Self-healing Polymers and Composites - Sottos Research Group

Self-healing Polymers and Composites - Sottos Research Group

Self-healing Polymers and Composites - Sottos Research Group

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

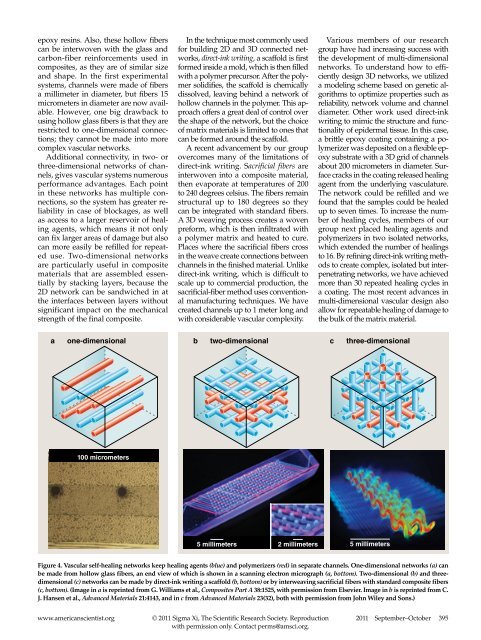

epoxy resins. Also, these hollow fiberscan be interwoven with the glass <strong>and</strong>carbon-fiber reinforcements used incomposites, as they are of similar size<strong>and</strong> shape. In the first experimentalsystems, channels were made of fibersa millimeter in diameter, but fibers 15micrometers in diameter are now available.However, one big drawback tousing hollow glass fibers is that they arerestricted to one-dimensional connections;they cannot be made into morecomplex vascular networks.Additional connectivity, in two- orthree-dimensional networks of channels,gives vascular systems numerousperformance advantages. Each pointin these networks has multiple connections,so the system has greater reliabilityin case of blockages, as wellas access to a larger reservoir of <strong>healing</strong>agents, which means it not onlycan fix larger areas of damage but alsocan more easily be refilled for repeateduse. Two-dimensional networksare particularly useful in compositematerials that are assembled essentiallyby stacking layers, because the2D network can be s<strong>and</strong>wiched in atthe interfaces between layers withoutsignificant impact on the mechanicalstrength of the final composite.In the technique most commonly usedfor building 2D <strong>and</strong> 3D connected networks,direct-ink writing, a scaffold is firstformed inside a mold, which is then filledwith a polymer precursor. After the polymersolidifies, the scaffold is chemicallydissolved, leaving behind a network ofhollow channels in the polymer. This approachoffers a great deal of control overthe shape of the network, but the choiceof matrix materials is limited to ones thatcan be formed around the scaffold.A recent advancement by our groupovercomes many of the limitations ofdirect-ink writing. Sacrificial fibers areinterwoven into a composite material,then evaporate at temperatures of 200to 240 degrees celsius. The fibers remainstructural up to 180 degrees so theycan be integrated with st<strong>and</strong>ard fibers.A 3D weaving process creates a wovenpreform, which is then infiltrated witha polymer matrix <strong>and</strong> heated to cure.Places where the sacrificial fibers crossin the weave create connections betweenchannels in the finished material. Unlikedirect-ink writing, which is difficult toscale up to commercial production, thesacrificial-fiber method uses conventionalmanufacturing techniques. We havecreated channels up to 1 meter long <strong>and</strong>with considerable vascular complexity.Various members of our researchgroup have had increasing success withthe development of multi-dimensionalnetworks. To underst<strong>and</strong> how to efficientlydesign 3D networks, we utilizeda modeling scheme based on genetic algorithmsto optimize properties such asreliability, network volume <strong>and</strong> channeldiameter. Other work used direct-inkwriting to mimic the structure <strong>and</strong> functionalityof epidermal tissue. In this case,a brittle epoxy coating containing a polymerizerwas deposited on a flexible epoxysubstrate with a 3D grid of channelsabout 200 micrometers in diameter. Surfacecracks in the coating released <strong>healing</strong>agent from the underlying vasculature.The network could be refilled <strong>and</strong> wefound that the samples could be healedup to seven times. To increase the numberof <strong>healing</strong> cycles, members of ourgroup next placed <strong>healing</strong> agents <strong>and</strong>polymerizers in two isolated networks,which extended the number of <strong>healing</strong>sto 16. By refining direct-ink writing methodsto create complex, isolated but interpenetratingnetworks, we have achievedmore than 30 repeated <strong>healing</strong> cycles ina coating. The most recent advances inmulti-dimensional vascular design alsoallow for repeatable <strong>healing</strong> of damage tothe bulk of the matrix material.a one-dimensional b two-dimensionalc three-dimensional100 micrometers5 millimeters 2 millimeters 5 millimetersFigure 4. Vascular self-<strong>healing</strong> networks keep <strong>healing</strong> agents (blue) <strong>and</strong> polymerizers (red) in separate channels. One-dimensional networks (a) canbe made from hollow glass fibers, an end view of which is shown in a scanning electron micrograph (a, bottom). Two-dimensional (b) <strong>and</strong> threedimensional(c) networks can be made by direct-ink writing a scaffold (b, bottom) or by interweaving sacrificial fibers with st<strong>and</strong>ard composite fibers(c, bottom). (Image in a is reprinted from G. Williams et al., <strong>Composites</strong> Part A 38:1525, with permission from Elsevier. Image in b is reprinted from C.J. Hansen et al., Advanced Materials 21:4143, <strong>and</strong> in c from Advanced Materials 23(32), both with permission from John Wiley <strong>and</strong> Sons.)www.americanscientist.org© 2011 Sigma Xi, The Scientific <strong>Research</strong> Society. Reproductionwith permission only. Contact perms@amsci.org.2011 September–October 395