more complete synopsis - Great Britain Philatelic Society

more complete synopsis - Great Britain Philatelic Society

more complete synopsis - Great Britain Philatelic Society

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

Tipps für einen erfolgreichen Rapsanbau!Ergebnisse aus den Rapsversuchen 2005-2006der Versuchstätigkeit der steirischen FachschulenZusammengestellt von Dir. Dr. Robier JohannEin früher Saattermin wird immer deutlich stärkere und höhere Rapspflanzen heranwachsenlassen. Eine Saat zwischen dem 1. und 15. September wird sich im Ertragkaum unterscheiden. Aussaaten nach dem 20. September führen zu Ertragsverlusten.Die Hybridsorte wuchs bei gleichem Saattermin der Liniensorte davon.Je früher die Saat desto höher der Ertrag, gerade bei niedriger Saatstärke.In den Versuchen war der früheste Saattermin der 30. August.Je geringer die Saatmenge, desto höher der Ertrag, dies besonders bei der Hybridsorte.Die niedrigste Saatmenge war 1,5 kg bei der Hybridsorte Extra.Das Auszählen der Pflanzen im Herbst brachte ein interessantes Ergebnis zu Tage.Die Saat von 35 Körnern/m² ließ 33 Pflanzen/m² heranwachsen, bei der Saat von 70Körnern/m² könnten nur 45 Pflanzen/m² gezählt werden.Ergebnis: Bei höheren Saatstärken verdrängen sich die Pflanzen selbst.Die letzte Stickstoffdüngung von 50 kg/ha Reinstickstoff vor der Rapsblüte (EndeApril) kann den Rapsertrag bis zu 1.000 kg verbessern.Die Sorte Extra ist im Versuchsjahr 2006 im Ertrag gesichert besser als die Liniensorte.Sie brachte um 600 kg/ha mehr als die Sorte Californium.Im Jahre 2006 zeigte die Sorte Extra beim frühesten Saattermin und bei der niedrigstenSaatstärke mit 4,7 Tonnen /ha den höchsten Ertrag.Der späte Saattermin im Oktober ließ nur wenig Pflänzchen auflaufen, brachte einedeutlich schlechtere Kultur, obwohl der Ertrag bei der Ernte am mit 1700kg (Californium)bis 2200 kg (Extra) doch noch überraschte. Der späte Saattermin kann jedochnicht empfohlen werden.Weiter Ergebnisse finden sie unter der Internetadressewww.versuchsreferat.atVersuchsreferat Steiermark Seite 43

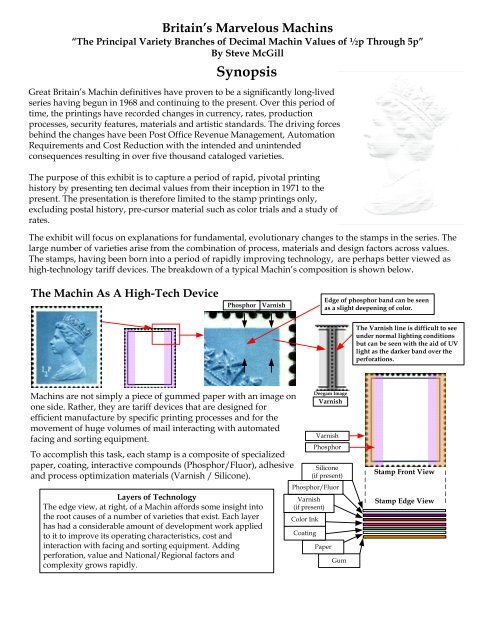

Exhibit Frame ProgressionBecause of the complexity of construction of a Machin stamp, as illustrated in the previous‘high-tech’ diagrams, this exhibit is organized in the following fashion:I. Base-Line Printings – These frames explore the Gum, Paper, Phosphor/Fluor materials asintended by printers’ implementation of Post Office specifications. The first five frames are anintroduction to the basic ½p-5p printings. After explanatory information in the left hand side ofFrame 1, the balance of Chapter I is laid out in a time-line sequence that may be viewedframe by frame or across to follow a particular value’s development. The time-line Paper-Gum color bars from page 1-MN are laid out across the top of the Frame with as much text aspossible sequestered at the bottom of the pages of the frame in an effort to ease the viewingof the material. I have included a copy of the Paper-Gum descriptive page (1-MN) with this<strong>synopsis</strong>. Paper-Gum combinations are at the most basic level for understanding Machinvariety. As a consequence, half of the exhibit is devoted to this topic.II. Interactive Technology – These frames explore variations in the application of phosphor/fluor inks as well as providing a brief history of their development and use of thesecompounds to drive automation.III. Visual Elements - As unadorned as the Machin design is, there are a surprising number offactors that produce distinctive visually discernable varieties. These are explored in the finalthree frames.Frame1Frame2Frame3Chapter IIntroductionBaseline PrintingsFrame4Frame5Frame Frame6 7Chapter IIInteractiveTechnologyFrame8Frame9Chapter IIIVisual ElementsFrame10Page Progression8.5" x 11"A ●●● DE●●●P11" x 17"A-B C-DE-F G-HI-J K-LM-N O-P■ Organization: This exhibit’s topics are allocated in the frame representation, above, in value-catalognumber-chronological order, at the page level, within each chapter, to the degree allowed by layoutconstraints. This permits a logical presentation of evolution and variation within each of the three majordevelopmental threads and means that, in general, chronological order moves from upper left to the rightand down in each chapter of the exhibit.■ Viewing: This exhibit has been designed to be accessible by Machin experts and beginners. If you arenew to the subject, the introductory pages in each chapter will assist you in understanding how variationarises. If you are familiar with Machins, moving directly to the ‘Printings’ pages of each chapter may bebeneficial.Completeness: Exhibiting one example of each variety, even with the limited scope of chosen values,would require space for 834 printings or about one and a half times greater frame space. Rather, I havechosen to categorize the display of the printings into three chapters containing major printing divisions eachof which contains variety subdivisions as defined predominately from the Deegam Catalog (see page 1-F).All major printings are represented and fully 95% of the subdivision varieties are represented with at leastone example from one or <strong>more</strong> values.

PresentationFour challenges to mounting a clear presentation of Machin development are:First, the fact that evolutionary changes often occur simultaneously across the developmentalthreads.Second, identification of a specific printing, presented as a single stamp, can be difficult even forexperts.Third, many significant varieties are difficult to see under normal light or without magnification.****Fourth, a high-level review of catalog information does not provide an easy understanding of whichvarieties exist within specific printings and <strong>complete</strong>ness of this exhibit.Paper-GumTo address these challenges, this exhibit’s topics are allocated in Chapter representation defined on theTitle page, in value-catalog number-chronological order within each Chapter. This permits theobservance of variation within each of the major developmental threads.Where multiple varieties occur on the same source item, the most significant varietal aspect will behighlighted so as to keep the Chapter thread intact.Next, every effort is made to display specific printings in source format – i.e., Cylinder block; Coil stripand Booklet pane for ease of printing identification.Graphics and overlays are used throughout the exhibit to overcome normal light and size limitations.Finally, graphic tables are employed in each chapter to define which variations are know by printing.Examples of the three principle tables are shown below and will serve as a guide to understanding<strong>complete</strong>ness of presentation. ‘Base-line’ printings for all values are exhibited. Every attempt to present a<strong>complete</strong> picture of variety has also been made but some examples are redundant across all values suchas the ‘Thin’ variety shown in the first graphic and are therefore not exhibited.Ext'rnl Coating Finish ThicknessChapter I: Paper-Gum VarietiesFrames 1-5Paper-Gum Printings & Variation SummaryTable PG-4FCP-GA ½p 1p 1½p 2p 2½p 3p 3½p 4p 4½p 5pCategoriesThickThin♦ ♦ ♦ ♦ ♦TranslucentRibbedGlossyDullLow OBAFBOUncoatedSilicone/Omtd ♦ ♦ ♦Error of PaperVarietyRangeA ♦ indicatesthe varietyexists and isexhibitedThickness: Includes Thick, Thin, Translucent and Ribbed paper. See original research page titled, “Thin-Thick,Translucent Paper” for measurement methodology. Definitions for Translucent and ribbed paper will be presentedwith the first examples.Finish: Glossy & Dull is a surface finish that results from variation in roller pressure in the printing process.Coating: Low Optical Brightening Agent (OBA) is a substandard level of OBA in the paper coating resulting in anoff-white paper color compared to normal paper coating containing OBA. Fluorescent Brightener Omitted (FBO) isa duller appearing paper than Low OBA. Lastly, Uncoated paper is paper entirely missing the coating.External: Silicone & Silicone Omitted – silicone was applied to some early printings to try to prevent coil jammingin vending machines. Silicone Omitted occurs when a coil leader indicates that silicone should have been appliedbut in fact is not present on the stamps. Error of Paper refers to the inadvertent substitution by the printer of anincorrect paper-coating material in place of the proper paper type.♦A ♦ indicatesthe varietyexists but isnot exhibitedBlackindicatesvalue notprinted inthiscombination.Values

BandsFormatFaultChapter II: Interactive Technology VarietiesPhosphor-Fluor Variation SummaryFrames 6-7OCP-PVA ½p 1p 1½p 2p 2½p 3p 3½p 4p 4½p 5pCategoriesRB LB CB Error ♦ ♦ ♦Narrow/WideReversed/Obv♦Missing/Omtd ♦ ♦ ♦ ♦ ♦ ♦ ♦ ♦ ♦250 DPI Screen ♦ ♦ ♦ ♦ ♦ ♦ ♦ ♦TintedInset ♦ ♦ShortNotchedPrintWeak AfterglowJet/Expmntl/B1Table PF-2♦Phosphor/Fluor Sub-VarietiesBandsCategoriesRB LB CB ErrorNarrow/BroadReversedMissing/OmtdDescription● Right Band / Left Band / Center Band Error – Bands appearing in an incorrect position from design specification.● Narrow / Broad Bands – Variation of width from standard for printing.● Reversed Bands – Bands laid down on the phosphor cylinder reversed vertically from intended design.● Missing / Omitted Bands – Caused by the phosphor ink reservoir having run dry. Omitted bands usually result from a print error.250 DPI Screen ● 250 DPI Screen - A variety of phosphor screen density. 150 DPI is considered normal.FormatFaultTintedInsetShortNotchedPrintWeak AfterglowJet/Expmntl/B1● Tinted Phosphor – An altering of the phosphor ink due to too much solvent in the color ink.● Inset / Short / Notched Bands – See page 6-B for visual representation. Either through design or through an error ofregistration of the phosphor ink, an offset of the phosphor band from its nominal position.● Print – Various errors of phosphor due to ink-doctor blade errors.● Weak Afterglow – Found in some early printings where phosphor compounds provided limited signal.● Jet / Experimental / B1 – Jet: Phosphor compound error / Exp: All-over phosphor + bands / B1: an error of phosphor ink.Chapter II covers the use and development of phosphorescent and fluorescent materialswhich permit the stamps to interact with sorting and handling equipment. The layout of thetable is the same as with Paper-Gum combinations, though the list of variations is different.Definitions of the variations can be found in the Deegam catalog and are presented in theexhibit.

Background Value Tablet HeadPrintChapter III: Appearance VarietiesFrames 8-10Appearance Variation SummaryTable AV-8Paper-Gum OCP-GA OCP-PVA FCP-PVA FCP-GA FCP-DEX PCP-DEX ACP-DEX OFPP OFNP-PVA4pTypes B1 B1 B3 B1 B1 B2 B1 B3 B2 B3 A2 B2 B4 B4 A1ShadesFloating SettingsThin / Screened SOriginal ArtworkJ. Mathews Redrawn♦ ♦ ♦ ♦♦♦♦♦♦ ♦ ♦Letter Types T1 T1 T2 T1 T1 T3 T1 T2 T1 T2 T3 T4 T3 T3Original PaletteJ. Mathews Palette♦ ♦ ♦ ♦ ♦ ♦♦ ♦ ♦Graduated / Flat F F F F F F F FShades ♦ ♦ ♦Process P G P G P G P G P G L P G L G GAppearance Variation SummaryPrint Background Value Tablet HeadTypesSub-VarietyShadesFloating SettingsThin / ScreenedOriginal ArtworkJ. Mathews RedrawnLetter TypesOriginal PaletteJ. Mathews PaletteGraduated/FlatShadesPerforationProcessDescription■ Head Types & Coloration – The original photographic artwork, has resulted a series ofvisually distinct head types and coloration.■ Value Tablets – Each printer implemented its own value artwork (Original Artwork). Thevalues implemented with photogravure have multiple positions or ‘settings’ and vary inthickness and occasionally exhibit a ‘screened’ effect making the numerals look as if theyhave a cellular structure (Thin / Screened). This collective artwork was later redrawn tobring uniformity to design (J. Mathews Redrawn).■ Background – Appearance varies substantially depending on whether the background isgraduated in color intensity of flatly uniform (Graduated / Flat). Colors (Original Palette)also changed due to re-issue of a value or during the switch to a new palette (J. MathewsPalette). Lastly, shades of color also occur.■ Print – Perforation at the source level follows the Stanley Gibbons conventions. Processesare Photogravure (PG), Lithography (L) and Gravure (G).Finally, Chapter III is focused on varieties that affect visual appearance. Here, the chapter isdivided up by denomination with each table reflecting varieties which occur within thevalue.This exhibit follows the catalog numberstructure found in the Deegam catalog withoccasional reference to the ConnoisseurCatalog numbering where distinct varietiesare not specified in Deegam. Catalognumbers are used throughout the exhibit toassist in identifying items that may appearsimilar on a page.Deegam Catalog Number PrimerCatalog SourceCC= ConnoisseurDG = DeegamValue TabletType = 1, 2, ...Position = _, a, b, ...Catalog Number FormatDG 50.3.1T1 C1 6/72Head TypeType = 1, 2, ...Catalog NumberValue . Major Division . Sub-VarietyDate FirstAppeared

Value Tablet Types & SettingsThe differences between Value Tablet types arises, as with the Heads, from different masternegatives that have been produced. The elements of Value Tablet were separated into the the numeralsand the letter, “P” with both of these elements’ design left to the printers.Value Tablet variations take three basic forms:■ The thickness of the “P”;■ Variation in size of the elements■ The relative position of the elements from each other.In 1984, numerals were changed to the Jeffery Mathews design for uniformity.TypesWhere type changes appear in the exhibit, amicrograph accompanies the presented itemwith Type identification. An example isshown below using the 2p Machin.Example – Type T3SettingsValue Tablet positions are defined on a grid. The Deegamgrid icon is presented below with the distance betweenany adjacent position letter (a through d) being 0.25mm.Example – Setting (Normal ½p)GHT3H=3.4mmG=.50mmValue Types are definedwithin the exhibit.Height, thickness andseparation are factors asshown in theenlargement at left.HVH = HorizontalV = VerticalMeasured in millimeters (mm)Positional GridArtwork fromDeegam & Used byPermissionSpecific StampTablet Position= Value TabletPositionMeasurementsfor SpecificStampValue Tablet Position IconTablet PositionsN = Nominal Positiona, ac, ad, … = Variant PositionsValue Position1.65 2.50HaVdFloating Positions IconValue Position1.65 2.50Ha1.65 2.401.65 2.30VdFloating PositionsSettings progressivelychange from stamp tostamp.Because the lightsensitive,carbon tissuegelatin was applied toValue, then Head, missalignmentfrom one to theother often occurred. Thiscaused the Value to ‘float’across the cylinder inprogressive fashion.Floating is found onHarrison low valuephotogravure printingsbut not on Litho or EME.

For those individuals interested in stamp variations, the Machin series is ideal. Not only is there an enormousrange of material from which to choose, the progression of the stamps through their printing history offersdocumentable evidence of the technological changes in production and materials. These changes continue,driven by cost management, public demand, interactive requirements and advances in materials, assuringnew Machin varieties into the future.BibliographyDeegam Machin Handbook, Douglas G. A. Myall, Third edition 2003, Printed by Maslands Ltd,Tiverton, Devon, U.K.. Supplemented On-line. Volume I for materials and production background.Volume II for Value catalog numbers. Values included are specifically covered within pages D5-1through D50-7. Note: Some printing catalog numbers have been revised in the on-line version.<strong>Great</strong> <strong>Britain</strong> Volume 4 Specialized Stamp Catalog, Tenth edition 2008, Printed by Stanley GibbonsLimited, Ringwood, Hants, U.K. Section UD for selvage marking explanations.Queen Elizabeth II Specialized Definitives Stamp Catalog Volume 1, First edition 2007, Printed by TheMachin Collectors Club, Aylsham, Norfolk, U.K. Sections “Coil strips” and “Small Format DecimalCylinder Blocks” for perforation, printer and leader information.Connoisseur Machin Catalog, On-Line edition, Published by Connoisseur Publications, 2008, Viewableat www.connoisseurcatalog.net for color shade and ATN paper varieties not listed in Deegam.“The Physics of Automatic Letter Sorting”, by Ron Paris, Post Office Engineer, published in PhysicsTechnology volume 19, 1988.“Facts to Remember About OBA”, by Aubrey Walker, Post Office Chief Chemist, <strong>Philatelic</strong> Bulletin,November 1979.General Background ReadingMachin Artist of an Icon, F. Machin, 2002, Published by Frontier Publishing, Kirstead, Norfolk, U.K. forartist’s background.A Timeless Classic, The Evolution of Machin’s Icon, Douglas N. Muir, Published by The British PostalMuseum 2007, for precursors to the selected artwork.AdvisorsJohn M. Deering - a dealer in modern GB stamps for over 28 years, and a recognized expert in the field of specializedMachins who regularly assists catalogue editors. John is also the author of the monthly magazine article, Machin Watch,which is published in Gibbons Stamp Monthly. Machin Watch has been published continuously for 25 years. Over his 28years in the field, John has handled many of the series’ rarities and has considerable technical experience.Anthony Walker – A former member of the Council of the <strong>Great</strong> <strong>Britain</strong> <strong>Philatelic</strong> <strong>Society</strong>, current member of theRoyal Mail Stamp Advisory Committee, author of, The Cambridge Colour Trials of 1969-1970 and International GoldAward winner for the Machin exhibit associated with the Colour Trials study, for edit advice on phosphor table layoutand for providing the Sterling-Decimal transitional information. Anthony’s extensive pre-decimal Machin experiencewas invaluable in this exhibitor’s understanding of the evolutionary ties that decimal Machin stamps have to theirQueen Elizabeth II Wilding series precursors.

Chapter I Summary of Paper Coating & Gum Evolution & Active Periods of Use by Printer‘71 ‘72 ‘73 ‘74 ‘75 ‘76 ‘77 ‘78 ‘79 ‘80 ‘81 ‘82 ‘83 ‘84 ‘85 ‘86 ‘87 ‘88 ‘89 ‘90 ‘91 ‘92 ‘93 ‘94 ‘95 ‘96 ‘97 ‘98 ‘99 ‘00 ‘01 ‘02 ‘03 ‘04 ‘05 ‘06 ‘07 ‘08 ‘09 ‘10½pOCP FCP PCPGA PVADEXWithdrawnJune 28, 19851pOCPGAPVAFCPPCPDEXACPFCPACPOFNPPVA1½pOCPPVAFCPDEXWithdrawn:Feb 8, 1977G3.2 CoilPPP briefly used asexpedientDG10.11.1 & DG20.8.12pOCPGAPVAFCPPCP ACP OFNPDEXPVA2½p3pOCP FCPPVAOCPFCPPVA3½p OCP FCP WithdrawnSep 23, 1975PVADEXDEXError of paper – paperused was intendedfor overseas postalcustomer. DG30.12.1bWithdrawnFeb 26, 1982PCP FCP ACPReissuedApr 5, 1983DEXDEXSold toExhaustionSold toExhaustionReintroduction of Gum Arabic (GA)When PVA was introduced, it was found that the Swedish ‘lawnmower’perforator produced poor results with this gum. This perforator wasreplaced by the rotary Jumelle in-line reel perforator. However, due tohigh demand for low value stamps in the 1972-73 period, this perforatorwas pressed into service again forcing the reintroduction of GA for abrief period of time.A blue arrow indicates reintroduction usage.4pOCPFCPPVA GA DEXWithdrawnFeb 8, 1977FCPPVAPCP FCP ACP OFNP OFPP OFNP OFNP WithdrawnApr 1, 2004DEXDEXPVA4½pFCPDEXPCPWithdrawnSep 23, 19755pGumGAPVADEXOCP FCP PCP FCP ACP OFNP OFPP OFNP OFNPPVA DEX DEX DEXPVALegendCoatingOCP Original Coated PaperFCP Fluorescent Coated PaperPPP Preprinted Phosphor PaperPCP Phosphor Coated PaperACP ‘A’ Phosphor Coated PaperOFNP OBA Free Non-Phosphorized PaperOFPP OBA Free Phosphorized PaperGum ArabicPolyVinyl AlcoholPVA + DextrinBarsTimeOCPPVAPVASingle printingonly DG5.7.1IndicatesPunctuated PrintingIndicates OverlappingPrintingsCoatingGumUse of FCP During All-OverPhosphorized Paper (PCP & ACP) PeriodFCP was used on the 1p, 2½p, 3p, 3½p, 4p and5p at this point because these stamps were part ofbooklets or coils containing 2 nd class stamps. As such,neither PCP or ACP were suitable for use since theygive an effective 2-Band (1 st class) response to sortingequipment. The use of FCP with phosphor bands is,therefore, logical.However, the Makeup rates 1p, 3½p, 4p and5p were all printed with single bands. Thiscontravenes the practice of makeup rate stamps being2-banded, followed before and after these printings.See Chapter II, covering phosphor use for furtheranalysis of these printings and completion of thisoriginal research.OFPP was used on the 4p and 5p at thesepoints as part of coil RD8.1, in 1995 and the souvenirsheer DMS-7, in 2000.Optical Brightening Agent (OBA)-Free coatings areintended to be <strong>more</strong> environmentally friendly. Withthe introduction of OFNP, printings once againrequired the application of phosphor bands, not usedwith PCP or ACP, to differentiate 1 st & 2 nd classletters.OFPP printings did not have phosphor bands appliedas the paper is phosphorized all over. This paperwould be seen as if it had two bands. Therefore the4p and 5p stamps, being makeup rates, would beproperly handled.The 1p, 2p and 5pdenominationsremain in print into2009 in OFNP-PVAformat.Note that there are six identifiable sub-typesof paper used as OFNP. The appearanceindicator (e.g. “Bright”) denotes theappearance of the paper under long-wave UVlight. These are listed in the table, below.OFNP Paper & Gum Varieties – ATN PrintingsTR3 – BTR3 – ITR3 – DHS2RMS – GRMS – LBright PaperIntermediate PaperDull PaperVery Dull PaperRoyal Mail Specification (Gravure)Royal Mail Specification (Litho)