1-...-20-03B 2:1 Helical gear (0.375 x 0.125)5.60 E-05 1.24 E-05 3.81 E-07EC1-...-40-03B 4:1 3.15 E-05 1.97 E-06 6.05 E-08EC2-…-10(L)-16B 1:13.18 E-04 1.07 E-05 2.60 E-05L I N E A R P O S I T I O N E R SEC2-…-15-16B 1.5:1 Belt/pulley1.54 E-04 4.96 E-06 1.20 E-05EC2-…-20-16B 2:1 16 x 161.01 E-04 2.68 E-06 6.51 E-06EC2-…-50-16B 5:15.37 E-05 4.25 E-07 1.03 E-06Helical gearEC2-…-100-16B 10:1 4.60 E-05 1.07 E-07 2.60 E-07EC2-…-10(L)-05B 1:12.90 E-04 8.30 E-06 2.54 E-06EC2-…-15-05B 1.5:1 Belt/pulley1.41 E-04 3.84 E-06 1.18 E-06EC2-…-20-05B 2:1 16 x 59.33 E-05 2.07 E-06 6.36 E-07EC2-…-50-05B 5:15.25 E-05 3.29 E-07 1.01 E-07Helical gearEC2-…-100-05B 10:1 4.57 E-05 8.29 E-08 2.54 E-08EC2-…-10(L)-04A 1:12.89 E-04 8.20 E-06 1.63 E-06EC2-…-15-04A 1.5:1 Belt/pulley1.41 E-04 3.79 E-06 7.53 E-07EC2-…-20-04A 2:1 16 x 49.33 E-05 2.05 E-06 4.07 E-07EC2-…-50-04A 5:15.25 E-05 3.25 E-07 6.45 E-08Helical gearEC2-…-100-04A 10:1 4.57 E-05 8.19 E-08 1.626 E-08EC1 with AKM13EC2 with AKM23www.kollmorg<strong>en</strong>.com17

EC Series Electric Cylinders: G<strong>en</strong>eral SpecificationsL I N E A R P O S I T I O N E R SEC Series <strong>Linear</strong> Positioner InertiaRotary Inertia (Reflected to Motor) = A + B* (Stroke, in) + C * (Load, lb)ModelScrew A B CRatio Reduction typeEC 3 Series Dia x Lead [mm (in)] lb-in-s 2 lb-in-s 2 / in lb-in-s 2 / lbEC3-…-10(L)-16B 1:11.19 E-03 1.18 E-05 2.60 E-05EC3-…-15-16B 1.5:1 Belt/pulley7.44 E-04 5.23 E-06 1.16 E-05EC3-…-20-16B 2:1 16 x 164.78 E-04 2.77 E-06 6.12 E-06EC3-…-50-16B 5:12.28 E-04 4.64 E-07 1.03 E-06Helical gearEC3-…-70-16B 7:1 1.98 E-04 2.40 E-07 5.31 E-07EC3-…-10(L)-10B 1:11.20 E-03 1.87 E-05 1.02 E-05EC3-…-15-10B 1.5:1 Belt/pulley7.43 E-04 8.33 E-06 4.52 E-06EC3-…-20-10B 2:1 20 x 104.81 E-04 4.41 E-06 2.39 E-06EC3-…-50-10B 5:12.29 E-04 7.38 E-07 4.01 E-07Helical gearEC3-…-70-10B 7:1 1.98 E-04 3.82 E-07 2.08 E-07EC3-…-10(L)-05B 1:11.20 E-03 1.87 E-05 1.02 E-05EC3-…-15-05B 1.5:1 Belt/pulley7.49 E-04 8.33 E-06 4.52 E-06EC3-…-20-05B 2:1 20 x 54.81 E-04 4.41 E-06 2.39 E-06EC3-…-50-05B 5:12.28 E-04 6.95 E-07 1.00 E-07Helical gearEC3-…-70-05B 7:1 1.97 E-04 3.60 E-07 5.19 E-08EC3-…-10(L)-04A 1:12.89 E-04 8.20 E-06 1.63 E-06EC3-…-15-04A 1.5:1Belt/pulley1.41 E-04 3.79 E-06 7.53 E-07EC3-…-20-04A 2:120 x 49.33 E-05 2.05 E-06 4.07 E-07EC3-…-50-04A 5:1Helical gear5.25 E-05 3.25 E-07 6.45 E-08EC3-…-70-04A 7:1 4.57 E-05 8.19 E-08 1.63 E-08EC3 with AKM2318K O L L M O R G E N

EC Series Electric Cylinders: G<strong>en</strong>eral SpecificationsEC Series <strong>Linear</strong> Positioner InertiaRotary Inertia (Reflected to Motor) = A + B* (Stroke, in) + C * (Load, lb)ModelScrew A B CRatio Reduction typeEC 4 Series Dia x Lead [mm (in)] lb-in-s 2 lb-in-s 2 / in lb-in-s 2 / lbEC4-…-10(L)-25B 1:14.91 E-03 7.01 E-05 6.36 E-05EC4-…-15-25B 1.5:1 Belt/pulley2.80 E-03 3.18 E-05 2.83 E-05EC4-…-20-25B 2:1 25 x 252.71 E-03 1.75 E-05 1.59 E-05EC4-…-50-25B 5:16.27 E-04 2.69 E-06 2.43 E-06Helical gearEC4-…-100-25B 10:1 3.47 E-04 7.00 E-07 6.35 E-07L I N E A R P O S I T I O N E R SEC4-…-10(L)-10B 1:14.68 E-03 5.54 E-05 1.02 E-05EC4-…-15-10B 1.5:1 Belt/pulley2.70 E-03 2.46 E-05 4.52 E-06EC4-…-20-10B 2:1 25 x 102.65 E-03 1.39 E-05 2.54 E-06EC4-…-50-10B 5:16.18 E-04 2.12 E-06 3.90 E-07Helical gearEC4-…-100-10B 10:1 3.45 E-04 5.53 E-07 1.020 E-07ModelScrew A B CRatio Reduction typeEC 5 Series Dia x Lead [mm (in)] lb-in-s 2 lb-in-s 2 / in lb-in-s 2 / lbEC5-...-10(L)-32B 1:15.63 E-03 1.67 E-04 1.04 E-04EC5-...-15-32B 1.5:1 Belt/pulley3.12 E-03 7.41 E-05 4.63 E-05EC5-...-20-32B 2:1 32 x 322.89 E-03 4.17 E-05 2.60 E-05EC5-...-50-32B 5:16.54 E-04 6.38 E-06 3.99 E-06Helical gearEC5-...-100-32B 10:1 3.55 E-04 1.66 E-06 1.04 E-06EC5-...-10(L)-10B 1:15.16 E-03 1.41 E-04 1.02 E-05EC5-...-15-10B 1.5:1 Belt/pulley2.91 E-03 6.26 E-05 4.52 E-06EC5-...-20-10B 2:1 32 x 102.78 E-03 3.52 E-05 2.54 E-06EC5-...-50-10B 5:16.37 E-04 5.39 E-06 3.90 E-07Helical gearEC5-...-100-10B 10:1 3.50 E-04 1.41 E-06 1.02 E-07www.kollmorg<strong>en</strong>.com19

Electric Cylinder - Servo System: Quick Selection GuideSpeed (in/sec) - Low SpeedL I N E A R P O S I T I O N E R SThrust (cont) lb1 2 4 6 8 10 1250 EC1-10(L)-03B / 13C EC1-10(L)-03B / 13C EC1-10(L)-03B / 13C EC1-10(L)-03B / 13C EC1-10(L)-03B / 13C EC1-10(L)-03B / 13C EC1-10(L)-03B / 13C100 EC1-20-03B / 13C EC1-20-03B / 13C EC1-20-03B / 13C EC1-20-03B / 13C N2-15-5B / 23D N2-15-5B / 23D N2-15-5B / 23D150 EC1-40-03B / 11C EC1-40-03B / 11C N2-15-5B / 23D N2-15-5B / 23D N2-15-5B / 23D N2-15-5B / 23D N2-15-5B / 23D200 N2-25-5B / 23D N2-25-5B / 23D N2-25-5B / 23D N2-20-5B / 23D N2-15-5B / 23D EC2-15-05B / 23D EC2-15-05B / 23D300 N2-25-5B / 23D N2-25-5B / 23D N2-25-5B / 23D N2-20-5B / 23D EC2-20-05B / 23D EC3-10-05B / 42G EC2-15-05B / 23D400 N2-20-5B / 23D N2-20-5B / 23D EC2-20-05B / 23D N2-20-5B / 23D EC3-15-05B / 42G EC3-10-05B / 42G EC2-15-05B / 23D500 EC2-50-05B / 23D EC2-50-05B / 23D EC2-20-05B / 23D EC2-20-05B / 23D EC3-15-05B / 42G EC3-10-05B / 42G EC3-15-10B / 42G600 EC2-50-05B / 23D EC2-50-05B / 23D EC2-20-05B / 23D EC2-20-05B / 23D EC3-15-05B / 42G EC4-10-10B / 52G EC4-20-10B / 52L700 EC3-50-05B / 23D EC2-50-05B / 23D EC3-50-10B / 42G EC3-15-05B / 42G EC3-15-05B / 42G EC4-10-10B / 52G EC4-20-10B / 52L800 EC3-50-05B / 23D EC2-50-05B / 23D EC3-50-10B / 42G EC3-15-05B / 42G EC4-20-10B / 52L EC4-20-10B / 52L EC4-20-10B / 52L900 EC3-50-10B / 42G EC3-50-10B / 42G EC4-20-10B / 52G EC3-15-05B / 42G EC4-20-10B / 52L EC4-20-10B / 52L EC4-20-10B / 52L1000 EC3-50-10B / 42G EC3-50-10B / 42G EC4-20-10B / 52G EC4-20-10B / 52L EC4-20-10B / 52L EC4-20-10B / 52L EC4-20-10B / 52L1100 EC3-50-10B / 42G EC3-50-10B / 42G EC4-20-10B / 52G EC4-20-10B / 52L EC4-20-10B / 52L EC4-20-10B / 52L EC4-20-10B / 52L1200 EC3-50-10B / 42G EC3-50-10B / 42G EC4-20-10B / 52G EC4-20-10B / 52L EC4-20-10B / 52L EC4-20-10B / 52L1300 EC4-20-10B / 52G EC4-20-10B / 52G EC4-20-10B / 52G EC4-20-10B / 52L1400 EC4-20-10B / 52G EC4-20-10B / 52G EC4-20-10B / 52G1500 EC4-50-10B / 42G EC4-20-10B / 52LSpeed (in/sec) - High Speed16 20 24 30 36 42 50Thrust (cont) lb50 N2-15-2B / 23D N2-15-2B / 23D N2-10-2B / 23D N2-10-2B / 23D EC2-15-16B / 23D EC2-15-16B / 23D EC2-10-16B / 23D75 N2-15-2B / 23D N2-15-2B / 23D N2-10-2B / 23D N2-10-2B / 23D EC2-15-16B / 23D EC3-10-16B / 42G EC4-10-25B / 42G100 N2-15-2B / 23D N2-15-2B / 23D EC2-20-16B / 23D EC3-15-16B / 42G EC3-10-16B / 42G EC3-10-16B / 42G EC4-10-25B / 42G150 EC2-10-05B / 23D EC3-10-10B / 42G EC3-15-16B / 42G EC3-10-16B / 42G EC3-10-16B / 42G EC4-15-25B / 42G EC4-10-25B / 52L200 EC3-15-10B / 42G EC3-10-10B / 42G EC3-15-16B / 42G EC4-20-25B / 42G EC4-15-25B / 52L EC4-15-25B / 52L EC4-10-25B / 52L245 EC3-15-10B / 42G EC3-10-10B / 42G EC3-15-16B / 42G EC4-20-25B / 52L EC4-15-25B / 52L EC4-15-25B / 52L EC5-15-32B / 52L290 EC3-15-10B / 42G EC4-10-10B / 52L EC4-20-25B / 52L EC4-20-25B / 52L EC4-15-25B / 52L EC4-15-25B / 52L340 EC3-15-10B / 42G EC4-10-10B / 52L EC4-20-25B / 52L EC4-20-25B / 52L EC4-15-25B / 52L400 EC4-15-25B / 52G EC4-10-10B / 52L EC4-20-25B / 52L EC4-20-25B / 52L460 EC4-15-10B / 52L EC4-10-10B / 52L EC4-20-25B / 52L600 EC4-15-10B / 52L EC4-10-10B / 52L775 EC4-15-10B / 52LQuick Selection Guide Refer<strong>en</strong>ceSystems listed in charts repres<strong>en</strong>t the most economical package to meet the criterion.1) Select chart for application speed rangeTop Chart - Low Speed - Speeds up to rated linear speed of 12 in/secBottom Chart - High Speed - Speeds greater than 12 in/sec2) Select system by required continuous thrust (lbs) and required rated speed (in/sec).Other applications considerations (system resolution, inertia ratio, desired safety margins, etc) may result in selection of a differ<strong>en</strong>tsystem. For additional S200 system specifications see pages 71-73. For detailed force speed system curves for drives series, S200,S300 and Smart Drive , see pages 25-39.Performance data repres<strong>en</strong>ts continuous thrust (lb) at rated speed (in/s).Based on S200 amplifier with 230 Vac, 3 phase supply.20K O L L M O R G E N

System Performance Summary - N2, EC1, EC2 SeriesPgSystemCont Thrust@ SpeedPeak Thrust@ SpeedMaxThrustlb in/s lb in/s lb25 N2-AKM23D-nnn-10-5B 188 12.0 600 11.0 60025 N2-AKM23D-nnn-15-5B 282 8.0 600 8.0 60025 N2-AKM23D-nnn-20-5B 375 6.0 600 6.0 60025 N2-AKM23D-nnn-25-5B 367 4.8 600 4.8 60025 N2-AKM23D-nnn-10-2B 75 30.0 275 25.0 27525 N2-AKM23D-nnn-15-2B 112 20.0 415 16.7 41525 N2-AKM23D-nnn-20-2B 150 15.0 552 12.5 55225 N2-AKM23D-nnn-25-2B 146 12.0 536 10.0 53626 N2-AKM23D-nnn-10-5A 84 12.0 306 10.0 30626 N2-AKM23D-nnn-15-5A 123 8.0 460 6.6 46026 N2-AKM23D-nnn-20-5A 170 6.0 600 5.4 60026 N2-AKM23D-nnn-25-5A 162 5.0 596 4.0 60027 EC1-AKM11B-nnn-10-03B 50 13.0 75 13.0 7527 EC1-AKM11B-nnn-20-03B 100 6.0 125 6.0 12527 EC1-AKM11B-nnn-40-03B 150 3.0 150 3.0 15027 EC1-AKM13C-nnn-10-03B 75 11.5 75 13.0 7527 EC1-AKM13C-nnn-20-03B 125 5.9 125 6.0 12528 EC1-CTP12nLF10-10L-03B 20 5.0 75 1.4 7528 EC1-CTP12nLF10-10-03B 18 5.0 75 1.2 7528 EC1-CTP12nLF10-20-03B 35 2.5 125 0.74 12528 EC1-CTP12nLF10-40-03B 71 1.25 150 0.61 150Continuous Thrust (lb) @ Speed0 100 200 300 400 5005075752018357184100112123125150146170162150188282375367L I N E A R P O S I T I O N E R S29 EC2-AKM23D-nnn-10-16B 59 50.0 220 32.0 22029 EC2-AKM23D-nnn-15-16B 85 35.0 293 23.2 32029 EC2-AKM23D-nnn-20-16B 116 26.0 251 21.0 35729 EC2-AKM23D-nnn-50-16B 286 7.2 810 7.2 810598511628630 EC2-AKM23D-nnn-10-05B 187 16.0 700 10.0 70030 EC2-AKM23D-nnn-15-05B 274 11.0 810 8.0 81030 EC2-AKM23D-nnn-20-05B 373 8.2 802 6.6 81030 EC2-AKM23D-nnn-50-05B 810 2.3 810 2.3 81018727437381030 EC2-AKM23D-nnn-10-04A 105 9.2 390 7.8 39030 EC2-AKM23D-nnn-15-04A 157 6.2 521 5.8 57230 EC2-AKM23D-nnn-20-04A 212 4.6 455 4.6 60030 EC2-AKM23D-nnn-50-04A 513 1.8 810 1.8 810105157212513Ratings are based on the AKM servomotor and the matching S200 Drive.See pages 65,66 for details on Drive & Motor System combinations.Specifications are based on 230 Vac, 3 phase voltage supply.Force Speed Curves located on pages 25-30.Plotted value is continuous thrust (lb), refer to chart for the associated rated speed value.www.kollmorg<strong>en</strong>.com21

System Performance Summary - EC3 SeriesL I N E A R P O S I T I O N E R SPgSystemCont Thrust@ SpeedPeak Thrust@ SpeedMaxThrustlb in/s lb in/s lb31 EC3-AKM23D-nnn-10-16B 62 50.0 219 31.5 21931 EC3-AKM23D-nnn-15-16B 88 35.0 330 20.0 33031 EC3-AKM23D-nnn-20-16B 121 25.0 452 12.8 45231 EC3-AKM23D-nnn-50-16B 244 6.3 890 6.3 90031 EC3-AKM23D-nnn-10-10B 96 21.0 350 19.7 35031 EC3-AKM23D-nnn-15-10B 140 21.0 525 13.0 52531 EC3-AKM23D-nnn-20-10B 192 16.0 723 10.0 72331 EC3-AKM23D-nnn-50-10B 393 3.9 1430 3.9 143032 EC3-AKM23D-nnn-10-05B 193 10.3 700 10.3 70032 EC3-AKM23D-nnn-15-05B 280 10.3 1050 6.0 105032 EC3-AKM23D-nnn-20-05B 384 8.0 1440 5.0 144032 EC3-AKM23D-nnn-50-05B 784 2.0 1610 2.0 161062Continuous Thrust (lb) @ Speed0 100 200 300 400 500881212449614019239319328038478432 EC3-AKM23D-nnn-10-04A 85 7.9 311 7.8 31132 EC3-AKM23D-nnn-15-04A 128 5.2 470 5.2 47032 EC3-AKM23D-nnn-20-04A 177 3.8 640 3.8 64032 EC3-AKM23D-nnn-50-04A 351 1.6 1270 1.6 12708512817735133 EC3-AKM42G-nnn-10-16B 160 42.2 601 24.0 62733 EC3-AKM42G-nnn-15-16B 237 28.0 515 23.0 72533 EC3-AKM42G-nnn-50-16B 664 6.2 1610 6.2 161016023766433 EC3-AKM42G-nnn-10-10B 255 21.0 962 15.1 100033 EC3-AKM42G-nnn-15-10B 378 17.6 824 14.4 105933 EC3-AKM42G-nnn-50-10B 1030 3.9 1610 3.9 161033 EC3-AKM42G-nnn-15-05B 710 10.3 1620 7.74 16202553781030710Ratings are based on the AKM servomotor and the matching S200 Drive.See pages 66,67 for details on Drive & Motor System combinations.Specifications are based on 230 Vac, 3 phase voltage supply.Force Speed Curves located on pages 31-33.Plotted value is continuous thrust (lb), refer to chart for the associated rated speed value.22K O L L M O R G E N

System Performance Summary - EC4 SeriesPgSystemCont Thrust@ SpeedPeak Thrust@ SpeedMaxThrustlbs in/s lbs in/s lbs34 EC4-AKM42G-nnn-10-25B 103 52.0 400 35.4 40034 EC4-AKM42G-nnn-15-25B 151 44.0 600 23.6 60034 EC4-AKM42G-nnn-20-25B 201 33.0 800 17.7 80034 EC4-AKM42G-nnn-50-25B 560 5.1 1958 5.1 195834 EC4-AKM42G-nnn-10-10B 260 21.0 1000 14.2 100234 EC4-AKM42G-nnn-15-10B 378 17.5 1504 9.5 150434 EC4-AKM42G-nnn-20-10B 503 13.2 2005 7.1 200534 EC4-AKM42G-nnn-50-10B 1400 2.0 2700 2.0 270035 EC4-AKM52G-nnn-10-25B 279 26.6 481 22.6 69235 EC4-AKM52G-nnn-15-25B 419 17.8 880 14.0 104135 EC4-AKM52G-nnn-20-25B 552 13.3 925 11.8 119935 EC4-AKM52G-nnn-50-25B 1364 5.2 2374 4.4 237435 EC4-AKM52G-nnn-10-10B 698 10.6 1204 9.4 170435 EC4-AKM52G-nnn-15-10B 1047 7.1 2200 5.6 260235 EC4-AKM52G-nnn-20-10B 1396 5.3 2320 4.6 269835 EC4-AKM52G-nnn-50-10B 2698 2.1 2698 2.1 269836 EC4-AKM52L-nnn-10-25B 240 52.5 420 52.5 72536 EC4-AKM52L-nnn-15-25B 291 46.5 741 43.1 108736 EC4-AKM52L-nnn-20-25B 388 34.9 784 33.0 118036 EC4-AKM52L-nnn-50-25B 1370 5.1 2374 5.1 2374103151201240291Continuous Thrust (lb) @ Speed0 320 640 960 1280 1600560260378503140027941955213646981047139626983881370L I N E A R P O S I T I O N E R S36 EC4-AKM52L-nnn-10-10B 600 21.0 1055 21.0 152636 EC4-AKM52L-nnn-15-10B 727 18.6 1852 17.2 269836 EC4-AKM52L-nnn-20-10B 970 13.9 1960 13.2 264536 EC4-AKM52L-nnn-50-10B 2698 2.1 2698 2.1 26986007279702698Ratings are based on the AKM servomotor and the matching S200 Drive.See pages 67-69 for details on Drive & Motor System combinations.Specifications are based on 230 Vac, 3 phase voltage supply.Force Speed Curves located on pages 34-36.Plotted value is continuous thrust (lb), refer to chart for the associated rated speed value.www.kollmorg<strong>en</strong>.com23

System Performance Summary - EC5 SeriesL I N E A R P O S I T I O N E R SPgSystemCont Thrust@ SpeedPeak Thrust@ SpeedMaxThrustlbs in/s lbs in/s lbs37 EC5-AKM42G-nnn-10-32B 87 52.5 313 45.4 31337 EC5-AKM42G-nnn-15-32B 119 52.5 470 30.2 47037 EC5-AKM42G-nnn-20-32B 158 42.2 627 22.7 62737 EC5-AKM42G-nnn-50-32B 436 6.6 1530 6.6 153037 EC5-AKM42G-nnn-10-10B 268 15.2 1002 14.2 100237 EC5-AKM42G-nnn-15-10B 382 15.2 1500 9.4 150037 EC5-AKM42G-nnn-20-10B 504 13.2 2000 7.1 200037 EC5-AKM42G-nnn-50-10B 1420 2.0 4895 2.0 489538 EC5-AKM52G-nnn-10-32B 216 34.2 376 28.7 54138 EC5-AKM52G-nnn-15-32B 327 22.7 694 17.2 81438 EC5-AKM52G-nnn-20-32B 436 17.0 723 15.0 104538 EC5-AKM52G-nnn-50-32B 1065 6.6 1854 5.7 185487119158268Continuous Thrust (lb) @ Speed0 320 640 960 1280 16004363825041420216327436106538 EC5-AKM52G-nnn-10-10B 700 10.6 1204 9.0 173038 EC5-AKM52G-nnn-15-10B 1050 7.0 2200 5.5 260238 EC5-AKM52G-nnn-20-10B 1396 5.3 2238 4.5 334338 EC5-AKM52G-nnn-50-10B 3440 2.1 5600 1.8 560039 EC5-AKM52L-nnn-10-32B 200 52.5 340 52.5 47739 EC5-AKM52L-nnn-15-32B 265 52.5 580 52.5 85039 EC5-AKM52L-nnn-20-32B 303 44.6 616 42.0 92239 EC5-AKM52L-nnn-50-32B 1033 6.6 1854 6.6 1854700105020026530310331396344039 EC5-AKM52L-nnn-10-10B 654 15.3 1108 15.3 152639 EC5-AKM52L-nnn-15-10B 727 15.3 1852 15.3 276239 EC5-AKM52L-nnn-20-10B 970 13.9 1971 13.2 295039 EC5-AKM52L-nnn-50-10B 3495 2.1 5620 2.1 56206547279703495Ratings are based on the AKM servomotor and the matching S200 Drive.See pages 67-69 for details on Drive & Motor System combinations.Specifications are based on 230 Vac, 3 phase voltage supply.Force Speed Curves located on pages 37-39.Plotted value is continuous thrust (lb), refer to chart for the associated rated speed value.24K O L L M O R G E N

Thrust Speed Curves - N2 SeriesSPEEDSPEEDSPEEDSPEEDN2-AKM23n-nnn-10-5BN2-5B Ballscrew Critical Speed Limit0 2 4 6 8 10 12 14 16 18 20 in201510TORQUE - N-m, lb-in0.0 0.7 1.3 2.0 2.7 3.3 4.00.0mm/s in/s5.9 11.8 17.7 23.6 29.5 35.4381 15305 12229 9152 676 30.0 050 120 240 360 480 600 7200 534 1068 1601 2135 2669 3203THR<strong>US</strong>T - lb, NN2-AKM23n-nnn-15-5BN2-AKM23-10-5B0 120 240 360 480 600 7200 534 1068 1601 2135 2669 3203THR<strong>US</strong>T - lb, NN2-AKM23-15-5B0in/s0 51 102 152 203 254 305 356 406 457 508 mmStroke L<strong>en</strong>gth45003600270018009000TORQUE - N-m, lb-in0.0 0.4 0.9 1.3 1.8 2.2 2.60.0mm/s in/s3.9 7.8 11.7 15.6 19.5 23.4254 104500203 83600152 62700102 4180051 29000.0 00*460 VacN2-AKM23n-nnn-20-5Bmm/s in/s191 7.5152 6.0114 4.576 3.038 1.50.0 0.0*460 VacTORQUE - N-m, lb-in0.0 0.3 0.7 1.0 1.3 1.7 2.00.0 3.0 5.9 8.9 11.8 14.8 17.70 120 240 360 480 600 7200 534 1068 1601 2135 2669 3203THR<strong>US</strong>T - lb, NN2-AKM23-20-5BN2-AKM23n-nnn-25-5B45003600270018009000TORQUE - N-m, lb-in0.0 0.3 0.7 1.0 1.4 1.7 2.10.0mm/s in/s3.0 6.1 9.1 12.1 15.2 18.2152 6.04500122 4.8360091 3.6270061 2.4180030 1.29000.0 0.000 120 240 360 480 600 7200 534 1068 1601 2135 2669 3203THR<strong>US</strong>T - lb, N*460 VacN2-AKM23-25-5BLeg<strong>en</strong>dMOTORMOTORMOTORMOTORRPMRPMRPMRPMUse for AKM23 LegeSPEEDSPEEDSPEEDSPEEDN2-AKM23n-nnn-10-2BTORQUE - N-m, lb-in0.0 0.8 1.5 2.3 3.1 3.8 4.60.0mm/s in/s6.8 13.5 20.3 27.0 33.8 40.6953 384500762 303600572 232700381 151800191 89000.0 000 55 110 165 220 275 3300 245 489 734 979 1223 1468THR<strong>US</strong>T - lb, NN2-AKM23n-nnn-15-2BN2-AKM23-10-2BTORQUE - N-m, lb-in0.0 0.8 1.5 2.3 3.1 3.8 4.60.0mm/s in/s6.8 13.6 20.4 27.2 34.0 40.8635 254500508 203600381 152700254 101800127 59000.0 000 83 166 249 332 415 4980 369 738 1108 1477 1846 2215THR<strong>US</strong>T - lb, NN2-AKM23-15-2BN2-AKM23n-nnn-20-2BTORQUE - N-m, lb-in0.0 0.8 1.5 2.3 3.1 3.8 4.60.0mm/s in/s6.8 13.6 20.3 27.1 33.9 40.7476 194500381 153600286 112700191 8180095 49000.0 000 110 221 331 442 552 6620 491 982 1472 1963 2454 2945THR<strong>US</strong>T - lb, NN2-AKM23n-nnn-25-2B25 km/ 1 M" LifeN2-AKM23-20-2BTORQUE - N-m, lb-in0.0 0.8 1.5 2.3 3.1 3.8 4.60.0mm/s in/s6.8 13.5 20.3 27.0 33.8 40.6381 154500305 123600229 92700152 6180076 39000.0 00100.0 460 0.0Vac 0 S300 1.5 /4.5 A460 Vac0 50SD 2.1 /4.2 A0230 Vac S200 3.0 /9.0 A115 Vac S200 3.0 /9.0 A* 460 Vac system limits are equival<strong>en</strong>t to 230 Vac system.0 107 214 322 429 536 6430 447 953 1430 1907 2384 2860THR<strong>US</strong>T - lb, NN2-AKM23-25-2BN2-2B Ballscrew Critical Speed Limit3530252015in/s0 2 4 6 8 10 12 14 16 18 20 in0 51 102 152 203 254 305 356 406 457 mmStroke L<strong>en</strong>gthMOTORMOTORMOTORMOTORRPMRPMRPMRPML I N E A R P O S I T I O N E R Swww.kollmorg<strong>en</strong>.com25

Thrust Speed Curves - N2 SeriesL I N E A R P O S I T I O N E R SSPEEDSPEEDN2-AKM23n-nnn-10-5Amm/s in/s381 15.0305 12.0229 9.0152 6.076 3.00.0 0.0TORQUE - N-m, lb-in0.0 0.8 1.5 2.3 3.1 3.8 4.60.0 6.8 13.5 20.3 27.1 33.8 40.60 61 122 184 245 306 3670 272 544 817 1089 1361 1633THR<strong>US</strong>T - lb, NN2-AKM23n-nnn-15-5A0 92 184 276 368 460 5520 409 818 1228 1637 2046 2455THR<strong>US</strong>T - lb, N45003600270018009000N2-AKM23-10-5A-BZTORQUE - N-m, lb-in0.0 0.8 1.5 2.3 3.1 3.8 4.60.0mm/s in/s6.8 13.6 20.4 27.1 33.9 40.7254 104500203 83600152 62700102 4180051 29000.0 00MOTORMOTORRPMRPMSPEEDSPEEDN2-AKM23n-nnn-20-5ATORQUE - N-m, lb-in0.0 0.7 1.5 2.2 3.0 3.7 4.50.0mm/s in/s6.6 13.3 19.9 26.5 33.2 39.8191 7.54500152 6.03600114 4.5270076 3.0180038 1.59000.0 0.000 120 240 360 480 600 7200 534 1068 1601 2135 2669 3203THR<strong>US</strong>T - lb, NN2-AKM23-20-5A-BZN2-AKM23n-nnn-25-5ATORQUE - N-m, lb-in0.0 0.8 1.5 2.3 3.1 3.9 4.60.0mm/s in/s6.8 13.7 20.5 27.3 34.1 41.0159 6.34688127 5.0375095 3.8281364 2.5187532 1.39380.0 0.000 120 240 360 480 600 7200 534 1068 1601 2135 2669 3203THR<strong>US</strong>T - lb, NMOTORMOTORRPMRPMN2-5A15105N2-AKM23-15-5A-BZLead Screw Critical Speed Limit0 2 4 6 8 10 12 14 16 18 20 inN2-5A200in/s 0 51 102 152 203 254 305 356 406 457 508 mmStroke L<strong>en</strong>gthLeg<strong>en</strong>dUse for AKM23 Lege N2-AKM23-25-5A-BZ25 km/ 1 M" Life100.0 460 0.0Vac 0 S300 1.5 /4.5 A460 Vac0 50SD 2.1 /4.2 A0230 Vac S200 3.0 /9.0 A115 Vac S200 3.0 /9.0 A26K O L L M O R G E N

Thrust Speed Curves - EC1 SeriesSPEEDSPEEDEC1-AKM11B-nnn-10-03BEC1-AKM11B-10-03BTORQUE - N-m, lb-in0.0 0.04 0.08 0.12 0.17 0.21 0.250.0 0.4 0.7 1.1 1.5 1.8 2.2mm/s in/s 0.0 0.4 0.7 1.1 1.5 1.8 2.2381 15.0305 12.0381 7200305 5760229 9.0229 4320152 6.0152 288076 3.076 14400.0 0.000.000.0151530304545 6060757590900.0 67 133 200 267 334 400*230 VacTHR<strong>US</strong>T - lb, NEC1-AKM11B-nnn-20-03BEC1-AKM11B-20-030.0 6.8 13.5 TORQUE 20.3 - 27.1 33.8 40.6N-m, lb-in2060960.0 0.03 0.07 0.10 0.14 0.17 0.2116 0.0 0.3 0.6 0.9 1.2 1.5 1.8mm/s in/s 0.0 0.3 0.6 0.9 1.2 1.5 1.8 4877191 7.5 127200 191 3658153 6.0 85760 153 2438115 4.54320 11576 3.042880 76121938 1.5 01440 38 00.0 0.00 140 280 420 560 700 840 0.0 000.025255050 75751001001251251501500.0 111 222 334 445 556 667MOTORMOTORRPMRPMSPEEDSPEEDEC1-AKM13C-10-03EC1-AKM13C-nnn-10-03Bmm/s in/s381 15.0305 12.0229 9.0152 6.076 3.00.0 0.0TORQUE - N-m, lb-in0.0 0.04 0.08 0.12 0.17 0.21 0.250.0 0.0 0.4 0.4 0.7 0.7 1.1 1.1 1.5 1.8 1.8 2.2 2.2381 7200305 5760229 4320152 288076 144000.000.0151530304545 6060757590900.0 67 133 200 267 334 400THR<strong>US</strong>T - lb, NEC1-AKM13C-nnn-20-03BEC1-AKM13C-20-03mm/s in/s191 7.5152 6.0114 4.576 3.038 1.50.0 0.0TORQUE - N-m, lb-in0.0 0.03 0.07 0.10 0.14 0.17 0.210.0 0.3 0.6 0.9 1.2 1.5 1.80.0 0.3 0.6 0.9 1.2 1.5 1.87200 1915760 1524320 1142880 761440 380.0 000.025255050 75751001001251251501500.0 111 222 334 445 556 667MOTORMOTORRPMRPML I N E A R P O S I T I O N E R S*230 VacTHR<strong>US</strong>T - lb, NEC2-AKM23-10-05B*230 VacTHR<strong>US</strong>T - lb, NSPEEDEC1-AKM11B-nnn-40-03BEC1-AKM11B-40-03TORQUE - N-m, lb-in0.0 0.02 0.04 0.06 0.08 0.10 0.12mm/s in/s0.00 0.0 0.18 0.18 0.37 0.55 0.74 0.74 0.92 0.92 1.11 1.1095 3.7576 3.0057 2.2538 1.507200 9557604320 572880 3819 0.751440 190.0 0.000.0 000.0 30 30 60 90 120 120 150 150 180 1800.0 133 267 400 534 667 801*230 VacTHR<strong>US</strong>T - lb, NBallscrew Critical Speed Limit0.0 2.0 3.9 5.9 7.92520151050in/s 0 50 100 150 200Stroke L<strong>en</strong>gthMOTORmmRPMLeg<strong>en</strong>dUse for AKM23 Lege25 km/ 1 M" Life100.0 460 0.0Vac 0 S300 1.5 /4.5 A460 Vac0 50SD 2.1 /4.2 A0230 Vac S200 1.5 /4.5 A115 Vac S200 1.5 /4.5 A* 230 Vac system limits are equival<strong>en</strong>t to 115 Vac system.www.kollmorg<strong>en</strong>.com27

L I N E A R P O S I T I O N E R SThrust Speed Curves - EC1 (w/CT Stepper) SeriesEC1-CTP12xLF10-10L-03BSPEEDSPEEDEC1-CTP12nLF10-10L-03BTORQUE - N-cm, lb-in0.0 3.70 7.50 11.2 15.0 18.7 22.5mm/s in/s 0.0 0.3 0.7 1.0 1.3 1.7 2.01526.06.0122 4.891 3.661 2.430 1.20.0 0.00.0 15 30 45 60 75 900 15 30 45 60 75 900.0 67 133 200 267 334 400EC1-CTP12xLF10-20-03BEC1-CTP12nLF10-20-03BTHR<strong>US</strong>T - lb, NTORQUE - N-cm, lb-in0.0 3.50 6.90 10.4 13.9 17.3 20.8mm/s in/s 0.0 0.3 0.6 0.9 1.2 1.5 1.876 3.061 2.446 1.830 1.215 0.60.0 0.00.0 25 50 75 100 125 1500 25 50 75 100 125 1500.0 111 222 334 445 556 66728802300173011505750.028802300173011505750.0MOTORMOTORRPMRPMSPEEDSPEEDEC1-CTP12nLF10-10-03BEC1-CTP12xLF10-10-03BTORQUE - N-cm, lb-in0.0 4.20 8.30 12.5 16.7 20.8 25.0mm/s in/s 0.0 0.4 0.7 1.1 1.5 1.8 2.2152 6.0122 4.891 3.661 2.430 1.20.0 0.00.0 15 30 45 60 75 900 15 30 45 60 75 900.0 67 133 200 267 334 400EC1-CTP12nLF10-40-03BEC1-CTP12xLF10-40-03BTHR<strong>US</strong>T - lb, NTORQUE - N-cm, lb-in0.0 2.10 4.20 6.20 8.30 10.4 12.5mm/s in/s 0.0 0.18 0.37 0.55 0.74 0.92 1.1138 1.530 1.223 0.915 0.68.0 0.30.0 0.00.0 30 60 90 120 150 1800 30 60 90 120 150 1800.0 133 267 400 534 667 80128802300173011505750.028802300173011505750.0MOTORMOTORRPMRPMTHR<strong>US</strong>T - lb, NTHR<strong>US</strong>T - lb, NBallscrew Critical Speed Limit0.0 2.0 3.9 5.9 7.92520151050in/s 0 50 100 150 200Stroke L<strong>en</strong>gthmmLeg<strong>en</strong>d36 Vdc24 Vdc28K O L L M O R G E N

Thrust Speed Curves - EC2 SeriesSPEEDSPEEDEC2-AKM23n-nnn-10-16Bmm/s in/s1588 62.51270 50.0953 37.5635 25.0318 12.50.0 0.0mm/s in/s158812709536353180.062.550.037.525.012.50.0TORQUE - N-m, lb-in0.0 0.9 1.7 2.6 3.5 4.4 5.20.0 7.7 15.5 23.2 30.9 38.7 46.40 50 100 150 200 250 3000 222 445 667 890 1112 1334THR<strong>US</strong>T - lb, NEC2-AKM23-10-16BEC2-AKM23n-nnn-15-16BTORQUE - N-m, lb-in0.0 0.9 1.7 2.6 3.5 4.4 5.20.0 6.1 12.3 18.4 24.5 30.7 36.80 58 117 175 233 292 3500 222 445 667 890 1112 1334THR<strong>US</strong>T - lb, N595347633572238111910893071445358357217860MOTORMOTORRPMRPMSPEEDSPEEDEC2-AKM23n-nnn-10-05BTORQUE - N-m, lb-in0.0 0.8 1.5 2.3 3.1 3.8 4.60.0mm/s in/s6.8 13.5 20.3 27.1 33.8 40.6508 206096406 164877305 123658203 82438102 412190.0 00mm/s in/s508 20406 16305 12203 8102 40.0 00 140 280 420 560 700 8400 623 1246 1868 2491 3114 3737THR<strong>US</strong>T - lb, NEC2-AKM23-10-05BEC2-AKM23n-nnn-15-05BTORQUE - N-m, lb-in0.0 0.6 1.2 1.8 2.4 3.0 3.60.0 5.3 10.5 15.8 21.1 26.3 31.60 160 320 480 640 800 9600 712 1423 2135 2847 3559 4270THR<strong>US</strong>T - lb, NEC2-AKM23-15-05B914473155486365818290MOTORMOTORRPMRPML I N E A R P O S I T I O N E R SSPEEDmm/s in/s1168 46.0935 36.8701 27.6467 18.4234 9.20.0 0.0EC2-AKM23-15-16BEC2-AKM23n-nnn-20-16BTORQUE - N-m, lb-in0.0 0.6 1.2 1.8 2.3 2.9 3.50.0 5.2 10.3 15.5 20.7 25.8 31.00 67 133 200 267 333 4000 297 583 890 1186 1483 1779THR<strong>US</strong>T - lb, N876370105258350517530MOTORRPMSPEEDEC2-AKM23n-nnn-20-05BTORQUE - N-m, lb-in0.0 0.4 0.9 1.3 1.7 2.2 2.6mm/s in/s0.0 3.9 7.7 11.6 15.5 19.3 23.2365 14.48763292 11.57010219 8.65258146 5.8350573 2.917530.0 0.000 160 320 480 640 800 9600 712 1423 2135 2847 3559 4270THR<strong>US</strong>T - lb, NMOTORRPMSPEEDEC2-AKM23-20-16BEC2-AKM23n-nnn-50-16BTORQUE - N-m, lb-in0.0 .06 1.2 1.8 2.4 3.0 3.60.0mm/s in/s5.3 10.6 15.9 21.3 26.6 31.9229 9.04286183 7.23429137 5.4257291 3.6171546 1.88570.0 0.000 165 330 495 660 825 9900 667 1334 2002 2669 3336 4003THR<strong>US</strong>T - lb, NMOTORRPMUse for AKM23 LegeSPEEDEC2-AKM23-20-05BEC2-AKM23n-nnn-50-05BTORQUE - N-m, lb-in0.0 0.2 0.4 0.5 0.7 0.9 1.10.0mm/s in/s1.6 3.2 4.8 6.5 8.1 9.773 2.9438258 2.3350544 1.7262929 1.2175315 0.68760.0 0.00*460 Vac0 160 320 480 640 800 9600 712 1423 2135 2847 3559 4270THR<strong>US</strong>T - lb, NMOTORRPMEC2-AKM23-50-16BEC2-16B Ballscrew Critical Speed Limit0.0 5.9 11.8 17.7 23.6 29.5 in50403020100in/s 0 150 300 450 600 750 mmStroke L<strong>en</strong>gthLeg<strong>en</strong>d25 km/ 1 M" Life100.0 460 0.0Vac 0 S300 1.5 /4.5 A460 Vac0 50SD 2.1 /4.2 A0230 Vac S200 3.0 /9.0 A115 Vac S200 3.0 /9.0 A* 460 Vac system limits are equival<strong>en</strong>t to 230 Vac system.EC2-AKM23-50-05BEC2-05B * 460VAC Ballscrew Critical Speed Limit0.0 5.9 11.8 17.7 23.6 29.5201612840in/s0 150 300 450 600 750Stroke l<strong>en</strong>gthinmmwww.kollmorg<strong>en</strong>.comEC2-16BEC2-05B29

Thrust Speed Curves - EC2 SeriesL I N E A R P O S I T I O N E R SSPEEDSPEEDEC2-AKM23n-nnn-10-04ATORQUE - N-m, lb-in0.0 0.8 1.6 2.4 3.1 3.9 4.70.0mm/s in/s7.0 13.9 20.9 27.9 34.8 41.8286 11.54382229 9.23505171 6.92629114 4.6175357 2.38760.0 0.000 80 160 240 320 400 4800 356 712 1068 1423 1779 2135THR<strong>US</strong>T - lb, NEC2-AKM23n-nnn-15-04AEC2-AKM23-10-04ATORQUE - N-m, lb-in0.0 0.8 1.5 2.3 3.1 3.9 4.6mm/s in/s 0.0 6.8 13.6 20.4 27.3 34.1 40.9191 7.54286152 6.03429114 4.5257276 3.0171538 1.58570.0 0.000 115 230 345 460 575 6900 512 1023 1535 2046 2558 3069THR<strong>US</strong>T - lb, NMOTORMOTORRPMRPMSPEEDSPEEDEC2-AKM23n-nnn-20-04Amm/s in/s146 5.8117 4.688 3.558290.0*460 Vac2.31.20.0TORQUE - N-m, lb-in0.0 0.6 1.2 1.8 2.4 3.0 3.50.0 5.2 10.5 15.7 20.9 26.2 31.40 120 240 360 480 600 7200 534 1068 1601 2135 2669 3203THR<strong>US</strong>T - lb, NEC2-AKM23-20-04AEC2-AKM23n-nnn-50-04A0 160 320 480 640 800 9600 712 1423 2135 2847 3559 4270THR<strong>US</strong>T - lb, N43823505262917538760TORQUE - N-m, lb-in0.0 0.3 0.7 1.0 1.3 1.6 2.0mm/s in/s 0.0 2.9 5.8 8.7 11.6 14.5 17.457 2.3428646 1.8342934 1.4257223 0.9171511 0.58570.0 0.00*460 VacMOTORMOTORRPMRPMEC2-AKM23-15-04AUse for AKM23 LegeCritical Speed (in/s)EC2-04ALead Screw Specifications0.0 5.9 11.8 17.7 23.6 29.511975200 150 300 450 600 750Stroke l<strong>en</strong>gthin7005604202801400mmColumn Load Limit (lbs)Leg<strong>en</strong>d25 km/ 1 M" LifeEC2-AKM23-50-04A100.0 460 0.0Vac 0 S300 1.5 /4.5 A460 Vac0 50SD 2.1 /4.2 A0230 Vac S200 3.0 /9.0 A115 Vac S200 3.0 /9.0 A* 460 Vac system limits are equival<strong>en</strong>t to 230 Vac system.30K O L L M O R G E N

Thrust Speed Curves - EC3 SeriesSPEEDSPEEDEC3-AKM23n-nnn-10-16BTORQUE - N-m, lb-in0.0 0.8 1.5 2.3 3.1 3.9 4.60.0mm/s in/s6.8 13.6 20.5 27.3 34.1 40.91588 62.559531270 50.04763953 37.53572635 25.02381318 12.511910.0 0.000 44 88 132 176 220 2640 196 391 587 783 979 1174THR<strong>US</strong>T - lb, NEC3-AKM23-10-16BEC3-AKM23n-nnn-15-16BTORQUE - N-m, lb-in0.0 0.8 1.5 2.3 3.1 3.9 4.6mm/s in/s0.0 6.8 13.6 20.5 27.3 34.1 40.91588 62.51270 50.0953 37.5635 25.0318 12.50.0 0.00 66 132 198 264 330 3960 294 587 881 1174 1468 1761THR<strong>US</strong>T - lb, N893071445358357217860MOTORMOTORRPMRPMSPEEDSPEEDEC3-AKM23n-nnn-10-10BTORQUE - N-m, lb-in0.0 0.8 1.5 2.3 3.1 3.8 4.6mm/s in/s 0.0 6.8 13.5 20.3 27.1 33.8 40.6635 253810508 203048381 152286254 101524127 57620.0 000 70 140 210 280 350 4200 311 623 934 1246 1557 1868THR<strong>US</strong>T - lb, NEC3-AKM23-10-10BEC3-AKM23n-nnn-15-10BTORQUE - N-m, lb-in0.0 0.8 1.5 2.3 3.1 3.8 4.6mm/s in/s0.0 6.8 13.5 20.3 27.1 33.8 40.6635 255715508 204572381 153429254 102286127 511430.0 000 105 210 315 420 525 6300 467 934 1401 1868 2335 2802THR<strong>US</strong>T - lb, NMOTORMOTORRPMRPML I N E A R P O S I T I O N E R SSPEEDmm/s in/s1111 43.8889 35.0667 26.3445 17.5222 8.80.0 0.0EC3-AKM23-15-16BEC3-AKM23n-nnn-20-16BTORQUE - N-m, lb-in0.0 0.8 1.5 2.3 3.1 3.8 4.60.0 6.8 13.5 20.3 27.0 33.8 40.50 90 180 270 360 450 5400 400 801 1201 1601 2002 2402THR<strong>US</strong>T - lb, N833466685001333416670MOTORRPMSPEEDEC3-AKM23n-nnn-20-10BEC3-BK23S-15-10BTORQUE - N-m, lb-in0.0 0.8 1.5 2.3 3.1 3.8 4.60.0mm/s in/s6.8 13.5 20.3 27.0 33.8 40.5635 25508 20381 15254 10127 50.0 00 144 288 432 576 720 8640 641 1281 1922 2562 3203 3843THR<strong>US</strong>T - lb, N762060964572304815240MOTORRPMSPEEDEC3-AKM23n-nnn-50-16BEC3-AKM23-20-16BTORQUE - N-m, lb-in0.0 0.8 1.5 2.3 3.1 3.9 4.60.0mm/s in/s6.8 13.6 20.5 27.3 34.1 40.9198 7.8158 6.236912953119 4.7221579 3.1147640 1.67380.0 0.000 180 360 540 720 900 10800 801 1601 2402 3203 4003 4804THR<strong>US</strong>T - lb, NMOTORRPMUse for AKM23 LegeSPEEDEC3-AKM23n-nnn-50-10BEC3-AKM23-20-10BTORQUE - N-m, lb-in0.0 0.8 1.5 2.3 3.1 3.8 4.60.0mm/s in/s6.8 13.5 20.3 27.1 33.8 40.6127 5.03810102 4.0304876 3.0228651 2.0152425 1.07620.0 0.000 286 572 858 1144 1430 17160 1272 2544 3817 5089 6361 7633THR<strong>US</strong>T - lb, NMOTORRPMEC3-16BEC3-AKM23-50-16BBallscrew Specifications0.0 7.9 15.7 23.6 31.5 39.4 inCritical Speed (in/s)60504030201000 200 400 600 800 1000Stroke l<strong>en</strong>gthwww.kollmorg<strong>en</strong>.com120010008006004002000mmColumn Load Limit (lbs)Leg<strong>en</strong>dEC3-AKM23-50-10BEC3-10B Ballscrew Specifications25 km/ 1 M" Life0.0 7.9 15.7 23.6 31.5 39.4 in100.0 460 0.0Vac 0 S300 1.5 /4.5 A261500211200460 Vac0 50SD 2.1 /4.2 A16900011600230 Vac S200 3.0 /9.0 A5300115 Vac S200 3.0 /9.0 A 000 200 400 600 800 1000 mmStroke l<strong>en</strong>gthCritical Speed (in/s)Column Load Limit (lbs)31

Thrust Speed Curves - EC3 SeriesL I N E A R P O S I T I O N E R SSPEEDSPEEDEC3-AKM23n-nnn-10-05Bmm/s in/s318 12.5254 10.0191 7.5127 5.064 2.50.0 0.0mm/s in/s318 12.5254 10.0191 7.5127 5.064 2.50.0 0.0TORQUE - N-m, lb-in0.0 0.8 1.5 2.3 3.1 3.8 4.60.0 6.8 13.5 20.3 27.1 33.8 40.60 140 280 420 560 700 8400 623 1246 1868 2491 3114 3737THR<strong>US</strong>T - lb, NEC3-AKM23-10-05BEC3-AKM23n-nnn-15-05BTORQUE - N-m, lb-in0.0 0.8 1.5 2.3 3.1 3.8 4.60.0 6.8 13.5 20.3 27.1 33.8 40.60 210 420 630 840 1050 12600 934 1868 2802 3737 4671 5605THR<strong>US</strong>T - lb, N38103048228615247620571545723429228611430MOTORMOTORRPMRPMSPEEDSPEEDEC3-AKM23n-nnn-10-04ATORQUE - N-m, lb-in0.0 0.8 1.5 2.3 3.1 3.8 4.60.0mm/s in/s6.8 13.5 20.3 27.0 33.8 40.5254 103810203 83048152 62286102 4152451 27620.0 000 62 124 186 248 310 3720 276 552 827 1103 1379 1655THR<strong>US</strong>T - lb, NEC3-AKM23n-nnn-15-04AEC3-AKM23-10-04ATORQUE - N-m, lb-in0.0 0.8 1.5 2.3 3.1 3.9 4.60.0mm/s in/s6.8 13.6 20.5 27.3 34.1 40.9165 6.53715132 5.2297299 3.9222966 2.6148633 1.37430.0 0.000 94 188 282 376 470 5640 418 836 1254 1673 2091 2509THR<strong>US</strong>T - lb, NMOTORMOTORRPMRPMSPEEDEC3-AKM23n-nnn-20-05BEC3-AKM23-15-05BTORQUE - N-m, lb-in0.0 0.8 1.5 2.3 3.1 3.8 4.60.0mm/s in/s6.8 13.5 20.3 27.0 33.8 40.5318 12.57620254 10.06096191 7.54572127 5.0304864 2.515240.0 0.000 288 576 864 1152 1440 17280 1281 2562 3843 5124 6405 7687THR<strong>US</strong>T - lb, NMOTORRPMSPEEDEC3-AKM23n-nnn-20-04AEC3-AKM23-15-04ATORQUE - N-m, lb-in0.0 0.8 1.5 2.3 3.1 3.8 4.60.0mm/s in/s6.8 13.5 20.3 27.0 33.8 40.5122 4.83620987349240.03.82.91.91.00.00 128 256 384 512 640 7680 569 1139 1708 2277 2847 3416THR<strong>US</strong>T - lb, N2896217214487240MOTORRPMEC3-AKM23n-nnn-50-05BEC3-AKM23-20-05BTORQUE - N-m, lb-in0.0 0.4 0.9 1.3 1.7 2.2 2.60.0mm/s in/s3.8 7.6 11.4 15.3 19.1 22.964 2.53810S51 2.03048P38 1.52286E25 1.01524ED 13 0.57620.0 0.000 322 644 966 1288 1610 19320 1432 2865 4297 5729 7162 8594*460 VacTHR<strong>US</strong>T - lb, NMOTORRPMUse for AKM23 LegeSPEEDEC3-AKM23-20-04AEC3-AKM23n-nnn-50-04ATORQUE - N-m, lb-in0.0 0.8 1.5 2.3 3.1 3.8 4.60.0mm/s in/s6.8 13.5 20.3 27.1 33.8 40.651 2.0381041 1.6304830 1.2228620 0.8152410 0.47620.0 0.000 254 508 762 1016 1270 15240 1130 2260 3390 4519 5649 6779THR<strong>US</strong>T - lb, NMOTORRPMEC3-05B Ballscrew Specifications0.0 7.9 15.7 23.6 EC3-AKM23-50-05B31.5 39.4 inCritical Speed (in/s)131085300 200 400 600 800 1000Stroke l<strong>en</strong>gth1875150011257503750mmColumn Load Limit (lbs)EC3-04A EC3-AKM23-50-04A Lead Screw Specifications25 km/ 1 M" Life0.0 7.9 15.7 23.6 31.5 39.4 in100.0 460 0.0Vac 0 S300 1.5 /4.5 A101200Leg<strong>en</strong>d460 Vac0 5081000SD 2.1 /4.2 A06800600230 Vac S200 3.0 /9.0 A44002200115 Vac S200 3.0 /9.0 A 000 200 400 600 800 1000 mm* 460 Vac system limits are equival<strong>en</strong>t to 230 Vac system.Stroke l<strong>en</strong>gthCritical Speed (in/s)Column Load Limit (lbs)32K O L L M O R G E N

Thrust Speed Curves - EC3 SeriesSPEEDSPEEDEC3-AKM42n-nnn-10-16Bmm/s in/s1340 52.81072 42.2804 31.7536 21.1268 10.60.0 0.0mm/s in/s889 35711 28533 21356 14178 70.0 0TORQUE - N-m, lb-in0.0 2.2 4.4 6.6 8.8 11.0 13.20.0 19.4 38.8 58.2 77.6 97.0 116.40 125 251 376 502 627 7520 558 1115 1673 2230 2788 3345THR<strong>US</strong>T - lb, NEC3-AKM42-10-16BEC3-AKM42n-nnn-15-16B0 145 290 435 580 725 8700 645 1290 1935 2580 3225 3870THR<strong>US</strong>T - lb, N502440203015201010050TORQUE - N-m, lb-in0.0 1.7 3.4 5.1 6.8 8.4 10.10.0 15.0 29.9 44.9 59.8 74.8 89.7500140013000200010000MOTORMOTORRPMRPMSPEEDSPEEDEC3-AKM42n-nnn-10-10Bmm/s in/s667 26.3533 21.0400 15.8267 10.5133 5.30.0 0.0TORQUE - N-m, lb-in0.0 2.2 4.4 6.6 8.7 10.9 13.10.0 19.3 38.7 58.0 77.3 96.7 116.00 200 400 600 800 1000 12000 890 1779 2669 3559 4448 5338THR<strong>US</strong>T - lb, NEC3-AKM42-10-10BEC3-AKM42n-nnn-15-10BTORQUE - N-m, lb-in0.0 1.5 3.1 4.6 6.2 7.7 9.30.0mm/s in/s13.7 27.3 41.0 54.6 68.3 82.0559 22.0447 17.6335 13.2224 8.8112 4.40.0 0.00 212 424 636 848 1060 12720 943 1886 2829 3772 4715 5658THR<strong>US</strong>T - lb, N40013200240016008000502940233017201210060MOTORMOTORRPMRPML I N E A R P O S I T I O N E R SSPEEDEC3-AKM42-15-16BEC3-AKM42n-nnn-50-16BTORQUE - N-m, lb-in0.0 1.4 2.8 4.1 5.5 6.9 8.30.0mm/s in/s12.2 24.4 36.6 48.7 60.9 73.1197 7.8157 6.236912953118 4.7221579 3.1147639 1.67380.0 0.000 322 644 966 1288 1610 19320 1432 2865 4297 5729 7162 8594THR<strong>US</strong>T - lb, N*460 VacMOTORRPMEC3-AKM42-15-05BSPEEDEC3-AKM42n-nnn-50-10Bmm/s in/s127 5.0102 4.076 3.051 2.025 1.00.0 0.0*460 VacEC3-AKM42-15-10BTORQUE - N-m, lb-in0.0 0.9 1.7 2.6 3.4 4.3 5.20.0 7.6 15.2 22.9 30.5 38.1 45.70 322 644 966 1288 1610 19320 1432 2865 4297 5729 7162 8594THR<strong>US</strong>T - lb, N38103048228615247620MOTORRPMEC3-AKM42-50-16BSPEEDEC3-AKM42n-nnn-15-05BTORQUE - N-m, lb-in0.0 1.1 2.3 3.4 4.6 5.7 6.9mm/s in/s 0.0 10.2 20.3 30.5 40.6 50.8 60.9318 12.5254 10.0191 7.5127 5.064 2.50.00 Use 300 for AKM42 600Lege900 1200 1500 18000 1334 2669 4003 5338 6672 8007THR<strong>US</strong>T - lb, N571545723429228611430MOTOREC3-AKM42-50-10BRPMEC3-16B Ballscrew Specifications0.0 7.9 15.7 23.6 31.5 39.4Critical Speed (in/s)60504030201000 200 400 600 800 1000Stroke l<strong>en</strong>gthwww.kollmorg<strong>en</strong>.comin120010008006004002000mmColumn Load Limit (lbs)EC3-10B Ballscrew Specifications25 km / 1 M " Life0.0 7.9 15.7 23.6 31.5 39.44605.0Vac SD 3.9 /7.8 A26Leg<strong>en</strong>d 0.0 7.6 460 0210.015.2 Vac S300 22.93.0 /7.5 30.5 A (Ip limit) 38.1 45.75.00 2 4 616230 Vac S200 6.0 /18.0 A38104.0304811115 Vac S200 6.0 /18.0 A53.02286115/230 Vac S300 6.0 /15.0 A (Ip limit)02.015240 200 400 600 800 1000* 4601.0Vac system limits are equival<strong>en</strong>t to 230 Vac system.Stroke l<strong>en</strong>gth0.00 322 644 966 1288 1610 1932Critical Speed (in/s)7620in150012009006003000mmColumn Load Limit (lbs)33EC3-AKM42-50-10B

Thrust Speed Curves - EC4 SeriesL I N E A R P O S I T I O N E R SSPEEDSPEEDEC4-AKM42n-nnn-10-25BTORQUE - N-m, lb-in0.0 2.2 4.4 6.6 8.7 10.9 13.1mm/s in/s0.0 19.3 38.7 58.0 77.3 96.7 116.01588 62.51270 50.0953 37.5635 25.0318 12.50.0 0.00 80 160 240 320 400 4800 222 445 667 890 1112 1334THR<strong>US</strong>T - lb, NEC4-AKM42-10-25BEC4-AKM42n-nnn-15-25BTORQUE - N-m, lb-in0.0 2.2 4.4 6.6 8.7 10.9 13.1mm/s in/s0.0 19.4 38.7 58.1 77.4 96.8 116.11397 55.01118 44.0838 33.0559 22.0279 11.00.0 0.00 120 240 360 480 600 7200 534 1068 1601 2135 2669 3203THR<strong>US</strong>T - lb, N38103048228615247620502940233018201210060MOTORMOTORRPMRPMSPEEDSPEEDEC4-AKM42n-nnn-10-10BTORQUE - N-m, lb-in0.0 2.2 4.4 6.6 8.7 10.9 13.10.0mm/s in/s19.3 38.7 58.0 77.4 96.7 116.0635 25.03810508 20.0381 15.0254 10.0127 5.00.0 0.0457 18.0343 13.5229 9.0114 4.50.0 0.00 200 400 600 800 1000 12000 890 1779 2669 3559 4448 5338THR<strong>US</strong>T - lb, NEC4-AKM42-10-10BEC4-AKM42n-nnn-15-10B304822861524TORQUE - N-m, lb-in0.0 2.2 4.4 6.6 8.7 10.9 13.10.0mm/s in/s19.3 38.7 58.0 77.3 96.6 116.0572 22.551440 300 600 900 1200 1500 18000 1334 2669 4003 5338 6672 8007THR<strong>US</strong>T - lb, N762041153086205710290MOTORMOTORRPMRPMSPEEDmm/s in/s1016 40.0813 32.0610 24.0406 16.0203 8.00.0 0.0EC4-AKM42-15-25BEC4-AKM42n-nnn-20-25BTORQUE - N-m, lb-in0.0 2.2 4.4 6.6 8.7 10.9 13.10.0 19.3 38.7 58.0 77.3 96.7 116.00 160 320 480 640 800 9600 712 1423 2135 2847 3559 4270THR<strong>US</strong>T - lb, N48773901292619519750MOTORRPMSPEED330 13.0248 9.8165 6.583 3.30.0 0.0EC4-AKM42-15-10BEC4-AKM42n-nnn-20-10BTORQUE - N-m, lb-in0.0 2.2 4.4 6.6 8.7 10.9 13.1mm/s in/s0.0 19.3 38.7 58.0 77.3 96.7 116.0413 16.349530 400 800 1200 1600 2000 24000 1779 3559 5338 7117 8896 10676THR<strong>US</strong>T - lb, N3962297219819910MOTORRPMSPEEDEC4-AKM42-20-25BEC4-AKM42n-nnn-50-25BTORQUE - N-m, lb-in0.0 2.2 4.5 6.7 8.9 11.2 13.40.0mm/s in/s19.8 39.6 59.4 79.2 99.0 118.8159 6.25127 5.0095 3.7564 2.5032 1.250.0 0.001905M1524 OTOR R1143 P762 M38100 400 800 1200 1600 2000 2400 Use for AKM42 Lege0 1779 3559 5338 7117 8896 10676THR<strong>US</strong>T - lb, NSPEEDEC4-AKM42-20-10BEC4-AKM42n-nnn-50-10BTORQUE - N-m, lb-in0.0 1.2 2.4 3.6 4.8 6.0 7.20.0mm/s in/s10.7 21.4 32.1 42.8 53.4 64.164 2.5190551 2.0152438 1.5114325 1.076213 0.53810.0 0.00*460 Vac0 540 1080 1620 2160 2700 32400 2402 4804 7206 9608 12010 14412THR<strong>US</strong>T - lb, NMOTORRPMEC4-AKM42-50-25BEC4-25B Ballscew Specifications0.0 9.8 19.7 29.5 39.4 49.2 59.1 inCritical Speed (in/s)655239261300 250 500 750 1000 1250 1500Stroke l<strong>en</strong>gth2375190014259504750mmColumn Load Limit (lbs)Leg<strong>en</strong>d25 km / 1 M " Life4605.0Vac SD 3.9 /7.8 A460 0.0 Vac 0 S300 3.0 /7.5 A (Ip limit)0 2 4 6230 Vac S200 6.0 /18.0 A115 Vac S200 6.0 /18.0 A115/230 Vac S300 6.0 /15.0 A (Ip limit)* 460 Vac system limits are equival<strong>en</strong>t to 230 Vac system.EC4-AKM42-50-10BEC4-10B Ballscrew Specification0.0 9.8 19.7 29.5 39.4 49.2 59.12016128400 250 500 750 1000 1250 1500Stroke l<strong>en</strong>gthCritical Speed (in/s)in2375190014259504750mmColumn Load Limit (lbs)34K O L L M O R G E N

Thrust Speed Curves - EC4 SeriesSPEEDSPEEDSPEEDEC4-AKM52Gn-nnn-10-25BTORQUE - N-m, lb-in0.0 3.8 7.6 11.5 15.3 19.1 22.9mm/s in/s 0.0 33.8 67.6 101.5 135.3 169.1 202.91588 62.538101270 50.03048953 37.52286635 25.01524318 12.57620.0 0.00mm/s in/s1016 40.0813 32.0610 24.0406 16.0203 8.00.0 0.00 140 280 420 560 700 8400 623 1246 1868 2491 3114 3737THR<strong>US</strong>T - lb, NEC4-AKM52G-10-25BEC4-AKM52Gn-nnn-15-25Bmm/s in/s762 30.0610 24.0457 18.0305 12.0152 6.00.0 0.0TORQUE - N-m, lb-in0.0 3.8 7.6 11.4 15.2 19.0 22.80.0 33.7 67.3 101.0 134.7 168.3 202.00 210 420 630 840 1050 12600 934 1868 2802 3737 4671 5605THR<strong>US</strong>T - lb, NEC4-AKM52G-15-25BEC4-AKM52Gn-nnn-20-25B36582926219514637320TORQUE - N-m, lb-in0.0 3.3 6.6 9.8 13.1 16.4 19.70.0 29.0 58.0 87.0 116.0 145.0 174.00 240 480 720 960 1200 14400 1068 2135 3203 4270 5338 6405THR<strong>US</strong>T - lb, N36582926219514637320MOTORMOTORMOTORRPMRPMRPMSPEEDSPEEDSPEEDEC4-AKM52Gn-nnn-10-10BTORQUE - N-m, lb-in0.0 3.7 7.4 11.1 14.9 18.6 22.30.0mm/s in/s32.9 65.8 98.6 131.5 164.4 197.3635 25.03810508 20.0381 15.0254 10.0127 5.00.0 0.00 340 680 1020 1360 1700 20400 1512 3025 4537 6050 7562 9074THR<strong>US</strong>T - lb, NEC4-AKM52Gn-nnn-15-10B0 520 1040 1560 2080 2600 31200 2313 4626 6939 9252 11565 13878THR<strong>US</strong>T - lb, NEC4-AKM52G-15-10B304822861524EC4-AKM52G-10-10BTORQUE - N-m, lb-in0.0 3.8 7.6 11.4 15.1 18.9 22.70.0mm/s in/s33.5 67.0 100.6 134.1 167.6 201.1413 16.33715330 13.02972248 9.82229165 6.5148683 3.37430.0 0.00EC4-AKM52Gn-nnn-20-10Bmm/s in/s318 12.5254 10.0191 7.5127 5.064 2.50.0 0.0TORQUE - N-m, lb-in0.0 2.9 5.9 8.8 11.8 14.7 17.70.0 26.1 52.2 78.3 104.4 130.5 156.60 540 1080 1620 2160 2700 32400 2402 4804 7206 9608 12010 14412THR<strong>US</strong>T - lb, N762038103048228615247620MOTORMOTORMOTORRPMRPMRPML I N E A R P O S I T I O N E R SEC4-AKM52G-20-25BSPEEDEC4-AKM52Gn-nnn-50-25BTORQUE - N-m, lb-in0.0 2.7 5.4 8.1 10.7 13.4 16.10.0mm/s in/s23.8 47.5 71.3 95.0 118.8 142.5159 6.251905M127 5.001524 OTOR R95 3.751143 P64 2.50762 M32 1.253810.0 0.000Use for AKM52G Leg0 480 960 1440 1920 2400 28800 2135 4270 6405 8541 10676 12811THR<strong>US</strong>T - lb, NSPEEDEC4-AKM52G-20-10BEC4-AKM52Gn-nnn-50-10BTORQUE - N-m, lb-in0.0 1.2 2.4 3.6 4.8 6.0 7.2mm/s in/s 0.0 10.7 21.4 32.1 42.8 53.5 64.164 2.5190551 2.0152438 1.5114325 1.076213 0.53810.0 0.00*460 Vac0 540 1080 1620 2160 2700 32400 2402 4804 7206 9608 12010 14412THR<strong>US</strong>T - lb, NMOTORRPMEC4-AKM52G-50-25BEC4-25B Ballscew Specifications0.0 9.8 19.7 29.5 39.4 49.2 59.1 inCritical Speed (in/s)655239261300 250 500 750 1000 1250 1500Stroke l<strong>en</strong>gth2375190014259504750mmColumn Load Limit (lbs)Leg<strong>en</strong>d25 km / 1 M " Life5.0460 Vac0.0 0SD 6.3 /12.7 A0 2 4 6460 Vac S300 6.0 /12.0 A (Ip limit)230 Vac S200 6.0 /18.0 A115 Vac S200 6.0 /18.0 A* 460 Vac system limits are equival<strong>en</strong>t to 230 Vac system.EC4-10B EC4-AKM52G-50-10B Ballscrew Specification0.0 9.8 19.7 29.5 39.4 49.2 59.12016128400 250 500 750 1000 1250 1500Stroke l<strong>en</strong>gthCritical Speed (in/s)in2375190014259504750mmColumn Load Limit (lbs)www.kollmorg<strong>en</strong>.com35

Thrust Speed Curves - EC4 SeriesL I N E A R P O S I T I O N E R SSPEEDSPEEDEC4-AKM52L-nnn-10-25Bmm/s in/s1588 62.51270 50.0953 37.56353180.025.012.50.0mm/s in/s1461 57.51168 46.0876 34.5584 23.0292 11.50.0 0.0TORQUE - N-m, lb-in0.0 3.9 7.9 11.8 15.7 19.7 23.60.0 34.8 69.6 104.4 139.2 174.0 208.80 144 288 432 576 720 8640 641 1281 1922 2562 3203 3843THR<strong>US</strong>T - lb, NEC4-AKM52S-10-25BEC4-AKM52L-nnn-15-25BTORQUE - N-m, lb-in0.0 4.0 8.0 12.0 16.0 20.0 24.00.0 35.5 70.9 106.4 141.8 177.3 212.80 220 440 660 880 1100 13200 979 1957 2936 3914 4893 5872THR<strong>US</strong>T - lb, N38103048228615247620525842063155210310520MOTORMOTORRPMRPMSPEEDSPEEDEC4-AKM52L-nnn-10-10Bmm/s in/s635 25.0508 20.0381 15.0254 10.0127 5.00.0 0.0mm/s in/s572 22.5457 18.0343 13.5229 9.0114 4.50.0 0.0TORQUE - N-m, lb-in0.0 3.3 6.6 9.8 13.1 16.4 19.70.0 29.0 58.0 87.0 116.0 145.0 174.00 300 600 900 1200 1500 18000 1334 2669 4003 5338 6672 8007THR<strong>US</strong>T - lb, NEC4-AKM52S-10-10BEC4-AKM52L-nnn-15-10BTORQUE - N-m, lb-in0.0 3.9 7.9 11.8 15.7 19.7 23.60.0 34.8 69.6 104.4 139.2 174.0 208.80 540 1080 1620 2160 2700 32400 2402 4804 7206 9608 12010 14412THR<strong>US</strong>T - lb, N38103048228615247620514441153086205710290MOTORMOTORRPMRPMSPEEDmm/s in/s1143 45.0914 36.0686 27.0457 18.0229 9.00.0 0.0EC4-AKM52S-15-25BEC4-AKM52L-nnn-20-25BTORQUE - N-m, lb-in0.0 3.3 6.6 9.8 13.1 16.4 19.70.0 29.0 58.0 87.0 116.0 145.0 174.00 240 480 720 960 1200 14400 1068 2135 3203 4270 5338 6405THR<strong>US</strong>T - lb, N548643893292219510970MOTORRPMSPEEDEC4-AKM52S-15-10BEC4-AKM52L-nnn-20-10BTORQUE - N-m, lb-in0.0 2.8 5.7 8.5 11.4 14.2 17.0mm/s in/s0.0 25.1 50.3 75.4 100.5 125.7 150.8445 17.55334356 14.04267267 10.53200178 7.0213489 3.510670.0 0.000 520 1040 1560 2080 2600 31200 2313 4626 6939 9252 11565 13878THR<strong>US</strong>T - lb, NMOTORRPMEC4-AKM52S-50-25BEC4-25B Ballscew Specifications0.0 9.8 19.7 29.5 39.4 49.2 59.1 inCritical Speed (in/s)EC4-AKM52L-nnn-50-25BEC4-AKM52S-20-25B655239261300 250 500 750 1000 1250 1500Stroke l<strong>en</strong>gth2375190014259504750mmColumn Load Limit (lbs)25 km / 1 M " Life5.0460 Vac0.0 0SD 6.3 /12.7 A0 2 4 6460 Vac S300 6.0 /12.0 A (Ip limit)230 Vac S200 6.0 /18.0 A115 Vac S200 6.0 /18.0 AEC4-AKM52L-nnn-50-10BEC4-AKM52S-50-10BEC4-10B Ballscrew Specification0.0 9.8 19.7 29.5 39.4 49.2 59.12016128400 250 500 750 1000 1250 1500Stroke l<strong>en</strong>gthCritical Speed (in/s)EC4-AKM52S-20-10BTORQUE - N-m, lb-inTORQUE - N-m, lb-in0.0 2.7 5.4 8.1 10.7 13.4 16.10.0 1.2 2.4 3.6 4.8 6.0 7.20.0mm/s in/s23.8 47.5 71.3 95.0 118.8 142.50.0mm/s in/s10.7 21.4 32.1 42.8 53.5 64.1159 6.3190564 2.51905SM SM127 5.0152451 2.01524POTOR RPOTOR R95 3.81143EP38 1.51143 PEE 64 2.5762 M25 1.0762 MED 32 1.3381D 13 0.53810.0Use0for AKM52G Leg0.00.0 0.000 480 960 1440 1920 2400 28800 540 1080 1620 2160 2700 32400 2135 4270 6405 8541 10676 128110 2402 4804 7206 9608 12010 14412THR<strong>US</strong>T - lb, NTHR<strong>US</strong>T - lb, N*230 Vac *230 VacLeg<strong>en</strong>d* 230 Vac system limits are equival<strong>en</strong>t to 115 Vac system.in2375190014259504750mmColumn Load Limit (lbs)36K O L L M O R G E N

Thrust Speed Curves - EC5 SeriesSPEEDSPEEDEC5-AKM42n-nnn-10-32Bmm/s in/s1588 62.51270 50.0953 37.5635 25.0318 12.50.0 0.0TORQUE - N-m, lb-in0.0 2.1 4.2 6.3 8.4 10.5 12.60.0 18.6 37.2 55.7 74.3 92.9 111.50 60 120 180 240 300 3600 267 534 801 1068 1334 1601THR<strong>US</strong>T - lb, NEC5-AKM42-10-32BEC5-AKM42n-nnn-15-32BTORQUE - N-m, lb-in0.0 2.1 4.2 6.3 8.4 10.5 12.6mm/s in/s0.0 18.6 37.1 55.7 74.2 92.8 111.31588 62.51270 50.0953 37.5635 25.0318 12.50.0 0.00 90 180 270 360 450 5400 400 801 1201 1601 2002 2402THR<strong>US</strong>T - lb, N2977238117861191595044653572267917868930MOTORMOTORRPMRPMSPEEDEC5-AKM42n-nnn-10-10BSPEEDTORQUE - N-m, lb-in0.0 2.2 4.4 6.6 8.7 10.9 13.10.0mm/s in/s19.3 38.7 58.0 77.4 96.7 116.0476 18.82858381 15.02286286 11.31715191 7.5114395 3.85720.0 0.000 200 400 600 800 1000 12000 890 1779 2669 3559 4448 5338THR<strong>US</strong>T - lb, NEC5-AKM42-10-10BEC5-AKM42n-nnn-15-10BTORQUE - N-m, lb-in0.0 2.2 4.4 6.6 8.7 10.9 13.10.0mm/s in/s19.3 38.7 58.0 77.3 96.6 116.0476 18.8381 15.0286 11.3191 7.595 3.80.0 0.00 300 600 900 1200 1500 18000 1334 2669 4003 5338 6672 8007THR<strong>US</strong>T - lb, N42863429257217158570MOTORMOTORRPMRPML I N E A R P O S I T I O N E R SSPEEDEC5-AKM42-15-32BEC5-AKM42n-nnn-20-32BTORQUE - N-m, lb-in0.0 2.1 4.2 6.3 8.4 10.5 12.6mm/s in/s0.0 18.5 37.1 55.6 74.2 92.7 111.31270 50.01016 40.0762 30.0508 20.0254 10.00.0 0.00 120 240 360 480 600 7200 534 1068 1601 2135 2669 3203THR<strong>US</strong>T - lb, N47633810285819059530MOTORRPMSPEEDmm/s in/s413 16.3330 13.0248 9.8165 6.583 3.30.0 0.0EC5-AKM42-15-10BEC5-AKM42n-nnn-20-10BTORQUE - N-m, lb-in0.0 2.2 4.4 6.6 8.7 10.9 13.10.0 19.3 38.7 58.0 77.3 96.7 116.00 400 800 1200 1600 2000 24000 1779 3559 5338 7117 8896 10676THR<strong>US</strong>T - lb, N49533962297219819910MOTORRPMSPEEDEC5-AKM42-20-32BEC5-AKM42n-nnn-50-32BTORQUE - N-m, lb-in0.0 2.1 4.3 6.4 8.6 10.7 12.90.0mm/s in/s19.0 38.0 57.0 76.0 95.0 114.0191 7.51786152 6.01429114 4.5107276 3.071438 1.53570.0 0.000 300 600 900 1200 1500 1800 Use for AKM42 Lege0 1334 2669 4003 5338 6672 8007THR<strong>US</strong>T - lb, NMOTORRPMSPEEDEC5-AKM42-20-10BEC5-AKM42n-nnn-50-10BTORQUE - N-m, lb-in0.0 2.2 4.4 6.6 8.8 11.0 13.20.0mm/s in/s19.4 38.8 58.2 77.6 97.0 116.464 2.5190551 2.0152438 1.5114325 1.076213 0.53810.0 0.000 980 1960 2940 3920 4900 58800 4359 8719 13078 17437 21796 26156THR<strong>US</strong>T - lb, NMOTORRPMEC5-32B65523926130Ballscrew Critical Speed Limit0.0 9.8 19.7 29.5 39.4 49.2 59.1in/s 0 250 500 750 1000 1250 1500 mmStroke l<strong>en</strong>gthEC5-AKM42-50-32BinLeg<strong>en</strong>d25 km / 1 M " Life4605.0Vac SD 3.9 /7.8 A460 0.0 Vac 0 S300 3.0 /7.5 A (Ip limit)0 2 4 6230 Vac S200 6.0 /18.0 A115 Vac S200 6.0 /18.0 A115/230 Vac S300 6.0 /15.0 A (Ip limit)EC5-AKM42-50-10BEC5-10B Ballscrew Critical Speed Limit1915118400.0 9.8 19.7 29.5 39.4 49.2 59.1in/s 0 250 500 750 1000 1250 1500Stroke l<strong>en</strong>gthinmmwww.kollmorg<strong>en</strong>.com37