Article in Shape Magazine (Issue 5) - Gurit

Article in Shape Magazine (Issue 5) - Gurit

Article in Shape Magazine (Issue 5) - Gurit

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

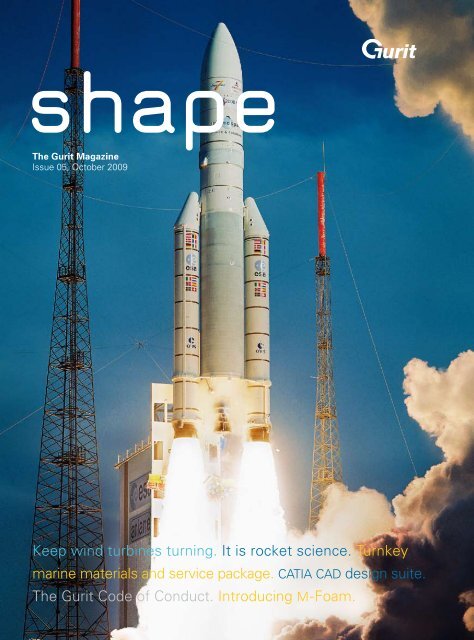

shapeThe <strong>Gurit</strong> Magaz<strong>in</strong>e<strong>Issue</strong> 05, October 2009Keep w<strong>in</strong>d turb<strong>in</strong>es turn<strong>in</strong>g. It is rocket science. Turnkeymar<strong>in</strong>e materials and service package. c at i a c a d design suite.The <strong>Gurit</strong> Code of Conduct. Introduc<strong>in</strong>g m-Foam.

Dear Reader,In the first half of 2009, <strong>Gurit</strong> achieved its target of ma<strong>in</strong>ta<strong>in</strong><strong>in</strong>g theoperational performance level of 2008, despite a sales decl<strong>in</strong>e <strong>in</strong> ourtarget markets of some 12% at constant currency translation rates.Ongo<strong>in</strong>g operational improvements, further progress <strong>in</strong> Group-widepurchas<strong>in</strong>g, together with rapidly <strong>in</strong>troduced and often pa<strong>in</strong>ful costsav<strong>in</strong>gmeasures compensated the negative effects from lowersales and thus lower capacity utilization. <strong>Gurit</strong> closed the period witha strong balance sheet and a remarkable net cash position. Ourhealthy f<strong>in</strong>ancial status gives us good reason to look ahead with confidence,although we expect markets only to broadly recover nextyear.In troubled times like these, it is very important to stay focused onthe longer-term perspectives. <strong>Gurit</strong> pushes firmly ahead with itsstrategy implementation. While our global capacities are not fullyloaded, we concentrate on even further improv<strong>in</strong>g our equipment,on tra<strong>in</strong><strong>in</strong>g our colleagues, on explor<strong>in</strong>g new market opportunities.Do<strong>in</strong>g so, we build a solid foundation for future success.We enhance our positions <strong>in</strong> all our target markets by provid<strong>in</strong>g ourcustomers with tailor-made solutions, expand<strong>in</strong>g our role as a lead<strong>in</strong>gmaterials and technology provider <strong>in</strong> advanced composites andby expand<strong>in</strong>g our addressable markets. In this edition of s h a p e, we<strong>in</strong>vite you to discover how <strong>Gurit</strong> contributes to br<strong>in</strong>g<strong>in</strong>g satellitessafely <strong>in</strong>to space, to mak<strong>in</strong>g passenger ferries more fuel efficient, tohelp<strong>in</strong>g expand the life span of w<strong>in</strong>d energy generators and to speedup automotive design projects.With our materials and technologies, <strong>Gurit</strong> contributes to mak<strong>in</strong>g ourone world more susta<strong>in</strong>able. Do<strong>in</strong>g bus<strong>in</strong>ess globally, we also acknowledgethe importance of adher<strong>in</strong>g world-wide to high standards,be it <strong>in</strong> terms of environment, health and safety, <strong>in</strong> terms of emloyerrelations, or with respect to our bus<strong>in</strong>ess conduct. Our efforts arewidely recognized wherever we do bus<strong>in</strong>ess: <strong>Gurit</strong> (Tianj<strong>in</strong>) – for <strong>in</strong>stance– was just presented with a prize for special social achievements<strong>in</strong> the Tianj<strong>in</strong> Economic Development Area, t e d a , <strong>in</strong> Ch<strong>in</strong>a.The various high standards <strong>Gurit</strong> sites and <strong>Gurit</strong> employees havebeen traditionally comply<strong>in</strong>g with locally have now been <strong>in</strong>tegrated<strong>in</strong>to our <strong>Gurit</strong> Code of Conduct also presented to you <strong>in</strong> this editionof s h a p e and on the <strong>Gurit</strong> website www.gurit.com.ContentsCorporate News 04 <strong>Gurit</strong> (Tianj<strong>in</strong>) recognized for outstand<strong>in</strong>g employeerelations 04 Governor of the Bank of England Visits <strong>Gurit</strong> (u k )04<strong>Gurit</strong> (Tianj<strong>in</strong>) receives i s o 14001 certification and is recognizedfor outstand<strong>in</strong>g employee relations 10 An <strong>in</strong>terview withRob<strong>in</strong> Price, Chief Purchas<strong>in</strong>g Officer 17 Stick<strong>in</strong>g to strategicpriorities Markets 06 Six hours – and the new bridge was there08It is rocket science 12 Cross<strong>in</strong>g over to Copenhagen’s Operanow saves 50% energy 14 Keep them turn<strong>in</strong>g 20 Turn-key materialsand services package TechTalk 11 c at i a reduces design anddevelopment time 18 M-Foam – the foam for all mar<strong>in</strong>e applicationsBe<strong>in</strong>g <strong>Gurit</strong> 05 Automotive Press Tour 05 <strong>Gurit</strong> congratulatesm b p v 22 Our Website <strong>in</strong> Ch<strong>in</strong>ese 22 Get on your bikes 23 The <strong>Gurit</strong>Code of ConductYours s<strong>in</strong>cerelyRudolf Hadorn, c e oImpr<strong>in</strong>t: <strong>Gurit</strong> Hold<strong>in</strong>g AG, Group CommunicationsEditor <strong>in</strong> Chief: Bernhard SchweizerThank you for your feedback at s h a p e@gurit.comPictures courtesy of: Ruag Space/ESA (1, 8, 9), Aston Mart<strong>in</strong> (5, 11)Rail Media Group/Birse Rail (6), www.schmidtaps.com (12/13 landscape), e w e a / Vestas (14, 15, 16)Nautor/Swan (20), istockphoto (22, 23) and Group company photo archivesConcept and Design: <strong>Gurit</strong> and Eclat AG, ErlenbachCover: <strong>Gurit</strong> supplies prepreg materials for the payload fair<strong>in</strong>gs of the Ariane 5 rockets.Inside Cover: W<strong>in</strong>dwand, designed by Ron Arad, is made from <strong>Gurit</strong> carbon fibre prepreg.This 50 metre needle pierces the sky above Canary Wharf <strong>in</strong> London.The <strong>Gurit</strong> Magaz<strong>in</strong>e 05_2009 03W<strong>in</strong>d energy Transportation Mar<strong>in</strong>e

Corporate NewsBe<strong>in</strong>g <strong>Gurit</strong><strong>Gurit</strong> (Tianj<strong>in</strong>) recognized foroutstand<strong>in</strong>g employee relationsThe Tianj<strong>in</strong> Economic Development Area (t e d a ) is the most successful<strong>in</strong>ward <strong>in</strong>vestment region <strong>in</strong> Ch<strong>in</strong>a, attract<strong>in</strong>g billions of dollars offoreign <strong>in</strong>vestment over the last 20 years. With over 4000 companiespresent, t e d a boasts 76 subsidiaries of «Fortune 500» companies. Tocelebrate the achievements of the Foreign Invested Companies,t e d a honoured 20 outstand<strong>in</strong>g General Managers who they felt hadcontributed to the local society and bus<strong>in</strong>ess success of t e d a . PhilHarnett, General Manager of <strong>Gurit</strong> (Tianj<strong>in</strong>), received one of the 20prestigious awards. The jury not only focused on the f<strong>in</strong>ancial successof the companies but also on how they contribute to society. Tra<strong>in</strong><strong>in</strong>gand staff development, labour relations, work<strong>in</strong>g atmosphere or staffturnover were important criteria as well as compliance with local environment,health and safety laws and policies or the general factorysafety and cleanl<strong>in</strong>ess.the British economic and monetary policy, and is therefore one ofthe most important public officials <strong>in</strong> the United K<strong>in</strong>gdom. He accompaniedthe Bank’s central Southern England agent, Chris Piper, on hisvisit to <strong>Gurit</strong> (u k ), as well as other bus<strong>in</strong>esses on the Isle of Wight.Feedback received from these bus<strong>in</strong>esses is used by the Bank tocompile a picture of the economic environment and the issues be<strong>in</strong>gfaced with<strong>in</strong> the region. At <strong>Gurit</strong>, the Governor was received byGraham Harvey, General Manager Mar<strong>in</strong>e and Manag<strong>in</strong>g Director of<strong>Gurit</strong> (u k ), and Mary Spradbery, Head of F<strong>in</strong>ance at <strong>Gurit</strong> (u k ), andwas treated to a tour of the <strong>Gurit</strong> premises and the operations factorybefore meet<strong>in</strong>g management to be updated on current marketconditions.Automotive Press TourIn late August, <strong>Gurit</strong> (u k ) had the pleasure of welcom<strong>in</strong>g a group ofVIP automotive journalists <strong>in</strong>clud<strong>in</strong>g Autocar and Car Design News tothe new u k based Automotive facility. The two-day press event wasarranged to launch the facility to <strong>Gurit</strong>’s target automotive and tradepress and highlight the benefits of carbon composites <strong>in</strong> automotivedesign. The first day of the tour started with an <strong>in</strong>troduction and tourof the <strong>Gurit</strong> (u k ) plant followed by presentations and <strong>in</strong>teractivedisplays on the benefits of composites <strong>in</strong> car design given by bothMart<strong>in</strong> Starkey, Manag<strong>in</strong>g Director Automotive, and the esteemedAutomotive Designer, Peter Stevens. The journalists were then treatedto a sail across the Solent from Yarmouth to Lym<strong>in</strong>gton <strong>in</strong> a Jeanneau45.2, followed by an <strong>in</strong>timate d<strong>in</strong>ner party hosted by <strong>Gurit</strong> andPeter Stevens <strong>in</strong> the Stanwell House hotel, Lym<strong>in</strong>gton. The agendaMBPV successful on its record hunts p, the mar<strong>in</strong>e bus<strong>in</strong>ess of <strong>Gurit</strong>, are proud to be part of the compositeeng<strong>in</strong>eer<strong>in</strong>g team for the Maxi Trimaran Banque Populaire v(m b p v ), the 40 metre by 23 metre boat. On Sunday August 2, 2009,this boat – eng<strong>in</strong>eered for a record hunt/s h a p e Nr 4 – beat the historicwest to east transatlantic record and secured the fastest24 hour run time, break<strong>in</strong>g the previous record by a stagger<strong>in</strong>g 12hours, 32 m<strong>in</strong>utes and 6 seconds. Congratulations to Skipper PascalBidégorry and his sail<strong>in</strong>g team, the architects v p l p and all the m b p vteam. Dur<strong>in</strong>g the race, which began <strong>in</strong> New York on July, 30, 2009 at22h 47m and which concluded at Lizard Po<strong>in</strong>t off Cornwall, at 16h13mn 13s (French time) on August 2, skipper Pascal Bidégorry andhis eleven person crew on board the m b p v also set a new 24hrrecord of travell<strong>in</strong>g 908 miles at an impressive average speed of 37,8<strong>Gurit</strong> achieved remarkable rank<strong>in</strong>gs <strong>in</strong> a number of categories. For<strong>in</strong>stance, <strong>Gurit</strong> (Tianj<strong>in</strong>) is reported to have the lowest personnel turnoverof all factories <strong>in</strong> the area. In addition, <strong>Gurit</strong>’s outstand<strong>in</strong>g recordof hav<strong>in</strong>g had only three m<strong>in</strong>or accidents s<strong>in</strong>ce its open<strong>in</strong>g two yearsago was also mentioned. Last but not least, it was noted with thanksthat the staff of <strong>Gurit</strong> (Tianj<strong>in</strong>) generously donated more than 20,000r m b to the Sichuan earthquake fund. Our picture shows Phil Harnettreceiv<strong>in</strong>g the award from Mr Li Yong, the Secretary of Party LeadershipGroup.<strong>Gurit</strong> (Tianj<strong>in</strong>) receivesISO 14001 certification<strong>Gurit</strong> (Tianj<strong>in</strong>) is pleased to announce that the company has beenawarded the iso 14001 certification for its Environmental ManagementSystems. Human Resources Manager Christ<strong>in</strong>a Y<strong>in</strong> (<strong>in</strong> redblouse) who is also responsible for e h&s at <strong>Gurit</strong> (Tianj<strong>in</strong>) had coord<strong>in</strong>atedthe process for the <strong>in</strong>dependent audit made by Det NorskeVeritas.cont<strong>in</strong>ued the follow<strong>in</strong>g day with a v i p tour around the Aston Mart<strong>in</strong>plant <strong>in</strong> Gaydon <strong>in</strong> which the guests viewed how the new technologycarbon body panels are fitted to the d b s Coupé and d b s Volante –the two models that feature <strong>Gurit</strong> made Class a carbon car bodyparts – and how they <strong>in</strong>tegrate alongside more established body technologies,such as alum<strong>in</strong>ium.knots. Franck Cammas on Groupama 3 also set off to beat his ownrecord just under 3 hours earlier, but then f<strong>in</strong>ish<strong>in</strong>g eleven m<strong>in</strong>utesafter m b p v . From the outset of the boat’s development, the worldlead<strong>in</strong>gFrench multihull naval architects v p l p, who designed m b p v ,had ambitions for the boat to become the largest and fastest offshoresail<strong>in</strong>g trimaran on the water. They aimed to challenge andbeat all exist<strong>in</strong>g offshore sail<strong>in</strong>g records, and utilized advanced compositematerials and the 20 years of experience of s p <strong>in</strong> conjunctionwith h d s to develop the boat structure which would go onto achievethis <strong>in</strong> triumphant style.Governor of the Bank of EnglandVisits <strong>Gurit</strong> (UK)<strong>Gurit</strong> (u k ) had the pleasure of welcom<strong>in</strong>g Mervyn K<strong>in</strong>g, Governor ofthe Bank of England, to its premises on June 19, 2009. The Governorvisited <strong>Gurit</strong> and other companies on the Isle of Wight to get a firsthandpicture of the economic environment with<strong>in</strong> the region. As Governorof the Bank of England, Mervyn Allister K<strong>in</strong>g holds the mostsenior position <strong>in</strong> the Bank of England. The Governor is also Chairmanof the Monetary Policy Committee, with a major role <strong>in</strong> guid<strong>in</strong>g<strong>Gurit</strong> (u k ) empf<strong>in</strong>g im Sommer den Governor der Bank of England undorganisierte e<strong>in</strong>e Tour für die Automobilpresse. <strong>Gurit</strong> (Tianj<strong>in</strong>) ist nun i s o14001-zertifiziert und wurde unlängst als beispielhafter Arbeitgeberausgezeichnet. 今 年 夏 天 , 固 瑞 特 ( 英 国 ) 接 待 了 英 国 银 行 行 长 的 来访 , 并 且 成 功 地 举 办 了 一 场 汽 车 之 旅 活 动 。 随 着 自 行 车 价 格 的 降低 , 固 瑞 特 英 国 公 司 越 来 越 多 的 同 事 选 择 骑 自 行 车 上 下 班 。 固 瑞 特天 津 ) 已 通 过 ISO14001 的 认 证 , 并 且 最 近 被 评 为 优 秀 经 理 人 。04 shapeThe <strong>Gurit</strong> Magaz<strong>in</strong>e 05_2009 05

Markets: TransportationIt is rocket science!Die Nutzlastverkleidungen der europäischenAriane 5 und Teile der amerikanischen AtlasRaketen werden bei Ruag Space mit <strong>Gurit</strong>-Prepregs hergestellt.欧 洲 阿 丽 亚 娜 5 号 火 箭 和 美 国 阿 特 拉 斯 火 箭的 有 效 载 荷 装 置 部 分 所 使 用 的 材 料 是 固 瑞特 公 司 生 产 的 预 浸 料 。<strong>Gurit</strong> high-performance composites have contributed to br<strong>in</strong>g<strong>in</strong>g numerous satellitessafely <strong>in</strong>to orbit. Satellites are carried <strong>in</strong>to space by launch vehicles – rockets mostpeople would say. The valuable cargo is <strong>in</strong>stalled at the top of the launcher under thepayload fair<strong>in</strong>g, which shelters the satellites before and dur<strong>in</strong>g the start and on theflight through the atmosphere from thermal, aerodynamic and acoustic effects andprovides the launcher with an aerodynamically optimized shape.The world’s first compositepayload fair<strong>in</strong>gsThe first payload fair<strong>in</strong>g eng<strong>in</strong>eered and designed by r u a g Spacewas for the European a r i a n e 1 launcher, which made its successfuldebut on December 24, 1979. While the first fair<strong>in</strong>g generationswere based on classical aircraft technology, i.e. alum<strong>in</strong>um construction,r u a g Space <strong>in</strong>troduced <strong>in</strong> 1988 the world’s first fair<strong>in</strong>g <strong>in</strong> compositetechnology based on alum<strong>in</strong>um honeycomb cores with carbon-fibre-re<strong>in</strong>forcedface sheets. Ever s<strong>in</strong>ce, r u a g Space uses <strong>Gurit</strong>carbon and comb<strong>in</strong>ed carbon/glass prepregs to build about 10 payloadfair<strong>in</strong>gs per year. «Let’s take the example of an a r i a n e 5 rocket»,says Paul Loeliger, Head of Production at r u a g s pa c e , on a tourthrough the fasc<strong>in</strong>at<strong>in</strong>g production site at Zürich/Switzerland. «Eachof these payload fair<strong>in</strong>gs is made up of a number of smaller shell elements.The tip of the rocket consists of two 180° ogives while thenext lower section is made up of four ogive 90° sections. The lastsection is then made up of cyl<strong>in</strong>drical extension panels. The f<strong>in</strong>ishedelements are then shipped to r u a g <strong>in</strong> Emmen, near Lucerne, wherethey are comb<strong>in</strong>ed <strong>in</strong>to two fair<strong>in</strong>g halves.»In two m<strong>in</strong>utes through the atmosphere«The payload fair<strong>in</strong>g is jettisoned as soon as the launcher has leftthe atmosphere at a height of about 120 km. This altitude is typicallyreached <strong>in</strong> about 2 m<strong>in</strong>utes of flight,» says Hendrik Thielemann,Head of Communications at r u a g Space. «That flight, however, isnot an easy ride. Shoot<strong>in</strong>g up through the atmosphere, the pressureimpact on the payload fair<strong>in</strong>g is enormous and the temperature atthe tip of the launcher easily reaches 600 centigrades.» This is whythe fair<strong>in</strong>gs are also protected by a layer of special cork material thatburns off dur<strong>in</strong>g the flight. By burn<strong>in</strong>g, the flames take the heat energyaway and protect the complex structural portion of the fair<strong>in</strong>g.The fair<strong>in</strong>g elements are produced <strong>in</strong> air-conditioned build<strong>in</strong>gs. Thedifferent layers of shell elements – i.e. the <strong>in</strong>ner face sheet of compositelam<strong>in</strong>ates, the honeycomb core, and the outer face sheet aswell as the thermal protection are laid up onto specially designedmoulds. The entire set-up is then processed <strong>in</strong> a gigantic autoclavecapable of cur<strong>in</strong>g elements of 4 meters <strong>in</strong> diameter and 6 meters <strong>in</strong>length. As one may imag<strong>in</strong>e, pressure greatly varies from the launchplatform to orbit. Numerous valves control the pressure and makesure the satellite rema<strong>in</strong>s well protected <strong>in</strong>side. «After the cur<strong>in</strong>gprocess <strong>in</strong> the autoclave, the shell elements are outfitted with thenecessary <strong>in</strong>serts and <strong>in</strong>terface equipment for the bespoke mission<strong>in</strong> our mach<strong>in</strong><strong>in</strong>g department,» expla<strong>in</strong>ed Paul Loeliger cont<strong>in</strong>u<strong>in</strong>gthe tour. Valves, holes and doors of vary<strong>in</strong>g sizes to access the satelliteonce the fair<strong>in</strong>g is mounted on the rocket, <strong>in</strong>terfaces to the launchtable mast and connections for on-ground payload cool<strong>in</strong>g, and allsorts of wir<strong>in</strong>g are added to the elements.Advantages of compositesover traditional material«Build<strong>in</strong>g the fair<strong>in</strong>gs <strong>in</strong> composite sandwich technology has numerousadvantages,» expla<strong>in</strong>s Paul Loeliger. «High-end composites notonly reduce the overall weight of the payload fair<strong>in</strong>g to some 2.7 tonsbut also allowed new attractive structural specifications comb<strong>in</strong><strong>in</strong>glow mass and high stiffness. The ogive shaped fair<strong>in</strong>g significantlyreduces the aerodynamic drag and <strong>in</strong>creases the launcher’s payloadcapacity.» At Emmen, the fair<strong>in</strong>g halves are then also pa<strong>in</strong>ted witha special coat<strong>in</strong>g to prevent electrostatic charg<strong>in</strong>g and provide thenecessary protection aga<strong>in</strong>st solar heat<strong>in</strong>g until launch. «Not onlyheat and pressure is taken <strong>in</strong>to consideration. Noise, too, is a seriousissue,» says Mr. Thielemann. «The noise of the eng<strong>in</strong>es reflectedupwards on the launch table, the atmospheric friction and thetransonic phase could seriously harm a satellite. This is why acousticelements are mounted on the <strong>in</strong>side of the fair<strong>in</strong>gs.»On the rocket, the two halves are connected by means of the verticalseparation system. The horizontal separation system fastens thefair<strong>in</strong>gs to the rocket itself. Triggered by the onboard computer atthe proper flight altitude, the pyrotechnical elements of the separationsystems are ignited, and the fair<strong>in</strong>g halves are jettisoned.They dis<strong>in</strong>tegrate and fall back to earth. As Arianespace launches itsrockets from the Guiana Space Centre at Kourou <strong>in</strong> French Guiana,where the proximity to the equator gives a significant advantage forthe launch, the jettisoned fair<strong>in</strong>gs fall <strong>in</strong>to the Atlantic Ocean. Uponimpact, they dis<strong>in</strong>tegrate even more and s<strong>in</strong>k to the ground, andapparently positively contribute to the local coral reef build<strong>in</strong>g.«So the <strong>Gurit</strong> materials are actually only used to protect the satellitesdur<strong>in</strong>g two m<strong>in</strong>utes?» s h a p e asked. «True, but they are key <strong>in</strong> provid<strong>in</strong>gexactly that high-performance protection,» said Paul Loeliger.«Composites technology is Rocket Science! Even the slightest materialdeviations matter. Us<strong>in</strong>g composites, we have materials at handwith unique physical characteristics that are able to handle extremepressure, enormous spans of temperature and are at the same timevery light.»How does r u a g qualify cooperation with <strong>Gurit</strong>? «Well, we are a verydemand<strong>in</strong>g customer. Material characteristics are to be very precisealready <strong>in</strong> aircraft technology. But space technology is many timesmore demand<strong>in</strong>g. Deviations of a hundredth of a millimeter equal atrip around the globe <strong>in</strong> this context. We rely on suppliers who live upto these tremendous standards, and I hope that <strong>Gurit</strong> cont<strong>in</strong>ues tosupply the high quality of materials we are gett<strong>in</strong>g today.»Unparalleled 100% mission successMore than 190 payload fair<strong>in</strong>gs have been commissioned for Europeanand u s -American launch vehicles. To date, all r u a g Spacepayload fair<strong>in</strong>gs built <strong>in</strong> a variety of sizes and configurations havean unrivalled 100% mission success. This qualifies r u a g Space asone of the world’s lead<strong>in</strong>g suppliers of payload fair<strong>in</strong>gs for launchers.Currently, fair<strong>in</strong>gs are produced for the European a r i a n e 5, the LockheedMart<strong>in</strong> Atlas v-500 launch vehicles and the small Europeanlauncher vega.08 shapeThe <strong>Gurit</strong> Magaz<strong>in</strong>e 05_2009 09

Interview with Rob<strong>in</strong> PriceA broader perspectiveof purchas<strong>in</strong>gMaterials and services bought make up for a big portion of <strong>Gurit</strong>’s cost base.«Worldclass»purchas<strong>in</strong>g plays an essential role <strong>in</strong> <strong>Gurit</strong>’s overall operations improvementscheme. s h a p e spoke with Chief Purchas<strong>in</strong>g Officer Rob<strong>in</strong> Price – a tell-tale name!TechTalkCATIA reduces designand development timeDer Wechsel zur c a d -Software c at i aerleichtert die Zusammenarbeit zwischen<strong>Gurit</strong> und Autobauern.CAD 制 图 软 件 CATIA 的 采 用 , 大 大 促进 了 与 汽 车 客 户 之 间 的 合 作 。It’s n<strong>in</strong>e months s<strong>in</strong>ce you jo<strong>in</strong>ed <strong>Gurit</strong> as Chief Purchas<strong>in</strong>gOfficer. What changes have you made?I was lucky to jo<strong>in</strong> a team that was already implement<strong>in</strong>g many facetsof good purchas<strong>in</strong>g practice, so I haven’t had to start from zero.The first th<strong>in</strong>g I’ve done is to structure the way we analyse our purchas<strong>in</strong>g<strong>in</strong>formation, and now we are able to give all the <strong>Gurit</strong> bus<strong>in</strong>essesa complete cost report each month and, more importantly,a cost forecast for the next 12 months. We call it the «Purchas<strong>in</strong>gRadar». The next stage has been to extend our focus. Traditionally,Group Purchas<strong>in</strong>g has concentrated on raw materials only. They arecerta<strong>in</strong>ly the most important costs for us to manage, but there arealso significant costs to control <strong>in</strong> other areas. I’ve split our wholespend <strong>in</strong>to five categories, each managed by a category manager:Chemicals, Production Consumables, Re<strong>in</strong>forcements, Indirect Materials,and Services. I’ve just appo<strong>in</strong>ted Julie Lavers as categorymanager for services. Initially, she will concentrate on manag<strong>in</strong>g ourexpenditure on freight, but she will then move on to other areas ofnon-raw material spend. Each category manager is responsible forwork<strong>in</strong>g with me to develop strategies for each commodity with<strong>in</strong>their categories. We then select the right set of suppliers to help usto achieve goals with<strong>in</strong> each strategy. The supply base should bedynamic. We expect constant improvement from suppliers and supplierdevelopment is someth<strong>in</strong>g that we will emphasise more. Somesuppliers will not make the grade, allow<strong>in</strong>g us to <strong>in</strong>troduce newsuppliers. Our customers are very demand<strong>in</strong>g of us, and we have tobe equally demand<strong>in</strong>g of our suppliers.You’ve just <strong>in</strong>troduced a new global purchas<strong>in</strong>g policy.Why was that?Every site spends money with suppliers. My team – currently n<strong>in</strong>e ofus located <strong>in</strong> the u k – manage the major share, but some non-rawmaterial spends are too small to centralise and will cont<strong>in</strong>ue to berun locally us<strong>in</strong>g the global processes outl<strong>in</strong>ed <strong>in</strong> the new policy. Thepolicy sets some standards to ensure that <strong>Gurit</strong> gets best value at allthe sites. The Group Purchas<strong>in</strong>g team will work more closely withthe sites and provide commercial expertise as necessary.What effect does the global recession have uponyour purchas<strong>in</strong>g activities?The economic climate is bad for everyone. However, we are seen asan attractive customer by our suppliers because of the good mixof <strong>in</strong>dustries we serve. Our target markets all promise considerablegrowth – if not this year, at least <strong>in</strong> the mid-term. And we are recog-nized as materials specialists at the forefront of technology. This issometh<strong>in</strong>g our suppliers like, and they take pride <strong>in</strong> be<strong>in</strong>g part of ourextended team.I th<strong>in</strong>k your aim is to produce a world-class purchas<strong>in</strong>gorganisation. Are you there yet?We’re gett<strong>in</strong>g better, and we look to improve even more. «Worldclass» is always a dest<strong>in</strong>ation on the horizon and no matter howmuch we improve there is always scope for further improvement.We recently sent out a questionnaire to key people with<strong>in</strong> <strong>Gurit</strong>. Thefeedback was that we’re on the right track <strong>in</strong> many areas, but there’splenty of ways for us to <strong>in</strong>crease our impact on the bus<strong>in</strong>ess. Part ofthat will come from communication. Many people still th<strong>in</strong>k that purchas<strong>in</strong>gis just about price. There’s so much more we can do to addvalue to our end customers, and we will only do that by talk<strong>in</strong>g moreto the bus<strong>in</strong>ess teams <strong>in</strong> <strong>Gurit</strong> to learn about our customers’ needs,and to give feedback on what we’ve learned about the market fromour suppliers.What about communication «up-stream»?Very important. The key phrases here are «reduc<strong>in</strong>g supply risk» and,as previously mentioned, «supplier development». We like to workas closely as possible with our suppliers. We provide them withfeedback on their performance and try wherever possible to helpthem improve their own processes. Secure supplies and consistentquality is essential for us. Seamless supplies, multiple sourc<strong>in</strong>g andaccurate news flow and communication allow us to reduce our<strong>in</strong>ventory levels. This gives us a benefit, but one that we balance aspart of our overall management of risk. If our suppliers improve qualityconsistency, reduce wastage and reach higher output levels, it isgood for both of us – supplier and purchaser. We have, for example,some ongo<strong>in</strong>g «six-sigma» work with some of our sourc<strong>in</strong>g partners,which are very promis<strong>in</strong>g.So after your first n<strong>in</strong>e months are you still enjoy<strong>in</strong>g it?Absolutely – no question about it! Every day is different and thereare the great people I work with both with<strong>in</strong> our company and at oursuppliers.<strong>Gurit</strong> wurde auch <strong>in</strong> der Materialbeschaffung deutlich <strong>in</strong>ternationaler undkompetitiver.固 瑞 特 公 司 在 原 材 料 开 发 方 面 的 成 就 已 变 得 日 趋 国 际 化 及 具 竞 争 力 。The <strong>Gurit</strong> Automotive team had first been us<strong>in</strong>g an entry-level c a d tool. They havenow made the switch to c at i a. Shar<strong>in</strong>g design <strong>in</strong>formation with o e m s us<strong>in</strong>g thesame data format greatly facilitates cooperation.Advis<strong>in</strong>g customers on composite-specific design matters for theircomponents is a key part of <strong>Gurit</strong>’s offer<strong>in</strong>g as a tier 1 automotivesupplier. Small changes <strong>in</strong> edge condition or draft angles can havea significant impact on a composite component’s manufacturabilityand price. Effective use of c a d , both as an analysis tool and a meansof communication between design teams, underp<strong>in</strong>s this process.Once the component geometry is f<strong>in</strong>alised, c a d work on tool<strong>in</strong>g conceptsbeg<strong>in</strong>s. This is largely an iterative process with <strong>in</strong>puts from thecustomer, from <strong>Gurit</strong> eng<strong>in</strong>eers and the toolmaker’s own designteam. Historically, <strong>Gurit</strong> had worked with an easy-to-use and relatively<strong>in</strong>expensive entry-level system as its primary 3d c a d system.«We used this system to develop the design of the production toolsfor the current Aston Mart<strong>in</strong> d b s coupé,» says Mart<strong>in</strong> Starkey, Manag<strong>in</strong>gDirector of <strong>Gurit</strong> Automotive. Interim designs are frequentlyexchanged and modified by all parties prior to f<strong>in</strong>al design sign-off.«With time, it became obvious, that our system did not fully fulfillall the requirements for day to day tasks <strong>in</strong> the demand<strong>in</strong>g automotiveenvironment. Especially the creation of files for data exchangeresulted <strong>in</strong> abnormally large files imped<strong>in</strong>g cross communicationbetween <strong>Gurit</strong> and its partners.»Communicat<strong>in</strong>g <strong>in</strong> CATIaTwo c a d systems are pre-em<strong>in</strong>ent <strong>in</strong> the automotive <strong>in</strong>dustry:i-d e a s was largely driven by the Ford Motor Company, merged withthe Unigraphics n x series of c a d systems and cont<strong>in</strong>ues to be usedat Ford and other companies. c at i a Version 4 and Version 5 havebeen adopted by a large number of automotive o e m s and are rapidlybecom<strong>in</strong>g a de facto standard for automotive design. Communicat<strong>in</strong>g<strong>in</strong> c at i a native file formats is a condition of becom<strong>in</strong>g a tier 1supplier for many o e m s. <strong>Gurit</strong> has therefore opted for c at i a v5. «Oursystem went live <strong>in</strong> November 2008 with onsite support and tra<strong>in</strong><strong>in</strong>g<strong>in</strong> its fundamental operation,» Alan Purves, Account Eng<strong>in</strong>eer<strong>in</strong>gDesign Manager remembered. Further, automotive-specific advancedtra<strong>in</strong><strong>in</strong>g took place at the supplier <strong>in</strong> April 2009. The hugevariety of c at i a modules offers scope to <strong>in</strong>tegrate other processesand ga<strong>in</strong> further improvements <strong>in</strong> productivity, for example programm<strong>in</strong>gof c n c cutter paths for future projects could be accomplishedfrom with<strong>in</strong> c at i a us<strong>in</strong>g the Mach<strong>in</strong><strong>in</strong>g Workbench. A key part of thedevelopment of c at i a has been to <strong>in</strong>tegrate composites manufactur<strong>in</strong>gand design operations, and the Composites Workbench allowsply shapes to be generated, developed and cut from with<strong>in</strong> a c at i aenvironment.Speed<strong>in</strong>g up design and developmenttime for Aston Mart<strong>in</strong>’s DBS VolanteAfter completion of the basic tra<strong>in</strong><strong>in</strong>g course, B-surface tool designwork was undertaken for <strong>Gurit</strong>’s <strong>in</strong>volvement <strong>in</strong> the Aston Mart<strong>in</strong>d b s Volante project, and the value of the <strong>in</strong>vestment <strong>in</strong> c at i a andassociated tra<strong>in</strong><strong>in</strong>g rapidly became clear: Us<strong>in</strong>g the former 3d packagefor the d b s Coupé had taken approximately 50 man hours. Us<strong>in</strong>gc at i a v5, a similar task for d b s Volante took just n<strong>in</strong>e man hours.Tool design for the d b s Volante model represented a significant progressionfor <strong>Gurit</strong> as the global lead<strong>in</strong>g carbon fibre parts supplier.«Through further development across all our processes and deploymentof powerful tools such as c at i a, the time taken from designfreeze to parts production has effectively been halved,» concludedMart<strong>in</strong> Starkey.10 shapeThe <strong>Gurit</strong> Magaz<strong>in</strong>e 05_2009 11

Markets: W<strong>in</strong>d EnergyKeep them turn<strong>in</strong>gW<strong>in</strong>d energy is still a relatively juvenile <strong>in</strong>dustry. W<strong>in</strong>d turb<strong>in</strong>es are not only erectedanew, they also need regular ma<strong>in</strong>tenance work to keep them turn<strong>in</strong>g. What is more,the ones <strong>in</strong>stalled <strong>in</strong> the 1980s are slowly ag<strong>in</strong>g. This opens the door for an ever morespecialized after-market service <strong>in</strong>dustry. <strong>Gurit</strong> has a special product offer<strong>in</strong>g target<strong>in</strong>gthe composite needs of this grow<strong>in</strong>g market.time, service costs form a smaller percentage of the overall costs asthe average size of w<strong>in</strong>d turb<strong>in</strong>es rise. The European W<strong>in</strong>d EnergyAssociation cites that 1.2 to 1.5 eurocents per kWh of w<strong>in</strong>d powerproduced over the total lifetime of a turb<strong>in</strong>e can be attributed tooperation and ma<strong>in</strong>tenance. Similar figures have been produced bythe Danish W<strong>in</strong>d Industry Association who state that the yearly ma<strong>in</strong>tenancecosts are typically 1.5% to 2% of orig<strong>in</strong>al <strong>in</strong>stalled w<strong>in</strong>d turb<strong>in</strong>egenerator cost. For a 1.5 m w w<strong>in</strong>d turb<strong>in</strong>e, cost<strong>in</strong>g Euro 1.2 m,this equates to Euro 24,000/year.Blade repairs are typically performed by the W<strong>in</strong>d Turb<strong>in</strong>e Generatoro e m s or the blade builders <strong>in</strong> the warranty period. The warrantyperiod is typically 2– 5 years depend<strong>in</strong>g on customer, and most bladerepairs dur<strong>in</strong>g this period <strong>in</strong>volve us<strong>in</strong>g the orig<strong>in</strong>al blade materialsand repair procedures def<strong>in</strong>ed by the o e m s.Outside the warranty period the blade repairs become the responsibilityof the w<strong>in</strong>d farm operator and the repairs can <strong>in</strong>volve the use ofmaterials that were not orig<strong>in</strong>ally used <strong>in</strong> the blade build and therepairs can be performed by sub contract repair companies.Several <strong>in</strong>dustry surveys have studied the outlook of the w<strong>in</strong>d energyafter market recently: With the ag<strong>in</strong>g of w<strong>in</strong>d farms, they conclude,the opportunity for after-market service providers is bound to grow.Currently, the global w<strong>in</strong>d turb<strong>in</strong>e ma<strong>in</strong>tenance, repair and overhaulservice market is estimated to grow from u s d 3.9 billion today toover u s d 9 billion by 2013, <strong>in</strong>clud<strong>in</strong>g work done on w<strong>in</strong>d turb<strong>in</strong>eblades, generators, gear boxes and other turb<strong>in</strong>e components. Thisequates to an 18% annual growth rate. With easily over 20% <strong>in</strong>creaseper year, <strong>in</strong>dustry analysts expect to see the biggest growth <strong>in</strong> NorthAmerica and Ch<strong>in</strong>a where the w<strong>in</strong>d energy capacity is believed toImag<strong>in</strong>e a car driv<strong>in</strong>g at 260 km/h for about 20 years along a w<strong>in</strong>dbatteredsea shore. What would that car possibly look like? The tipsof w<strong>in</strong>d turb<strong>in</strong>e blades cut at about that speed through the air and aredesigned to last 20 years. Twenty years is commonly believed to bethe average life expectancy of a w<strong>in</strong>d turb<strong>in</strong>e on land, off-shore it willprobably be more like 25 years as w<strong>in</strong>ds are less turbulent there.Typical blade repair workThe blade production market is characterised by rapid technical advances,global blade manufactur<strong>in</strong>g/assembly sites, new entrantsand the fast <strong>in</strong>troduction of new larger blades. These market trends,comb<strong>in</strong>ed with environmental considerations, <strong>in</strong>evitably lead to bladerepairs which fall <strong>in</strong>to three categories:1. Manufactur<strong>in</strong>g issuesa. Fibre wav<strong>in</strong>ess and lam<strong>in</strong>ate overlapsb. Bad bonds, delam<strong>in</strong>ations and voidsc. Quality issues that relate to a batch of blades;res<strong>in</strong>/adhesive issues or errors <strong>in</strong> blade process<strong>in</strong>g2. Transport damagea. Damage on the trail<strong>in</strong>g edge due to movementof the transport secur<strong>in</strong>g strapsb. Accidental damage from transport/<strong>in</strong>stallation;damage caused by fork lifts or cranes.3. Environmental damagea. Lead<strong>in</strong>g edge erosionb. Trail<strong>in</strong>g edge splitsc. Lighten<strong>in</strong>g strikes – Scorch<strong>in</strong>g and blade tip splitsThe most common repairs are related to lightn<strong>in</strong>g strikes. W<strong>in</strong>dturb<strong>in</strong>es are designed to take lightn<strong>in</strong>g strikes and are typically protectedby a strong copper wire surfac<strong>in</strong>g at regular <strong>in</strong>tervals <strong>in</strong> theblade and especially at the tip of the blade where lightn<strong>in</strong>g strikesoccur most frequently. If a lightn<strong>in</strong>g bolt is too big to be absorbed bythe rod, the excess heat at the po<strong>in</strong>t of entry bursts the compositesurround<strong>in</strong>g the copper wire.Blade damage is not easy to detect; often it is a change <strong>in</strong> the soundfrom one of the blades that signals a change <strong>in</strong> its aerodynamics.Composite specialists then clean out the damaged section and laydown new layers of fibre fabric, res<strong>in</strong> and gelcoats for smoothsurface – not unlike repair<strong>in</strong>g the hull of a boat, except for the factthat this work is usually done <strong>in</strong> airy heights.Regular servic<strong>in</strong>g of blades is a key element <strong>in</strong> reduc<strong>in</strong>g downtimeand ga<strong>in</strong><strong>in</strong>g the optimum power output from the w<strong>in</strong>d turb<strong>in</strong>e generator.As an example, W<strong>in</strong>d Energy Services <strong>in</strong> the US claim thatlead<strong>in</strong>g edge erosion on blades can result <strong>in</strong> a 5%–10% power lossper blade.The advent of a grow<strong>in</strong>g service <strong>in</strong>dustryWith<strong>in</strong> the last 10 years, the <strong>in</strong>stalled w<strong>in</strong>d energy capacity rose fromabout 7 g w worldwide to well over 120 g w today. All these turb<strong>in</strong>esneed to be serviced. Service costs certa<strong>in</strong>ly depend on the location,on the type of turb<strong>in</strong>e, on its age and size. It is fair to expect ma<strong>in</strong>tenancecosts to rise along with the age of the equipment. At the same14 shapeThe <strong>Gurit</strong> Magaz<strong>in</strong>e 05_2009 15

grow above average <strong>in</strong> the next five years, while this market is expectedto grow at some 14% <strong>in</strong> Europe. Currently, ma<strong>in</strong>tenance,repair and complete overhaul and replacement costs contribute between20 to 25% of expenditures <strong>in</strong> the global w<strong>in</strong>d turb<strong>in</strong>e market,research papers say.With the wide range of w<strong>in</strong>d energy participants rang<strong>in</strong>g from largepower utility, to manufacturers and niche players, the <strong>in</strong>dustry specialistsreckon that there is a true need for a structured and reliableservice bus<strong>in</strong>ess model to meet the needs of this after-market. Upto today, the after-market has been dom<strong>in</strong>ated by the Orig<strong>in</strong>al EquipmentManufacturers. As the market matures and the demand forspecialized after-market services outgrows the exist<strong>in</strong>g capacity,<strong>in</strong>dependent third-party service providers are expected to fill thisris<strong>in</strong>g demand gap. <strong>Gurit</strong> is ready to supply them with a comprehensivecomposite blade repair system.<strong>Gurit</strong> W<strong>in</strong>d Turb<strong>in</strong>e Blade Repair SystemsCategory Product Description Mix ratiores<strong>in</strong>:hardener(by volume)WetLam<strong>in</strong>at<strong>in</strong>gAmpreg 21Low viscosity wetlam<strong>in</strong>at<strong>in</strong>g systemwith range of hardenerspeedsInfusion PRIME 20LV Low viscosity <strong>in</strong>fusionsystem with good cureprogression & hightoughness at ambientonly cure. Range ofhardener speedsAdhesives Spabond 340LV High strength & toughnessstructural adhesivewith range of hardenerspeedsSpabond 730Fast cur<strong>in</strong>g structuraladhesive. Gels <strong>in</strong> 10 m<strong>in</strong>utes,solid <strong>in</strong> 2 hours &full properties achievedovernightApplication100:38 Structural repairs toblade shells100:31 Structural repairs toblade shells & <strong>in</strong>jection<strong>in</strong>to voids100:50 Trail<strong>in</strong>g edge splits damagedue to lightn<strong>in</strong>gstrikes, delam<strong>in</strong>ations& bad bonds100:100 Small repairs/splits ontrail<strong>in</strong>g edge sectionsFillers 15 M<strong>in</strong> Spot filler Fast cur<strong>in</strong>g spot filler 100:100 Fill<strong>in</strong>g & fair<strong>in</strong>g of lead<strong>in</strong>gedge and defectson blade surfaceGelcoatSP8682 withSP7856 hardener& SP7857accelerator3 component UV stableEpoxy GelcoatTargeted Market Approach <strong>in</strong> the US<strong>Gurit</strong> and Composites One have jo<strong>in</strong>ed together to offer a speciallydeveloped range of blade repair materials for the North AmericanW<strong>in</strong>d Energy market. These competitively priced products are specificallydesigned for repair, possess the appropriate approval by g land/or o e m s, and are available to all developed w<strong>in</strong>d resource states<strong>in</strong> the u s at very short lead times. Alongside this specifically designedservice, Composites One and <strong>Gurit</strong> are also launch<strong>in</strong>g a productselection guide that will detail the range of materials used torepair the most commonly found damage to <strong>in</strong> service blades. Theguide conta<strong>in</strong>s detailed guides to repair<strong>in</strong>g <strong>in</strong>field blades, as well asrecommended materials. Compiled by <strong>Gurit</strong> and Composites One,the guide is based upon the comb<strong>in</strong>ed experience of the two companieswho have supplied materials and technology <strong>in</strong>to the w<strong>in</strong>denergy market for 15 years.100:37.7:upto 3.5Repair of topcoat usedon prepreg bladesproduced by Vestas &GamesaAvailabilitySmall 1.33kg packs up to1000kg IBCs3.9kg packs to 1000kg IBC400ml cartridges up to200kg drums400ml cartridges1kg res<strong>in</strong> & hardenerup to 24kg res<strong>in</strong> + 24kghardener.1.6kg packs<strong>Gurit</strong> produces a range of products for blade repairs. These products have been used by a number of W<strong>in</strong>d Turb<strong>in</strong>e Generator o e m s fororig<strong>in</strong>al blade builds but are supplied <strong>in</strong> small, more user friendly packs for <strong>in</strong>-field blade repairs. The range of repair materials offered by <strong>Gurit</strong>are suitable for both structural and blade surface repairs on epoxy <strong>in</strong>fused and prepreg blades.Die Wartung von W<strong>in</strong>dturb<strong>in</strong>en ist e<strong>in</strong> wachsender Markt, den <strong>Gurit</strong> mite<strong>in</strong>em speziellen Produktpaket gezielt angeht.对 风 力 涡 轮 机 的 维 护 是 一 个 朝 阳 的 行 业 , 固 瑞 特 公 司 致 力 于 该 项 特别 材 料 的 研 发 。Interview with Rudolf HadornStick<strong>in</strong>g to strategicpriorities2009 is a year of global recession. Recovery comes slower and more gradually thananticipated. shape wanted to know from ceo Rudolf Hadorn how <strong>Gurit</strong> was cop<strong>in</strong>gwith the current challenges.What does <strong>Gurit</strong> need most <strong>in</strong> challeng<strong>in</strong>g times like these?Three th<strong>in</strong>gs, I would say: A clear strategic goal, discipl<strong>in</strong>e <strong>in</strong> execution,besides, of course, the f<strong>in</strong>ancial means to safely stay <strong>in</strong> bus<strong>in</strong>ess.Let me put that <strong>in</strong>to perspective: Some of our customers witnessrather substantial sales reductions this year versus 2008. Andthis clearly affects <strong>Gurit</strong>, too. Yet, while we are suffer<strong>in</strong>g from lowersales and decl<strong>in</strong><strong>in</strong>g capacity utilizations, we adjust our cost baseas best as we can to protect our profitability and the solidity of ourbalance sheet. And we stay focused on the implementation of ourlong-term strategy.What about <strong>Gurit</strong>’s capacity utilization?Two years ago, <strong>Gurit</strong> <strong>in</strong>vested <strong>in</strong>to the global expansion of its productioncapabilities – based on the growth projections expected for thecom<strong>in</strong>g years at that time. Last year, our production capacities werenot fully loaded. In the first half of 2009, sales to our target marketsdecl<strong>in</strong>ed by 12% based on constant currency translation rates. Whilethe situation <strong>in</strong> our European works is just about satisfactory, theload<strong>in</strong>g of our prepreg works <strong>in</strong> Canada is disappo<strong>in</strong>t<strong>in</strong>g, and <strong>in</strong> Ch<strong>in</strong>awe also have considerable reserves <strong>in</strong> prepreg, while we are full <strong>in</strong>our foam expansion and kitt<strong>in</strong>g activities. While we believe that theidle capacity will be beneficial <strong>in</strong> the next upturn, the task now is touse the low capacity utilization for retrofit programs, targeted mach<strong>in</strong>eryupgrades and for additional employee tra<strong>in</strong><strong>in</strong>g. We want tobe <strong>in</strong> the best shape possible when markets recover.Where exactly is <strong>Gurit</strong> <strong>in</strong>vest<strong>in</strong>g right now?We have just about doubled our foam kitt<strong>in</strong>g capability <strong>in</strong> Ch<strong>in</strong>a withthe purchase of two new 5-axis routers to kit Corecell foam this fall.And <strong>in</strong> Europe, we have launched a targeted retrofit program for ourprepreg mach<strong>in</strong>es. 2009 will not see massive capital expenditures,but wisely targeted and effective <strong>in</strong>vestments <strong>in</strong> l<strong>in</strong>e with our longtermstrategy.What are the major strategic objectives?For the whole <strong>Gurit</strong> Group, we certa<strong>in</strong>ly want to be <strong>in</strong> the best shapeand ready for the next upsw<strong>in</strong>g. Therefore we cont<strong>in</strong>ue to <strong>in</strong>vest <strong>in</strong>our product development and aim to expand our addressable markets.Look<strong>in</strong>g at the various target markets, our strategy can be summarizedas follows: In W<strong>in</strong>d Energy, we want to be recognized as thelead<strong>in</strong>g materials and technology partner for all w<strong>in</strong>d rotor bladesmanufactur<strong>in</strong>g technologies. We have considerably strengthenedour W<strong>in</strong>d Energy market<strong>in</strong>g and sales force for North America andthe Nordic countries <strong>in</strong> Europe. Apart from prepreg we are thus alsostrengthen<strong>in</strong>g our presence <strong>in</strong> formulated products and especially <strong>in</strong>core products. The acquisition of a majority stake <strong>in</strong> the companyCh<strong>in</strong>a Techno Foam <strong>in</strong> Ts<strong>in</strong>gdao also has to be seen <strong>in</strong> that context:We want to extend our foam presence <strong>in</strong> Ch<strong>in</strong>a with locally sourced,locally produced core materials for the Ch<strong>in</strong>ese market. Mov<strong>in</strong>g ourproduction as close as possible to our customers is another strategicthrust. As Ch<strong>in</strong>a will be one of the major growth markets for W<strong>in</strong>dEnergy, we are also <strong>in</strong>stall<strong>in</strong>g some of our capacities for res<strong>in</strong> formulationat <strong>Gurit</strong> (Tianj<strong>in</strong>).In Transportation, we want to ma<strong>in</strong>ta<strong>in</strong> our leadership position <strong>in</strong> aircraft<strong>in</strong>teriors materials <strong>in</strong> Europe and leverage this know-how <strong>in</strong>toother <strong>in</strong>terest<strong>in</strong>g markets such as Rail. We are aga<strong>in</strong> supply<strong>in</strong>g materialsfor a next generation of high-speed tra<strong>in</strong>s <strong>in</strong> Ch<strong>in</strong>a. Last butnot least, we want to br<strong>in</strong>g our Automotive bus<strong>in</strong>ess up to a nextlevel. In the second half of this year we will start supply<strong>in</strong>g Class-Acarbon car body parts to a second premium car maker. We hope toturn the broad <strong>in</strong>terest we see <strong>in</strong> the market for this technology <strong>in</strong>toreal sales figures when the economy picks up aga<strong>in</strong>.In Mar<strong>in</strong>e – a very difficult market for the time be<strong>in</strong>g – we work hardand successfully on expand<strong>in</strong>g our customer base. We have expandedour market<strong>in</strong>g efforts especially <strong>in</strong> the Nordic and the Mediterraneanboat market with Italy be<strong>in</strong>g a special focal po<strong>in</strong>t. In addition,we want to penetrate that market deeper with newly developedmaterials such as M-Foam and comprehensive materials and technologypackages for high-end production boat builders. The newcontract with Nautor/Swan is an important step <strong>in</strong> that direction.Klar auf die mittelfristige Strategie ausgerichtet,meistert <strong>Gurit</strong> die Herausforderungen derRezession.采 访 Hadorn 以 中 期 战 略 为 重 点 , 固 瑞 特 公司 迎 接 并 对 抗 全 球 经 济 衰 退 的 挑 战 。16 shapeThe <strong>Gurit</strong> Magaz<strong>in</strong>e 05_2009 17

Markets: Mar<strong>in</strong>es p beliefert Nautor <strong>in</strong> den nächsten Jahren mit e<strong>in</strong>emumfassenden Produkt- und Eng<strong>in</strong>eer<strong>in</strong>g-Paket.在 今 后 的 几 年 ,SP 会 为 Nautor 公 司 提 供 全 面 的产 品 及 技 术 服 务 。s p has ga<strong>in</strong>ed a three-year exclusive supply agreement with Nautor who builds theworld renowned Swan range of sail boats rang<strong>in</strong>g from 40 –130 feet. All newly designedSwans will be built <strong>in</strong> <strong>Gurit</strong>’s patented s p r i n t ® technology, Corecell structural foamcore, and Spabond structural adhesives. s p will also be contracted for the structuraleng<strong>in</strong>eer<strong>in</strong>g for all future boats.Turn-key materials andservices packageNautor has a long and illustrious history as a quality production boatbuilder that specialises <strong>in</strong> performance driven, ocean-go<strong>in</strong>g, luxurysail<strong>in</strong>g yachts. Although Nautor has been a very valuable customer tos p for well over a decade, they have <strong>in</strong> the past utilised various manufactur<strong>in</strong>gmethods with non-s p products. The last eight years hasseen the F<strong>in</strong>nish company expand their manufactur<strong>in</strong>g techniquesand push boundaries with the use of s p’s materials and technology.As a result, the most sophisticated Nautor yachts produced to datewill be launched later this year – the full s p r i n t ® carbon epoxy highperformance Swan 60 and 80. Paul Riley, Mar<strong>in</strong>e Sales Account Manager,expla<strong>in</strong>s how Nautor and s p have shared a close work<strong>in</strong>g partnershipand forged significant technical developments throughoutthe project. «Nautor was the first mar<strong>in</strong>e company to adopt s p r i n t ®technology <strong>in</strong> the production of a large structure and this was applied<strong>in</strong> the manufacture of the Swan 45 and 601 ranges. The lightweightdecks on this full bred racer cruiser provided practical productionexperience for s p and allowed the s p r i n t ® range to be ref<strong>in</strong>ed to <strong>in</strong>creaserobustness, and flexibility <strong>in</strong> fabric and res<strong>in</strong> selection. The45’s production process also <strong>in</strong>itiated the <strong>in</strong>troduction of tack films forwork on vertical surfaces. In turn, Nautor’s commitment to the projecthas seen the company make considerable <strong>in</strong>vestment <strong>in</strong> newproduction facilities, <strong>in</strong>clud<strong>in</strong>g a 100 foot computer controlled cur<strong>in</strong>goven which facilitates precise temperature control throughout thecur<strong>in</strong>g process,» Paul Riley expla<strong>in</strong>ed. On completion, the Swan 45performed beautifully and consistently achieved good results on therace course.Production boats built like one-off yachtsNautor was obviously keen to capitalise on the successful performanceof this first s p r i n t ® production boat, and the concept of theNautor 601 was born and latterly the new 60 and 80. The designhouse of German Frers and the eng<strong>in</strong>eer<strong>in</strong>g expertise of SP’s structuraleng<strong>in</strong>eer<strong>in</strong>g team were called upon with the aim of produc<strong>in</strong>ga superior performance yacht, normally only associated with customone-off builds, yet produced as a series production boat. From a productionperspective, the vessel must be uncomplicated to constructwithout compromis<strong>in</strong>g the values Nautor customers expect: superiorquality of <strong>in</strong>terior comfort and stylish fit-out, all comb<strong>in</strong>ed with impressiverac<strong>in</strong>g performance. This brief called for the use of stateof-the-artmaterials, <strong>in</strong>novative manufactur<strong>in</strong>g processes, comb<strong>in</strong>edwith an <strong>in</strong>telligent approach to eng<strong>in</strong>eer<strong>in</strong>g.Production Process<strong>in</strong>gWith the one-design concept, every aspect of the build of the boatmust be repeatable. s p r i n t ® with its fixed res<strong>in</strong> content, fibre weightsand pre-catalysed res<strong>in</strong> systems means accurate weight and lam<strong>in</strong>atethickness can be produced consistently <strong>in</strong> a simple process withthe opportunity for error removed. A prototype was not produced forthe Swan 60 project, so each boat <strong>in</strong> the series, <strong>in</strong>clud<strong>in</strong>g the first,had to be exact and delivered at the correct weight with no marg<strong>in</strong>for error as future modifications could not be made.With a team of eight men, the <strong>in</strong>ner sk<strong>in</strong> of the 60 was then laid. Thiswhole process took only three and a half days before apply<strong>in</strong>g thevacuum bag and cur<strong>in</strong>g – an extremely rapid lam<strong>in</strong>at<strong>in</strong>g time by ord<strong>in</strong>arystandards. The <strong>in</strong>clusion of extra res<strong>in</strong> with<strong>in</strong> the s p r i n t ® materialto facilitate core bond<strong>in</strong>g resulted <strong>in</strong> further time-sav<strong>in</strong>gs <strong>in</strong> whatwould normally be a very time consum<strong>in</strong>g process of prim<strong>in</strong>g the core,or the use of glue films, on either side of the core material. Not onlywas the procedure extremely time-efficient but it was also very clean,completely eradicat<strong>in</strong>g the need for any wet systems and the associateddrawbacks. Good standards and cont<strong>in</strong>uous improvement ofHealth and Safety practices are a very important issue for Nautorwho cont<strong>in</strong>uously strives to improve the environment forits operators.All the <strong>in</strong>ternal structure, bulkheads, transverse, longitud<strong>in</strong>al beams,keel box and eng<strong>in</strong>e mount<strong>in</strong>g structure were produced separately <strong>in</strong>female moulds. The Swan 60’s bulkheads and <strong>in</strong>ternal frames areconstructed with flanges so they can be sited and bonded <strong>in</strong>to placewith high strength structural adhesives – aga<strong>in</strong> m<strong>in</strong>imis<strong>in</strong>g wet lam<strong>in</strong>at<strong>in</strong>gprocesses and reduc<strong>in</strong>g man-hours and labour costs considerably.On s p’s technical team’s recommendation, the structure wasbonded <strong>in</strong>to the hull us<strong>in</strong>g a comb<strong>in</strong>ation of s p’s Spabond 345, 340lvand 130 adhesives.Reliable and predictable materialWork<strong>in</strong>g with s p r i n t ® and female moulds also means the lam<strong>in</strong>atethickness is extremely predictable and repeatable. This comb<strong>in</strong>edwith a consistent surface f<strong>in</strong>ish allows certa<strong>in</strong> tolerances to beachieved, enabl<strong>in</strong>g the secondary bond<strong>in</strong>g of the <strong>in</strong>ternal structure tobe a relatively simple process. The need to compensate for miscalculationsthat can result <strong>in</strong> the fill<strong>in</strong>g of large gaps or cutt<strong>in</strong>g of lam<strong>in</strong>atesis also removed.«Once we became familiar with the process, s p r i n t ® has proven tobe a reliable and predictable material, as well as sav<strong>in</strong>g valuable manhours.It also enables you to accurately predict f<strong>in</strong>al weights andproperties of lam<strong>in</strong>ates which makes boatbuild<strong>in</strong>g much easier.» MrKjell Vesto, Nautor’s Technical Director commented, «We are able torepeatedly produce lam<strong>in</strong>ates with very low void contents, correctfibre to res<strong>in</strong> ratios and predict mechanical properties – exactly whata reputable boat builder needs!»20 shapeThe <strong>Gurit</strong> Magaz<strong>in</strong>e 05_2009 21

Be<strong>in</strong>g <strong>Gurit</strong><strong>Gurit</strong> Website Now Available <strong>in</strong> Ch<strong>in</strong>eseIn order to enhance and develop our bus<strong>in</strong>ess <strong>in</strong> Ch<strong>in</strong>a, <strong>Gurit</strong> hascreated a dedicated Ch<strong>in</strong>ese website www.gurit.cn. Be<strong>in</strong>g already aprime W<strong>in</strong>d Energy market for <strong>Gurit</strong>, Ch<strong>in</strong>a also offers great opportunitiesfor our Transportation and Mar<strong>in</strong>e products. The website waslaunched <strong>in</strong> time to support <strong>Gurit</strong>’s presence at Ch<strong>in</strong>a Composites<strong>in</strong> September 2009. The Ch<strong>in</strong>ese website is a condensed versionof the ma<strong>in</strong> website summariz<strong>in</strong>g all current, exist<strong>in</strong>g materialsand <strong>in</strong>formation. The gurit.cn website covers all ma<strong>in</strong> market areasand associated products <strong>in</strong>clud<strong>in</strong>g W<strong>in</strong>d Energy, Aerospace, Rail,Automotive and Mar<strong>in</strong>e. The website has been fully translated <strong>in</strong>toCh<strong>in</strong>ese and will further enhance and strengthen our customer baseand product offer<strong>in</strong>g.Get on your bikes!<strong>Gurit</strong> (u k ) has various <strong>in</strong>itiatives to keep employees <strong>in</strong> shape: theonsite gym is used by many colleagues over lunch-time and afterwork. Others keep fit swimm<strong>in</strong>g at Gurnard P<strong>in</strong>es, the local leisureclub. The easiest available daily fitness tra<strong>in</strong><strong>in</strong>g, however, is to ridethe bike to work. «<strong>Gurit</strong> not only l<strong>in</strong>ked its site to the public cycle pathThe <strong>Gurit</strong> Code of ConductApart from hard facts and f<strong>in</strong>ancial <strong>in</strong>formation, topics like Corporate Governance,Social Responsibility and Bus<strong>in</strong>ess Ethics <strong>in</strong>creas<strong>in</strong>gly become <strong>in</strong>vestment criteriaand areas of general <strong>in</strong>terest. The Board and Management of <strong>Gurit</strong> have signed offon the <strong>Gurit</strong> Code of Conduct – a comprehensive Guide of bus<strong>in</strong>ess pr<strong>in</strong>ciples applicablethroughout the Group.<strong>Gurit</strong> IR website contentranks 25th out of 500The websites of all Swiss companies listed on s i x Swiss Exchangeare annually be<strong>in</strong>g analysed <strong>in</strong> terms of <strong>in</strong>vestor relevant content.S<strong>in</strong>ce 2007, the communication bachelor students of h w z , the ZürichUniversity of Applied Sciences, have rated the websites of the publiclylisted companies us<strong>in</strong>g a pre-def<strong>in</strong>ed list of criteria. <strong>Gurit</strong> endedex aequo on rank 25 together with Allreal, Baloise, Comet, Logitechand Swisscom. The 10 best rated websites were analyzed a secondtime by an <strong>in</strong>dependent jury consist<strong>in</strong>g of analysts, f<strong>in</strong>ancial on-l<strong>in</strong>ejournalists, on-l<strong>in</strong>e specialists and faculty. Georg Fischer’s websitescored highest, followed by Credit Suisse and Roche.network on the Isle of Wight, we also have special bicycle offers forour employees,» says John Frogatt who eagerly advocates the «Geton your bikes» <strong>in</strong>tiative or the car shar<strong>in</strong>g scheme to relieve somespace <strong>in</strong> the car park. «We offer a great selection of bikes at a considerablediscount.» Work<strong>in</strong>g together with a local bicycle and sportsshop, Avocet Sports, <strong>Gurit</strong> can provide its employees – and families –with cycles at some 30% discounts. Some 30 bicycles have alreadybeen sold <strong>in</strong> the context of this programme. s h a p e spoke with WarwickLauder, Design Eng<strong>in</strong>eer, who recently got an 18-speed mounta<strong>in</strong>bike through the «Get on your bikes» plan. «I th<strong>in</strong>k it is a great<strong>in</strong>itiative, promot<strong>in</strong>g true green transportation to and from <strong>Gurit</strong>,and I would like to congratulate John on that brilliant idea. It certa<strong>in</strong>lygot me on my bike. I live about 4 miles from <strong>Gurit</strong>, accessible by thelovely bike path that runs beside the Med<strong>in</strong>a River. This is really avery nice ride to work.» And Warwick does not limit his bicycle rideto nice and sunny days. «This summer I have been rid<strong>in</strong>g to workreally every day along that bike path. The shower and gym facilitiesat <strong>Gurit</strong> (u k ) allow you to ride <strong>in</strong>to work – whatever weather condition.I usually hit the gym when I get to <strong>Gurit</strong> <strong>in</strong> the morn<strong>in</strong>g anyway,then refresh myself before I start my work<strong>in</strong>g day.»Die <strong>Gurit</strong> Website ist nun auch auf Ch<strong>in</strong>esischaufgeschaltet. Preislich attraktive Fahrräder überzeugenimmer mehr <strong>Gurit</strong>-Mitarbeitende zur Arbeit zu radeln.固 瑞 特 网 站 已 经 开 通 了 中 文 。The core activities of <strong>Gurit</strong> today were formed both organically and bya series of acquisitions over the last decade. Grow<strong>in</strong>g <strong>in</strong>to a s<strong>in</strong>gleorganization, we developed a set of values, called «Values4Success»and discussed <strong>in</strong> earlier editions of s h a p e. They are based on a mutualunderstand<strong>in</strong>g of our personal values such as trust, respect, honesty,loyalty and <strong>in</strong>tegrity. The «Values4Success» provide a frameworkto guide our daily actions and the way we respond to difficultdecisions.• Customers – our priority• Renewal through <strong>in</strong>novation• Profit through empowerment• Success through people<strong>in</strong> accordance with the lawWhile we conduct bus<strong>in</strong>ess with<strong>in</strong> the framework of «Values4Success»,our bus<strong>in</strong>ess conduct also must be strictly <strong>in</strong> accordance withnational and <strong>in</strong>ternational law and many additional rules and regulations.As the social and economic environment is chang<strong>in</strong>g at an everfaster pace, we want to uphold the strengths of <strong>Gurit</strong>. Establish<strong>in</strong>gclear guidel<strong>in</strong>es which <strong>in</strong>tegrate our cont<strong>in</strong>uously grow<strong>in</strong>g set of standardsis an essential step <strong>in</strong> that direction. The <strong>Gurit</strong> Code of Conductsets out those same standards of conduct that our employees havealways applied us<strong>in</strong>g good common sense and is designed to helpdeal with ethical and legal compliance <strong>in</strong> our day-to-day work andapplies to the entire <strong>Gurit</strong> Group. We will therefore ask senior <strong>Gurit</strong>staff to study and sign the <strong>Gurit</strong> Code of Conduct and share anddiscuss this Code with all colleagues.shared, discussed and publiclymade AvailableThe <strong>Gurit</strong> Code of Conduct is not only shared and regularly discussedwith each and every employee <strong>in</strong> the context of the yearly appraisals,but also made publicly available on our website www.gurit.comSpecial chapters are dedicated to our full compliance with the law,our <strong>in</strong>formation procedures, our environment, health and safety policy,our bus<strong>in</strong>ess ethics rules, our employee and customer relationspolicies and – last but not least – compliance.<strong>Gurit</strong> is determ<strong>in</strong>ed to adhere to the <strong>Gurit</strong> Code of Conduct and expectsall employees – and where applicable also all external partieswe work with – to fully comply with the Code.Der <strong>Gurit</strong> Code of Conduct vere<strong>in</strong>t die für <strong>Gurit</strong> undalle <strong>Gurit</strong>-Mitarbeitenden relevanten Verhaltensgrundsätze<strong>in</strong> e<strong>in</strong>em e<strong>in</strong>heitlichen Dokument.行 为 守 则 : 固 瑞 特 公 司 的 行 为 守 则 通 过 一 本 手册 整 合 了 所 有 组 织 相 关 的 准 则 , 标 准 及 员 工 行为 规 范 。22 shapeThe <strong>Gurit</strong> Magaz<strong>in</strong>e 05_2009 23

GURIT AGENDA 2009⁄2010<strong>Gurit</strong> will showcase its wide range of material packages, solutionsand technologies at a trade show near you.The <strong>Gurit</strong> teams look forward to meet<strong>in</strong>g you and <strong>in</strong>troduc<strong>in</strong>g youto the latest <strong>in</strong> advanced composites at the follow<strong>in</strong>g shows:» 3rd International Tidal Energy Summit 2009, London10 – 11 November 2009» METS 2009, Amsterdam17 – 19 November 2009» JEC Composites Show, Paris13 – 15 April 2010Schaffhauserstrasse 339CH - 8050 Zürich/OerlikonSwitzerlandwww.gurit.com