Welding safety

Welding safety

Welding safety

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

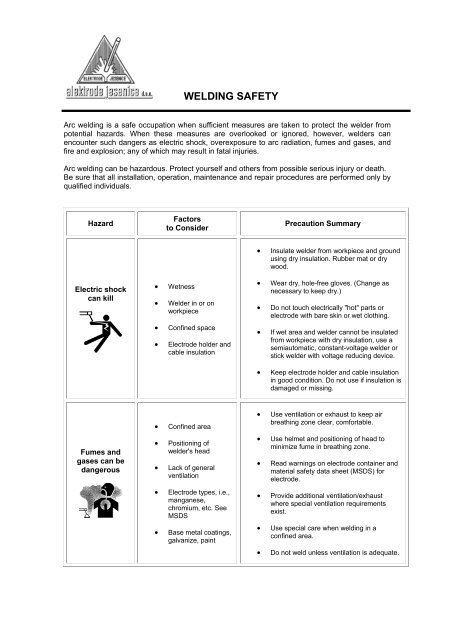

WELDING SAFETYArc welding is a safe occupation when sufficient measures are taken to protect the welder frompotential hazards. When these measures are overlooked or ignored, however, welders canencounter such dangers as electric shock, overexposure to arc radiation, fumes and gases, andfire and explosion; any of which may result in fatal injuries.Arc welding can be hazardous. Protect yourself and others from possible serious injury or death.Be sure that all installation, operation, maintenance and repair procedures are performed only byqualified individuals.HazardFactorsto ConsiderPrecaution SummaryInsulate welder from workpiece and groundusing dry insulation. Rubber mat or drywood.Electric shockcan killWetnessWelder in or onworkpieceConfined spaceElectrode holder andcable insulationWear dry, hole-free gloves. (Change asnecessary to keep dry.)Do not touch electrically "hot" parts orelectrode with bare skin or wet clothing.If wet area and welder cannot be insulatedfrom workpiece with dry insulation, use asemiautomatic, constant-voltage welder orstick welder with voltage reducing device.Keep electrode holder and cable insulationin good condition. Do not use if insulation isdamaged or missing.Fumes andgases can bedangerousConfined areaPositioning ofwelder's headLack of generalventilationUse ventilation or exhaust to keep airbreathing zone clear, comfortable.Use helmet and positioning of head tominimize fume in breathing zone.Read warnings on electrode container andmaterial <strong>safety</strong> data sheet (MSDS) forelectrode.Electrode types, i.e.,manganese,chromium, etc. SeeMSDSBase metal coatings,galvanize, paintProvide additional ventilation/exhaustwhere special ventilation requirementsexist.Use special care when welding in aconfined area.Do not weld unless ventilation is adequate.

WELDING SAFETYHazardFactorsto ConsiderPrecaution Summary<strong>Welding</strong> sparkscan cause fire orexplosionContainerswhich have heldcombustiblesFlammablematerialsDo not weld on containers which have heldcombustible materials (unless strict AWS F4.1procedures are followed). Check beforewelding.Remove flammable materials from weldingarea or shield from sparks, heat.Keep a fire watch in area during and afterwelding.Keep a fire extinguisher in the welding area.Wear fire retardant clothing and hat. Useearplugs when welding overhead.Arc rays can burneyes and skin Process: gasshieldedarcmost severeSelect a filter lens which is comfortable for youwhile welding.Always use helmet when welding.Provide non-flammable shielding to protectothers.Wear clothing which protects skin whilewelding.Confined spaceMetal enclosureWetnessRestricted entryHeavier than airgasWelder inside oron workpieceCarefully evaluate adequacy of ventilationespecially where electrode requires specialventilation or where gas may displacebreathing air.If basic electric shock precautions cannot befollowed to insulate welder from work andelectrode, use semiautomatic, constant-voltageequipment with cold electrode or stick welderwith voltage reducing device.Provide welder helper and method of welderretrieval from outside enclosure.

WELDING SAFETYHazardFactorsto ConsiderPrecaution SummaryGeneral workarea hazards Cluttered area Keep cables, materials, tools neatly organized.