Self-healing Polymers and Composites - Sottos Research Group

Self-healing Polymers and Composites - Sottos Research Group

Self-healing Polymers and Composites - Sottos Research Group

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

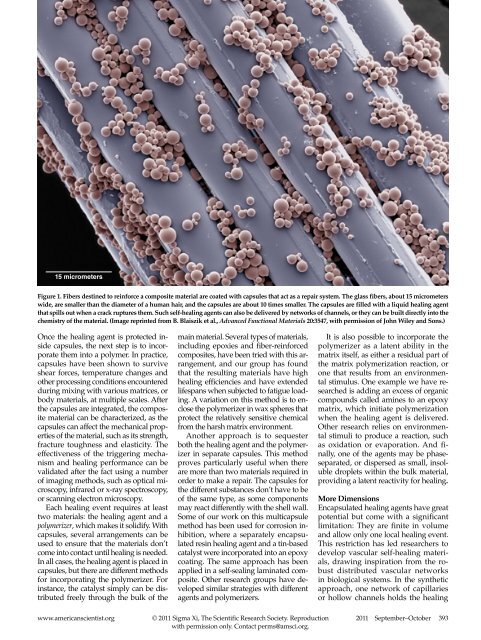

15 micrometersFigure 1. Fibers destined to reinforce a composite material are coated with capsules that act as a repair system. The glass fibers, about 15 micrometerswide, are smaller than the diameter of a human hair, <strong>and</strong> the capsules are about 10 times smaller. The capsules are filled with a liquid <strong>healing</strong> agentthat spills out when a crack ruptures them. Such self-<strong>healing</strong> agents can also be delivered by networks of channels, or they can be built directly into thechemistry of the material. (Image reprinted from B. Blaiszik et al., Advanced Functional Materials 20:3547, with permission of John Wiley <strong>and</strong> Sons.)Once the <strong>healing</strong> agent is protected insidecapsules, the next step is to incorporatethem into a polymer. In practice,capsules have been shown to surviveshear forces, temperature changes <strong>and</strong>other processing conditions encounteredduring mixing with various matrices, orbody materials, at multiple scales. Afterthe capsules are integrated, the compositematerial can be characterized, as thecapsules can affect the mechanical propertiesof the material, such as its strength,fracture toughness <strong>and</strong> elasticity. Theeffectiveness of the triggering mechanism<strong>and</strong> <strong>healing</strong> performance can bevalidated after the fact using a numberof imaging methods, such as optical microscopy,infrared or x-ray spectroscopy,or scanning electron microscopy.Each <strong>healing</strong> event requires at leasttwo materials: the <strong>healing</strong> agent <strong>and</strong> apolymerizer, which makes it solidify. Withcapsules, several arrangements can beused to ensure that the materials don’tcome into contact until <strong>healing</strong> is needed.In all cases, the <strong>healing</strong> agent is placed incapsules, but there are different methodsfor incorporating the polymerizer. Forinstance, the catalyst simply can be distributedfreely through the bulk of themain material. Several types of materials,including epoxies <strong>and</strong> fiber-reinforcedcomposites, have been tried with this arrangement,<strong>and</strong> our group has foundthat the resulting materials have high<strong>healing</strong> efficiencies <strong>and</strong> have extendedlifespans when subjected to fatigue loading.A variation on this method is to enclosethe polymerizer in wax spheres thatprotect the relatively sensitive chemicalfrom the harsh matrix environment.Another approach is to sequesterboth the <strong>healing</strong> agent <strong>and</strong> the polymerizerin separate capsules. This methodproves particularly useful when thereare more than two materials required inorder to make a repair. The capsules forthe different substances don’t have to beof the same type, as some componentsmay react differently with the shell wall.Some of our work on this multicapsulemethod has been used for corrosion inhibition,where a separately encapsulatedresin <strong>healing</strong> agent <strong>and</strong> a tin-basedcatalyst were incorporated into an epoxycoating. The same approach has beenapplied in a self-sealing laminated composite.Other research groups have developedsimilar strategies with differentagents <strong>and</strong> polymerizers.It is also possible to incorporate thepolymerizer as a latent ability in thematrix itself, as either a residual part ofthe matrix polymerization reaction, orone that results from an environmentalstimulus. One example we have researchedis adding an excess of organiccompounds called amines to an epoxymatrix, which initiate polymerizationwhen the <strong>healing</strong> agent is delivered.Other research relies on environmentalstimuli to produce a reaction, suchas oxidation or evaporation. And finally,one of the agents may be phaseseparated,or dispersed as small, insolubledroplets within the bulk material,providing a latent reactivity for <strong>healing</strong>.More DimensionsEncapsulated <strong>healing</strong> agents have greatpotential but come with a significantlimitation: They are finite in volume<strong>and</strong> allow only one local <strong>healing</strong> event.This restriction has led researchers todevelop vascular self-<strong>healing</strong> materials,drawing inspiration from the robustdistributed vascular networksin biological systems. In the syntheticapproach, one network of capillariesor hollow channels holds the <strong>healing</strong>www.americanscientist.org© 2011 Sigma Xi, The Scientific <strong>Research</strong> Society. Reproductionwith permission only. Contact perms@amsci.org.2011 September–October 393