Oxy-acetylene equipment - Zinser Schweisstechnik GmbH

Oxy-acetylene equipment - Zinser Schweisstechnik GmbH

Oxy-acetylene equipment - Zinser Schweisstechnik GmbH

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

S i n c e 1 8 9 8 p e r f o r m a n c e a n d p r o g r e s s Flame cutting<br />

systems<br />

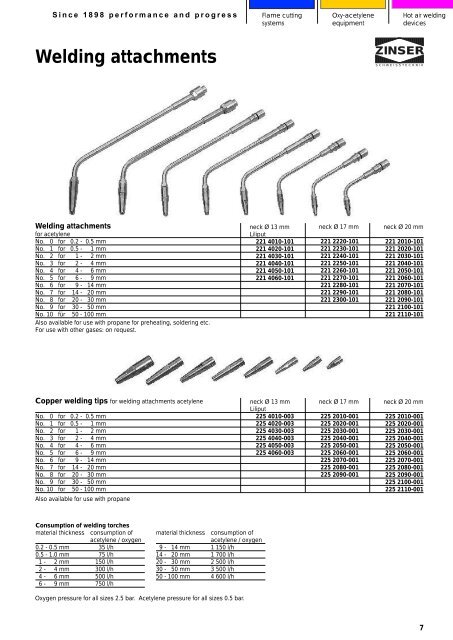

Welding attachments<br />

Welding attachments<br />

for <strong>acetylene</strong><br />

No. 0 for 0.2 - 0.5 mm<br />

No. 1 for 0.5 - 1 mm<br />

No. 2 for 1 - 2 mm<br />

No. 3 for 2 - 4 mm<br />

No. 4 for 4 - 6 mm<br />

No. 5 for 6 - 9 mm<br />

No. 6 for 9 - 14 mm<br />

No. 7 for 14 - 20 mm<br />

No. 8 for 20 - 30 mm<br />

No. 9 for 30 - 50 mm<br />

No. 10 für 50 - 100 mm<br />

Also available for use with propane for preheating, soldering etc.<br />

For use with other gases: on request.<br />

Copper welding tips for welding attachments <strong>acetylene</strong><br />

No. 0 for 0.2 - 0.5 mm<br />

No. 1 for 0.5 - 1 mm<br />

No. 2 for 1 - 2 mm<br />

No. 3 for 2 - 4 mm<br />

No. 4 for 4 - 6 mm<br />

No. 5 for 6 - 9 mm<br />

No. 6 for 9 - 14 mm<br />

No. 7 for 14 - 20 mm<br />

No. 8 for 20 - 30 mm<br />

No. 9 for 30 - 50 mm<br />

No. 10 for 50 - 100 mm<br />

Also available for use with propane<br />

Consumption of welding torches<br />

material thickness consumption of<br />

<strong>acetylene</strong> / oxygen<br />

0.2 - 0.5 mm 35 l/h<br />

0.5 - 1.0 mm 75 l/h<br />

1 - 2 mm 150 l/h<br />

2 - 4 mm 300 l/h<br />

4 - 6 mm 500 l/h<br />

6 - 9 mm 750 l/h<br />

material thickness consumption of<br />

<strong>acetylene</strong> / oxygen<br />

9 - 14 mm 1 150 l/h<br />

14 - 20 mm 1 700 l/h<br />

20 - 30 mm 2 500 l/h<br />

30 - 50 mm 3 500 l/h<br />

50 - 100 mm 4 600 l/h<br />

<strong>Oxy</strong>gen pressure for all sizes 2.5 bar. Acetylene pressure for all sizes 0.5 bar.<br />

<strong>Oxy</strong>-<strong>acetylene</strong><br />

<strong>equipment</strong><br />

ZINSER<br />

S C H W E I S S T E C H N I K<br />

Hot air welding<br />

devices<br />

neck Ø 13 mm<br />

Liliput<br />

neck Ø 17 mm neck Ø 20 mm<br />

221 4010-101 221 2220-101 221 2010-101<br />

221 4020-101 221 2230-101 221 2020-101<br />

221 4030-101 221 2240-101 221 2030-101<br />

221 4040-101 221 2250-101 221 2040-101<br />

221 4050-101 221 2260-101 221 2050-101<br />

221 4060-101 221 2270-101 221 2060-101<br />

221 2280-101 221 2070-101<br />

221 2290-101 221 2080-101<br />

221 2300-101 221 2090-101<br />

221 2100-101<br />

221 2110-101<br />

neck Ø 13 mm<br />

Liliput<br />

neck Ø 17 mm neck Ø 20 mm<br />

225 4010-003 225 2010-001 225 2010-001<br />

225 4020-003 225 2020-001 225 2020-001<br />

225 4030-003 225 2030-001 225 2030-001<br />

225 4040-003 225 2040-001 225 2040-001<br />

225 4050-003 225 2050-001 225 2050-001<br />

225 4060-003 225 2060-001 225 2060-001<br />

225 2070-001 225 2070-001<br />

225 2080-001 225 2080-001<br />

225 2090-001 225 2090-001<br />

225 2100-001<br />

225 2110-001<br />

7