DOUBLE CHECK ASSEMBLIES MODELS 850 ... - Backflow Supply

DOUBLE CHECK ASSEMBLIES MODELS 850 ... - Backflow Supply

DOUBLE CHECK ASSEMBLIES MODELS 850 ... - Backflow Supply

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

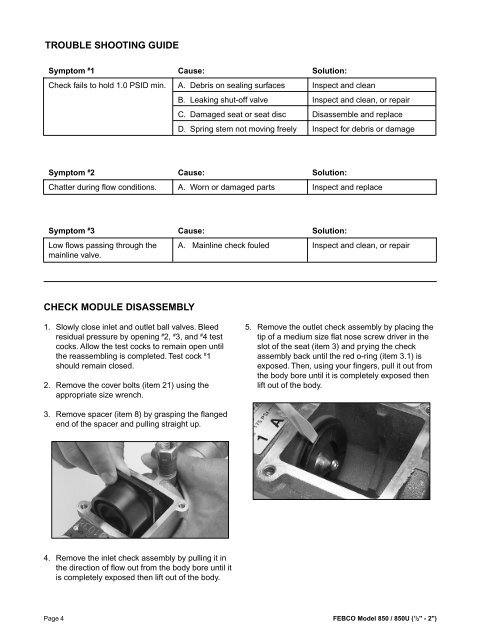

TROUBLE SHOOTING GUIDESymptom # 1Check fails to hold 1.0 PSID min.Cause:A. Debris on sealing surfacesB. Leaking shut-off valveC. Damaged seat or seat discD. Spring stem not moving freelySolution:Inspect and cleanInspect and clean, or repairDisassemble and replaceInspect for debris or damageSymptom # 2Chatter during flow conditions.Cause:A. Worn or damaged partsSolution:Inspect and replaceSymptom # 3Low flows passing through themainline valve.Cause:A. Mainline check fouledSolution:Inspect and clean, or repair<strong>CHECK</strong> MODULE DISASSEMBLY1. Slowly close inlet and outlet ball valves. Bleedresidual pressure by opening # 2, # 3, and # 4 testcocks. Allow the test cocks to remain open untilthe reassembling is completed. Test cock # 1should remain closed.2. Remove the cover bolts (item 21) using theappropriate size wrench.5. Remove the outlet check assembly by placing thetip of a medium size flat nose screw driver in theslot of the seat (item 3) and prying the checkassembly back until the red o-ring (item 3.1) isexposed. Then, using your fingers, pull it out fromthe body bore until it is completely exposed thenlift out of the body.3. Remove spacer (item 8) by grasping the flangedend of the spacer and pulling straight up.4. Remove the inlet check assembly by pulling it inthe direction of flow out from the body bore until itis completely exposed then lift out of the body.Page 4 FEBCO Model <strong>850</strong> / <strong>850</strong>U ( 1 /2" - 2")