Coagulation and Flocculation Purpose of Coagulation and ...

Coagulation and Flocculation Purpose of Coagulation and ...

Coagulation and Flocculation Purpose of Coagulation and ...

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

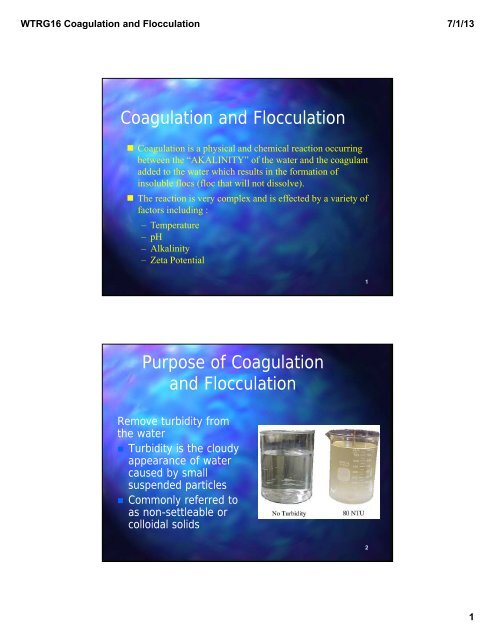

WTRG16 <strong>Coagulation</strong> <strong>and</strong> <strong>Flocculation</strong> 7/1/13<strong>Coagulation</strong> <strong>and</strong> <strong>Flocculation</strong>• <strong>Coagulation</strong> is a physical <strong>and</strong> chemical reaction occurringbetween the “AKALINITY” <strong>of</strong> the water <strong>and</strong> the coagulantadded to the water which results in the formation <strong>of</strong>insoluble flocs (floc that will not dissolve).• The reaction is very complex <strong>and</strong> is effected by a variety <strong>of</strong>factors including :– Temperature–pH– Alkalinity– Zeta Potential1<strong>Purpose</strong> <strong>of</strong> <strong>Coagulation</strong><strong>and</strong> <strong>Flocculation</strong>Remove turbidity fromthe water• Turbidity is the cloudyappearance <strong>of</strong> watercaused by smallsuspended particles• Commonly referred toas non-settleable orcolloidal solids21

WTRG16 <strong>Coagulation</strong> <strong>and</strong> <strong>Flocculation</strong> 7/1/13Particles in Water• Chemicals in solution (have beencompletely dissolved in the water).• Colloidal solids, also known asnonsettleable solids (do not dissolve inwater although they are electricallycharged).• Suspended, or settleable solids (willsettle out <strong>of</strong> water over time).3Conventional<strong>Coagulation</strong>/<strong>Flocculation</strong> Process• Pretreatment• Chemical Feed• Flash Mixing• <strong>Coagulation</strong>& <strong>Flocculation</strong>• Sedimentation• Filtration• Disinfection42

WTRG16 <strong>Coagulation</strong> <strong>and</strong> <strong>Flocculation</strong> 7/1/13Pretreatment Considerations in the<strong>Coagulation</strong>/<strong>Flocculation</strong> ProcessFactors that May Dictate Pretreatment– Leaves, plant material <strong>and</strong> silt– Seasonal raw water qualitychanges caused by drought, highwater or temperature changes– Potential upstream pollution– Wind conditions– Algae blooms– Bacterial problems5Particle Removal by <strong>Coagulation</strong>Negatively chargedparticles repel each otherdue to electricity.Positively charged coagulantsattract to negatively chargedparticles due to electricity.• Coagulants neutralize negative charged particles• Allows particles to come closer <strong>and</strong> form larger clumps• Provides “agglomeration sites” for larger floc63

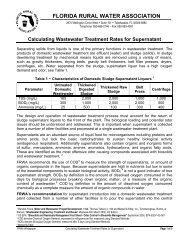

WTRG16 <strong>Coagulation</strong> <strong>and</strong> <strong>Flocculation</strong> 7/1/13Factors Affecting the Effectiveness<strong>of</strong> the <strong>Coagulation</strong> Process• Best pH (pH Range: Al, 5 – 7 ; Fe, 5 – 8)• Alkalinity <strong>of</strong> water (> 30 PPM residual)• Concentration <strong>of</strong> Salts (affect efficiency)• Turbidity (constituents <strong>and</strong> concentration)• Type <strong>of</strong> Coagulant used (Al <strong>and</strong> Fe salts)• Temperature (colder requires more mixing)• Adequacy <strong>of</strong> mixing (dispersion <strong>of</strong> chemical)7Chemical Coagulants used inWater TreatmentChemical Name Chemical Formula PrimaryCoagulantAluminum Sulfate Al 2 (SO 4 ) 3 XFerrous Sulfate FeSO 4 XFerric Sulfate Fe(SO 4 ) 3 XFerric Chloride FeCl 3 XCationic Polymer Various X XCalcium Hydroxide Ca(OH) 2 X a XCalcium Oxide CaO X a XSodium Aluminate Na 2 Al 2 O 4 X a XBentonite Clay XCalcium Carbonate CaCO 3 XSodium Silicate NaSiO 3 XAnionic Polymer Various XNonionic Polymer Various Xa- Used as primary coagulant in water s<strong>of</strong>tening processes.CoagulantAid84

WTRG16 <strong>Coagulation</strong> <strong>and</strong> <strong>Flocculation</strong> 7/1/13Primary Coagulants• Primary coagulants are always used in thecoagulation/flocculation process. Alum <strong>and</strong> ferricsulfate are most commonly used.• Different sources <strong>of</strong> water need different coagulantsto react over a wider pH range.• Primary coagulants have multivalent charges (+2,+3, +4) which allow them to react with thenegatively charged colloidal materials in the water.• All <strong>of</strong> the coagulant chemicals will remove alkalinityfrom the water.9Coagulant Aids• Add density to slow-settling floc <strong>and</strong> addtoughness to the flocs so that they will notbreak up during mixing <strong>and</strong> settlingprocesses.• Not always required <strong>and</strong> are generallyused to reduce flocculation time.• Effective at extending pH ranges forprimary coagulant performance.• Most are expensive.105

WTRG16 <strong>Coagulation</strong> <strong>and</strong> <strong>Flocculation</strong> 7/1/1311Use <strong>of</strong> Alum as aCoagulant• Earliest <strong>and</strong> most widely used coagulant• Effective range pH 5.0 to 7.0; (6.5optimal)• Effective range for color is ~ 5.5• Reacts with alkalinity to form floc -results in drop in pH• For every 2 mg/l Alum; 1 mg/l Lime isadded to replace alkalinity126

WTRG16 <strong>Coagulation</strong> <strong>and</strong> <strong>Flocculation</strong> 7/1/13Floc Formation• The positively charged aluminum ions (Al +3 ) attract thenegatively charged particles that cause color <strong>and</strong> turbidity, thusforming micr<strong>of</strong>loc.Al +3 Al +3 Al +3 Al +3• The positive charged micr<strong>of</strong>loc particles begin to attract <strong>and</strong>hold more negatively charged particles in the water.• The micr<strong>of</strong>loc grows into large settable floc due to adsorption<strong>and</strong> collison <strong>of</strong> other floc particles13Use <strong>of</strong> Ferrous Sulfate (Copperas)<strong>and</strong> Lime for <strong>Coagulation</strong>• Combination produces Ferric Hydroxide• pH 8.4 range to 9.0• Oxygen must added by aeration orchemically such as chlorine• Very Effective for turbid water• Care must be taken because color notremoved at high pH147

WTRG16 <strong>Coagulation</strong> <strong>and</strong> <strong>Flocculation</strong> 7/1/13Use <strong>of</strong> Ferric Chloride asa Coagulant• Has wider pH range than FerrousSulfate• Typically used where color removal isalso desirable.• Does not require oxygen supplement15Use <strong>of</strong> Ferric Sulfateas a Coagulant• Does not require oxygen supplement• Effective over wider pH ranges• Effective within all temperature ranges• Eliminates odors from existingHydrogen Sulfide• Lower doses required than FerrousSulfate168

WTRG16 <strong>Coagulation</strong> <strong>and</strong> <strong>Flocculation</strong> 7/1/13Use <strong>of</strong> Coagulant Aids• Lime• Weighting Agents• Polymers– Cationic +– Anionic -– Nonionic17Coagulant Mixing <strong>and</strong>Flash Mixers<strong>Purpose</strong> <strong>of</strong> the flash mix process is to rapidlymix <strong>and</strong> equally distribute the coagulantchemical throughout the water.• Coagulant must make contact with all <strong>of</strong> thesuspended particles.• Process occurs in seconds.• First results are formation <strong>of</strong> very small particles.• Detention time <strong>and</strong> the speed <strong>of</strong> the mixer shouldbe sufficient to thoroughly mix all the chemical withno breakup <strong>of</strong> floc particles.189

WTRG16 <strong>Coagulation</strong> <strong>and</strong> <strong>Flocculation</strong> 7/1/13Mixing Coagulants<strong>and</strong> Coagulant Aids• Rapid/Flash Mixtypically occurs in atank• Mixing velocity 5 – 7fps• Coagulant <strong>and</strong>coagulant aidsadded in firstchamber19Static Mixer for Polymers• Used prior to<strong>Coagulation</strong>• Addition <strong>of</strong> oxidizingagents, GAC <strong>and</strong>polymers• Used as far aspossible upstream tomaximize contacttime2010

WTRG16 <strong>Coagulation</strong> <strong>and</strong> <strong>Flocculation</strong> 7/1/13<strong>Flocculation</strong> Process• <strong>Flocculation</strong> is a slow stirringprocess that causes thegathering together <strong>of</strong> small,coagulated particles intolarger, settleable particles.• Controlled by the rate <strong>of</strong>collisions between particles<strong>and</strong> the effectivenesspromoting attachment.• Changes in temperature cannecessitate longer detentiontimes.21<strong>Flocculation</strong> Followed bySedimentation• Instantaneous mix <strong>of</strong> coagulants• Neutralizes the negative charges on colloids• During the gentle mixing <strong>of</strong> flocculation, allowsparticles to agglomerate into larger particles• Heavier particles are removed by settling2211

WTRG16 <strong>Coagulation</strong> <strong>and</strong> <strong>Flocculation</strong> 7/1/13Importance <strong>of</strong> Flocculator Speed• If the speed <strong>of</strong> the stirring process is to greatthen the floc particles will be “sheared” orbroken apart causing an increase in turbidity.• If flocculator speed is to slow then “shortcircuiting”may occur.• <strong>Purpose</strong> is to create a floc <strong>of</strong> good size (0.1to 3mm), density, <strong>and</strong> toughness for laterremoval in the sedimentation <strong>and</strong> filtrationprocesses.23What is Short-Circuiting?“A condition that occurs intanks or basins when some <strong>of</strong>the water travels faster thanthe rest <strong>of</strong> the flowing water.”May result in shorter contact, reaction,or settling times.2412

WTRG16 <strong>Coagulation</strong> <strong>and</strong> <strong>Flocculation</strong> 7/1/13Desirable Floc Quality• A popcorn flake is a desirable floc appearance.• Smooth circular particles tend to settle quickerwhile irregular shaped particles settle slower.• Tiny alum floc may be an indication that thechemical dosage is too low.• If the water has a milky appearance or a bluishtint, the alum dose is probably too high.• Should be increasing in size as it moves throughthe basins25Performance Monitoring• Mixing needs to be adequate• Monitor pH for optimum conditionsWhat adjustment shouldbe made in the speed <strong>of</strong>flocculators when thewater temperaturedrops?Increase Speed• Flow measurement is important to accuratelyestablish chemical feed rates, wash waterrates, <strong>and</strong> unit loadings• Chemical feed systems need dosage control• Jar Test at the Start <strong>of</strong> Every Shift or more!2613

WTRG16 <strong>Coagulation</strong> <strong>and</strong> <strong>Flocculation</strong> 7/1/13Performance MeasurementUsing the Jar Test• A jar test is a laboratory procedure where varyingdosages <strong>of</strong> coagulant are tested in a series <strong>of</strong> glassor plastic jars under identical conditions.• The jars are injected with coagulant dosages <strong>and</strong>gently paddled or flocculated to match fieldconditions as closely as possible.• After a set <strong>of</strong> time to simulate field conditions thejars are observed to determine which dosageproduces the largest, strongest floc or which dosageproduces the floc that settles the fastest.• Other laboratory tests sometimes include a jar test todetermine the optimal pH or determine the turbidity<strong>of</strong> the settled water <strong>and</strong> its filterability. 27Jar Test Apparatus <strong>and</strong>Procedures• Six paddles• One container iscontrol• RPM gauge allowsfor mixing speedto match plantFlash Mix: 1 Minute at 80 RPM conditions<strong>Flocculation</strong>: 30 Minutes at 20 RPMSettling: 30 Minutes2814

WTRG16 <strong>Coagulation</strong> <strong>and</strong> <strong>Flocculation</strong> 7/1/13Jar Test Plot for Low AlkalinityWater• Alum initially reactswith low alkalinity• With Ferric Chloriderequires chemical toreach optimal pHbefore reacting• Adding too muchcoagulant increasesturbidity29Jar Test Plot for HigherAlkalinity Water• Higher Coagulantdoses are needed forhigh alkalinity waters• Ferric Chloriderequired morechemical but reachedlower turbidity• Since Alum did notproduce water < 1NTU a coagulant aid isnecessary3015

WTRG16 <strong>Coagulation</strong> <strong>and</strong> <strong>Flocculation</strong> 7/1/13Evaluation <strong>of</strong> Jar Test Results• Rate <strong>of</strong> Floc Formation (15 min.)• Type <strong>of</strong> Floc Particles (circular or popcorn)• Clarity <strong>of</strong> the Water between the Floc• Size <strong>of</strong> the Floc (.1 to 3 mm)• Amount <strong>of</strong> Floc (too little may need agent)• Clarity <strong>of</strong> Water above Settled Floc (clear)• Volume <strong>of</strong> Floc31<strong>Coagulation</strong>-<strong>Flocculation</strong> ProcessMonitoring <strong>and</strong> Sampling PointsSourceRaw WaterTU, TEMP, ALKColor, pH<strong>Coagulation</strong>EffluentpH, VIS<strong>Flocculation</strong>EffluentTU, ALK,pH, VISRaw Water∞Flash MixKEY:(<strong>Coagulation</strong>TU – TurbidityTEMP – TemperatureALK – AlkalinityVIS – Visual ObservationHighSpeed∞ ∞ ∞MediumSpeed<strong>Flocculation</strong>BasinSlowSpeedSedimentationBasin3216