ELCO History of FFC/FPC - AVX

ELCO History of FFC/FPC - AVX

ELCO History of FFC/FPC - AVX

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

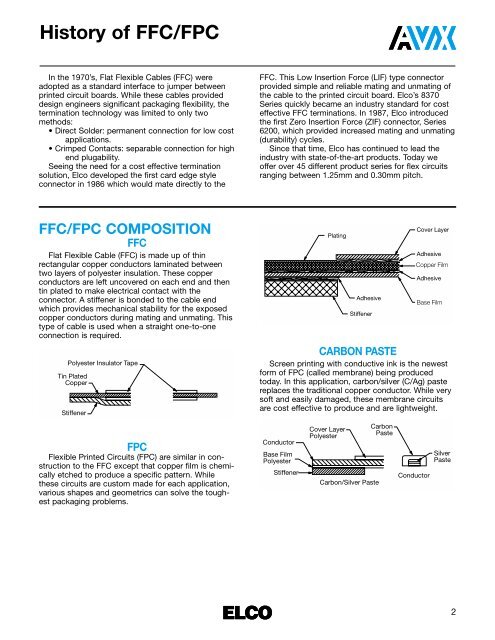

<strong>History</strong> <strong>of</strong> <strong>FFC</strong>/<strong>FPC</strong>In the 1970’s, Flat Flexible Cables (<strong>FFC</strong>) wereadopted as a standard interface to jumper betweenprinted circuit boards. While these cables provideddesign engineers significant packaging flexibility, thetermination technology was limited to only twomethods:• Direct Solder: permanent connection for low costapplications.• Crimped Contacts: separable connection for highend plugability.Seeing the need for a cost effective terminationsolution, Elco developed the first card edge styleconnector in 1986 which would mate directly to the<strong>FFC</strong>. This Low Insertion Force (LIF) type connectorprovided simple and reliable mating and unmating <strong>of</strong>the cable to the printed circuit board. Elco’s 8370Series quickly became an industry standard for costeffective <strong>FFC</strong> terminations. In 1987, Elco introducedthe first Zero Insertion Force (ZIF) connector, Series6200, which provided increased mating and unmating(durability) cycles.Since that time, Elco has continued to lead theindustry with state-<strong>of</strong>-the-art products. Today we<strong>of</strong>fer over 45 different product series for flex circuitsranging between 1.25mm and 0.30mm pitch.<strong>FFC</strong>/<strong>FPC</strong> COMPOSITION<strong>FFC</strong>Flat Flexible Cable (<strong>FFC</strong>) is made up <strong>of</strong> thinrectangular copper conductors laminated betweentwo layers <strong>of</strong> polyester insulation. These copperconductors are left uncovered on each end and thentin plated to make electrical contact with theconnector. A stiffener is bonded to the cable endwhich provides mechanical stability for the exposedcopper conductors during mating and unmating. Thistype <strong>of</strong> cable is used when a straight one-to-oneconnection is required.Polyester Insulator TapeTin PlatedCopperStiffenerPlatingAdhesiveStiffenerCover LayerAdhesiveCopper FilmAdhesiveBase FilmCARBON PASTEScreen printing with conductive ink is the newestform <strong>of</strong> <strong>FPC</strong> (called membrane) being producedtoday. In this application, carbon/silver (C/Ag) pastereplaces the traditional copper conductor. While verys<strong>of</strong>t and easily damaged, these membrane circuitsare cost effective to produce and are lightweight.<strong>FPC</strong>Flexible Printed Circuits (<strong>FPC</strong>) are similar in constructionto the <strong>FFC</strong> except that copper film is chemicallyetched to produce a specific pattern. Whilethese circuits are custom made for each application,various shapes and geometrics can solve the toughestpackaging problems.ConductorBase FilmPolyesterStiffenerCover LayerPolyesterCarbon/Silver PasteCarbonPasteConductorSilverPaste<strong>ELCO</strong>2

<strong>History</strong> <strong>of</strong> <strong>FFC</strong>/<strong>FPC</strong>CONTACT DESIGNIn keeping pace with <strong>FFC</strong>/<strong>FPC</strong> Technology, Elcohas developed two different contact geometrics toguarantee reliable gas tight connections. The standardcontact, which is available in all series, was designedto mate with all copper based <strong>FFC</strong>/<strong>FPC</strong>. This initialcontact system proved to be too damaging to thes<strong>of</strong>ter carbon silver paste. In 1985, Elco introducedthe first contact specifically designed for thisapplication. Incorporating a radiused point, this newcontact provides the reliability needed to meet today’smechanical and environmental environments.STANDARD CONDUCTORC/Ag CONDUCTORCONNECTOR TERMINOLOGYZIF (Zero Insertion Force)This connector style allows the highest possiblenumber <strong>of</strong> mating cycles (30) for <strong>FFC</strong>/<strong>FPC</strong>. Thisconnector incorporates a mechanical slidermechanism which snaps down over the cable after itis inserted into the insulator body.LIF (Low Insertion Force) / NON ZIFThis style is the most cost effective <strong>FFC</strong>/<strong>FPC</strong>connector while still providing reliability. Theprepared cable is gently pressed into the insulatorslot. There are no moving parts, however, maximumdurability is 10 mating cycles.FUNCTIONAL COMPARISON OF ZIF AND LIFDurability Reliability Cost SizeZIF Better Better Good GoodLIF Good Good Better BetterPCB TERMINATION STYLETHROUGH HOLESURFACE MOUNTRight Angle Straight Right Angle Straight3 <strong>ELCO</strong>

<strong>History</strong> <strong>of</strong> <strong>FFC</strong>/<strong>FPC</strong>PLACEMENT FEATURESThese help to position the connector on theprinted circuit board and provide mechanicalsupport, especially in SMT applications.KINKED LEGSMETAL TAB / STRAIN RELIEFMOUNTING BOSSCONTACT ORIENTATIONDual Sided Contacts (LIF Only): Cableorientation is not as critical.Single Sided Contacts (Includes Top andBottom): This style requires the <strong>FFC</strong>/<strong>FPC</strong> to beinserted into the insulator where by the exposedcopper matches with the contact.Choosing the correct connector eliminates flipping the<strong>FFC</strong>/<strong>FPC</strong> 180°. EXAMPLES:Bottom TopContact Contact1.00mm ZIF 6200 62240.50mm ZIF 6210 62120.50mm LIF 6222 6223DUAL SIDEDSINGLE SIDED-BOTTOM CONTACTFUNCTIONAL COMPARISON OF DUAL AND SINGLE SIDED LIF CONTACTSDurability Reliability Cost OrientationDual Good Better Good NoneSingle Better Good Better Yes<strong>ELCO</strong>4

<strong>History</strong> <strong>of</strong> <strong>FFC</strong>/<strong>FPC</strong>TYPICAL SINGLE SIDED CONTACT APPLICATION6210 SeriesBottom Contact Type6212 SeriesTop Contact TypeNEW FEATURES TO LOOK FOR:• Standard 30-50 position 0.50mm pitch ZIF connectors(Series 6240)• 0.90mm insulator height – lowest in the industry(Series 6250 and 6252)• New cost effective 0.50mm LIF connectors(Series 6222 and 6223)• Enhanced line <strong>of</strong> 1.00mm LIF connectors(Series 6226, 6227 and 6232)• Integral pick and place flange (eliminates Kapton tape)for straight SMT application (Series 6232)• New time saving flip-top ZIF (Series 6239 and 6240)The flip-top/one-touch lock saves time in inserting or withdrawing the cable.Additionally, it saves valuable PCB space as the lock does not extend outsidethe footprint pr<strong>of</strong>ile <strong>of</strong> the connector when opened.5 <strong>ELCO</strong>