BM 16-30 Pipe Bending Machine - Maats

BM 16-30 Pipe Bending Machine - Maats

BM 16-30 Pipe Bending Machine - Maats

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

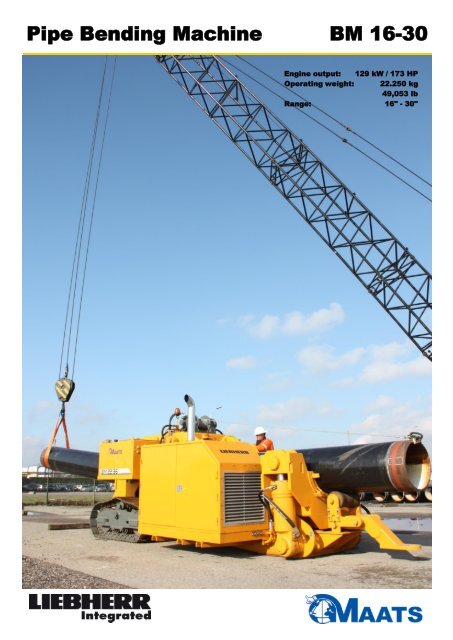

<strong>Pipe</strong> <strong>Bending</strong> <strong>Machine</strong><strong>BM</strong> <strong>16</strong>-<strong>30</strong>Engine output: 129 kW / 173 HPOperating weight: 22.250 kg49,053 lbRange: <strong>16</strong>" - <strong>30</strong>"

Basic machineEngineHydraulic systemDiesel engine Liebherr D934-L-A6, Emission regulationsSystem Load sensing proportional pump flow controlaccording to 97/68/EG, 2004/26/EG stage IIIA and Pump typeSwash plate, variable displacement piston pumpEPA/CARB Tier 3Pump flow max.297 l/min / 65.4 gpmRating (ISO9249) 129 kW / 173 HPPressure limitation 350 bar / 5,075 PSIRating (SAE J1349) 129 kW / 170 HPControl valve 5 segments, hydraulic actuatedRated speed 1.800 rpmFilter system Return filter with magnetic rod in the hydraulicDisplacement7,0 l / 426 cu. In.tankDesign 4-cylinder-in-line engine, water cooled, turbo-Control 5 hydraulic actuated levers for all functionscharged, air-to-air intercoolerInjection systemDirect injection, pump-line-nozzle system,electronic engine managementEngine lubricationPressurised lube system, engine lubricationguaranteed for inclinations up to 45 degreesOutboard cylinder 2x Liebherr, 240 x 500Operating voltage 24 VInboard cylinder 2x Liebherr, 150 x 145Alternator 80 AWedge cylinder 1x Liebherr, 120 x 600Starter 5,4 kWClamp cylinder 1x Liebherr, 100 x 400Batteries2 x 110 Ah / 12VAir cleanerDual stage dry type with safety element, precleaner,service gauge at operator standCooling systemCombi radiator, comprising radiators for water,Refill capacitieshydraulic fluid and charge air. Hydrostatic driven.ChainsLubricated, single grouser shoes; track chaintensioning by boltsTrack links28 (each side)Track rollers / carrier rollers 2 / 1 (each side)Track shoes standard 458 mm / 18"Fuel tank 200 l Track shoes option 508 mm / 20"Cooling system<strong>30</strong> lEngine oil with filters29 lHydraulic oil tank540 lHydraulic cylindersUndercarriageWinchNoise emissionExterior sound pressure Lp A = 72-86 dB(A) (distance @ 1 m.)(2000/14/EC)Rated line pull6.350 kg / 14,000 lbsGearingWormgearGear ratio 48 : 1Maximum oil pressure<strong>16</strong>0 bar / 2320 PSIMaximum oil flow60 l/min / <strong>16</strong> gpmCable length25 m / 82.02 ftCable diameter13 mm / 0.51"<strong>Bending</strong> dataMaximum wall thickness by grade at max. system pressure of 360 bar / 5240 PSI (based on 85% efficiency)<strong>Pipe</strong> size X52 X60 X70 X80 X100 RadiusInch / mm Inch / mm Inch / mm Inch / mm Inch / mm Inch / mm feet / meterMax. degreeper 40 feet /12 meter joint<strong>16</strong> / 406 2,000 / 50,8 2,000 / 50,8 2,000 / 50,8 2,000 / 50,8 2,000 / 50,8 38 / 11,5818 / 457 2,000 / 50,8 2,000 / 50,8 2,000 / 50,8 2,000 / 50,8 2,000 / 50,8 52 / 15,8520 / 508 2,000 / 50,8 2,000 / 50,8 2,000 / 50,8 2,000 / 50,8 2,000 / 50,8 64 / 19,5122 / 559 2,000 / 50,8 2,000 / 50,8 2,000 / 50,8 2,000 / 50,8 1,500 / 38,1 72 / 21,9524 / 610 2,000 / 50,8 2,000 / 50,8 1,750 / 44,4 1,500 / 38,1 1,200 / <strong>30</strong>,5 76 / 23,<strong>16</strong>26 / 660 2,000 / 50,8 1,750 / 44,4 1,437 / 36,5 1,250 / 31,7 0,937 / 23,8 82 / 24,9928 / 711 1,750 / 44,4 1,437 / 36,5 1,200 / <strong>30</strong>,5 1,063 / 27,0 0,800 / 20,3 88 / 26,82<strong>30</strong> / 762 1,437 / 36,5 1,250 / 31,7 1,031 / 26,2 0,875 / 22,2 0,700 / 17,8 96 / 29,2640,829,724,421,620,218,917,6<strong>16</strong>,2These figures are recommended only and do not constitute a warrantyAll bends shown are based on the use of <strong>Maats</strong> bending mandrels and bending dies. The figures given are "average", they will vary due to:- The wall thickness of the pipe- The actual (as opposed to the nominal) yield of the pipe- Skill of the operator in handling the bending machine and the mandrel- The origin of the pipe (pipe mill, plate mill, etc.) and quality of the pipe- The type of pipe, spiral seam pipe will normally accept 75% of the recommended bend- The type of die and or bending set being used (eg. polyurethane lining or special radius dies)An unbent end (tangent) is produced at each end of the pipe where the pipe contacts the stiff back and the pin up. Normal unbent tangents are approx.<strong>16</strong> feet / 5 meters.2 <strong>BM</strong><strong>16</strong><strong>30</strong>

Dimensions and weightsDimensionsWeightsHeight over winch 2.758 mm / 9.05 ft Operating weight 22.250 kg / 49,053 lbOverall length 7.456 mm / 24.46 ft Weight bending set (avg.) 2.<strong>30</strong>0 kg / 5,071 lbWidth2.615 mm / 8.58 ftMax. shipping width 2.695 mm / 8.84 ft<strong>Bending</strong> setsStandard sizes <strong>16</strong>", 18", 20", 22", 24", 26", 28", <strong>30</strong>"Special sizes are available on requestStandard sets are bare. Coated sets are available on request<strong>BM</strong><strong>16</strong><strong>30</strong> 3

Documentation Technical <strong>BM</strong><strong>16</strong><strong>30</strong> English Rev. 1EquipmentBasic machine s o Electrical system sTowing lug front ● Starter motor 5,4 kW ●Battery compartment, lockable ● Working lights ● Hydraulic system pressure (Analog) ●Cold start device ● Battery main switch, mechanical ● Engine RPM (digital) ●Radiator guard ● On-board system 24 V ● <strong>Machine</strong> hours (digital) ●Engine doors, hinged, lockable ● Alternator 80 A ● % Engine load at current RPM (digital) ●Lugs for crane lifting ● Beacon ● Coolant temperature (digital) ●Fuel water separator ● Oil pressure (digital) ●Air filter, dry-type, dual step ● Fuel economy (digital) ●Toolkit ● Active service codes (digital) ●Cyklon pre-filter●Tier II engine ● High torque motor ●Tier IV engine ● Dual stage planetary differential gearing ●AttachmentssLoad control valve●Spring engaged freespooling clutch ● Hydraulic PTO for mandrel ●Undercarriage s oTrack frame, closedSprocket segments, boltedTracks oil lubricatedTrack frame, rigidTrack shoes 458 mmTrack shoes 508 mmSpecial track sizes (width / length)●●●●●●●WinchCable 13 mm x 25 m ● Compressor for mandrel ●Cable 13 mm x 35 msoo●Control and warninglightssooS = Standard, O = OptionSubject to changeOptions and / or special attachments, suppliedby vendors other than <strong>Maats</strong>, are only to beinstalled with the knowledge and approval of<strong>Maats</strong> to retain warranty.<strong>Maats</strong> <strong>Pipe</strong>line EquipmentBreukersweg 4 / P.O.Box <strong>16</strong>5, 7470 AD Goor (The Netherlands)Tel: +31 (0) 547-260000, Fax: +31 (0) 547-2610004 <strong>BM</strong><strong>16</strong><strong>30</strong> www.maats.com, E-mail: info@maats.com