Self-Sealing Evaporation Ponds for Desalination Facilities in Texas

Self-Sealing Evaporation Ponds for Desalination Facilities in Texas

Self-Sealing Evaporation Ponds for Desalination Facilities in Texas

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

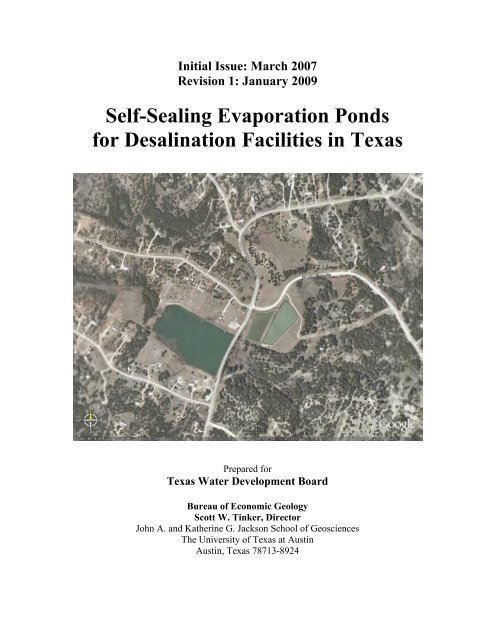

Cover photo: aerial view of River Oaks Ranch evaporation ponds and facility (Hays County).Courtesy of Google Earth.

Table of ContentsTable of Contents .......................................................................................................................... iiiList of Figures ............................................................................................................................vList of Tables .......................................................................................................................... ixGlossary and Abbreviations........................................................................................................... xiAcknowledgments........................................................................................................................ xiiiExecutive Summary.........................................................................................................................11 Introduction ............................................................................................................................52 Background Technical In<strong>for</strong>mation on <strong>Evaporation</strong> <strong>Ponds</strong>.....................................................72.1 <strong>Desal<strong>in</strong>ation</strong> Primer .........................................................................................................72.2 <strong>Desal<strong>in</strong>ation</strong> <strong>Facilities</strong> <strong>in</strong> <strong>Texas</strong> <strong>in</strong> 2006..........................................................................72.3 How Do <strong>Evaporation</strong> <strong>Ponds</strong> Operate? ...........................................................................122.3.1 <strong>Evaporation</strong> Rates <strong>in</strong> <strong>Texas</strong> .........................................................................................122.3.2 Typical M<strong>in</strong>eral Suite—Chemical Divide ...................................................................192.4 Geochemical Model<strong>in</strong>g In<strong>for</strong>mation..............................................................................213 Approach and Sources of In<strong>for</strong>mation...................................................................................233.1 Feedwater Chemistry .....................................................................................................233.1.1 Groundwater Data........................................................................................................233.1.2 Surface-Water Data......................................................................................................283.1.3 Feedwater Groups and <strong>Evaporation</strong> Rates...................................................................293.2 Regulatory Review.........................................................................................................303.3 Field Sampl<strong>in</strong>g and Technical Interviews......................................................................304 Analysis and Results..............................................................................................................314.1 Legislative Options ........................................................................................................314.1.1 Regulatory Framework ................................................................................................314.1.1.1 Federal Statutory and Regulatory Requirements .............................................. 314.1.1.2 <strong>Texas</strong> Statutory Requirements .......................................................................... 314.1.1.3 <strong>Texas</strong> Regulatory Requirements....................................................................... 324.1.2 Policy Overview...........................................................................................................344.1.2.1 Pond Siz<strong>in</strong>g ....................................................................................................... 344.1.2.2 Pond L<strong>in</strong>er......................................................................................................... 344.1.2.3 Alternative L<strong>in</strong>er Requirements........................................................................ 354.1.3 Regulatory Programs <strong>in</strong> Selected Southwestern States ...............................................354.1.3.1 Arizona.............................................................................................................. 354.1.3.2 Oklahoma.......................................................................................................... 364.1.3.3 New Mexico...................................................................................................... 374.1.4 Factors to Reduce Complexity and Cost <strong>in</strong> <strong>Texas</strong>.......................................................384.1.4.1 L<strong>in</strong>er Requirements........................................................................................... 384.1.4.2 Permit Process<strong>in</strong>g.............................................................................................. 384.1.4.3 Leak Monitor<strong>in</strong>g ............................................................................................... 384.1.5 What if Someth<strong>in</strong>g Goes Wrong?................................................................................394.1.6 Regulatory Conclusions...............................................................................................394.2 Range of Likely Membrane Concentrate Compositions................................................404.2.1 Out-of-State Examples.................................................................................................414.2.2 <strong>Texas</strong> Data ...................................................................................................................45iii

4.2.3 Conclusions on the Range of Likely Membrane Concentrate Compositions ..............474.3 <strong>Self</strong>-<strong>Seal<strong>in</strong>g</strong> Geochemical Calculations.........................................................................474.3.1 Mechanics of <strong>Self</strong> <strong>Seal<strong>in</strong>g</strong> ...........................................................................................474.3.2 Literature Review of Analogs......................................................................................484.3.2.1 Industrial <strong>Ponds</strong>—Lagoons............................................................................... 484.3.2.2 Sepiolite ............................................................................................................ 484.3.2.3 Natural Analogs ................................................................................................ 494.3.2.4 Experiments ...................................................................................................... 504.3.2.5 Additives........................................................................................................... 514.3.3 Geochemical Simulation Parameters ...........................................................................514.3.3.1 Balance of Influx and <strong>Evaporation</strong> Rates ......................................................... 524.3.3.2 M<strong>in</strong>erals Allowed to Precipitate ....................................................................... 544.3.3.3 Simulation Parameters ...................................................................................... 564.3.3.4 Scal<strong>in</strong>g of PHREEQC results............................................................................ 584.3.4 Geochemical Simulation Results .................................................................................594.3.5 Conclusions on <strong>Self</strong>-<strong>Seal<strong>in</strong>g</strong> Geochemical Calculations.............................................614.4 Design Specifics and Cost Estimates.............................................................................654.4.1 Pond Siz<strong>in</strong>g ..................................................................................................................654.4.2 Conta<strong>in</strong>ment Equivalence ............................................................................................714.4.2.1 Equivalence to Clay L<strong>in</strong>er ................................................................................ 714.4.2.2 Equivalence to Geomembrane L<strong>in</strong>er with a Leak-Detection System orGroundwater Monitor<strong>in</strong>g System..................................................................... 714.4.3 Conclusions on Conta<strong>in</strong>ment Equivalence ..................................................................724.4.4 Cost Analysis ...............................................................................................................735 Conclusions, Recommendations, and Future Work...............................................................776 References ..........................................................................................................................797 Appendix List.........................................................................................................................878 Appendix A: Groundwater and Surface-Water Sample Locations and Piper Plots..............899 Appendix B: Relevant TAC/TCEQ Rules and Excerpts from Form TCEQ 10411/10055-Instructions.....................................................................................................11310 Appendix C: Example of Permit to Discharge Wastewater to an <strong>Evaporation</strong> Pond..........12111 Appendix D: Panhandle Sal<strong>in</strong>e Lake Sampl<strong>in</strong>g...................................................................12712 Appendix E: <strong>Evaporation</strong> Pond Sampl<strong>in</strong>g ...........................................................................13113 Appendix F: A Few Words about Clay M<strong>in</strong>erals ................................................................14914 Appendix G: Commented Geochemical Input Files............................................................15515 Appendix H: Results of Some Geochemical Runs ..............................................................16316 Appendix I: Disposal of As-Rich Residuals as Hazardous Wastes .....................................20917 Appendix J: Conceptual Draw<strong>in</strong>gs of <strong>Evaporation</strong> <strong>Ponds</strong>...................................................21318 Appendix K: Responses to Review Comments ...................................................................21719 Appendix L: List of Changes <strong>in</strong> Revision 1.........................................................................225iv

List of FiguresFigure 2-1. Feedwater TDS distribution. .........................................................................................8Figure 2-2. Map of desal<strong>in</strong>ation facilities show<strong>in</strong>g design capacity................................................9Figure 2-3. Map of desal<strong>in</strong>ation facilities (≥0.025 MGD DC) show<strong>in</strong>g concentrate disposalmethod.........................................................................................................................9Figure 2-4. Map of desal<strong>in</strong>ation facilities show<strong>in</strong>g TDS of feedwater..........................................10Figure 2-5. Map of <strong>Texas</strong> desal<strong>in</strong>ation facilities show<strong>in</strong>g feedwater orig<strong>in</strong>..................................10Figure 2-6. Average temperature (a) month of July, (b) annual. ...................................................14Figure 2-7. Average annual precipitation rate. ..............................................................................15Figure 2-8. Average annual gross lake evaporation rate................................................................16Figure 2-9. Net average annual fresh-water evaporation rates across <strong>Texas</strong>.................................17Figure 2-10. Net average annual evaporation rates across <strong>Texas</strong> from a low-sal<strong>in</strong>ity waterbody...........................................................................................................................18Figure 2-11. Net average annual evaporation rates across <strong>Texas</strong> from a high-sal<strong>in</strong>ity waterbody...........................................................................................................................19Figure 2-12. Conceptual model of concentrate evolution..............................................................20Figure 3-1. Map of counties with no, low to medium (30 <strong>in</strong>ches) netevaporation rates and of groundwater samples with TDS >1,000 and 1,000 ppm..................28Figure 3-4. Surface-water stations with chemical analyses of major ions and TDS >1,000ppm. ..........................................................................................................................29Figure 3-5. Net average annual evaporation rate <strong>for</strong> each water sampl<strong>in</strong>g group. ........................30Figure 4-1. Piper plot of feedwater (F) and concentrate (C) of selected desal<strong>in</strong>ation facilities<strong>in</strong> the Middle East. ....................................................................................................42Figure 4-2. Piper plot of feedwater (F) and concentrate (C) of selected <strong>Texas</strong> desal<strong>in</strong>ationfacilities.....................................................................................................................45Figure 4-3. Mix<strong>in</strong>g scheme of numerical model<strong>in</strong>g.......................................................................54Figure 4-4. Comparison of total m<strong>in</strong>eral accumulation (<strong>in</strong>ches) at 5 years <strong>for</strong> noneng<strong>in</strong>eered(“natural”) and eng<strong>in</strong>eered (addition of sepiolite precursor) systems. .....................61Figure 8-1. TDS distribution of slightly brackish waters ..............................................................91Figure 8-2. Map and Piper plot of all groundwater samples on map of Figure 3-1.......................94Figure 8-3. Map and Piper plot of Mixed Alluvium group............................................................95Figure 8-4. Map and Piper plot of Rio Grande and Brazos Alluvium groups...............................96Figure 8-5. Map and Piper plot of Seymour group........................................................................97Figure 8-6. Map and Piper plot of Bolson group...........................................................................98Figure 8-7. Map and Piper plot of Ogallala group.........................................................................99Figure 8-8. Map and Piper plot of Pecos Valley group ...............................................................100Figure 8-9. Map and Piper plot of Gulf Coast group...................................................................101Figure 8-10. Map and Piper plot of Eocene group.......................................................................102Figure 8-11. Map and Piper plot of Cretaceous Limestone group...............................................103Figure 8-12. Map and Piper plot of Cretaceous Sandstone group ...............................................104Figure 8-13. Map and Piper plot of Triassic Sandstone group ....................................................105Figure 8-14. Map and Piper plot of Permian Evaporite group ....................................................106v

Figure 8-15. Map and Piper plot of Permian Limestone group ...................................................107Figure 8-16. Map and Piper plot of Permian Sandstone group....................................................108Figure 8-17. Map and Piper plot of Bone Spr<strong>in</strong>g – Victorio Peak and Capitan groups ..............109Figure 8-18. Map and Piper plot of Pennsylvanian group...........................................................110Figure 8-19. Map and Piper plot of Llano Uplift group ..............................................................111Figure 8-20. Map and Piper plot of surface-water group.............................................................112Figure 11-1. Locations of Panhandle sal<strong>in</strong>e lakes .......................................................................130Figure 12-1. Location map of the four sampled evaporation ponds............................................135Figure 12-2. Piper plots of samples from selected <strong>Texas</strong> desal<strong>in</strong>ation facilities.........................136Figure 12-3. Examples of X-ray diffraction patterns of bottom pond sediments: HorizonMUD sample 3 (a), Abilene sample 1 (b), River Oaks Ranch sample 1 (c) andBrady sample 1 (d)..................................................................................................137Figure 12-4. M<strong>in</strong>eral precipitation sequence as evaporation progresses us<strong>in</strong>g sampledconcentrate as the source. .......................................................................................139Figure 12-5. Aerial view of River Oaks Ranch evaporation pond show<strong>in</strong>g sampl<strong>in</strong>g location(courtesy of Google Earth)......................................................................................141Figure 12-6. View of River Oaks Ranch evaporation pond from sampl<strong>in</strong>g po<strong>in</strong>t #4 show<strong>in</strong>gthe gypsum crust .....................................................................................................142Figure 12-7. View of River Oaks Ranch evaporation pond show<strong>in</strong>g concentrate outfall andwater-level gage......................................................................................................142Figure 12-8. Aerial view of Horizon MUD evaporation ponds show<strong>in</strong>g approximate waterlimits at time of sampl<strong>in</strong>g and sampl<strong>in</strong>g locations (courtesy of Google Earth)......143Figure 12-9. Horizon City MUD north evaporation pond show<strong>in</strong>g the sampled water; outfallis on the far left-hand side of the picture beh<strong>in</strong>d the trees......................................144Figure 12-10. Horizon MUD south pond (not active) be<strong>in</strong>g scraped ..........................................144Figure 12-11. Aerial view of evaporation pond of City of Abilene desal<strong>in</strong>ation facilityshow<strong>in</strong>g sampl<strong>in</strong>g location (courtesy of Google Earth) .........................................145Figure 12-12. City of Abilene east pond show<strong>in</strong>g some of the sampled water (“2” and “3”).....146Figure 12-13. City of Abilene west pond show<strong>in</strong>g the l<strong>in</strong>ers emplaced to control wave action .146Figure 12-14. Aerial view of the evaporation pond of City of Brady desal<strong>in</strong>ation facilityshow<strong>in</strong>g sampl<strong>in</strong>g location (courtesy of Google Earth) .........................................147Figure 12-15. City of Brady evaporation pond show<strong>in</strong>g the sampled water ...............................148Figure 12-16. City of Brady evaporation pond seen from the western berm. The pond water isvisible under the l<strong>in</strong>e of vegetation on the right-hand side of the picture...............148Figure 15-1. M<strong>in</strong>eral precipitation sequence as evaporation progresses us<strong>in</strong>g computedconcentrate as the source <strong>in</strong> noneng<strong>in</strong>eered conditions ..........................................167Figure 15-2. Comparison of results of selected groups run with different databases: mixedalluvium with Pitzer (a), mixed alluvium with LLNL (b), surface water withPitzer (c), and surface water with LLNL (d)...........................................................175Figure 15-3. Specific accumulation (<strong>in</strong>ches) and sepiolite fraction <strong>in</strong> accumulation <strong>for</strong> twopond depths (3 and 12 <strong>in</strong>ches) <strong>for</strong> all water groups................................................176Figure 15-4. M<strong>in</strong>eral precipitation sequence as evaporation progresses us<strong>in</strong>g computedconcentrate as the source <strong>in</strong> eng<strong>in</strong>eered conditions (0.01 mol/L of sepioliteprecursor compounds).............................................................................................184Figure 15-5. Specific accumulation (<strong>in</strong>ches) and sepiolite fraction <strong>in</strong> accumulation <strong>for</strong> allwater groups <strong>in</strong> eng<strong>in</strong>eered and natural sett<strong>in</strong>gs (pond depth is 3 <strong>in</strong>ches)..............192vi

Figure 15-6. M<strong>in</strong>eral precipitation sequence as evaporation progresses us<strong>in</strong>g computedconcentrate as the source <strong>in</strong> noneng<strong>in</strong>eered conditions—Ca-Montmorillonite(d)is allowed to precipitate ..........................................................................................200Figure 17-1. Conceptual draw<strong>in</strong>g ((layout and cross-section) of evaporation pond <strong>for</strong> facility<strong>in</strong> quadrangle 608....................................................................................................215vii

List of TablesTable 2-1. Concentrate disposal method statistics (<strong>Texas</strong> PWS plants with ≥0.025 MGD DC).....8Table 2-2. Characteristic summary of <strong>Texas</strong> desal<strong>in</strong>ation facilities with capacity ≥0.025MGD and us<strong>in</strong>g evaporation pond <strong>for</strong> disposal..........................................................11Table 3-1. List of water sample groups (12,720 samples).............................................................25Table 4-1. Feedwater and concentrate chemical composition from a few Middle Easterndesal<strong>in</strong>ation facilities..................................................................................................43Table 4-2. Facility characteristics..................................................................................................44Table 4-3. Feedwater and concentrate chemical composition from selected <strong>Texas</strong>desal<strong>in</strong>ation facilities..................................................................................................46Table 4-4. Mix<strong>in</strong>g parameter <strong>for</strong> monthly periods.........................................................................54Table 4-5. Important allowed (“A”) and suppressed (“S”) m<strong>in</strong>erals.............................................56Table 4-6. Average m<strong>in</strong>eral accumulation thickness and sepiolite fraction at 5 and 30 years <strong>in</strong>a 3-<strong>in</strong>ch-depth pond <strong>in</strong> noneng<strong>in</strong>eered conditions (assumes a porosity of 0%).........62Table 4-7. Average m<strong>in</strong>eral accumulation thickness and sepiolite fraction at 5 years <strong>in</strong> a 3–<strong>in</strong>ch-depth pond <strong>in</strong> noneng<strong>in</strong>eered and eng<strong>in</strong>eered conditions (assumes a porosityof 0%).........................................................................................................................63Table 4-8. Average m<strong>in</strong>eral accumulation thickness and sepiolite fraction at 30 years <strong>in</strong> a 3-<strong>in</strong>ch-depth pond <strong>in</strong> noneng<strong>in</strong>eered and eng<strong>in</strong>eered conditions (assumes a porosityof 0%).........................................................................................................................64Table 4-9. Generic pond size <strong>for</strong> 1-MGD facilities located near the sampled ponds....................66Table 4-10. Pond water balance <strong>for</strong> quadrangle 709, represent<strong>in</strong>g the River Oaks Ranch site....67Table 4-11. Pond water balance <strong>for</strong> quadrangle 608, represent<strong>in</strong>g the Brady site. .......................68Table 4-12. Pond water balance <strong>for</strong> quadrangle 508, represent<strong>in</strong>g the Abilene site. ....................69Table 4-13. Pond water balance <strong>for</strong> quadrangle 601, represent<strong>in</strong>g the Horizon MUD site...........70Table 4-14. Conta<strong>in</strong>ment equivalence summary ...........................................................................73Table 4-15. Summary of approximate costs and cost sav<strong>in</strong>gs features <strong>for</strong> generic evaporationponds ..........................................................................................................................76Table 8-1. Samples best represent<strong>in</strong>g the central value of each group (units are ppm) ................93Table 11-1. Chemical analysis results of Panhandle sal<strong>in</strong>e lake, summer 2006 field sampl<strong>in</strong>g..129Table 11-2. X-ray analyses of sal<strong>in</strong>e lake sediments (f<strong>in</strong>e-gra<strong>in</strong>ed fraction) ..............................129Table 12-1. X-ray analyses of pond bottom sediments and crusts ..............................................133Table 12-2. <strong>Evaporation</strong> pond sampl<strong>in</strong>g results ..........................................................................134Table 13-1. Physical characteristics of clay m<strong>in</strong>erals.................................................................152Table 13-2. Environmental conditions <strong>for</strong> magnesian clay associations.....................................154Table 15-1. Correspondence table between evaporation progress as given <strong>in</strong> plot abscissa andduration (calendar years) ..........................................................................................165ix

Glossary and AbbreviationsADEQ Arizona Department of Environmental QualityARS Arizona Revised StatutesASTM American Society <strong>for</strong> Test<strong>in</strong>g and MaterialsBADCTCWADCDODWEDEDREPEPAGCLGWHDPEINDIRRiWUDLALLNLMCLMFMGDmilNCDCNFNMACNMEDNPDESNRCSOACODEQBest Available Demonstrated Control TechnologyClean Water ActDesign capacityDissolved oxygenDr<strong>in</strong>k<strong>in</strong>g waterElectrodialysisElectrodialysis reversal<strong>Evaporation</strong> pondEnvironmental Protection AgencyGeosynthetic clay l<strong>in</strong>erGroundwaterHigh-density polyethyleneIndustrialIrrigationTCEQ water utility database search eng<strong>in</strong>eLand applicationLawrence Livermore National LaboratoryMaximum contam<strong>in</strong>ant levelMicrofiltrationMillion gallons per day1/1000 th of 1 <strong>in</strong>chNational Climatic Data CenterNanofiltrationNew Mexico Adm<strong>in</strong>istrative CodeNew Mexico Environment DepartmentNational Pollutant Discharge Elim<strong>in</strong>ation SystemNatural Resources Conservation Service (<strong>in</strong> New Mexico)Oklahoma Adm<strong>in</strong>istrative CodeOklahoma Department of Environmental Qualityxi

ppmPVCPWSROSISSEPSWSWATSTACTCEQTCLPTDSTLAPTNRCCTNRISTPDESTWDBUFUSGSWWTPpart per millionPolyv<strong>in</strong>yl chloridePublic water systemReverse osmosisSaturation <strong>in</strong>dex<strong>Self</strong>-seal<strong>in</strong>g evaporation pondSurface waterSurface Water and Treatment System<strong>Texas</strong> adm<strong>in</strong>istrative code<strong>Texas</strong> Commission on Environmental QualityToxicity Characteristic Leach<strong>in</strong>g ProcedureTotal dissolved solids<strong>Texas</strong> Land Application Permit<strong>Texas</strong> Natural Resources Conservation Commission; name changed to TCEQ<strong>Texas</strong> Natural Resources In<strong>for</strong>mation System<strong>Texas</strong> Pollutant Discharge Elim<strong>in</strong>ation System<strong>Texas</strong> Water Development BoardUltrafiltrationUnited States Geological SurveyWastewater treatment plantxii

AcknowledgmentsThe authors would like to thank all <strong>in</strong>dividuals and organizations that helped make this worksuccessful. Patrick V. Brady, senior researcher and project manager at Sandia NationalLaboratories, revived the concept of self-seal<strong>in</strong>g evaporation ponds <strong>for</strong> desal<strong>in</strong>ation facilities.James Krumhansl, senior researcher also at Sandia, did X-ray analyses of the sal<strong>in</strong>e lake andevaporation pond sediments at no charge. Andrew Tachovsky at BEG collected the sal<strong>in</strong>e lakesamples and did the cation chemical analyses. Thanks to David Yohe, Henry Ochella (RiverOaks plant), and Toby Alvarado and Joe Paxton (Horizon MUD) from ECO Resources, Inc., <strong>for</strong>allow<strong>in</strong>g us to visit and sample their facilities. Thanks also to Kenny Hutch<strong>in</strong>s and RodneyTaylor (City of Abilene) and Rufus Beam (City of Brady) <strong>for</strong> their help <strong>in</strong> sampl<strong>in</strong>g water atvarious locations of their facility. Thanks to Sanjeev Kalaswad at the <strong>Texas</strong> Water DevelopmentBoard (TWDB) and Travis Swanson (BEG) <strong>for</strong> their help <strong>in</strong> the sampl<strong>in</strong>g.We would also like to thank the <strong>Texas</strong> Commission on Environmental Quality (TCEQ) staff, <strong>in</strong>particular, Kelly Holligan, Michael Chadwick, and Kathy H. Brown, <strong>for</strong> their <strong>in</strong>put on theregulatory aspects. We also benefited from discussions with Jorge Arroyo, Team Leader atTWDB, and Hari Krishna, Contract Manager, also at TWDB. We are grateful as well to LanaDieterich <strong>for</strong> the thorough edit<strong>in</strong>g of this report.xiii

Executive SummaryThe State of <strong>Texas</strong> has taken a renewed <strong>in</strong>terest <strong>in</strong> desal<strong>in</strong>ation of brackish water. Because the<strong>Texas</strong> population is expected to grow tremendously <strong>in</strong> com<strong>in</strong>g decades, many municipalities andother water-supply<strong>in</strong>g entities will need to supplement their current fresh-water sources.<strong>Desal<strong>in</strong>ation</strong> of brackish water is high on the list of water-source alternatives <strong>for</strong> supply<strong>in</strong>g someor all of the <strong>in</strong>creased water needs <strong>in</strong> many communities. However, disposal of desal<strong>in</strong>ationconcentrates may pose legal, technical, and economic barriers, especially <strong>for</strong> smallercommunities with water supplies of less than one million gallons per day (MGD). In this report,we exam<strong>in</strong>e evaporation ponds and the possibility of <strong>in</strong>corporat<strong>in</strong>g a low-permeability layer(precipitant) <strong>in</strong>to the pond-l<strong>in</strong>er system as a l<strong>in</strong>er component or possibly as the l<strong>in</strong>er itself. Oneaspect of this analysis was to <strong>in</strong>vestigate the regulatory requirements and barriers of us<strong>in</strong>g selfseal<strong>in</strong>gponds, if this strategy proves to be a technically viable alternative to standard pond l<strong>in</strong>ers.Another part of the work consisted of understand<strong>in</strong>g the favorable chemical conditions, naturalor <strong>in</strong>duced, <strong>for</strong> the precipitation of such a compound(s). The third and last facet of this work wasto <strong>in</strong>vestigate the sav<strong>in</strong>gs or extra costs of this approach.The follow<strong>in</strong>g observations characterize the regulatory issues relat<strong>in</strong>g to self-seal<strong>in</strong>g pond l<strong>in</strong>ers.(1) No significant regulatory barriers currently exist that would prevent the permitt<strong>in</strong>g of selfseal<strong>in</strong>gevaporation pond-l<strong>in</strong>er technologies at desal<strong>in</strong>ation facilities <strong>in</strong> <strong>Texas</strong>. (2) No Federalauthorizations are required, but a <strong>Texas</strong> Land Application Permit (TLAP) must be obta<strong>in</strong>ed fromthe <strong>Texas</strong> Commission on Environmental Quality (TCEQ) Water Quality Division. (3) TCEQhas considerable latitude <strong>for</strong> approv<strong>in</strong>g alternative permit requirements <strong>for</strong> <strong>in</strong>dustrial permits.Rules <strong>for</strong> municipal wastewater treatment are used as guides <strong>for</strong> the evaluation of <strong>in</strong>dustrialevaporation ponds but do not impose strict regulatory requirements. Currently approved pondl<strong>in</strong>ers <strong>in</strong>clude a 3-foot-thick layer of <strong>in</strong> situ clay or compacted clay (with a maximum hydraulicconductivity of 10 -7 cm/s) or a geomembrane l<strong>in</strong>er (polyv<strong>in</strong>yl chloride [PVC], high-densitypolyethylene [HDPE], butyl rubber, polypropylene, etc) of 30 mils (0.76 mm) or more with leakdetectionmonitor<strong>in</strong>g. An alternative l<strong>in</strong>er technology may be approved by TCEQ if it can bedemonstrated to achieve and ma<strong>in</strong>ta<strong>in</strong> equivalent conta<strong>in</strong>ment capabilities to the pre-approvedl<strong>in</strong>ers and that the result<strong>in</strong>g l<strong>in</strong>er material(s) will not deteriorate because of reactivity withsal<strong>in</strong>ity or other compounds <strong>in</strong> the effluent stream or other ambient conditions. Support<strong>in</strong>gdemonstration <strong>in</strong><strong>for</strong>mation may <strong>in</strong>clude previous research, pilot projects, and monitor<strong>in</strong>g datafrom exist<strong>in</strong>g operational facilities currently utiliz<strong>in</strong>g the proposed technology. Regulatoryprocess<strong>in</strong>g <strong>for</strong> the permitt<strong>in</strong>g of an evaporation pond could be simplified if the self-seal<strong>in</strong>gtechnology were recognized by the TCEQ as an accepted type of l<strong>in</strong>er, equivalent to compactedclay or geomembrane l<strong>in</strong>ers. No statutory change or rulemak<strong>in</strong>g would be required to revise thepermit <strong>in</strong>structions to add self-seal<strong>in</strong>g pond l<strong>in</strong>ers to the list of acceptable methods, althoughcompell<strong>in</strong>g scientific and eng<strong>in</strong>eer<strong>in</strong>g evidence would be necessary to justify such amodification.The technical part of this study started with the assessment of previous laboratory experimentsand natural analogs, such as sal<strong>in</strong>e lakes. The assessment suggests that precipitation of a specificclay m<strong>in</strong>eral called sepiolite, which is composed of mostly magnesium oxide and silica, couldhave many advantages. It has the flow properties of clay m<strong>in</strong>erals but is not expandable whenexposed to water or to a change <strong>in</strong> sal<strong>in</strong>ity or aqueous ionic makeup. Despite the absence ofsepiolite <strong>in</strong> the few samples collected from <strong>Texas</strong> evaporation ponds, geochemical numerical1

simulations per<strong>for</strong>med us<strong>in</strong>g U.S. Geological Survey (USGS) code PHREEQC suggests thatsepiolite does precipitate <strong>in</strong> evaporation ponds but <strong>in</strong> small quantities. Calcite and gypsum arethe two m<strong>in</strong>erals that precipitate <strong>in</strong> significant amounts. After 5 years of operation, an averageprecipitate thickness is approximately 0.15 <strong>in</strong>ch, conta<strong>in</strong><strong>in</strong>g about 15% sepiolite, with largegeographic variability. Addition of low-cost sepiolite precursors to the concentrate stream hasbeen shown to <strong>in</strong>crease the amount of sepiolite precipitated (with a pH ma<strong>in</strong>ta<strong>in</strong>ed at 8.5), to anaverage of 0.38 <strong>in</strong>ch after 5 years of operation, with a sepiolite fraction of approximately 60%.Water-chemical composition <strong>in</strong>puts to the numerical simulations were derived from databasesconta<strong>in</strong><strong>in</strong>g <strong>in</strong><strong>for</strong>mation on thousands of brackish groundwater samples at the <strong>Texas</strong> WaterDevelopment Board (TWDB) and surface-water samples from TCEQ. They were categorized<strong>in</strong>to 20 groups correspond<strong>in</strong>g to aquifers or group of aquifers, except <strong>for</strong> one group comprisedentirely of all surface-water samples. Although the range and variety of water composition arelarge, results are essentially qualitatively similar <strong>for</strong> all groups: without precursors, mostlycalcite, gypsum, and some m<strong>in</strong>or m<strong>in</strong>erals precipitate, whereas with addition of precursors, asignificant amount of sepiolite can precipitate. This study did not per<strong>for</strong>m laboratoryexperiments on the precipitates and, there<strong>for</strong>e, does not present <strong>in</strong>dependent hydraulicconductivity analyses. However, other <strong>in</strong>vestigators have measured hydraulic conductivity of avariety of precipitants <strong>in</strong> laboratory experiments. They have observed that measured conductivityvalues of the precipitant are still too high and above the threshold value of 10 -7 cm/s. Overall,while develop<strong>in</strong>g self-seal<strong>in</strong>g ponds is not technically challeng<strong>in</strong>g, do<strong>in</strong>g so at a lower cost thanthat of present simple technology may be difficult.The regulation section of this study showed that the practical way to make use of self-seal<strong>in</strong>gproperties is to exercise an option to demonstrate that the alternative l<strong>in</strong>er will achieve equivalentconta<strong>in</strong>ment. Even <strong>in</strong> the case of pre-approved l<strong>in</strong>ers, self-seal<strong>in</strong>g deposition could beadvantageous <strong>in</strong> sett<strong>in</strong>gs where an additional defense-<strong>in</strong>-depth layer is needed, such as areas withan underly<strong>in</strong>g unconf<strong>in</strong>ed aquifer sensitive to contam<strong>in</strong>ation.Substantial sav<strong>in</strong>gs can be achieved if waivers are granted. Sav<strong>in</strong>gs can be as high as 90% if thepond consists of little more than an excavation <strong>in</strong>to the ground. Large sav<strong>in</strong>gs may also beachieved if the leak-detection system is not required <strong>for</strong> geomembrane l<strong>in</strong>ers. Our analysissuggests that the precipitant, even with a hydraulic conductivity >1×10 -7 cm/s could efficientlyplug holes and defects of the geomembrane. This analysis also suggests that, because defects andholes can be plugged with no operator <strong>in</strong>tervention, a th<strong>in</strong>ner geomembrane could be used, <strong>in</strong>comb<strong>in</strong>ation or not with the leak detection system waiver. This possibility, however, needs to beconfirmed by experiments and pilot tests.On the other hand, equivalent conta<strong>in</strong>ment can be achieved <strong>for</strong> clay l<strong>in</strong>ers—common <strong>in</strong> <strong>Texas</strong>—mostly by sheer accumulation of the precipitated material at the bottom of the pond. The modestthickness of at most a few <strong>in</strong>ches of precipitant after a few years of operation suggests that theprecipitated material needs to have a hydraulic conductivity much lower than 1×10 -7 cm/s toimpart the required properties to a scaled-down l<strong>in</strong>er and to be successfully substituted <strong>in</strong> part orall of the clay l<strong>in</strong>er. As <strong>in</strong> the case of geomembranes, precipitant may plug small cracks thatcould appear throughout the life of the pond, reduc<strong>in</strong>g the cost of operator <strong>in</strong>tervention.In summary:2

- There are no regulatory hurdles <strong>in</strong> us<strong>in</strong>g self-seal<strong>in</strong>g evaporation ponds; however, theburden of prov<strong>in</strong>g the validity of the approach <strong>in</strong> each specific case is on the permitapplicant.- Calcite and gypsum are the most common m<strong>in</strong>eral precipitates. Some clay m<strong>in</strong>eral(s)(notably sepiolite) may also precipitate, especially if additives are added to theconcentrate stream. M<strong>in</strong>erals, however, precipitate <strong>in</strong> small amounts (typically

1 Introduction<strong>Evaporation</strong> ponds are a relatively simple and low-ma<strong>in</strong>tenance option <strong>for</strong> manag<strong>in</strong>g anddispos<strong>in</strong>g of desal<strong>in</strong>ation concentrate <strong>in</strong> small-scale applications. They may be particularlyattractive <strong>for</strong> small communities <strong>in</strong> arid environments with level topography and where landcosts are low. Typically the largest outlay <strong>for</strong> evaporation ponds is that of the constructed ormanufactured l<strong>in</strong>er—which might potentially leak. In some cases, the chemistry of theconcentrate can be changed with additives to create a relatively impermeable layer that makesthe base of the pond self seal<strong>in</strong>g. This study addresses the chemical, physical, legal, andeconomic conditions to be met <strong>for</strong> the use of self-seal<strong>in</strong>g evaporation ponds <strong>in</strong> <strong>Texas</strong> by(1) determ<strong>in</strong><strong>in</strong>g ranges of likely membrane concentrate compositions <strong>in</strong> <strong>Texas</strong>, (2) calculat<strong>in</strong>gthe ability of additives to impart self-seal<strong>in</strong>g characteristics to the pond walls and bottom,(3) exam<strong>in</strong><strong>in</strong>g any regulatory constra<strong>in</strong>ts to reliance on self-seal<strong>in</strong>g evaporation ponds, and(4) provid<strong>in</strong>g cost estimates <strong>for</strong> a self-seal<strong>in</strong>g evaporation pond <strong>for</strong> a 1-million-gallon-per-day(MGD) brackish groundwater desal<strong>in</strong>ation facility.The present report documents results <strong>for</strong> the three tasks described <strong>in</strong> the scope of work ofContract # 2005-483-027 “<strong>Self</strong>-seal<strong>in</strong>g <strong>Evaporation</strong> <strong>Ponds</strong>.” Task 1 consisted of a mostlydesktop geochemistry study aimed at understand<strong>in</strong>g the technical basis beh<strong>in</strong>d the concept andaddressed items (1) and (2) above. The geochemistry work was per<strong>for</strong>med <strong>in</strong> parallel to, but<strong>in</strong>dependent of, similar work per<strong>for</strong>med at Sandia National Laboratory (Sandia) under thedirection of Dr. Patrick Brady. A study of the regulatory aspects was undertaken <strong>in</strong> Task 2.Task 3 consisted of estimat<strong>in</strong>g cost <strong>in</strong>frastructure and potential sav<strong>in</strong>gs and of design<strong>in</strong>g ageneric self-seal<strong>in</strong>g evaporation pond.The report first gives an overview of relevant <strong>in</strong><strong>for</strong>mation on desal<strong>in</strong>ation facilities <strong>in</strong> <strong>Texas</strong>(Section 2). Section 2 also describes the scientific underp<strong>in</strong>n<strong>in</strong>gs of evaporation ponds andcomputes the net evaporation rates applicable across <strong>Texas</strong>. Section 3 lays out the sources of<strong>in</strong><strong>for</strong>mation <strong>for</strong> the water chemical composition and presents the general approach. Section 4successively presents the regulatory framework <strong>in</strong> <strong>Texas</strong> and <strong>in</strong> some southwestern states and thelikely composition of desal<strong>in</strong>ation concentrates across <strong>Texas</strong>. It then documents the geochemicalnumerical simulations and their results and moves on to describ<strong>in</strong>g design specifics and costestimates. Lengthy and/or secondary <strong>in</strong><strong>for</strong>mation has been attached <strong>in</strong> several appendices(derivation of water groups, documentation on regulation, example of a permit of an evaporationpond <strong>for</strong> desal<strong>in</strong>ation facility, results of field sampl<strong>in</strong>g, <strong>in</strong><strong>for</strong>mation on clay m<strong>in</strong>erals, a fewwords about those facilities with above-maximum contam<strong>in</strong>ant level (MCL) arsenic, andexamples and results of geochemical simulations).5

2 Background Technical In<strong>for</strong>mation on <strong>Evaporation</strong> <strong>Ponds</strong>2.1 <strong>Desal<strong>in</strong>ation</strong> PrimerAll public water supply (PWS) desal<strong>in</strong>ation facilities <strong>in</strong> <strong>Texas</strong> use membrane technology. Thereare two k<strong>in</strong>ds of membrane processes: pressure driven and electro-potential driven. Pressuredrivenmembrane processes are further described as microfiltration (MF), ultrafiltration (UF),nanofiltration (NF), and reverse osmosis (RO). MF and UF act only mechanically, block<strong>in</strong>gbacteria and suspended particles (10–0.05 μm) because they are too large to flow through themembrane pores. UF also blocks colloids and macromolecules (0.05–0.005 μm). In contrast, NF(0.005–0.0005 μm) blocks solutes as small as organic molecules and divalent ions. RO (0.001–0.0001 μm) blocks particles as small as monovalent ions. Both RO and NF operate ma<strong>in</strong>lythrough diffusion and chemical <strong>in</strong>teraction between membrane and solutes. NF is also calledlow-pressure RO, or water-soften<strong>in</strong>g membrane. NF removes more calcium and magnesium thanchloride, result<strong>in</strong>g <strong>in</strong> softer waters. NF also removes more sulfate and bicarbonate than chloride.The two electro-potential-driven processes are electrodialysis (ED) and electrodialysis reversal(EDR). The latter process is very similar to ED, with the added benefit of reduced scal<strong>in</strong>gbecause potentials are reversed periodically. However, ED/EDR does not remove unchargedspecies, such as silica. Below ~3,000 to 3,500 part per million total dissolved solids (ppm TDS),both RO and ED/EDR processes can be competitive and can produce low-sal<strong>in</strong>ity water at lowcost. RO plants are the most widely used <strong>in</strong> the nation <strong>for</strong> desal<strong>in</strong>ation, with 72 % of plants us<strong>in</strong>gbrackish-water RO, 2 % seawater RO, 15 % ED/EDR, and 11 % NF (Mickley, 2001).<strong>Desal<strong>in</strong>ation</strong> concentrates are produced dur<strong>in</strong>g removal of salts from low-quality water <strong>in</strong> ROand ED/EDR plants. The amount of concentrate as a percentage of feedwater varies accord<strong>in</strong>g todesal<strong>in</strong>ation method, percentage of recovery, and chemical additives. In RO systems thatproduce dr<strong>in</strong>k<strong>in</strong>g water, a typical pretreatment consists of acidification and addition ofantiscalant chemicals. Disposal of the concentrate could be a major issue <strong>in</strong> sit<strong>in</strong>g of a newfacility.2.2 <strong>Desal<strong>in</strong>ation</strong> <strong>Facilities</strong> <strong>in</strong> <strong>Texas</strong> <strong>in</strong> 2006A comprehensive survey of PWS desal<strong>in</strong>ation facilities <strong>in</strong> <strong>Texas</strong> was recently per<strong>for</strong>med <strong>for</strong> theTWDB (Nicot et al., 2005). The concentrate disposal method was one of the features<strong>in</strong>vestigated. The number of desal<strong>in</strong>ation facilities <strong>in</strong> <strong>Texas</strong> has <strong>in</strong>creased sharply <strong>in</strong> the pastdecade (Nicot et al., 2005). In 2005, the State of <strong>Texas</strong> was host to about 38 PWS facilities witha desal<strong>in</strong>ation design capacity of ≥0.025 million gallons a day (MGD), a cumulative desal<strong>in</strong>ationdesign capacity (DC) of ~52 MGD (Figure 2-2), and another approximately 50 facilities withsmaller desal<strong>in</strong>ation design capacity, <strong>for</strong> a cumulative desal<strong>in</strong>ation design capacity of

with a design capacity of ≥0.025 MGD (as of summer 2005) have evaporation ponds as anexclusive or nonexclusive method <strong>for</strong> dispos<strong>in</strong>g of concentrate (Table 2-1 and Table 2-2), towhich can be added many other PWS facilities with a design capacity of

ShermanAbileneLake GranburyHorizon Regional M.U.D.Rob<strong>in</strong>sonFort StocktonBrady<strong>Desal<strong>in</strong>ation</strong> DesignCapacity (MGD)0.023 - 0.050.05 - 0.50.5 - 11 - 33 - 55 - 8Dual-Use Facility¹PrimeraSWRA0 50 100 200 300 400MilesNote: Location of some facilities is only approximate; facilities with a desal<strong>in</strong>ation design capacity ≥1.5 MGD arenamed; map from Nicot et al. (2005)Figure 2-2. Map of desal<strong>in</strong>ation facilities show<strong>in</strong>g design capacity.#*")XW")")#*#*#* XWXWXW XW#*")#*Disposal MethodXW<strong>Evaporation</strong> Pond") Land Application#* Surface Water BodyXWMunicipal Sewer¹0 50 100 200 300 400MilesNote: Location of some facilities is only approximate; map from Nicot et al. (2005)Figure 2-3. Map of desal<strong>in</strong>ation facilities (≥0.025 MGD DC) show<strong>in</strong>g concentrate disposalmethod.XW#*XW#*#* #* #* ")#*#*XW9

#*")")%, #*")") #*#*#*%,Total Dissolved Solids (ppm)") Unknown

Table 2-2. Characteristic summary of <strong>Texas</strong> desal<strong>in</strong>ation facilities with capacity ≥0.025 MGDand us<strong>in</strong>g evaporation pond <strong>for</strong> disposal.DesignCapacity(MGD) Use SourceStartupYearBlend<strong>in</strong>g?DisposalMethodPlant Name CountyProcessPWS Plants with Design Capacity ~≥ 0.025 MGDCity ofAbilene Taylor 8 DW SW 2004 RO No EPCity of Brady McCulloch 1.5 DW SW D 2005 RO Yes EPRiver OaksRanch Hays 0.14 DW GW 1987 RO No EPMidlandCountry Club—fairways &greens A Midland 0.11DW/IRR GW 2004 RO No EPBig BendMotor Inn Brewster 0.072 DW GW 1992 RO No EPCity ofBayside Refugio 0.029 DW GW 1990 RO No EPHorizonRegionalM.U.D. El Paso 2.2 DW GW 2001 RO YesHaciendasDel NorteWaterImprovementDistrict El Paso 0.05 DW GW 1981 RO YesLA/IRR/EPLA/IRR/EPEsperanzaFresh WaterSupply Hudspeth 0.023 DW GW 1990 RO Yes EP BCity of LosYbanez Dawson 0.022 B DW GW 1991 RO Yes EP BOther Plants (not comprehensive) CTMPAGibbonsCreek Bryan 0.144 IND SW 1982 RO No EPCountryView Estates Med<strong>in</strong>a 0.014 DW GW 2002 RO Yes EPSource: Nicot et al. (2005); Mickley (2006) (see note B )Note: DW=dr<strong>in</strong>k<strong>in</strong>g water; IND=<strong>in</strong>dustrial; GW=groundwater; SW=surface water; RO=reverse osmosis;EDR=electrodialysis reversal; EP=evaporation pond; IRR=irrigation; LA=land applicationA Dual-use facility: public water supply and irrigationB Nicot et al. (2005) did not provide disposal method <strong>for</strong> those two facilities, but Mickley (2006) did(p. 59)C Survey presented <strong>in</strong> Nicot et al. (2005) does not systematically <strong>in</strong>vestigate plants with design capacity

2.3 How Do <strong>Evaporation</strong> <strong>Ponds</strong> Operate?Impoundments and conta<strong>in</strong>ment ponds are common <strong>in</strong> water/wastewater treatment and other<strong>in</strong>dustrial and agricultural operations. There is no fundamental difference between anevaporation pond and other types of conta<strong>in</strong>ment ponds, except <strong>for</strong>, by design, the lack of anoutlet. Regulatory requirements are similar (see Section 4.1). Typical evaporation ponds are notto be confused with sophisticated sal<strong>in</strong>ity-gradient solar ponds, whose pr<strong>in</strong>ciple relies on acontrast <strong>in</strong> sal<strong>in</strong>ity (Lu et al., 2002; Swift et al., 2002). Solar ponds function because of the largesal<strong>in</strong>ity/density gradient that prevents convection and mix<strong>in</strong>g of the dense lower layer anddissipation of the solar energy. They are, <strong>in</strong> general, delicate to operate and fundamentallyrepresent an energy-sav<strong>in</strong>g element more than a disposal feature. Solar lakes naturallyfunction<strong>in</strong>g as solar ponds have been observed (Hudec and Sonnenfeld, 1980; Sonnenfeld andHudec, 1980). They are, however, usually artificial, and all show a contrast <strong>in</strong> density betweentop and bottom of the water sheet of at least 15 g/L. The density contrast is often created byadd<strong>in</strong>g salt/br<strong>in</strong>e at the bottom of the pond.2.3.1 <strong>Evaporation</strong> Rates <strong>in</strong> <strong>Texas</strong>Monthly precipitation and evaporation data as given by TWDB (2006a) from 1954 to 2004 arepresented <strong>in</strong> detail <strong>in</strong> this section. Ambient temperature is another important parameter <strong>for</strong>geochemical model<strong>in</strong>g (Figure 2-6). Temperature data were obta<strong>in</strong>ed from the National ClimaticData Center (NCDC, 2006). <strong>Evaporation</strong> ponds rely on solar energy to reduce the liquid wastevolume by evaporat<strong>in</strong>g water. The rema<strong>in</strong><strong>in</strong>g liquid becomes more and more concentrated,lead<strong>in</strong>g to precipitation of m<strong>in</strong>erals at the bottom of the ponds. The nature of precipitat<strong>in</strong>gm<strong>in</strong>erals is site-specific and a strong function of the outfall chemical composition. Sludge maybe evacuated as part of normal operations <strong>in</strong> the course of the plant’s life, or it may rema<strong>in</strong> at thebottom of the pond until closure of the facility. In both cases, the sludge is generally directed to alandfill. <strong>Evaporation</strong> ponds operate best <strong>in</strong> climatic environments with limited ra<strong>in</strong>fall and highevaporation rates. <strong>Evaporation</strong> rates are reported <strong>in</strong> different ways: gross lake surfaceevaporation rate (depth that a lake surface is reduced by evaporation) and pan A evaporation rate,measured <strong>in</strong> a standard 10-<strong>in</strong>ch-deep, 4-foot-diameter pan. Only the latter is directly accessible<strong>for</strong> measurement, and a correction must be applied to obta<strong>in</strong> the <strong>for</strong>mer, which is the parameterof <strong>in</strong>terest. The correction factor, also called the pan coefficient, varies through the year and islocation specific (0.57 to 0.92 across <strong>Texas</strong>, TWDB, 2006a). So that mean<strong>in</strong>gful gross lakeevaporation rates could be generated, it was decided <strong>in</strong> 1960 (Tschirhart and Rodriguez, 1998,p. 4) that the smallest practical area <strong>for</strong> evaporation calculation was a square 1° latitude and 1°longitude <strong>in</strong> size (as apparent <strong>in</strong> Figure 2-9). A total of 75 quadrangles cover <strong>Texas</strong>.Net evaporation rate is site specific. It is positive on an annual basis when annual precipitationrate (Figure 2-7) is smaller than annual evaporation rate (Figure 2-8). Net evaporation ratefollows the general weather patterns and most of <strong>Texas</strong>, and except <strong>for</strong> a limited band along theLouisiana border, net annual evaporation rates are positive (Figure 2-9). A study by Moore andRunkles (1968, figures 18–24) shows a similar pattern, although they used different pancoefficients, now out of date, result<strong>in</strong>g <strong>in</strong> different absolute values of net annual evaporation rate.Many reports document the impact of sal<strong>in</strong>ity on evaporation rate (e.g., Harbeck, 1955). Mickley(2006, p. 162) suggested apply<strong>in</strong>g a coefficient of 0.7 to account <strong>for</strong> the sal<strong>in</strong>ity of the pond.When such a coefficient is applied, the areas with positive net evaporation rates are shiftedsomewhat to the west (Figure 2-10 and Figure 2-11). In calculation of net evaporation rates,12

“evaporation × sal<strong>in</strong>ity correction factor – precipitation” was calculated on a yearly basis thenaveraged and not done simply on evaporation and precipitation averages. A value of 0.7 isappropriate only if the ponds are projected to reach salt saturation dur<strong>in</strong>g their expected lives.Our sampl<strong>in</strong>g of a few <strong>Texas</strong> evaporation ponds (Appendix E) suggests that they do not reachextreme sal<strong>in</strong>ity (that is, >30% salt by weight). A sal<strong>in</strong>ity correction factor of 0.9 (“low-sal<strong>in</strong>ity”water body—Figure 2-10) is used <strong>in</strong> the course of this work. This correction factor would beapplied to sal<strong>in</strong>ity <strong>in</strong> the 100,000- to 150,000-ppm range (Harbeck, 1955, Fig. 2). The lower endof the concentration range corresponds to a small fresh-water evaporation rate, whereas the highend of the concentration range corresponds to an annual fresh-water evaporation rate of ~150<strong>in</strong>ches/yr (Harbeck, 1955, Fig. 2).13

Average JulyTemperature (Deg. C)15.6 - 21.121.1 - 26.726.7 - 32.2¹(a)Average Annual Temperature (Deg. C)10.0 - 12.812.8 - 15.615.6 - 18.318.3 - 21.1> 21.1¹0 50 100 200 300 400Miles(b)Source: NCDC Website (NCDC, 2006); desal<strong>in</strong>ation facility capacity from Nicot et al. (2005)Figure 2-6. Average temperature (a) month of July, (b) annual.14

¹0 100 200 300 40050MilesSource: <strong>Desal<strong>in</strong>ation</strong> facility capacity from Nicot et al. (2005); annual precipitation rate from TWDB Website(TWDB, 2006a)Figure 2-7. Average annual precipitation rate.15

¹0 50 100 200 300 400MilesSource: <strong>Desal<strong>in</strong>ation</strong> facility capacity from Nicot et al. (2005); annual gross lake evaporation rate from TWDBWebsite (TWDB, 2006a)Figure 2-8. Average annual gross lake evaporation rate.16

¹0 50 100 200 300 400MilesSource: <strong>Desal<strong>in</strong>ation</strong> facility capacity from Nicot et al. (2005); annual precipitation and gross lake evaporation ratefrom TWDB Website (TWDB, 2006a)Figure 2-9. Net average annual fresh-water evaporation rates across <strong>Texas</strong>.17

¹0 50 100 200 300 400MilesSource: <strong>Desal<strong>in</strong>ation</strong> facility capacity from Nicot et al. (2005); annual precipitation and gross lake evaporation ratefrom TWDB Website (TWDB, 2006a); sal<strong>in</strong>ity correction factor of 0.9 is applied to gross lake evaporationrate to account <strong>for</strong> the water sal<strong>in</strong>ityFigure 2-10. Net average annual evaporation rates across <strong>Texas</strong> from a low-sal<strong>in</strong>ity water body.18

¹0 50 100 200 300 400MilesSource: <strong>Desal<strong>in</strong>ation</strong> facility capacity from Nicot et al. (2005); annual precipitation and gross lake evaporation ratefrom TWDB Website (TWDB, 2006a); multiplicative coefficient of 0.7 is applied to gross lake evaporationrate to account <strong>for</strong> the water sal<strong>in</strong>ityFigure 2-11. Net average annual evaporation rates across <strong>Texas</strong> from a high-sal<strong>in</strong>ity water body.2.3.2 Typical M<strong>in</strong>eral Suite—Chemical DivideIn the chemical evolution of an evaporation pond (with no overflow), general rules can be drawndespite the always complex chemical <strong>in</strong>teractions and geochemical site specificity. Major ionsmak<strong>in</strong>g up most groundwater—fresh or sal<strong>in</strong>e—are Ca +2 , Mg +2 , Na + , K + , SO 4 -2 , HCO 3 - , and Cl - ,to which SiO 2 can be added as a major neutral molecule. They <strong>for</strong>m the bulk of the m<strong>in</strong>eralsprecipitat<strong>in</strong>g when the solution is progressively concentrated. Most clay m<strong>in</strong>erals require Al toprecipitate. Al is generally present <strong>in</strong> m<strong>in</strong>ute amounts <strong>in</strong> solution but <strong>in</strong> much larger amounts asoxide/hydroxide colloids. As seen <strong>in</strong> an extensive geologic record, evaporation of seawater19

yields the follow<strong>in</strong>g precipitation sequence of major m<strong>in</strong>erals: calcite (CaCO 3 ), gypsum(CaSO 4 .2H 2 O), and halite (NaCl). Calcite precipitates right away, gypsum precipitates only afterapproximately 80% of seawater has been removed, and halite does so when ~90% hasevaporated. Because the activity of the water decreases as evaporation progresses, gypsum canbe replaced by an anhydrous calcium sulfate: anhydrite (CaSO 4 ). More complex precipitationfollows when about 95% of the water has been removed and when other ions start precipitat<strong>in</strong>g<strong>in</strong>to soluble salts (e.g., sylvite—KCl; carnallite—MgCl 2 .6H 2 O). It should be noted that this salttrajectory is specific to seawater and waters of similar chemical composition.In general, the first major m<strong>in</strong>erals to precipitate are calcite and gypsum, sometimesaccompanied by m<strong>in</strong>or authigenic clays. Common precipitates (calcite, gypsum, and anhydrite)have a retrograde solubility; that is, their solubility decreases with temperature. It follows that <strong>in</strong>the summer, when pond water is warmer than the concentrate, precipitation can occur with noevaporation. Despite the obvious parallel that these m<strong>in</strong>erals should dissolve back dur<strong>in</strong>g thew<strong>in</strong>ter because of their <strong>in</strong>creased solubility, the mass dissolved is typically less than the massprecipitated because fluid-m<strong>in</strong>eral <strong>in</strong>teractions are limited ow<strong>in</strong>g to the smaller surface areaexposed to the aqueous environment. Such seasonal temperature variations were not addressed <strong>in</strong>this work. Evaporative concentration of groundwater follows well-known chemical pathwayswith multiple chemical divides. If aqueous concentrations <strong>in</strong>crease, some m<strong>in</strong>erals becomesupersaturated and start precipitat<strong>in</strong>g, remov<strong>in</strong>g ions from solution. Calcium is a prime example,and it precipitates with bicarbonate and sulfate as calcite or gypsum, respectively. However,when the system is open to the atmosphere, bicarbonate concentration cannot rise as high as thatof sulfate (e.g., Boyd and Kreitler, 1986, Fig. 11) and stays more or less constant <strong>in</strong> equilibriumwith atmospheric CO 2 . Hardie and Eugster (1970) and Eugster and Jones (1979) described ageneric evolution (Figure 2-12):Source: Boyd and Kreitler (1986, p. 28) and Domenico and Schwartz (1990, p. 554)Figure 2-12. Conceptual model of concentrate evolution.This is the pr<strong>in</strong>ciple of chemical divide with critical po<strong>in</strong>ts. Calcite is often the first m<strong>in</strong>eral toprecipitate from evaporation of groundwater (e.g., caliche layers), accord<strong>in</strong>g to the reactionCa 2+ + 2 HCO 3 - = CaCO 3 + CO 2 + H 2 O. If calcium concentration (<strong>in</strong> equivalents) is higher thanthat of bicarbonate, calcium will be available to precipitate with sulfate to <strong>for</strong>m gypsum. If not,20

most calcium will be consumed, and magnesium will then be available to precipitate as sepiolite.Sepiolite was chosen as the magnesium s<strong>in</strong>k <strong>in</strong> the Hardie and Eugster (1970) model because it isconsistent with observations of sal<strong>in</strong>e lakes of some western states. However, the chemistry ofmagnesium silicates is complex, and this choice may not be appropriate <strong>in</strong> all cases. Drever(1988, p. 239) stated that the most common magnesium m<strong>in</strong>erals are magnesium smectites,dolomite, or magnesium-rich calcite. In this work, ow<strong>in</strong>g to cont<strong>in</strong>uous dilution of the pondwater by outfall water, precipitation is limited to the most <strong>in</strong>soluble m<strong>in</strong>erals, and the wholesequence of evaporites does not occur.Other major ions, such as sodium and chloride, stay <strong>in</strong> solution longer and may precipitatetogether as halite. No major reaction controls sodium concentration <strong>in</strong> the way that calcium iscontrolled by the precipitation of calcite and gypsum. Sodium <strong>in</strong>teractions with clays have, <strong>in</strong>general, a limited impact on sodium aqueous concentration. Magnesium is the third mostabundant ion <strong>in</strong> seawater, although a distant third to sodium and chloride. Dolomites are a majors<strong>in</strong>k, but they typically result from the <strong>in</strong>teraction of limestones with magnesian br<strong>in</strong>es.Potassium concentration is controlled mostly by <strong>in</strong>teractions with clay m<strong>in</strong>erals. At high ionicstrength, it will also precipitate <strong>in</strong> sylvite (KCl) and other evaporites.2.4 Geochemical Model<strong>in</strong>g In<strong>for</strong>mationThe USGS-developed code PHREEQC (Parkhurst and Appelo, 1999) was used <strong>in</strong> thesimulations. Several thermodynamic databases are available to the user, <strong>in</strong>clud<strong>in</strong>g Pitzer andLLNL databases. Because of the <strong>in</strong>creas<strong>in</strong>g ionic strength of pond water as the pond matures, thePitzer database provided with the freeware was used. Only major ions (calcium, magnesium,sodium, potassium, chloride, sulfate, and bicarbonate) are relevant <strong>for</strong> the simulations at handbecause <strong>in</strong>terest is <strong>in</strong> the bulk of the precipitation and not <strong>in</strong> less common species.Thermodynamic <strong>in</strong><strong>for</strong>mation <strong>for</strong> relevant m<strong>in</strong>eral species not present <strong>in</strong> the Pitzer database wasimported from the LLNL database, especially m<strong>in</strong>erals such as alum<strong>in</strong>um and/or silica <strong>in</strong> theirstructure. Such an addition renders results of the study more semiquantitative than if only theofficial Pitzer database had been used. In<strong>for</strong>mation about m<strong>in</strong>eral molar volume was obta<strong>in</strong>edfrom the EQ3/6 data0 database (e.g., Daveler and Wolery, 1992).21

3 Approach and Sources of In<strong>for</strong>mationIn agreement with the scope of work, this project has two ma<strong>in</strong> objectives: (1) to determ<strong>in</strong>ewhether any regulatory hurdle will obstruct the use of self-seal<strong>in</strong>g evaporation ponds, especially<strong>in</strong> <strong>Texas</strong>, and (2) to assess the cost effectiveness of the self-seal<strong>in</strong>g technique through a desktopanalysis, supported by field data and a literature review. The two aspects of the project werepursued relatively <strong>in</strong>dependently. The regulatory analysis relied on <strong>in</strong>terviews with TCEQ staffat the Aust<strong>in</strong> headquarters, <strong>in</strong>terviews with desal<strong>in</strong>ation plant operators and utility managers, andconsultation of official documents (regulations, actual permits). The technical analysis could bedivided <strong>in</strong>to two parts. One part consisted of determ<strong>in</strong><strong>in</strong>g the amount and nature of the materialprecipitat<strong>in</strong>g from solution as water evaporates from the pond by us<strong>in</strong>g a numerical geochemicalmodel. Un<strong>for</strong>tunately, such a desktop analysis does not provide hydraulic conductivity data; onlyfield and laboratory experiments can do so. Instead, several publications supplied the needed<strong>in</strong><strong>for</strong>mation. The second part of the technical analysis <strong>in</strong>volved <strong>in</strong>tegrat<strong>in</strong>g diverse regulatoryoptions with the <strong>in</strong>sights provided by model<strong>in</strong>g to quantify possible cost sav<strong>in</strong>gs <strong>in</strong> implement<strong>in</strong>ga self-seal<strong>in</strong>g pond.This section focuses mostly on the methodology used to establish composition of feedwater <strong>for</strong>desal<strong>in</strong>ation facilities across the state. Nature and amount of precipitates are a function of thefeedwater and concentrate chemical composition. A later section (Section 4.2) will show that thechemical nature of the concentrate is not changed by RO and that it can be <strong>in</strong>ferred <strong>in</strong> generalterms from the feedwater chemical composition.3.1 Feedwater ChemistryIn order to produce results specific to <strong>Texas</strong>, specific water chemical composition from <strong>Texas</strong>had to be used. <strong>Desal<strong>in</strong>ation</strong> facility feedwater can be from either groundwater or surface water.Brackish groundwater is available across the state, but surface water is also an option <strong>in</strong> thenortheast quarter of the state. Source <strong>in</strong><strong>for</strong>mation and preprocess<strong>in</strong>g of water samples aredescribed next. Because water chemical composition is used <strong>in</strong> geochemical model<strong>in</strong>g, str<strong>in</strong>gentconditions must be applied on the set of samples reta<strong>in</strong>ed <strong>for</strong> analysis.3.1.1 Groundwater DataThe TWDB groundwater database (TWDB, 2006b) conta<strong>in</strong>s approximately 105,000 waterqualitysamples from about 55,000 unique locations across the state (<strong>in</strong>clud<strong>in</strong>g ~1,600 samplesrepresent<strong>in</strong>g a mix from two aquifers). We first selected all samples with a TDS >1,000 mg/Land 1,000 mg/Land

pH data or pH outside of the 5–9.5 range, or with a TWDB-def<strong>in</strong>ed reliability of “01” or “02”(Nordstrom and Qu<strong>in</strong>cy, 1999) had been deleted, the number of acceptable samples had beenreduced to 21,823. Keep<strong>in</strong>g only the most recent sample <strong>for</strong> each unique location brought thenumber of available samples to 13,583 over <strong>Texas</strong>, to 12,835 <strong>in</strong> areas with positive net annualevaporation rates, and to 7,642 <strong>in</strong> areas with high net annual evaporation rates (Figure 3-1).Positive net evaporation rates occur when potential evaporation rates are larger than precipitationrates. They can be def<strong>in</strong>ed with<strong>in</strong> a variety of time periods but are generally def<strong>in</strong>ed on an annualbasis.Samples are categorized accord<strong>in</strong>g to their concentration <strong>in</strong> major ions—calcium (Ca),magnesium (Mg), sodium (Na), potassium (K), chloride (Cl), sulfate (SO 4 ), and bicarbonate(HCO 3 )—to which silica (SiO 2 ) can be added, as represented on the Piper plot of Figure 8-2(Appendix A). Given the large variety of aquifer types <strong>in</strong> <strong>Texas</strong>, it is not surpris<strong>in</strong>g to see thatalmost every type of water is present <strong>in</strong> the state. In order to have a manageable data set, we firstdivided the larger set up <strong>in</strong>to smaller significant data sets, correspond<strong>in</strong>g to the selectedrepresentative samples <strong>for</strong> each aquifer (Table 3-1). A total of 12,720 samples were distributedamong 19 groundwater groups, correspond<strong>in</strong>g to TWDB-def<strong>in</strong>ed aquifers when possible. Forexample, the “Eocene” group <strong>in</strong>cludes the Carrizo-Wilcox major aquifers and the Queen City,Sparta, and Yegua-Jackson m<strong>in</strong>or aquifers, as well as other samples outside of these ma<strong>in</strong><strong>for</strong>mations, such as sandier facies of the Midway group (typically assumed to be the bottomconf<strong>in</strong><strong>in</strong>g unit of the Carrizo-Wilcox aquifer). On the other hand, the “Seymour,” the “BrazosRiver Alluvium,” and the “Ogallala” groups correspond to the Seymour, Brazos River Alluvium,and Ogallala aquifers, respectively. There is no TWDB-def<strong>in</strong>ed Rio Grande River Alluviumaquifer, but we def<strong>in</strong>ed a “Rio Grande Alluvium” group because of its specific geochemicalproperties. Similarly, there are several water-bear<strong>in</strong>g <strong>for</strong>mations of Pennsylvanian or Permianage <strong>in</strong> North-Central <strong>Texas</strong> between the TWDB-def<strong>in</strong>ed Ogallala and Tr<strong>in</strong>ity aquifers that havenot been officially sanctioned by the state as m<strong>in</strong>or or major aquifers. Because those groups areoperationally def<strong>in</strong>ed mostly <strong>for</strong> the purpose of understand<strong>in</strong>g their behavior <strong>in</strong> evaporationponds, some s<strong>in</strong>gle aquifers have been split to allow <strong>for</strong> the difference <strong>in</strong> lithology. For <strong>in</strong>stance,Tr<strong>in</strong>ity aquifer samples have been <strong>in</strong>cluded <strong>in</strong> either the “Cretaceous Limestone” or the“Cretaceous Sandstone” groups, depend<strong>in</strong>g on the nature of the host rock (e.g., Hosston Sands orGlenrose Limestone).Geochemical characteristics of the 19 groundwater groups (and the one surface-water groupdiscussed subsequently) are described <strong>in</strong> Appendix A. It should be noted that the geochemicalnature of the brackish samples does not necessarily represent that of the fresh-water samples ofthe same aquifers. One can consult the water-quality section of the relevant GAM models(http://www.twdb.state.tx.us/gam/<strong>in</strong>dex.htm) <strong>for</strong> a better picture of the geochemistry of a givenaquifer as a whole. Figure 3-2 plots the location of the central sample of each group (seeAppendix A) on a Piper plot and demonstrates the wide range of the chemical composition ofslightly brackish waters <strong>in</strong> the state. Out of the 20 groups, 4 stand out <strong>in</strong> their composition:Capitan Reef, Bone Spr<strong>in</strong>g / Victorio Peak, Permian Evaporite, and Brazos River Alluvium.Central values of all other groups occupy a relatively compact area of the Piper plot. They tendto plot toward the sodium and potassium apex, with calcium be<strong>in</strong>g generally second <strong>in</strong> molarconcentration and toward the chloride apex and sulfate second <strong>in</strong> anion abundance. PermianEvaporite water shows a dom<strong>in</strong>ant calcium sulfate water, whereas Capitan Reef and Bone Spr<strong>in</strong>g/ Victorio Peak waters also tend to a less-dom<strong>in</strong>ant calcium sulfate composition. Brazos RiverAlluvium has a strong bicarbonate impr<strong>in</strong>t and tends toward a calcium carbonate water type.24

Table 3-1. List of water sample groups (12,720 samples)Group NameNumber of Samples with TDS>1,000 and

Water samples with TDS between 1,000 and 5,000 ppmCounties with net evaporation >30 <strong>in</strong>ch/yrCounties with net evaporation >0 and

Mg20%AOLHCMGOAI40%Mixed Alluvium GroupBrazos River Alluvium GroupRio Grande Alluvium GroupSeymour GroupBolson GroupOgallala GroupPecos Valley Aquifer GroupGulf Coast Sandstone GroupEocene GroupCretaceous Limestone Group60%P80%80%60%20%40%20%40%40%SO 4 + Cl60%Na + K20%80%60%40%20%HCO 360%M MCAOGAPIHODLOHCLOA80%80%OPCMGM OAIPHLDO CH Cretaceous Sandstone GroupD Triassic Sandstone GroupP Permian Evaporite GroupP Permian Limestone GroupA Permian Sandstone GroupC Bone Spr<strong>in</strong>g – Victorio Peak GroupM Capitan Reef GroupL Pennsylvanian GroupO Llano Uplift GroupO Surface Water GroupHLOA80%60%20%Ca + Mg40%20%O40%P60%80%CMILDMGHAOHPACLOO60%80%SO 440%20%CaClFigure 3-2. Piper plot of central values of all 20 groups.27

3.1.2 Surface-Water DataThe TCEQ surface-water database (TCEQ, 2006b) (“<strong>Texas</strong> Clean Rivers Program”) conta<strong>in</strong>ssurface-water chemical analyses dat<strong>in</strong>g back to 1968 <strong>in</strong> approximately 8,400 unique locationsacross the state, mostly <strong>in</strong> the east half of the state (Figure 3-3). Out of these, 49 stations have atleast 1 complete chemical analysis (often only chloride is analyzed) with TDS >1,000 ppm andare located (Figure 3-4) <strong>in</strong> the section of river bas<strong>in</strong>s (Canadian, Red, Brazos, Tr<strong>in</strong>ity, Sab<strong>in</strong>e,and Colorado) with net positive evaporation rates and where desal<strong>in</strong>ation facilities havehistorically used surface water as feedwater. The 49 stations have a comb<strong>in</strong>ed 496 relevantchemical analyses.River Bas<strong>in</strong>BrazosCanadianColoradoCypressNechesRedSab<strong>in</strong>eSulphurTr<strong>in</strong>ity¹0 50 100 200 300 400MilesSource: Feedwater from Nicot et al. (2005); station location and analyses from TCEQ (2006b)Figure 3-3. Surface-water stations with at least one sample with a TDS >1,000 ppm.28