Packaging workflow with HelioCom - hell gravure systems

Packaging workflow with HelioCom - hell gravure systems

Packaging workflow with HelioCom - hell gravure systems

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

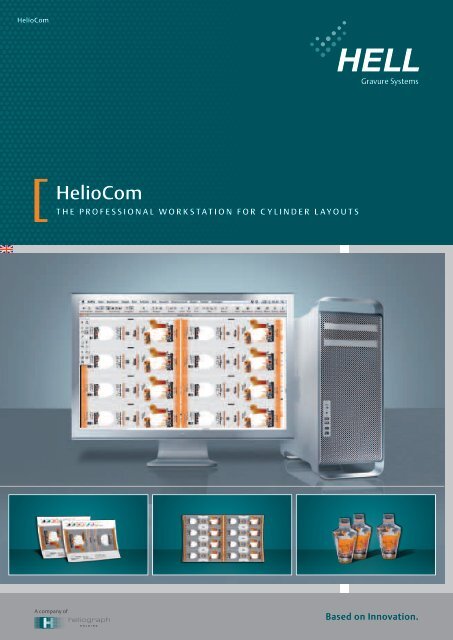

<strong>HelioCom</strong>3<strong>HelioCom</strong>Creates cylinder layouts simply, quickly and reliably<strong>HelioCom</strong> makes TIFF direct engraving extremely simple, <strong>with</strong> a whole hostof professional functions and powerful hardware.The direct path to success<strong>HelioCom</strong> is a workstation for designing cylinderlayouts in packaging <strong>gravure</strong> that features extremelyuser-friendly operation, unique functionsand powerful Mac hardware. <strong>HelioCom</strong> was developedjointly by HELL and Esko Artwork, the leadingmanufacturer of professional prepress software forpackaging. With over 500 units installed, <strong>HelioCom</strong>is the number 1 worldwide for professional layoutcreation and cylinder engraving.Impressive functionsWith <strong>HelioCom</strong>, cylinder layouts are created underconstant visual control. This applies to full-color andseparated views and to both coarse- and fine-imagemodes. A large number of powerful tools are availablefor assembly. These include the convenient step &repeat function, predefined cylinder samples, freepositioning, rotation, mirroring, coordinate display,Importing directly from Artpro and PDFs<strong>HelioCom</strong> is the only layout workstation that supportsprepress data directly from Artpro <strong>with</strong>outany format conversion. It also has a very reliable andpowerful PDF interpreter to transfer packaging datafrom other prepress <strong>systems</strong>.Ingeniously simple <strong>with</strong> TIFF direct engraving<strong>HelioCom</strong> creates separated TIFF complete formsthat are engraved directly by the HelioKlischograph.The TIFF engraving data can also be opened andprocessed by any image processing software, forexample Photoshop.<strong>HelioCom</strong> and HelioKlischograph– all that is neededfor entry-level engravingsymbol generation and management, intelligentcontrol marks, a multilevel undo function, a versioncounter and version comparison – to name but afew. A proof can be created directly on large outputdevices for layout control purposes. <strong>HelioCom</strong>thinks of everything – even complex and nestedcylinder layouts can be created extremely easily.Growth built inA <strong>HelioCom</strong> layout station and a HelioKlischographare all that is needed for entry-level cylinder engraving.What’s more, <strong>HelioCom</strong> is equipped for futuregrowth – one <strong>HelioCom</strong> workstation typically suppliesup to four HelioKlischograph units <strong>with</strong> engravingdata.

4Job ticketsTurbocharged cylinder engravingCentral job preparationcuts makeready timesJob ticketsenable automationTIFF direct engraving plus job ticketsTIFF direct engraving enables simple and flexiblecylinder engraving. HELL has taken this global standarda step further <strong>with</strong> job tickets, ensuring evengreater productivity and transparency.Standardized cylinder engravingThe job ticket is a digital document containing allthe production-related data for the cylinder layout,the layout proof and engraving. Each componentin the system (<strong>HelioCom</strong>, HelioFormproof, HQH,HelioKlischograph and Cellaxy) takes job parametersfrom the job ticket and adds further details asnecessary.Mounting the cylinder is the only manual steprequired for engraving <strong>with</strong> a HelioKlischographor Cellaxy. The AutoCon production line even runs<strong>with</strong>out any involvement at all on the part of theoperator.Flexibility right to the output stageThe <strong>HelioCom</strong> <strong>workflow</strong> is based on output-neutralTIFF engraving data. As a result, the output method(vibration engraving or XtremeEngraving <strong>with</strong> K5 /K50 / K500 or direct laser engraving <strong>with</strong> Cellaxy)can be decided on just before engraving. BecauseTIFF engraving data and job tickets are processedindependently, job data can also be modified atany point until immediately before engraving startson the HelioKlischograph or Cellaxy. It is useful ifengraving jobs do not have to be returned to the jobpreparation stage for modifications, in particularwhen engraving test cylinders.Accurately reproducible cylindersJob tickets and TIFF engraving data can be archivedusing standard software and are then availablewhenever required. This enables repeat jobs to bereproduced very simply and accurately.General<strong>HelioCom</strong>HelioFormproofHelioKlischographCellaxy• Job name• TIFF resolution• Color On Proofer• Screen• Screen• Job format• Oversampling• Mirroring• Screen angle• Screen angle• Comments• Color on proofer• Testcut positioning • Gradation• GradationThe job ticket preventsduplicated entriesJobticket• Number of colors• Engraving time• Ink consumption• Testcut position• Fast crossfeed• HistogramHQH• Color• Starting point• Helical / polar line• Testcut• Quality• Testcut• Quality• Thickness• XtremeGreater reliabilityin production thanks toonline accessJob preparation <strong>with</strong> MIS connectionWith HelioDisk, job data from MIS <strong>systems</strong> is transferredfor engraving job preparation via a JDF interface.If all the job data is already in the MIS system,job tickets can even be generated fully automatically<strong>with</strong>out any operator input. This preventsduplicated entries and errors.Productive <strong>with</strong>out preliminary processes<strong>HelioCom</strong> is far more productive than other <strong>workflow</strong>solutions because there are no compute-intensivepreliminary processes. For example, full-colormonitor displays, engraving time calculations andink volume calculations are performed instantlyon the fly.

<strong>HelioCom</strong>5Professional<strong>workflow</strong> systemREPROMIS<strong>HelioCom</strong>HelioDiskTIFF complete formsjob ticketsServer<strong>with</strong> HQH andHelioFormproofHelioFormproofK5K500K500 XtremeCellaxyFrom entry-level solution to professional <strong>workflow</strong> – the configuration levels for digital engraving <strong>with</strong> <strong>HelioCom</strong>.

6The components at a glanceEnhancing performance at every levelDigital engraving <strong>with</strong> HelioDisk can be scaled up in stages from the entrylevelsolution to a professional <strong>workflow</strong> system.HelioDiskThe HelioDisk job ticket editor is used forcentral job preparation in engraving andopens up the way for a job-ticket-based<strong>workflow</strong>. HelioDisk is installed on the<strong>HelioCom</strong> station, for instance.Standardized job preparation <strong>with</strong> Helio-Disk greatly improves reliability in production.Logging and archiving of job parametersmeans that all jobs can be reproducedat any time. In addition, HelioDisk includesa JDF interface to transfer job data fromMIS <strong>systems</strong>.<strong>HelioCom</strong><strong>HelioCom</strong> is a workstation for designingcylinder layouts in packaging <strong>gravure</strong> thatfeatures extremely user-friendly operation,unique functions and powerful Mac hardware.<strong>HelioCom</strong> was developed jointly by HELLand Esko Artwork, the leading manufacturerof professional prepress software forpackaging. With over 500 units installed,<strong>HelioCom</strong> is the number 1 worldwide forprofessional layout creation and cylinderengraving.ServerAny well-equipped PC <strong>with</strong> a Windowsoperating system can be used as the engravingserver. Requirements depend on thenumber of stations <strong>with</strong> access, the cylinderthroughput, the availability of data,the required level of data security and thenumber of applications that are to run onthe server (HelioFormproof, HQH).MIS-RemoteHelioFormproofHelioDiskHelioDiskHQH<strong>HelioCom</strong>ServerHelioDiskMIS-Remote<strong>HelioCom</strong>HelioDiskServerHelioFormproofHQHHelioDisk<strong>HelioCom</strong>ServerHQHHelioDiskMIS-RemoteHelioFormproof

7A comparison:Output <strong>with</strong> HQH (top)Output <strong>with</strong>out HQH (bottom)High Quality Hinting (HQH)HQH software delivers much better printresults for text and fine elements. Reprodata is often prepared using manual correctionin line <strong>with</strong> specific engraving requirements.HQH automates this process byexamining engraving data for fine lines andtexts and automatically optimizing theseelements according to preset criteria.The hardware platform is a PC <strong>with</strong> Windowsoperating system. HQH works in thebackground <strong>with</strong>out any operator interventionby combining hot folder technology<strong>with</strong> job ticket control.HelioFormproofHelioFormproof has been designed specificallyfor packaging <strong>gravure</strong> and is anextremely powerful system for in-houseand customer proofs. Up to 16 colors of acylinder set can be output automatically onlarge-format printers.The hardware platform is a PC <strong>with</strong> Windowsoperating system. HelioFormproofworks in the background <strong>with</strong>out any operatorintervention by combining hot foldertechnology <strong>with</strong> job ticket control.MIS RemoteEven the basic version of HelioDisk includesthe „MIS Link“ offline interface forexchanging data <strong>with</strong> MIS <strong>systems</strong>.The „MIS Remote“ option also offers ahigh-performance online connection.MIS Remote enables automatic creationof job tickets directly from an MIS, bypassingHelioDisk. The latest production andquality data for engraving jobs in progresscan also be checked online.<strong>HelioCom</strong>ServerHQHHelioDiskHelioFormproofHQHServerHelioFormproofHelioDiskMIS-RemoteHelioFormproofMIS-RemoteHelioDiskHelioDisk<strong>HelioCom</strong>HelioDiskMIS-Remote<strong>HelioCom</strong>HelioDiskHQHServer

Based on Innovation. HELLHELL solutions satisfy the toughest demands in terms of print quality, cylinder servicelife and printing speeds. Printing forms engraved using HELL equipment benefit fromsimplified color matching, minimal start-up waste and optimum engraving results <strong>with</strong>high print densities, soft vignettes, brilliant contones and razor-sharp lines.Your local HELL representative will be happy to provide further information and personaladvice on our products and services at any time. For contact addresses and additionalproduct information, see our website www.HELL-Gravure-Systems.comHELL Gravure Systems GmbH & Co. KG, Philipp-Reis-Weg 5, 24148 Kiel, Germany, Tel. +49 (0)431-2377-0, Fax +49 (0)431-2377-1235info@HELL-Gravure-Systems.com, www.HELL-Gravure-Systems.comDesign changes and errors reservedE5Code-39*052012A*www.ma-design.de